- Like Westshore Marine & Leisure on Facebook!

- Follow Westshore Marine & Leisure on Twitter!

- Check out the Westshore Marine & Leisure google plus page!

- Check out the Westshore Marine & Leisure Youtube page!

- Highway 68 & Main St Arborg MB R0C 0A0

- Follow Westshore Marine & Leisure on Wordpress!

- Toll Free Phone: 855-534-7333

Boat Transom Heights – The Beginner’s Guide

Whether your on a pontoon boat, fishing boat, or speedboat boating is always one of the best times you can have. As summer approaches there will be more boaters taking to the water.

Among them will be first-timers or those who have recently purchased their boats.

Buying a boat can be an exciting purchase. With it comes a lot of responsibility and new things to learn including boat maintenance and boat basics. Here we will guide you in how to get the right boat transom height.

Before we get started let’s see what a boat transom is and what it does. The transom is the flat vertical section at the rear of the boat. It is where the outboard is mounted, and some boat owners place the name of the boat.

The height of the transom is calculated by measuring from the bottom of the hull to the top of the transom, using the center line.

On most newer center consoles and offshore boat transoms might include a rear door leading to a swim platform as well as a molded setback bracket.

Why your boat transom needs to be the right height

It is extremely important that the boater understands the significance of the transom’s height.

The height of the boat transom dictates the size of the outboard motor. The motor is what powers the boat so the two go hand-in-hand.

If the height of the boat transom is off it can cause major issues. A reverse transom that sits too high can impact the propellers of the motor and motor bracket. The propellers will also have trouble reaching the water.

When the boat transom is too low, the motor could end up underwater. This would not be a good thing.

The short and long of transom heights

As mentioned above, the operation of the propeller relies on the transom height. To achieve this, the motor itself has to be attached at the correct height.

Beginning boaters should be aware of the boat’s measurements.

Industry standards dictate that for short shaft engines the transom height should be 15″. A long shaft engine requires a height of 20″ and extra-long shaft engines will need a transom height of 25″.

While this is the case there is certain saltwater motors that are extra extra long at 30″ and 35″ shaft.

Keep these numbers in mind if you ever have a need for a new outboard motor for your boat.

The pros and cons of properly mounting the outboard motor to the transom

Mounting the outboard motor in accordance with the industry standards is important. However, there may be times when a boater strays away from these recommendations.

Knowing how this can affect the overall operation of the boat is a factor to be considered.

Here we look at the effects of standard, lower and higher mounting.

Standard mounting is always best for the beginner

Of course, it’s always best to go with standard practices when choosing the best boat engine .

Generally, the anti-ventilation plate on most engines is aligned with the bottom of the vessel. This is measured by the propeller shaft being parallel to the vessel’s bottom.

The outboard comes with mounting holes and brackets. These are vertically aligned so the boater can make adjustments.

As with anything, there are exceptions to the rule. If you decide to make adjustments, please consult a marine engine dealer about the boat design.

Lower mounting is not for the beginning boater

In lower mounting, the engine is set lower than the recommended standard. Doing this can have adverse effects.

Mounting the motor lower on the boat transom can create excessive spray, increase case drag, reduce underwater clearance, and negatively impact faster boats.

It also cuts into speed and fuel efficiency.

This could also effect your travelling capabilities on the boat trailer. It is possible that the motor could hang low while transporting on the boat trailer causing future boat repairs.

There is a simple test to see if your outboard motor is set at the best height. Simply start with the engine in idle, followed by trimming the motor out by one-half to full trim.

Safely but briskly accelerate. If the propeller fails to ventilate, the motor is mounted to low.

There are instances where a lower mount may be okay. Some fishing boats can handle the motor being underwater. This, however, is not recommended for the beginning boater.

Higher mounting is the most complex

Higher mounting decisions should be left to the professionals. One of the main concerns is causing the engine to overheat if not enough water reaches the engine to keep it cool.

The boater must also consider if the boat transom support is designed to bear the weight of a higher mount. No one wants to have issues with a new transom or boat repairs.

Boaters who consider going with a higher mount can see increased speeds. It can also improve the experience of driving a faster boat.

Increased RPM and additional horsepower feed the need for speed. This alone can outweigh the negatives when deciding to adjust the mount upwards.

On the downside, a higher mount can interfere with the boaters steering capabilities.

All things considered, sticking with the industry standard is best for the beginner. Always weigh the risks of making adjustments.

Calculating your boat’s transom angle

Another important measurement is the transom angle.

