By Product Categories

Small Boat Blocks

Big Boat Blocks

Complementary Hardware

Travelers & Genoa Leads

Mainsail Handling

Headsail Handling

Mooring Solutions

Spare Parts

Accessories

Harken Canvas

Sportfishing

Fly Soft-Attach Blocks

Carbo Air Blocks

Small Boat Classic

Flip-Flop Small Boat

GP Catamaran Ceramic Mainsheet Systems

Protexit™ Exit Blocks

Through-Deck

Wire High-Strength

Dinghy Vang

Small Boat Deck Organizers

Midrange Classic

Midrange Deck Organizers

Zircon Blocks

Element Blocks

Black Magic Air Blocks

Cruising ESP Blocks

Megayacht Blocks

Stainless Steel Blocks

Black Magic Air Runners

FlatWinder Powered Blocks

Mastbase Blocks

Over-the-Top

Crossover Blocks

Big Boat Deck Organizers

Cam Cleats & Kits

Cam Cleat Accessories

Cam Cleat Bases

Stand-Up Bases

Deck Organizers

Spinnaker Pole Cars

Soft Attachments

Fixed Padeyes

Removable Padeyes

Bolt-Down Fairleads

Grand Prix Jib Leads

Halyard Tensioners

Tiller Extensions

Peter's Desk Drawer

Dinghy Jib Leads

Crossbow Pivoting Self-Tacking Jib Traveler

13 mm Micro

22 mm Small Boat

27 mm Midrange

32 mm Big Boat

Windward Sheeting

42 mm Mini-Maxi

T-Track Genoa Lead

Access Rail System

13 mm AA Battcar System

22 mm A Battcar System

27 mm B Battcar System

32 mm C Battcar System

18 mm Switch Battcar System

26 mm Switch Battcar System

26 mm Trysail Switch

32 mm Switch Battcar System

32 mm Trysail Switch

40 mm Switch Battcar System

40 mm Trysail Switch System

Furling Mainsail Outhaul Systems

Single Line Reefing

Harken Vang-Master

Carbo Racing Foil

Small Boat Furling

Small Boat Underdeck

Reflex Furling

MKIV Jib Reefing & Furling

MKIV Underdeck Jib Reefing & Furling

Furling Accessories

Powered Furling

MKIV Ocean Furling

SnubbAir (Not a Winch)

Grand Prix Winches

Air Winches

Circuit Breakers

Analog Switches

Digital System Switch

Aluminum, Chrome & Bronze Winch Handles

Carbo OneTouch Locking Winch Handle

Service Kits

CLR Mooring Winches

Electric Captive Reel Winches

Hydraulic Captive Reel Winches

UniPower Radial

Single-Acting Integral Backstay Adjuster

Single-Acting Cylinders

Locking Cylinders

Double-Pull Cylinders

Grand Prix Cylinders

Hydraulic Cylinder Rod End Blocks

Hydraulic Cylinder End Fittings

Control Valves

Control Manifolds

Control Panels

Compact Control Panel

Rotary Pumps

Hydraulic Pump Handles

Power Systems

Repair Kits

Ball Bearings

Block Spare Parts

Traveler Cars

Furling Spare Parts

Winch Spare Parts

Winch Service Kits

Blockheads Gear

Promo & Gifts

Marine Grip

Jeep/Truck tops

Garage storage

One-design Covers

Boat accessories

Canvas bags

By Type of Sailing

Dinghy / One-Design

Offshore Racing

Coastal / Day Cruising

Bluewater Cruising

Megayachts / Custom

Service Guide

Tech/Service

deck layouts

Data Sheets (SDS)

How to choose

System diagrams

Calculators

Reeving diagrams

Traveler Purchase Selection Guide

How to Choose

Testimonials

Hoister Videos

Request a Quote

Request Samples

Fabric details

Cover Styles

Canvas Videos

Contract Services

Materials and Components

Our Equipment

Contract Cut-and-Sew Project Spotlight

- Harken at the front

- Safety & Rescue

Manuals/Drawings

- Self-contained

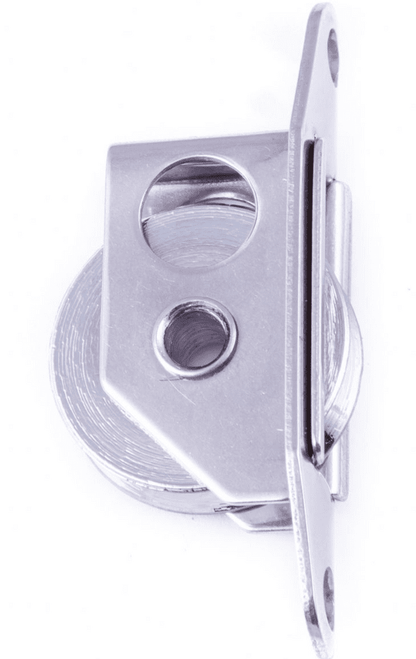

- Narrow halyard / steering

Shop / Complementary Hardware

Self-contained sheaves are designed for sailors to use in custom applications. Big Boat and high-load sheaves are available for special applications as well as for replacement sheaves in Big Boat blocks. Narrow high-load sheaves in mastheads improve sail handling, speed sail changes, and allow the use of smaller, lighter halyard winches. High-load titanium V sheaves feature the same incredibly efficient bearing set of angled titanium rollers as Harken’s V blocks. Perfect for running lines underdeck, in mainsheet and spinnaker sheet or drop line systems. They are also perfect to rig clean backstay systems to steady today’s slender masts and adjust mast bend.

51mm Midrange Sheave

51mm Aluminum Midrange Sheave

64mm Wide Sheave

29mm Bullet Sheave

29mm Dual Bullet Sheave

203mm High-Load Sheave

38mm Big Bullet Sheave

57mm Delrin® Sheave

22mm Micro Sheave

Product categories.

- United States

- New Zealand

- United Kingdom

Harken US Offices will be closed Thursday, July 4 . Any orders placed after 11 a.m. Wednesday, July 3, will be processed upon re-opening on Friday, July 5.

- Sailboat Hardware

Sea Sure Replacement sheave for 03.48/50/51/52/53

Sea Sure Halyard Block (Metal Sheave)

Sea Sure Deck Lead Block (Metal Sheave)

Sea Sure Inline Mast Block (Metal Sheave) 01.12

Sea Sure Inline Mast Block (Metal Sheave)

Sea Sure Metal Sheave Block with Hollow Rivets

Sea Sure Metal Sheave Block with Becket

Sea Sure Metal Sheave Block with Clevis Pin

Sea Sure Metal Sheave Block with shackle

91217 - Deck Organizer - Quadruple - Aluminum Sheaves 60 mm

92662 - Single Ratchet with Cam and Double Swivel 57 mm Blocks with Becket

92747 - Fiddle Double Swivel- Double Ratchet-double Cam and Single Cross 39 mm Aluminum Sheave

92746 - Fiddle Double Swivel - Double Ratchet and Double Aluminum Cam Cleat

92772 - Single Swivel Ratchet with Cam and Double 39 mm Swivel

95010 - Friction Sheave - 40 mm Sheave- Web - Tie Sheave - Control Line Eye

95011- 60 mm Sheave- Web - Tie Sheave - Control Line Eye

95012- Friction Sheave - 80 mm Solid Sheave- Web - Tie Sheave - Control Line Eye

92550 - Micro Block - Single Swivel with Aluminum Sheave

92551 - Micro Block - Single Swivel with Becket and Aluminum Sheave - High Load

92525 - Micro Block - Double Fixed with Becket

The $tingy Sailor

Diy trailerable sailboat restoration and improvement without throwing your budget overboard.