The transom angle is the vertical incline of the transom and is measured in degrees. The boat transom can be flat with zero degree angles. Or it can have an angle degree as high as 30.

The average transom angle is around 14 degrees.

Boat transom angles play a pivotal role in the flexibility of the boats trimming abilities.

Trimming in, trimming down, and trimming out are all terms that a beginning boater should learn. Each one has a totally different effect on the boat’s performance.

You don’t have to be a mathematician to determine the correct boat transom angle. However, you will need an understanding of how the degrees will alter the boat’s usability.

It doesn’t matter if you have a fiberglass boat, bay boat, big or small boat. Take your time and understand your boat and your entire transom.

Now that you have a better understanding of boat transom heights it’s time to take out the ruler and get the perfect measurements.

How can Westshore Marine & Leisure help?

If you decide to make some custom adjustments we have the experience and know-how to make it happen.

Whether you already own a boat or looking for your first watercraft we are here to service your needs. If you have a question or need additional information, contact us today.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

- About Click&Boat

- Everything you need to know about renting a boat

- Best destinations to set sail

- Boat owners

- Nautical Knowledge

What is a Boat Transom? Your Ultimate Guide!

- 25 July 2023

- 4 minute read

Alice Martin

Share the post "What is a Boat Transom? Your Ultimate Guide!"

In our most recent blog post, we continue with the world of sailboat anatomy looking at the often overlooked but important transom. We investigate the various types of transoms, their placement, and their composition, and shed light on the difference between a stern and a transom. So, let’s set sail and find out about the boat transom!

What is a boat transom?

Let’s begin our journey by understanding what a boat transom is. Tucked away at the stern, the transom is more than just a part of the boat’s anatomy. It acts as protection against the water’s resistance, shaping the boat’s wake, and serving as an essential platform for various components and activities.

Which type of boats have a transom?

The transom is a fundamental component of boat design and most boats will have one. You’ll find transoms on small fishing boats, where they often provide a mounting point for outboard engines. You’ll also see them on larger recreational boats like yachts and sailboats, where they might house additional features such as swim platforms or diving boards. Commercial vessels like ferries or cruise ships have them too, though they’re often hidden under various structures or equipment. From dinghies to ocean liners, the transom is a common feature across a broad spectrum of boat types.

Where is the boat transom located?

The transom is relatively easy to spot! Picture the stern (rear end) of your boat. That flat or curved surface that takes on the water’s resistance? That’s the transom! It’s essentially the backbone of your boat, giving it strength and rigidity while helping shape the wake. Many boat owners put the name of their boat on the transom, which is another way to locate where it is!

What is a boat transom made of?

A transom is as good as the material it’s made of. Traditionally, it is made from materials such as plywood, fiberglass, or aluminium.

Plywood is often the go-to choice for boat builders due to its strength and affordability.

Fiberglass is lightweight yet durable, and resistant to water damage, which is a big tick for anything boat-related!

Aluminum is tough and resistant to corrosion, offering a long-lasting solution for transoms.

What are the different types of boat transoms?

Moving on to the types of boat transoms, we look at three main types: full transom, reverse transom, and cutaway transom. Whether you’re prioritising space, style, or speed, understanding these different transom types will help you make a more informed choice when picking your next vessel with Click&Boat .

Full Transom

As the name suggests, full transoms span the entire width of the boat, giving it maximum strength and space. You can easily spot these on fishing boats or cruising sailboats.

Reverse Transom

Next up is the reverse transom. It tilts backward, creating an illusion of a longer waterline and offering more space on the deck.

Cutaway Transom

The cutaway transom, as the name suggests, has a chunk ‘cut away’, creating a ‘V’ shape at the stern. This type enhances performance by reducing drag and adds a sleek look to the boat.

What is a boat transom used for?

There are various uses for the transom and you would be surprised how important it is! Here are a few:

Protect and support the back of the boat

Not only does it add protection to the back of the boat, it also acts as a barrier to prevent water from entering.

Supports the outboard motor

Some recreational boats require a motor that needs to be attached to the back of the boat. The transom provides a sturdy place for the motor to attach to.

Provides a space for accessories

In addition to mounting the motor, the transom is used to mount boating equipment such as ladders or a swing platform.

What is the Difference Between a Stern and a Transom?

The terms stern and transom might be used interchangeably, but it’s important to know that they are not actually the same thing. The stern refers to the whole back end of the boat, while the transom is specifically the flat (or sometimes curved) surface on the stern. In simple terms, the transom is a part of the stern.

As we’ve explored in this blog post, the transom serves multiple purposes, from providing protection against water resistance to acting as a platform for various components. Whether you’re on a small fishing boat, a luxurious yacht, or a commercial vessel, chances are you’ll find a transom that plays a vital role in the design and functionality of the boat. We hope that understanding the different types of transoms means next time you are booking your boat, you will be able to spot one!

Essential Marine Navigation Tools and Techniques

- 14 July 2023

- Clara Chambers

Sunset Sailing: The Complete Handbook

- 31 July 2023

You May Also Like

- Featured Posts: The Latest News

What to bring on board: your boating checklist

- 20 March 2024

Our tips for a family sailing holiday on a catamaran

- 15 March 2024

Smooth Sailing: Budgeting Your Perfect Sailing Holiday

- 14 March 2024

Sailboat or Catamaran: which one to choose?

- 13 March 2024

Organize your sailing travel plans: 6 tips from Click&Boat

- 6 March 2024

- Destination Information

Sailing Under the Stars: A Maui Stargazing Adventure

- 25 November 2023

Deciding which boat to rent on Click&Boat

- 16 October 2023

Making waves with peer to peer boat rental

- 14 October 2023

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Input your search keywords and press Enter.

- Anchoring & Mooring

- Boat Anatomy

- Boat Culture

- Boat Equipment

- Boat Safety

- Sailing Techniques

Boat Transom: A Comprehensive Guide

The boat transom, often considered the backbone of a vessel, plays a crucial role in a boat’s overall performance and appearance. It’s the vertical or near-vertical surface at the stern of a boat, providing structural support and a platform for mounting essential components like outboard engines, swim platforms, and other accessories.

They come in various types and materials, each with unique advantages and characteristics. In this comprehensive guide, we’ll explore the different designs and materials used in construction and how they impact a boat’s performance. We’ll also discuss essential maintenance and repair tips to keep your boat in shape.

Key Takeaways

- There are various types of boat transoms, including flat, curved, reverse, Euro-style, and inboard designs.

- Transoms can be made from different materials, such as wood, fiberglass, aluminum, and carbon fiber, each with its own construction methods and properties.

- Transom shape and angle can significantly impact a boat's performance, including planing, stability, and maneuverability.

- Matching the transom type and hull shape is essential for optimal performance, with different combinations suited for displacement, semi-displacement, and planing hulls.List Item

- Transom-mounted components and accessories include outboard engines, stern drives, transducers, underwater lights, live bait wells, trim tabs, and hydrofoils.

- Transom reinforcement may be necessary when adding heavier engines or equipment, and adhering to the transom's weight capacity is essential for safety and preventing damage.

- The terms "stern" and "transom" are often mistakenly used interchangeably; the stern refers to the entire rear of the boat, while the transom is the vertical surface at the back of the hull.

Types of Boat Transoms

Flat transoms are the simplest and most traditional type. They have a vertical or near-vertical surface at the stern of the boat. They’re common in small to medium-sized boats and provide a large, stable platform for mounting outboard engines or other equipment.

Curved transoms have a gentle curve from the waterline to the top of the transom. This design is often seen in classic and vintage boats. The curved shape provides a smooth, elegant appearance and can help reduce turbulence and drag when the boat is in motion.

Reverse transoms angle inward from the waterline to the top of the transom, creating a distinctive and modern look. This design can improve the boat’s performance by reducing drag and providing a smoother ride in rough water. It also allows for increased cockpit space and easier access to the water.

Euro-style transoms are sleek, angular and may incorporate integrated swim platforms or steps. These are popular in modern sport boats and luxury yachts . They offer a stylish appearance and can provide additional functionality, such as seating or storage.

Inboard transoms are designed for boats with inboard engines or inboard/outboard (I/O) setups. These typically have a cutout or recessed area to accommodate the engine, drive shaft, and propeller. Inboard transoms can improve the boat’s balance and performance by keeping the engine weight closer to the boat’s center.

Materials and Construction

Wood has been used for centuries in boatbuilding and is still popular. There are two main methods for constructing wooden transoms:

Traditional wooden construction : This involves using solid planks or beams, often made from hardwoods like oak or mahogany. These planks are joined together using various techniques, such as mortise and tenon joints, to create a strong and durable transom.

Plywood and epoxy composite construction : Modern wooden transoms often use plywood as the primary material. Layers of plywood are glued together using epoxy resin, creating a strong and lightweight structure. This construction method is resistant to rot and moisture damage, making it a popular choice for today’s wooden boats.