Install Oversize Masthead Sheaves for More Halyard Choices

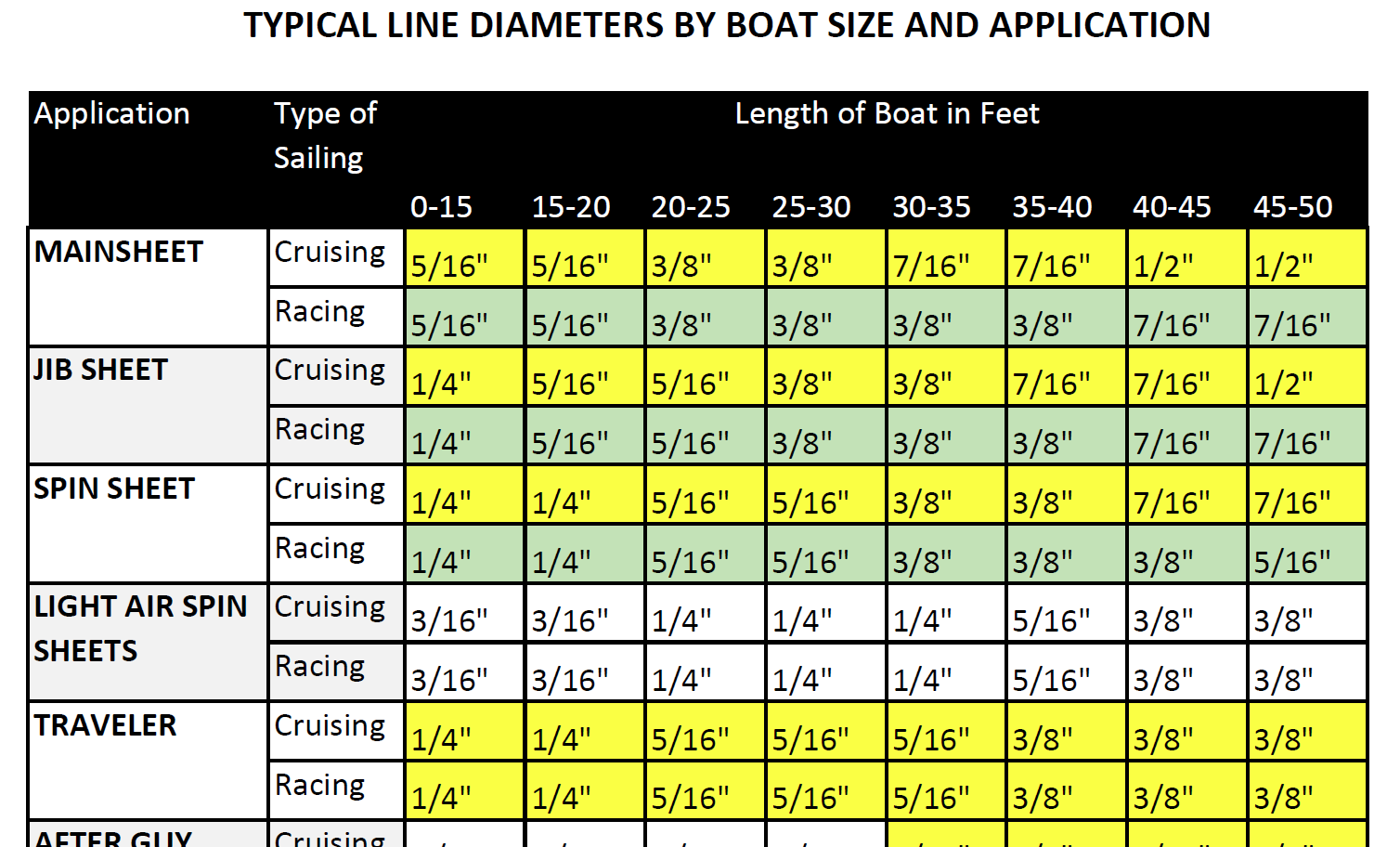

When planning the replacement of my wire/rope halyards with all line halyards so that I could lead them aft to the cockpit, I decided to use all 8mm (.314″) rope. Along with cockpit convenience for single-handing, I wanted easier line handling and less stretch, especially for hardening the luffs since I don’t have halyard winches. The cost is not much more than the standard 1/4″.

Eight millimeters is larger than the standard equipment 1/4″ rope that is used for external halyards on first generation C-22s. If you have internal halyards, they are probably 5/16″ (.3125″). With internal halyards, there are only two sheaves in the masthead, one forward (headsail) and one aft (mainsail). They each take up the entire width of the sheave slot. Each of the two pairs of external halyard sheaves must sit side by side in that same slot along with a spacer between them to keep the lines from jamming in the masthead.

Some of you might be thinking, “But wait a minute, 8mm is too big for the 1/4″ masthead sheaves,” and you’d be right. Even if I switched the four masthead sheaves for the external all line halyard sheaves from a certain Catalina parts dealership, those too can only accommodate 1/4″ halyards and would be too narrow for 8mm lines. CD states that theirs are the only sheaves that will fit in the masthead. That might have been true when they first started selling them, but it’s not so true today.

Getting a big head at the masthead

Ronstan RF251 sheaves are the same inside and outside diameters as the original equipment sheaves but wide enough for 8mm or 5/16″ lines. This means that they are slightly wider than 1/4″ sheaves. Two pairs of them will fit in the masthead with no modification other than a thinner spacer between them. The stock spacer is 2.5 mm thick. I fabricated one out of 1.75 mm aluminum and it fits in the masthead along with the new sheaves and room for them to turn freely.

Instead of making a new spacer, you could sand down the original spacer using a reverse sanding block technique. Afix the spacer to a the bottom of a hand-size scrap of wood with carpet tape and hold it against a belt sander or a piece of coarse sandpaper on a flat surface. Move the block over the sandpaper instead of vice versa. You’ll have much more control and a flatter spacer than if you try to sand the spacer by holding the sandpaper in your hands, even on a sanding block. If your spacer has grooves worn in it from the sheaves like mine did, sand one side halfway, flip the spacer over on the block, and sand the other side halfway.

To remove the old sheaves, unstep the mast, remove the cotter pins from the sheave pins and tap out the pins. The spacer will come out with the forward sheave pair. The aft pin doesn’t go through the spacer. Note the orientation of the spacer in the masthead. It can be accidentally reassembled upside down (don’t ask me how I know this). If the pins don’t come out easily, see my post on galvanic corrosion for some tips and warnings.

To install the new sheaves, first mount the aft pair of sheaves in the masthead without the spacer using a new cotter pin or ring in the sheave pin. Then slide the end of the spacer that does not have a hole in it between the top halves of the two aft sheaves. The angled edge of this end should be facing up. Rotate the front of the spacer down into place between the two forward sheaves where you can pin it together with the sheaves. Reave the halyards through the masthead while you have the mast down. This would be a good time to also inspect the backstay and forestay terminations and fasteners, the masthead attachment, and any masthead accessories such as your anchor light and Windex.

The Bottom Line

Suggested price: $46.88 $tingy Sailor cost: $18.96 Savings: $27.92

Share this:

8 thoughts on “ install oversize masthead sheaves for more halyard choices ”.

Hi there, I just did this project today, wanted to say thank you for all the great advice, part numbers and step by step instructions! It’s going to make raising and lowering my sails so much smoother. Fair winds – Deb in NH

Really glad it helped! Thanks for your comment.

If converting to internal, is it advisable to run four halyards, adding one for the spinnaker and one for a topping lift? If so what would you recommend for exit blocks?

I wouldn’t recommend 4 internal halyards for a C-22 for the following reasons:

- The mast doesn’t have much room left inside if you consider electrical conduit for a steaming light or anchor light.

- All the tapping screws inside the mast for jam cleats and other external hardware that can shred the halyards and would have to be replaced or modified.

- Running the topping lift down the mast would add too much friction and cost for nearly zero convenience. I almost never use it while under sail, so having it on the boom works fine and reduces weight aloft.

- The masthead exit location is poor for a spinnaker halyard. It should be higher and as far forward as possible from the jib halyard and forestay. That’s why you see spinnaker “cranes” to provide a better position.

So the only lines that make sense to run internal are the mainsail and headsail halyards. You can do it with two of your existing 4 external halyard masthead sheaves or convert the masthead to 2 centered sheaves.

I’d recommend exit blocks at the base of the mast like the Harken #131. The halyards can lead directly from those to your deck organizers so you don’t need a mast step plate with turning blocks if you don’t already have them. Makes for a cleaner, simpler installation.

Hello, thank you for all the information! I was wondering if it is possible to switch to all rope halyards without changing out the sheaves? Is there a certain diameter of halyard that would be strong enough but a small enough diameter for this? Thanks for your time!

1/8″ Dyneema would probably fit the sheaves but it would be painful on the hands and more difficult to handle. That is, unless you spliced a length of larger (5/16″+) onto the working end similar to your current combination rope/wire halyards. But with that much of a difference in diameters and considering how low friction Dyneema is, I doubt a standard, tapered splice would work well.

Thanks for your question, $tingy

I managed the replacement of sheaves with the suggested Ronstan sheaves, and “machined” spacer (aka did a LOT of sanding) down to the necessary thickness. After re-assembly the new and slightly larger sheaves moves freely and I’m ready to install 5/16 halyards. As always, I greatly appreciate your clear and comprehensive information and directions!

Very nice blog you have here

Leave a comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

× You are using an outdated browser. Please upgrade your browser to improve your experience.

We Ship Worldwide! | FREE SHIPPING! for US Continental orders over $99. Click for details.

Shopping Cart

Your cart is currently empty..

FREE SHIPPING! for US Continental orders over $99 click for details

Sailboat Rigging Sheaves

If you have a broken or worn-out sheave, we at MAURIPRO Sailing have the replacement sheave for your block, mast, or deck organizer. Various sizes are available to replace sheaves for many sailboat applications. Reduce friction and increase your sailing power with any of the sheaves we carry.

MAURIPRO Sailing, your direct access to Sailboat Rigging Sheaves and all your other sailing and boating needs.

Copyright © 2024 MAURIPRO Sailing LLC.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Pearson 37 and 37-2 Used Boat Review

DIY Survey Checklist for Used-Boat Buying

Valiant 40: Reshaping the Cruising Hull

Bristol Channel Cutter 28: Circumnavigator’s Choice

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

How Does the Gulf Stream Influence our Weather?

Can You Run a Marine Air-Conditioner on Battery Power?

Practical Sailor Classic: The Load on Your Rode

Anchor Rodes for Smaller Sailboats

Ground Tackle Inspection Tips

Shoe Goo II Excels for Quick Sail Repairs

Dinghy Outboard Diagnostics

Spring Season Engine Start-Up for Winterized Engines

Solutions for a Stinky Holding Tank

Diesel Performance Additives

Vinyl Boat Lettering DIY Application and Repair

Those Extras you Don’t Need But Love to Have

Hidden Maintenance Problems: Part 3 – Gremlins in the Electrics

Three-Model BBQ Test

Alcohol Stoves— Swan Song or Rebirth?

Living Aboard with an Alcohol Stove

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

Re-sealing the Seams on Waterproof Fabrics

Chafe Protection for Dock Lines

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

- Sails, Rigging & Deck Gear

Practical Sailors Guide to Choosing Cost-Efficient Halyard Materials

Practical sailor testers evaluate the many cordage choices available for both furling sail halyards and conventional sail halyards, with a look at the different rope fibers out there and a specific focus on cost vs. line stretch..

Sail performance is directly affected by the type and condition of your halyards. Upgrading your halyards to a low-stretch fiber helps ensure youre getting the sails full power, and it can add life your sails. After testing a sampling of lines from New England Ropes, Novatech Braids, Samson Rope, and Yale Cordage, Practical Sailor found that line stretch decreases significantly as cost increases. And while the very-low- to no-stretch high-tech lines often come with through-the-roof prices, there are low-stretch halyard options available for the budget-minded sailor. This article offers a line cost vs. line stretch analysis and an overview of the fibers available. UV resistance and other factors like abrasion resistance and ease of splicing will be the subject of future tests on these halyard materials.

****

While considerable development continues in the realm of high-tech, high-budget halyards, cruising sailors and club racers face a variety of choices but few new products since our last comprehensive halyard comparison (“For All-Rope Halyards, Its Hard to Beat New England Ropes Sta-Set,” December 1997). One recent addition to the range is VPC, from New England Ropes, which brings the low-stretch, low-creep characteristics of Vectran into an affordable upgrade from polyester double braid. Creep is a fibers taffy-like gradual elongation over time while under a static tensile load, and given how most sailors today are relying on at least one permanently hoisted sail, this factor will likely come into play.

Over the last decade or so, the large production-boat builders have found that more than 80 percent of new-boat buyers are choosing in-mast furling mainsails on boats 30 feet and longer. These boats all have roller-furling headsails, too, so the selection of halyard material is simplified somewhat: The halyards for these sails are rarely handled, so “hand” becomes a less-important quality to consider.

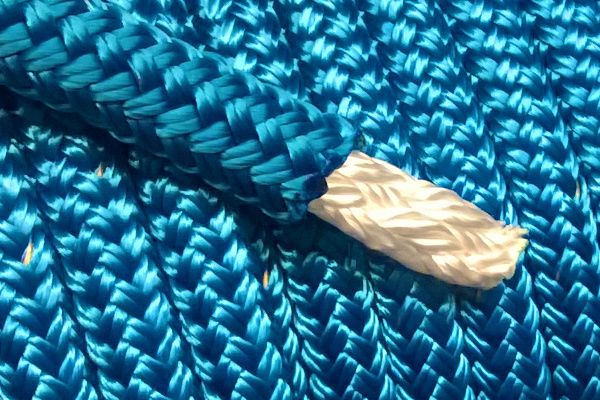

Another attribute, though, becomes more important: durability under load. The working end of the halyard spends its life under tension, bent around a sheave at the masthead. Because the sail remains aloft indefinitely, the halyard is rarely inspected, and must be trusted to perform without supervision throughout a season, or longer, if the boat is sailed year-round. All of these lines, except the Amsteel, have polyester covers, so one can expect similar service lives.

For sailors who have conventional sails and use the halyards on a regular basis, hand remains important. So too does the lines willingness to run free without snagging. And these sailors have plenty of opportunities to inspect the line for wear at its critical points.

Clutch slippage is also a factor. In last years rope clutch test (“ Clutch Play ,” April 2006), we used three of the halyards featured in this comparison. Subjected to 400-pound loads in two of our preferred clutches, the Lewmar D2 (the easiest to bleed) and the Spinlock XAS (the best gripping), Yales Vizzion proved to hold the best (average slippage 3/8-inch), followed by Samson Warpspeed (13/32-inch) and New England Ropes Sta-Set (7/16-inch). We will be looking at all these halyards clutch performance in a future test.

Regardless of sail type or deck gear, one factor always affects the choice of line for any halyard, and that is stretch. When the goal is to get the best performance out of a sail, its halyard should stretch as little as possible when it comes under additional load from a freshening breeze or sailing closer to the wind. When a halyard stretches, it allows the sail fabric to move aft. The draft of the sail moves with it. This results in the driving force rotating aft, creating more heeling moment and more weather helm. The boat is sailing less efficiently than it could, and you may be forced to reef earlier than you otherwise would.

As its fabric pulls aft, a sail on a mast track will scallop between the slides, and horizontal wrinkles will form at the slides. Apart from looking unseamanlike and making life less pleasant aboard, this also puts uneven stress on the sail fabric, which could&emdash;depending on how much sailing you do under these conditions&emdash;shorten its useful life.

So, heres another reason to renew your halyards, and perhaps even upgrade them: to save wear and tear on your sails.

Ironically, a cruising-boat owners budget is often expended on comforts and electronics, while the sails, which one would suppose are the boats reason for existing in the first place, get short shrift. When it finally comes time to specify the halyards and running rigging, the pot is empty. Ultimately, for the sake of a hundred dollars saved on a halyard, the owner never sees the full performance he paid for in his new sail.

For an average boat in the mid-30-foot range, a new mainsail can cost from $2,000 upward, and the premium for a “performance” mainsail over a basic Dacron model starts at about $500. Anyone investing that much would be well advised to hoist it on a halyard that does it justice. For about $100 over the cost of a basic polyester double braid, halyard stretch can be reduced by 75 percent, and the sail will be better able to deliver its promised performance.

By the same token, if you have an aging sail thats rather stretchy along the luff, you could eke another season or two out of it while you save up for a new one by spending a couple of hundred dollars on a less stretchy halyard. The halyard you bought will still be good for the new sail a few years down the road.

Another benefit of a low-stretch halyard is that it reduces effort in the cockpit. Trim-conscious sailors will find they have to make fewer adjustments to the halyard to keep the draft where they want it.

How We Tested

For this article, we looked exclusively at the cost/stretch aspect of new halyards. The Stretch to Cost Table on page 14 shows quite dramatically how great the benefit is for an additional investment that is really quite small, relative to the cost of a new sail. While we specifically looked at a main halyard, the results apply equally to a jib halyard for the same reasons.