This is widely used for its strength, durability, and low maintenance requirements. There are two main techniques:

Hand lay-up technique : This method involves applying fiberglass cloth or mat layers to a mold, then saturating them with resin. The layers are built up to the desired thickness, and the transom is left to cure before removal from the mold.

Vacuum infusion process : This advanced technique uses a vacuum to draw resin through the layers of fiberglass, ensuring even distribution and a high-quality finish. This method can produce a stronger and lighter transom compared to hand lay-up.

Aluminum is popular due to its lightweight, strength, and corrosion resistance. There are two main methods for constructing aluminum transoms:

Welded aluminum construction : Aluminum sheets or plates are welded together to create a rigid structure. This method offers excellent strength and durability, as well as corrosion resistance.

Bolted aluminum construction : Aluminum sheets or plates are joined using bolts or other fasteners. This method is less labor-intensive than welding but may require more regular maintenance to ensure the connections remain secure.

Carbon fiber

Carbon fiber is a high-performance material becoming increasingly popular in high-end and racing boats. Transoms made from carbon fiber are extremely strong, lightweight, and stiff, which can lead to improved boat performance. These are typically constructed using advanced techniques, such as vacuum infusion or prepreg molding, to ensure the best possible quality and strength.

Transom and Hull Shape Interactions

Transom design can significantly impact a boat’s performance in several areas, including planing, stability, and maneuverability.

Planing : The transom shape affects how quickly a boat gets on the plane and how efficiently it maintains plane at various speeds. Flatter transoms can help a boat plane faster, while more angled transoms can improve efficiency at higher speeds.

Stability : The transom design can influence a vessel’s stability, particularly regarding side-to-side motion. Wider, flatter transoms can provide increased stability at rest, while curved or angled transoms can offer better stability when the boat is underway.

Maneuverability : Transom shape can impact a boat’s ability to turn and respond to changes in direction. Certain designs, such as reverse transoms, can enhance maneuverability by reducing drag and allowing the boat to turn more smoothly.

Matching transom type to hull shape

Displacement : These are designed to push through the water rather than plane on top of it. Boats with displacement hulls typically benefit from a curved or angled transom, which can help to reduce drag and improve efficiency at lower speeds.

Semi-displacement : Semi-displacement hulls can both push through the water and plane, depending on their speed. Semi-displacement boats often work well with various designs, but a flatter transom can help the boat transition from displacement to planing more easily.

Planing : Planing hulls are designed to ride on top of the water at higher speeds. These boats generally benefit from a flatter transom, which can help the boat get on plane quickly and maintain speed efficiently.

Transom angle and its impact on boat performance

The angle can also affect a boat’s performance. A steeper transom angle can reduce drag and improve efficiency at higher speeds, while a shallower angle can provide better stability at lower speeds or when the boat is at rest. The ideal angle depends on the boat’s intended use and performance goals.

Transom-mounted Components and Accessories

Outboard engines.

These are among the most common components mounted on boat transoms. These engines can be set up in different configurations, depending on the boat’s size and performance requirements.

Single engine setup : This configuration is common on small to medium-sized boats. One engine is mounted in the center of the transom, providing power and propulsion.

Twin engine setup : Larger boats may have two outboard engines mounted side by side on the transom. This setup provides increased power and redundancy, improving performance and reliability.

Triple or more engine setups : Some high-performance boats and larger vessels may have three or more outboard engines mounted on the transom. These configurations offer exceptional power and speed capabilities but require more maintenance and fuel.

Stern drives (inboard/outboard)

Stern drives, also known as inboard/outboard (I/O) drives, combine features of both inboard and outboard engines. The engine is mounted inside the boat, while the drive unit (propeller and lower gearcase) is mounted on the transom. This setup offers improved balance and performance compared to a traditional outboard engine.

Transom height and engine compatibility

When selecting an outboard engine for your boat, it’s crucial to match the transom height with the appropriate engine shaft length . Standard transom heights include 15 inches (short), 20 inches (standard or long), and 25 inches (extra-long). Choosing the correct shaft length ensures optimal performance and reduces the risk of damage to the engine and the transom. If the shaft is too short, it can result in insufficient water intake, causing the engine to overheat. Conversely, if the shaft is too long, it can create excessive drag, reducing speed and fuel efficiency.

Self-draining Ttansoms

A self-draining transom is a valuable feature that helps keep the cockpit dry and prevents water from accumulating in the boat. This design incorporates strategically placed scuppers or drain holes in the transom, allowing water to flow out of the boat rather than pooling inside.

Self-draining transoms are especially beneficial for boats frequently exposed to rough water or inclement weather, as they can reduce the risk of swamping and improve overall safety.

Swim platforms and ladders

Swim platforms and ladders are popular accessories mounted on a boat’s transom. These features provide easy access to the water for swimming, diving, or other activities and are available in different designs to suit your boat’s style and needs.

Trim tabs and hydrofoils

Trim tabs and hydrofoils can improve a boat’s performance and handling. They are mounted on the transom and help adjust the boat’s attitude, or angle, in the water. Trim tabs are adjustable plates that can be lowered or raised to change the boat’s pitch, while hydrofoils are fixed fins that help lift the stern and reduce drag.

Transom-mounted equipment

Transducers : Transducers are essential components of fishfinders and depth sounders. They’re mounted on the transom and send sonar signals to detect fish, measure depth, and provide information about the underwater environment.

Underwater lights : These can be mounted to illuminate the water around your boat. These lights enhance the boat’s appearance and improve safety by making the boat more visible at night.

Live bait wells : Live bait wells are containers that hold live bait for fishing. They can be mounted for easy access and are available in various sizes and designs to suit your fishing needs.

Maintenance and Repair

Inspecting for damage or wear.

Visual inspection : Examine the transom for any visible signs of damage, such as cracks, splits, or discoloration. Pay close attention to the areas around the engine mount and any other transom-mounted components.

Tap testing for delamination : Using a small plastic or rubber mallet, gently tap the surface of the transom. A solid, consistent sound indicates a healthy transom, while a hollow or dull sound may suggest delamination or other internal issues.

Moisture meter testing : Use a moisture meter to check for excessive moisture within the transom, particularly for wooden or fiberglass transoms. High moisture levels can lead to rot or delamination.

Common issues and their causes

Rot in wooden transoms : Prolonged exposure to moisture can cause wooden transoms to rot. This can weaken the structure and lead to further damage if left untreated.

Delamination : Fiberglass can experience delamination, where the layers separate. This issue often results from moisture intrusion or manufacturing defects and can compromise strength.

Corrosion in aluminum transoms : Aluminum can suffer from corrosion, particularly in saltwater environments. Corrosion can weaken and cause structural problems if not addressed promptly.

Stress Cracks and Gelcoat Damage

Stress cracks and gelcoat damage are common issues affecting a boat’s transom. Various factors, including impact, age, or poor manufacturing, can cause these cracks. Preventive measures include regular inspections, avoiding overloading, and using proper lifting techniques when the boat is out of the water.

For minor gelcoat damage or stress cracks, a DIY repair can be performed using a gelcoat repair kit. For more severe cases, it’s recommended to consult a professional boat repair service to ensure proper restoration and maintain the integrity of the transom.

Repair methods

Wooden transom repair : Rotting wooden transoms can be repaired by removing the affected area and replacing it with new wood or marine plywood. Ensure proper sealing and waterproofing to prevent future moisture damage.

Fiberglass transom repair : First, remove any damaged or loose material to repair the delamination. Then, apply new layers of fiberglass cloth and resin to restore the transom’s strength and integrity. Finish with a gelcoat for a smooth, waterproof surface.

Aluminum transom repair : Repairing corroded aluminum transoms typically involves removing the affected area and welding in a new piece of aluminum. Ensure the welds are watertight and apply a protective coating to prevent future corrosion.

Reinforcing for added strength

In some cases, reinforcing a transom may be necessary, especially when adding heavier engines or equipment. Reinforcement can be achieved by adding additional layers of material, such as plywood or fiberglass, to the structure. Alternatively, install support brackets or specially designed transom reinforcement plates to help distribute stress and increase the transom’s overall strength.

Additional Information

The relationship between transoms and trailers.

Importance of boat trailering : Properly trailering your boat helps prevent damage to the transom and other parts of the boat. Ensure the watercraft is correctly positioned and secured on the boat trailer to minimize stress on the transom during transport.

Transom savers and their role in trailering : Transom savers are devices designed to support the transom and engine during trailering. They distribute the weight of the outboard motor and reduce stress, helping to prevent damage.

Transom support and reinforcement

Inspecting transoms for stress from motors : Regularly check the transom for signs of stress or damage, particularly around the engine mount. This can help identify any issues before they become severe.

Strengthening the transom for added durability : Reinforcing it can increase strength and durability, especially when adding heavier engines or equipment.

Transom designs in different types of boats

Fishing boats : Fishing boats often have transoms with built-in live wells, rod holders, and other fishing-specific features.