For our comparison, to keep the math simple, our hypothetical test boat was somewhere around 35 feet, with a mainsail luff length of 40 feet. Running the halyard back to the cockpit, we assumed 50 feet of line between the winch and the head of the fully hoisted sail. Again for simplicity, we assumed a halyard load of 1,000 pounds, which is a reasonable maximum to expect the mainsail to exert on it&emdash;after that, its time to reef. (Once reefed, stretch resistance becomes even more important on a conventional sail, because the exposed halyard is now longer by the depth of the reef. When a luff-furling sail is reefed, adjusting halyard tension is pointless.)

For each sample of cordage we examined, we took the manufacturer-supplied stretch characteristics and calculated the stretch in inches that would result from our 1,000-pound load acting on the 50-foot standing part of the halyard. To simplify the pricing, we assumed buying 100 feet of line to provide an ample tail in the cockpit and enough extra length to allow “freshening the nip” a few times over the halyards life.

Our baseline rope was double-braid polyester, 7/16-inch in diameter. This kept our assumed 1,000-pound load at no more than 15 percent of the lines average breaking strength. A smaller diameter would probably suffice in the real world, but it would stretch more, precisely the opposite of what were trying to achieve.

The resulting graph of inches of stretch plotted against cost produced a dramatic curve, from which its quite obvious that the first $100 you spend over the basic polyester double-braid halyard buys a significant reduction in stretch. We should note that the values used for stretch are interpolated from data provided by the manufacturers in their literature or on their websites. While they may not be precise, we are confident that they reliably illustrate the argument. We intend to do our own testing on all of these lines, including stretch, to be reported on in a future issue.

The prices used in the graph are the lowest prices we found for each product. While researching these, we were reminded of how important it is to shop around. The price sources we used, and they are by no means exhaustive, appear in the “PS Value Guide Halyards” at left.

Learning the Ropes

The fibers commonly used in the products we studied are polyester, ultra-high-molecular weight polyethyline (UHMPE, sometimes written UHMWPE), para-aramids, and liquid-crystal polyester polyarylate (LCP). Polyolefin (polypropylene) is also used to add bulk to some fiber combinations.

This side of the Atlantic, polyester is usually known by its Dupont trade name, Dacron. It is inexpensive (relatively), has good tensile strength, and resists degradation by UV light, but it has a low Youngs Modulus (meaning, its stretchy). Compared to 7×19 stainless-steel wire, which was commonly used in the past for halyards, its very stretchy.

UHMPE comes under two common brand names, Spectra and Dyneema. Each of these has variants, but thats beyond the scope of this article. UHMPE has high strength and low stretch, which in combination with its generally good resistance to UV makes it well suited to halyards.

Para-aramids include Kevlar, Technora, and Twaron, variations on a molecular theme from different manufacturers. They exhibit similar strength to UHMPE at a lower price, but the trade-off is theyre not totally happy bending, they don’t perform well under abrasion, and they don’t stand up to sunlight as well. In sailing applications, they are usually found protected by a covering of some sort, except when they are the protection&emdash;against the heat generated when highly loaded lines are blown off a winch.

Vectran is the only LCP found in marine rope. It has high strength, low stretch, and better abrasion resistance than the para-aramids. It is far less susceptible to creep that UHMPE, and for that reason, it is useful when under standing loads. It, too, needs protection from UV.

Polyolefin, sometimes listed as MFP, is an inexpensive fiber used to bulk up small volumes of high-tech fibers to increase diameter and improve “hand.” It is basically polypropylene, and used by itself, appears in ski-tow ropes and on life-saving equipment. Its light, and it floats, but it doesn’t stand up to UV light.

Plotting Price vs. Stretch

Plotting cost against stretch using the same 1,000-pound load on a range of ropes produces a very clear picture of what youre buying. (For loads other than our 1,000 pounds, scaling up or down should produce the same relationship between stretch and cost.) You can almost halve the stretch by simply upgrading from 7/16-inch Sta-Set to the same size in Sta-Set X. Going up another level (see rope list) halves the stretch again, even with a reduction to 3/8-inch diameter to reduce cost. As stretch approaches zero, cost goes through the roof, but thats of little consequence even to the serious club racer, because several choices lie within a reasonable price point.

One way to use the graph would be to pick a maximum cost youd be comfortable with and look at the individual plots to the left of that number. Youll find that some of them are higher-tenacity material at smaller diameters. We figured 5/16-inch (8 millimeters) is as small as is comfortable to handle. Depending on your boats current winches, rope clutches, and sheaves, these may not work for you.

We included one single-braid line, Amsteel, simply for comparison. If youre tempted to go that route, you should consult a rigger about covering it so that it can lock properly in stoppers.

UV resistance and other factors like abrasion resistance and ease of splicing will be the subject of future tests on these halyard materials.

Conclusions

When it comes to making your decision, you will have to take into account factors beyond dollars and stretch&emdash;nothings simple. And until we do further testing, any definitive recommendations would be premature. Nonetheless, using the accompanying tables you should be able to find a good halyard that best meets your requirements and budget.

First: What size and type of line do you currently have? If this is original equipment, the entire halyard system may have been designed around it, from the masthead sheaves to the turning blocks at the base of the mast, to the clutch on the cabin top. Before electing to go down a size, or even two, in line diameter, you need to be sure this wont trigger a cascade of modifications necessary to accommodate it.

If you had wire, you will have to change the masthead sheaves to suit any synthetic line (and those sheaves are probably due for replacement anyway). Sheaves grooved for wire will make short work of a synthetic replacement. The higher high-tech lines, such as the 12-strand, single-braid Dyneema or Spectra (Amsteel, for example), work best under high loads in a sheave with a flatter-profile groove. The line flattens, reducing the difference in tension between the inner and outer fibers. Double-braid lines, which are the most suited to cruisers and casual racers anyway, are less fussy.

Going down a size in diameter will help your halyard systems efficiency by reducing internal friction as it turns around the now relatively larger sheaves. Most rope manufacturers specify a sheave-to-line-diameter ratio of 8:1 for optimal performance, but you rarely see this in many production-boat setups.

Going down two sizes, from 7/16-inch to 5/16-inch, will certainly get you into the high-tech material within your budget, but you may not get the stretch savings you hoped for. Also, you may find your stoppers wont accommodate the line.

Check the range of sizes your clutch or stopper will handle. If it will accommodate a size smaller than your present halyard, you can move up to a higher tenacity fiber core for better performance and down in diameter, and still gain the low-stretch advantage.

If you have permanently hoisted sails, you might want to look at a low-creep fiber for the halyards. This usually means a Vectran blend, and therefore more expense, but you wont suffer from gradual loss in luff tension as the season goes by. Because your sail is either all the way up or off the boat, the fall of the halyard, the part that would be hung on the mast or wherever when the sail is up, doesn’t have to be high-tech. A good rigger will be able to combine a single-braid standing part with a cover-only tail, saving both weight aloft and money.

Make sure you make both the tail and standing part long enough to permit freshening the nip a few times. Where the halyard sits on the masthead sheave, it will wear, and it will be exposed to ultraviolet (UV) light. Regular inspection, and cutting off and replacing the splice once in a while should prevent an untimely failure.

All of the lines discussed here can be spliced, but their differing constructions will dictate just what type of splice to use. Splice required is listed in the Value Guide, with additional information available on the manufacturers websites. Most of the suppliers also offer splicing services, and depending on line size and splice complexity, $15 to $30 seems like a bargain when measured against frustration most of us part-time riggers will suffer should we attempt the job ourselves.

- Practical Sailor Halyard Lines Value Guide

- Stretching Dollars

- Splice-Ability

RELATED ARTICLES MORE FROM AUTHOR

So why is the plot of price vs. strech included?

Where are the “accompanying tables” ?

To Karen- The tables are in the Also With this Article links at the bottom. To Darrell- Your pricing guide is really out of date. APS does not exist anymore. Hall Spars does not appear to sell line. DR Marine does not sell Portland Braid. The prices seem way out of date. Novabraid Polyspec was extremely hard to find online which raises concerns about it. I found it from The Chandlery Online for $1.69/ft.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Hanse 410: What You Should Know | Boat Tour

Sailboat vs Fishing Boat – Rules of the Road

Catalina 445: What You Should Know | Boat Review

How to Wax and Polish Your Boat

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Not All Line is Equal: How to Choose the Right Line for the Job

March 6, 2018

With the wide array of rope available today and continuous technological advances in line design, deciding on the best rope for each use can be baffling. Use this guide to ensure you choose the right rope for each application.

Using the proper line for each use isn’t just important for performance; it’s also important for keeping your sails safe. Break a sheet or lose a halyard while sailing, and you’ll likely find yourself breaking out your onboard sail repair kit or ending the race and heading to the loft for repairs. Our service team details what you need to know about the line options available, how they’re made, and how to choose the right one. At Quantum, we’re big fans of New England Ropes . They make a great product and have an option for just about every sailor and type of sailing. All of our examples and recommendations below are from the New England Ropes collection.

COMMON ROPE FIBER

POLYESTER (PET)

- PROS: Polyester is a great option for applications that require strength, durability, and low stretch. PET is moderately priced, and there are lots of colors available.

- CONS: Polyester is low stretch, but it does stretches a lot compared to it's higher priced cousins, both initially and over time. It is heavy, and absorbs water easily. PET has poor abrasion resistance and a fairly low break strength compared to the diameter. The strength of the line relies on both the outer cover and inner core. When either of those loses strength or has an abrasion, the overall strength of the line is reduced.

- EXAMPLE: Sta-Set

Aramid (Technora®, Twaron®, Kevlar®)

- PROS: Aramid is a popular low stretch material with great heat resistance and strength.

- CONS: Aramid has a low UV resistance and does not bend around sharp edges well.

- EXAMPLE: T-900

Liquid Crystal Polymer (Vectran®)

- PROS: Vectran® is an extremely low stretch material with a very high breaking strength, and it is the only line with zero creep. Vectran® also has high heat resistance. Overall, it is lightweight and doesn’t absorb water. The cover can be stripped for weight saving. Vectran® comes in a selection of colors.

- CONS: Vectran® does not have great durability or high UV resistance. Stripping the cover is not recommended and will weaken the durability of the line. Vectran® doesn’t do well with sharp corner bends, so care must be taken with small sheaves and tight turns. Vectran® also has a high price point.

- EXAMPLE: V-100

HMPE (Spectra®, Dyneema ® )

- PROS: Dyneema® has strong heat resistance, excellent stretch resistance, and excellent break strength. It has the lowest stretch at the break strength of all synthetic fibers. Overall, it is lightweight, and the cover can be stripped for weight-saving. Dyneema® offers color and vendor options.

- CONS: Dyneema® permanently creeps over time. It also has a high price point.

- EXAMPLE: Endura Braid

CHOOSING THE RIGHT LINE

In determining your rope priorities, start out by considering the type of sailing you’ll be doing.

If you’re cruising on a budget, choose line with great durability and UV resistance. If treated well, polyester braids for all or most applications are a good option. With the high-load applications associated with larger cruising vessels, such as sheets and halyards, you’ll need line that can handle a heavier load than polyester braids can. A blended double braid Beltran® or Spectra® rope is a better option than polyester braids for these high-load applications.

For club racing, ensure that the line has the proper break strength on higher load applications. Use a blended braid Vectran® or Spectra® line for the halyards, jib sheets, and guys. Avoid using polyester for these high-load applications so that you don’t have to get extra-large diameters. Polyester can be used in control lines and other lower load lines.

In Grand Prix racing, just about all of the line on the boat should be stretch resistant with a strong breaking point. Spectra®- or Vectran®-based rope is a great option for this. Many high-quality constructions of Spectra® are being made. New covers are even being made out of Spectra® and Technora®, which adds greater grip around winches and reduces abrasion to practically zero. If you’re stripping the cover on some of these lines to reduce weight, only do so on spinnaker sheets, spinnaker halyards, and other control lines where the load or use is low.

If a brand new high-load, low-stretch line is purchased for a given application, it’s a good idea to check the fittings it is running through. When ball bearings are missing, a winch or sheave doesn’t spin like it should. You hear odd noises, elongation occurs, and it’s probably time to replace or repair the deck fitting. If any fiberglass cracking or “spider webs” are appearing on deck fittings, it is a good idea to check the deck around the fitting and possibly reinforce the deck if any lamination issues have occurred.

Main Halyard and Jib/Genoa Halyard

- PRIORITIES: Very low stretch and high break strength.

- DESIRABLE: Light weight to reduce weight aloft.

- IDEAL TYPES: Spectra® or Vectran® core with a spectra chafe cover close to the shackle. With the added chafe cover at the shackle, it’s nearly impossible for the sheave to tear the halyard.

- RECOMMENDED LINE: Endura Braid , V-100 , VPC , T-900

Spinnaker Halyard

- PRIORITIES: A high break point is essential. Low stretch is important, but not as necessary as it is for other halyards.

- DESIRABLE: Light weight to reduce weight aloft.

- IDEAL TYPES: Spectra with a chafe cover near the shackle. Spectra is a low stretch rope that handles the shock loads from the spinnaker well. The cover of the rope can be removed from a portion of the halyard that doesn’t reach the winch.

- RECOMMENDED LINE: Endura Braid

Mainsheet

- PRIORITIES : Dependent on system used. On a multi-purchase system, Spectra® or polyester single braids are great options. They are strong ropes and great for grip. On a winch system, low stretch and high break strength is desirable, making Spectra double braid the best option. On a block-and-tackle purchase system, some stretch in the line is okay due to low loads per each purchase. A comfortable feel on the hands is necessary.

- Block and Tackle: Salsa Line , Sta-Set , Nexus Pro

- Winch: Endura Braid , Poly Tec

Jib/Genoa Sheet

- PRIORITIES: Low stretch and high break strength is essential.

- TOP CHOICE: Spectra core with a high-tech cover. A high-tech material resists abrasion from winches and blocks.

- RECOMMENDED LINE: Poly Tec , Endura Braid

Spinnaker Sheet

- PRIORITIES: Very lightweight rope is essential, especially for lighter air. Lines that float are a great option because they don’t add extra weight from moisture absorption.

- DESIRABLE: Low stretch and high break strength.

- IDEAL TYPES: Spectra core with a polyester cover. The cover can be removed from a portion of the line that doesn’t go through blocks and winches. This keeps the line light and reduces water absorption.

- RECOMMENDED LINE: Endura Braid , Nexus Pro , Flight Line

Guys and Tacklines

- IDEAL TYPE: Spectra or Vectran core with a polyester cover; add a chafe cover near the shackle. The chafe cover resists chafe and abrasion from the sprit or pole end.

Control Lines

- PRIORITIES: Depends on the application. Most control lines don’t see much use or load, so having stretchy and low break load lines is usually ok.

- DESIRABLE: Since most control lines are pulled manually, having a comfortable feel on the hands can be helpful.

- IDEAL TYPE: Spectra or polyester. Spectra can be used if wanting to remove the cover for weight reduction. Polyester is a great choice for lower load applications.

- RECOMMENDED LINE: Sta-Set , Endura Braid , Bzzz Line

"Dinghy and small boat mainsheet trimmers and helmsmen all choose New England Ropes Buzz Line." ©New England Ropes

Endura Braid

"Endura Braid delivers optimal performance, strength and durability for the competitive sailor. It features a specially engineered 12-strand Dyneema® core, with marine-tech coating and a 24 carrier braided polyester cover." ©New England Ropes

Flight Line

"A lightweight line perfect for light air spinnaker sheets, as well as mainsheets and control lines in smaller boats." ©New England Ropes

"Designed for today's newest one design sheets and control lines. Perfect for boats that require high tensile such as J70, Etchells, Melges, J24, and larger one-design products." ©New England Ropes

"An ideal balance of Technora® fiber and polyester and engineered to the demanding standards of riggers worldwide." ©New England Ropes

"Salsa Line from New England Ropes is an excellent main sheet for one design keelboats and large dinghies." ©New England Ropes.

"The number one polyester double braid on the market. Sta-Set is the quintessential proven performance double braid." ©New England Ropes

"A low stretch and low creep halyard option. T-900 features our pioneering blend of Dyneema® and Technora® in its core with a durable polyester jacket." ©New England Ropes

"V-100 features a braided 100% Vectran® 12-strand single braid core treated with our unique marine-tech coating with a highly durable and attractive polyester cover." ©New England Ropes

"The ultimate in high load performance. V-100 features a braided 100% Vectran® 12-strand single braid core treated with our unique marine-tech coating with a highly durable and attractive polyester cover." ©New England Ropes

The Discussion

I’m looking for the best line for a centerboard pendant. Top priority is good abrasion resistance. Second would be low stretch and strength.

This website uses cookies and collects usage statistics. Privacy Policy

Us, too. We pour that passion into each of our newsletters to help you enjoy sailing even more.

Home > Resources > Halyards, Sheets, and Lines: A Guide to Choosing and Maintaining Your Sailboat Rigging

Halyards, Sheets, and Lines: A Guide to Choosing and Maintaining Your Sailboat Rigging

11 May 2023

Ask Precision Sails , Hardware , Maintenance , Technical

How to Choose the Right Halyard/Sheet

When choosing a halyard for your sailboat, several factors come into play. These include the weight of the sail, the type of sail, the sailboat’s size, and the expected wind conditions. You should also consider the halyard’s stretch, which affects sail shape and performance. It is essential to choose a halyard that matches the load the sail will have on the line. Low-stretch halyards are ideal for racing and performance sailing, where every fraction of a knot counts.

Some Things to Consider when Choosing a Halyard or Sheet Include:

- Material: The material you choose for your line can affect its strength, durability, and stretch resistance.

- Diameter: The diameter of your halyard or sheet should be appropriate for the load the sail will apply to it and the size of your boat.

- Length: The length of your halyard or sheet should allow you to run your lines wherever they are needed, plus some extra for you to trim and tie off with.

- Attachment: The type of attachment you choose for your halyard or sheet can change depending on how you run your sheets and how the head of your sail is configured.

- Review Your Options: Making a decision about lines can be daunting, luckily Precision Sails has made it easy for you to pick your halyard or sheets by simplifying the process into two groups and pre-selecting the diameter, length, and attachment for your boat and line.

Here is a Quick Guide to Explain Material Choice:

The Precision Cruising series employs high-quality polyester lines, which are a good all-around option for starting and performing well. Polyester halyards and sheets are the most common and suitable for most sizes of sailboats, but they do stretch more than other lines like dyneema, spectra, or stirotex, which can affect sail shape and performance.

To address this, the Precision Performance series focuses on using stronger and stretch-resistant inner cores, making them ideal for racing sailboats that require high precision and tight tolerances. These lines are made of stirotex, which you may recognize by the name of spectra or dyneema. Stirotex is a chemically identical variation. The parent compound in these high-tension lines is HMPE. These lines are the strongest and least stretchy, making them the top choice for high-performance racing sailboats.

How to Maintain Your Halyards, Sheets, and Lines

Proper maintenance of your halyards is crucial for their longevity and reliability. Some tips for maintaining your halyards include:

Maintenance Checklist

- Regular inspection: Check your lines regularly for signs of wear, fraying, or damage.

- Cleaning: Clean your halyards and sheets periodically with soap and water to remove dirt and salt buildup.

- Lubrication: Lubricate your halyards and sheets with a silicone spray or dry lubricant to reduce friction and wear.

- Storage: When not in use, store your lines coiled neatly and out of direct sunlight if you can.

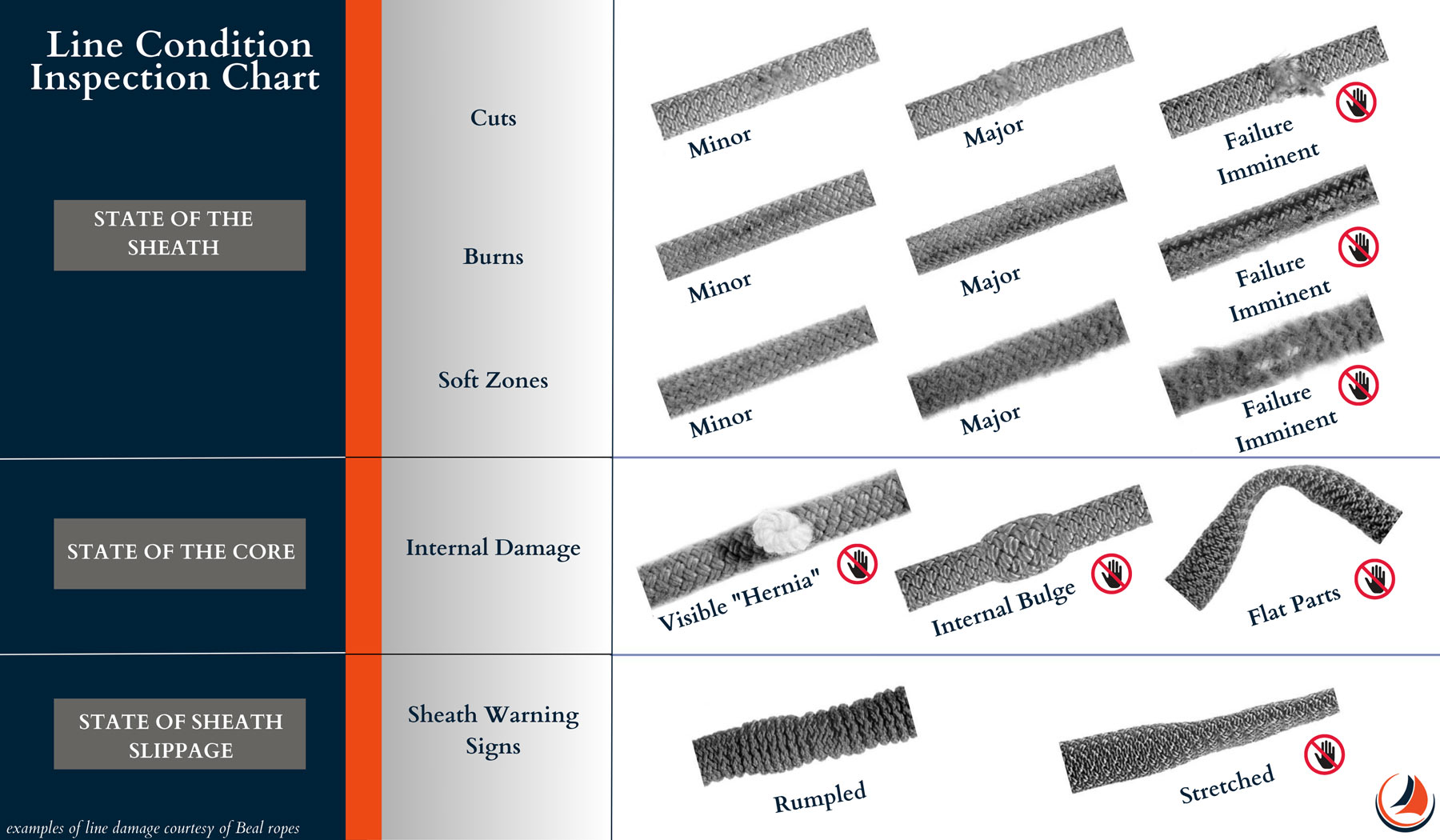

Signs of Wear – How to Inspect Your Lines

Lines that show obvious signs of deterioration must be discarded and replaced immediately. One of the most apparent and hazardous signs of wear on a line is a cut or damaged sheath that exposes the core. In such cases, it is important to retire the line immediately to prevent any further damage or potential failures.

Other signs may include hardness around the sheath or fuzziness. These signs may be particularly evident near the connection points or any areas of high friction. It’s also important to pay attention to any changes in the handling or feel of the line, as this may indicate internal damage or other issues that require attention.

A way to protect your investment is proper care and cleaning and avoiding the use of harsh chemicals or high-pressure washers, which can damage the fibers. This can be done by soaking them in a bucket of warm water with mild soap or detergent, then rinsing thoroughly and allowing them to air dry. This helps to remove any salt, dirt, or grime that may have accumulated, which can cause premature wear and tear if left unchecked.

A way to visualize this is to envision dirt particles getting trapped between the fibers of the line and causing small tears in the weave. When the line is put under tension, these dirt particles act like miniature saw blades, gradually weakening the line over time and potentially leading to catastrophic failures. Therefore, regular cleaning and maintenance of your lines, including halyards and sheets, is essential to ensure their longevity and reliability and to avoid any dangerous situations while out on the water.

Inspecting Your Lines for Damage

Pro tip: Usage level and proper care is a more important indicator than age

Let’s dispel some common misconceptions about when to retire a sailboat line. For example, some sailors may retire a line based solely on its age, rather than its condition. We want to stress the importance of inspecting lines regularly and retiring them when signs of wear or damage are detected, regardless of their age. Here’s a helpful checklist so you know what to look for on your lines.

Inspection Checklist

- Check for visual signs of wear and tear, such as fraying or abrasions, which can weaken the line and compromise its strength. Be sure to examine the line thoroughly, paying particular attention to any areas of high friction or wear.

- Run your hands along the length of the line, feeling for any hard or soft spots, which can indicate internal damage or wear. If you detect any abnormalities, consider retiring the line or seeking professional advice.

- Look for any signs of UV damage, which can cause the line to degrade over time. This is particularly important for lines that are exposed to sunlight for extended periods.

- Check the diameter of the line, ensuring that it matches the manufacturer’s specifications. Any significant deviations may indicate that the line has been stretched or otherwise damaged.

- Examine the connection points, including splices and knots, ensuring that they are secure and free from any signs of wear or damage.

To recap, lines, halyards, and sheets are an essential component of any sailing vessel, and choosing the right halyard for your boat is a necessary part of outfitting your vessel. Regular maintenance and proper care of your halyards can ensure their longevity and reliability. We hope this article has provided valuable insights into halyards, sheets, and lines, though we understand that it may seem like a lot of information.

If you feel overwhelmed by the amount of information, don’t worry, we have simplified the process of finding the right line for your boat. Simply fill out a form , and we will send you the best fit and our professional opinion based on the type of sailing you plan on doing. If you have any questions, comments, or wish to order lines from our sail consultants, please don’t hesitate to contact us.

FAQ’s

Q: What is a sailboat halyard?

A: Halyards are ropes or lines used to hoist sails, flags, and other equipment on a boat.

Q: What is a sailboat sheet?

A: A sailboat sheet is a line that is attached to the lower corner of a sail and used to control its position relative to the wind. The sheet is usually led through a block or a series of blocks, which allow the sailor to adjust the sail’s angle and trim it for maximum efficiency. In addition to controlling the sail’s position, the sheet also helps to control the sail’s shape and tension, which can affect the boat’s speed and handling.

Q: Can different types of materials be used to make halyards, sheets, and lines?

A: Yes, lines can be made of various materials such as polyester, nylon, stirotex, and dyneema. Each material has its own strengths and weaknesses, and the choice of material depends on the type of sailing and personal preference.

Q: How do I determine the length of halyard I need for my sailboat?

A: It’s important to consult with a sail consultant or experienced sailor to ensure you get the correct length. The length of halyard you need will depend on the height of your mast, the type and size of the sail you will be using, and where you plan on trimming your sails. Calculating the length is more complex than simply taking a guess, not to worry though, we have made it easy. Give us a call or fill out our form to let our system crunch the numbers for you.

Q: How do I know if my halyard or sheets are due for replacement?

A: Look for signs of wear and tear such as fraying, kinking, or stretching. If the line feels stiff or brittle, it may be time to replace it. Additionally, if you notice any damage to the sheave or winch, this may also indicate the need for a replacement. See the checklist above for detailed instructions.

Q: Are there any safety precautions I should take when using halyards and sheets?

A: Yes, it’s important to properly understand how to use a winch and don’t wrap the rope around your arm or fingers. Always be aware of your surroundings and avoid getting entangled in halyards or other lines. It’s also recommended to have a backup halyard in case of failure or emergency situations.

Q: How can halyards affect the performance of a sailboat?

A: The type of halyard used can have an impact on the performance of the sailboat. For instance, a stretchy halyard may cause the sail to lose its shape by releasing the tension on the sail over time, while a stretch-resistant halyard can help the sail maintain its shape in strong winds.

Q: Is it possible to splice or repair a damaged halyard or sheet?

A: It is possible to splice or repair a damaged halyard, depending on the extent of the damage and the material of the halyard. However, it’s essential to have the repair done by a professional or experienced sailor to ensure the halyard’s continued reliability and safety.

Q: How often should I replace my lines?

A: The lifespan of halyards and sheets can vary depending on factors such as usage, exposure to weather, and material. It’s recommended to regularly inspect your lines for wear and tear and replace them as needed. Condition is a much stronger indicator than age. Assuming light use and good condition, some materials like Stirotex have a longer lifespan, other materials may need to be replaced more often. In general, halyards and sheets should be replaced every 3-5 years for optimal safety and efficiency.

Related Posts

Full Battens vs Partial Battens vs 2 Full plus 2 Partial Battens

Full Battens VS Partial Battens At

Precision Sails we are asked every day during our customer quote consultation “Should I choose Full Battens or Partial Battens for my new mainsail?” Whether you are cruising or racing you will need to examine the pros and cons of adding full battens to your main sail.Positive Aspects of Full […]

My Need for Cruising Speed Demands a Great Suit of Sails

My Need for Cruising Speed Demands a Great Suit of SailsI like to sail fast mostly in the heavy winds that Lake Ontario throws.

How to Fold a Sail (Mainsail or Headsail) For safe Storage

Knowing how to fold a sail correctly will make your sails last longer and make them easier to set. Replacement sails are an investment and folding them properly is important to their longevity.

" * " indicates required fields

Thanks for telling us a bit about yourself and your boat. Our team will send you a preliminary quote based on information we have gathered from sailors similar to you.

We will give you a call in order to narrow down the options on your quote and improve the accuracy. If you want us to call you at a specific time, feel free to schedule a time on our calendar!

Thanks for telling us a bit about yourself and your boat. Our team will reach out to offer some suggestions and get started on finding you the perfect sail!

|

| |

| |

| | |

| - Replacement Sheaves for Blocks and Spar Applications. . - Cleats by Type, Size, & Manufacturer. - Line Stoppers & Replacement Parts by Manufacturer. - Quick-release, High load Shackles. . | |

| - Primarily used for Mainsail Halyards. - Primarily used for Jib & Spinnaker Halyards. | |

| , Fixed | |

| - for leading Halyards & other lines aft. - Flat mounted Turning Blocks for Deck & Spar Applications. - Deck mounted Turning Blocks for Jib & Spinnaker Sheets. - Deck mounted Stand Up Blocks.

- for Spar & Deck Applications. | |

| - Hanging Blocks for Halyards, Lifts, Mainsheets, etc. - Jib/ Genoa Blocks with integral Track slides. - Jiffy Reefing Blocks on Track slides. - for & Masts. | |

| - in and . - in Stainless Steel. - in and . - One-Handed, Quick-release SS Pins. | |

| - T-Track, , misc. Tracks, & related Hardware. T-Track & Fittings --- - - Extruded Toerails for Hull and Deck joint Applications. , & - For Lifelines & Pulpits. - Rigging to Hull Attachment Points. - Deck mounted Tank Fillers for Water, Waste, & Fuel. - Hatches, Ports, Portlights and related Parts & Hardware. - SS, Aluminum & Cast Bronze. - Traditional Cast Bronze Stemheads & Chocks. - For use stowing an Inner Forestay. | |

| - Pintles, Gudgeons, Rudder & Tiller Heads, Rudder Bushings. - Hull mounted Bailers for Small Keel Boats & Dingys. - Winches & Parts by Manufacturer, and related Hardware. | |

FREE SHIPPING IN CONTINENTAL U.S. ON ORDERS OVER $100

- Deck Hardware

- Jib Furlers and Accessories

Mast Hardware

- Carbon Fiber Winch Handle

- Schaefer Specials

- Clearance Items

- Ideal Windlass

- SeaSure Products

- Hawk Wind Indicators

- General Usage Chart

- 508-995-9511

Your Cart is Empty

- $0.00 USD Subtotal

Taxes and shipping calculated at checkout

I Agree with the Terms & Conditions

Do Your Masthead Sheaves Need Replacing?

Published by rigworks on october 26, 2020.

Question: My halyard is binding. What’s up?

From the Rigger: Most boat owners do not climb their masts regularly, but our riggers spend a lot of time up there. And they often find badly damaged or worn sheaves.

Your halyards pass though sheaves mounted in the top of your mast. These sheaves are often plastic and, due to marine exposure, they are subject to fatigue, abrasion, and corrosion. Damaged sheaves can result in friction and resistance, making your sails increasingly difficult (and eventually impossible) to hoist and/or lower.

The sheaves in the photo are from a boat we repaired last week. The owner was trying to lower the genoa, and the sail stuck half way down. We were able to remove the damaged sheaves and have a new set fabricated from Delrin, an acetal polymer that is very resistant to wear. We also cleaned the furler foil which was dirty and showing signs of surface corrosion. Now the sail goes up and down smoothly, and our customer is enjoying some great sailing.

If your sails appear to be binding, give us a call. We would be happy to take a look and recommend the appropriate maintenance.

Related Posts

Ask the Rigger

Standing rigging (or ‘name that stay’).

Question: When your riggers talk about standing rigging, they often use terms I don’t recognize. Can you break it down for me? From the Rigger: Let’s play ‘Name that Stay’… Forestay (1 or HS) – Read more…

Selecting Rope – Length, Diameter, Type

Question: Do you have guidelines for selecting halyards, sheets, etc. for my sailboat? From the Rigger: First, if your old rope served its purpose but needs replacing, we recommend duplicating it as closely as possible Read more…

Spinlock Deckvest Maintenance

Question: What can I do to ensure that my Spinlock Deckvest is well-maintained and ready for the upcoming season? From the Rigger: We are so glad you asked! Deckvests need to be maintained so that Read more…

| | | --End of comment 2018 NA--> |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COMMENTS

Zephyrwerks is The Sheave Factory! We make sheaves, both anodized aluminum sheaves and isomat sheaves. Get your sheaves customized to individual specifications for mastheads, staysails, booms, halyards, and for all sailboat rigging new and replacement sheave needs.

Narrow high-load sheaves in mastheads improve sail handling, speed sail changes, and allow the use of smaller, lighter halyard winches. High-load titanium V sheaves feature the same incredibly efficient bearing set of angled titanium rollers as Harken's V blocks. Perfect for running lines underdeck, in mainsheet and spinnaker sheet or drop ...

Type 1: Boats up to 250 lbs Dollies. Type 2: Laser, Byte & Invitation Dollies. Type 3: Curled Gunwale Boats Dollies. Type 4.1: Small/Med Bowsprit Boats Dollies. Type 4.2: Heavier Sprit Boats Dollies. Type 5: Heavier Doble-Handed Boats Dollies.

Ronstan RF251 sheaves are the same inside and outside diameters as the original equipment sheaves but wide enough for 8mm or 5/16″ lines. This means that they are slightly wider than 1/4″ sheaves. Two pairs of them will fit in the masthead with no modification other than a thinner spacer between them. The stock spacer is 2.5 mm thick.

Reduce friction and increase your sailing power with any of the sheaves we carry. MAURIPRO Sailing, your direct access to Sailboat Rigging Sheaves and all your other sailing and boating needs. Shop sailboat Rigging Sheaves at MAURIPRO Sailing Store. Complete selection and technical information on all. Free shipping on orders over $99.

Aug 28, 2001. #6. Sheaves. Unless you have internal halyards it is unlikely that you can replace the sheaves while hanging on either halyard. In a standard rig with external halyards the main halyard goes up the front of the mast, over a sheave, across to the after side, over another sheave and down to the sail.

Ultimately, for the sake of a hundred dollars saved on a halyard, the owner never sees the full performance he paid for in his new sail. For an average boat in the mid-30-foot range, a new mainsail can cost from $2,000 upward, and the premium for a "performance" mainsail over a basic Dacron model starts at about $500.

With the added chafe cover at the shackle, it's nearly impossible for the sheave to tear the halyard. RECOMMENDED LINE: Endura Braid, V-100, VPC, T-900; Spinnaker Halyard . PRIORITIES: A high break point is essential. Low stretch is important, but not as necessary as it is for other halyards. DESIRABLE: Light weight to reduce weight aloft.

Catalina 310, hull #73, built Dec 2000. I'd like to replace the sheave at the masthead, the main halyard is hard to pull when there is tension on it. Before I go up (or send someone up) I'd rather have the parts in hand and do it in one pass. I called Catalina Support, they referred me to Charleston Spar (Sparcraft), saying they built the mast up.

Q: How can halyards affect the performance of a sailboat? A: The type of halyard used can have an impact on the performance of the sailboat. For instance, a stretchy halyard may cause the sail to lose its shape by releasing the tension on the sail over time, while a stretch-resistant halyard can help the sail maintain its shape in strong winds.

Sailboat Hardware Rig-Rite stocks a large selection of Specialty Hardware and hard-to-find parts for a variety of Systems. ... Sheaves - Replacement Sheaves for Blocks and Spar Applications. Sheave Bushings. Cleats - Cleats by ... Swivel Blocks - Hanging Blocks for Halyards, Lifts, Mainsheets, etc. Track Mounted Blocks - Jib/ Genoa Blocks with ...

Schaefer manufacturers a wide variety of mast hardware including SS Sail track, Halyard restrainers, Halyard exit boxes and exit plates as well as spinnaker pole hardware. ... Exit Box/ Single 2" Sheave 34-35 $373.75 USD 7/8" S.S. Sail Track Stop 74-42 mast-hardware. Quick View 7/8" S.S. Sail Track Stop 74-42 $110.75 USD Spinnaker Pole Slider ...

From the Rigger: Most boat owners do not climb their masts regularly, but our riggers spend a lot of time up there. And they often find badly damaged or worn sheaves. Your halyards pass though sheaves mounted in the top of your mast. These sheaves are often plastic and, due to marine exposure, they are subject to fatigue, abrasion, and corrosion.

The J/30 and J/24 use the same size sheaves in the mast crane. There are two sheaves at the top. The Main Halyard Delrin Sheave is 1.75" OD x 3/8" ID x 1/2" wide with the Main Halyard Sheave Bronze Bushing 3/8" OD x 1/4" ID x 1/2" Wide. Look at my old post at this link with the info. I bought new Delrin sheaves, pins and bushings from Annapolis ...

Diameter of sheaves: 2" (most often referred to as "A") Width of sheaves: 7/16" (often referred to as "B") Width of supporting plate in center of masthead box: 3/16" Diameter of sheave pins: 3/8" (usually referred to as "C") There are problems. Whoever it was that overtightened the tensioner bolt on the masthead box, cracked the box on one side.

Halyard Boxes & Sheaves. Offering the ultimate in strength, weight and performance, we stock a wide range of halyard sheaves in varying styles and sizes from top of the top marine manufacturers, including Allen, SuperSpar and Selden. If you cannot see the item you require or you'd like some technical advice, please give us a call on 01604 ...

A 5/16" high tech line might be equal to a ⅜" old school line. Rigging refers to the blocks, sheaves, cleats, and so on. A smaller line will always run better through bigger blocks and sheaves, but won't work in bigger line stoppers. The halyard sheave size is probably the limiting factor. Small line works in big sheaves, big lines won't work ...

The bushings and axel that halyard sheaves spin on should be closely inspected. Ralph Naranjo . This is also the time to sort out halyards that are rubbing against external or internal obstructions. I use a bright, narrow-beam LED flashlight for a good visual inspection of the internal portion of the mast.

Sheets and Halyard Selection Chart. You can also find further information on the infographic below. The stretch percentages are based on a 500kg working load rather than an ultimate breaking load. This accounts for the difference between the infographic and the table above. Shop for Sheets and Halyards.

Catalina 27 Mission Bay, San Diego. Jan 14, 2014. #3. Those sheaves are designed to accommodate both wire and rope. There is no need to change the sheaves because you're going all rope. However, if you feel Mitiempo's comments apply I suggest you remove one for closer inspection. You could polish it with a wire brush, perhaps.

We're going to change the sheaves to probably accomodate a 5/16" 12 strand line. So that means up the bosins chair to measure and take out existing sheaves. Over to the local Marine Supply store to buy said sheaves. Back up the bosins chair to install those newly purchased sheaves and then ready for the halyards.

Maybe because I wasn't able to sail for a 7-8 month period last winter, and my masthead sheaves sat unused, my main halyard now isn't running as freely as before. I can tell by pulling the halyard up/down by hand that sheave is still free and is not catching. Just protesting a bit. The "exit" sheaves at the mast base are rotating fine.