Sailboats : Sailboats typically have transoms designed to minimize drag and provide easy access to the water for swimming or boarding.

Offshore boats : Offshore and center console boats may have transoms designed for increased durability and strength and accommodating multiple engines for high-performance capabilities.

A common misconception and interchangeable term

Differences between a boat’s stern and transom : The stern refers to the entire rear of the boat, while the transom is the vertical surface at the back of the hull.

Degradation and protection

Effects of salt water and corrosion : Saltwater can cause corrosion, particularly on aluminum transoms. Regularly rinsing the transom with freshwater and applying a protective coating can help prevent corrosion.

Leak prevention and maintenance : Inspect the transom for leaks, particularly around fittings, hardware, or transom-mounted equipment. Repair any leaks promptly and ensure proper sealing to prevent water intrusion and potential damage to the transom.

Swim platforms, ladders, and rear doors

- Integration with transom design : Swim platforms, ladders, and rear doors are often integrated into the transom design to provide easy access to the water, improve the boat’s aesthetics, and enhance overall usability.

- Importance of proper fitting and installation : Ensuring these components are correctly fitted and installed is crucial for their functionality and preventing transom damage. Regularly inspect the mounting points for signs of wear, corrosion, or stress, and address any issues as needed.

Transom Weight Capacity

Adhering to the transom’s weight capacity is essential to prevent overloading, which can cause damage and affect the boat’s performance. Exceeding the recommended weight limit can strain the transom, leading to stress cracks, structural damage, or even failure.

Additionally, overloading the transom can negatively impact the boat’s stability and handling, posing safety risks. Always consult the boat manufacturer’s guidelines and ensure that the combined weight of the engine, fuel, and any additional equipment mounted on the transom does not exceed the specified capacity.

Final Thoughts

Understanding the role of the boat transom and the various designs, materials, and construction techniques available can significantly impact your vessel’s performance, appearance, and durability. By exploring the different types of transoms and their interactions with hull shape and mounted components, you can make informed decisions to ensure your boat performs optimally in its intended environment.

Furthermore, regular maintenance and proper care of your boat’s transom will help prolong its life and prevent costly repairs. As boats continue to evolve, so will transom designs, incorporating new materials and technologies to enhance overall performance and aesthetics, making it essential to stay informed about the latest trends and innovations.

A transom is a vertical or near-vertical surface at the stern (rear) of a boat’s hull. It provides structural support and is often used to mount outboard engines or other equipment.

The main types of boat transoms are flat, curved, reverse, and Euro-style. Each type has its unique characteristics, aesthetics, and performance implications.

The transom design can significantly impact a boat’s planing, stability, and maneuverability. It can also influence the boat’s efficiency and ability to turn smoothly at various speeds.

Common materials used for boat transoms include wood, fiberglass, aluminum, and carbon fiber. Each material has advantages and disadvantages regarding strength, weight, durability, and maintenance requirements.

Match the transom height with the appropriate engine shaft length. Standard transom heights include 15 inches (short), 20 inches (standard or long), and 25 inches (extra-long). Choosing the correct shaft length ensures optimal performance and reduces the risk of damage to the engine and transom.

A self-draining transom is a design feature that helps keep the cockpit dry and prevents water from accumulating in the boat. It incorporates strategically placed scuppers or drain holes in the transom, allowing water to flow out of the boat rather than pooling inside.

A transom saver is designed to support the transom and engine during trailering. It distributes the weight of the outboard motor and reduces stress on the transom, helping to prevent damage.

Digital Selective Calling (DSC) – A Comprehensive Guide

Reefing a sail: a comprehensive guide, related posts, understanding the boom of a boat, understanding the importance of boat chines, hull speed calculator, leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

- Cookie Policy

- Privacy Statement

© 2023 TIGERLILY GROUP LTD, 27 Old Gloucester Street, London, WC1N 3AX, UK. Registered Company in England & Wales. Company No. 14743614

Welcome Back!

Login to your account below

Remember Me

Retrieve your password

Please enter your username or email address to reset your password.

Add New Playlist

- Select Visibility - Public Private

Boat Deadrise Explained: Understanding the Importance of Hull Design

If you are a boater or simply interested in boating, you may have heard the term “deadrise” mentioned when referring to the hull design of a boat. Deadrise is an essential element of a boat’s design, affecting its performance and overall efficiency. In this article, we will explore the concept of deadrise and explain its significance in boat design.

What is Boat Deadrise?

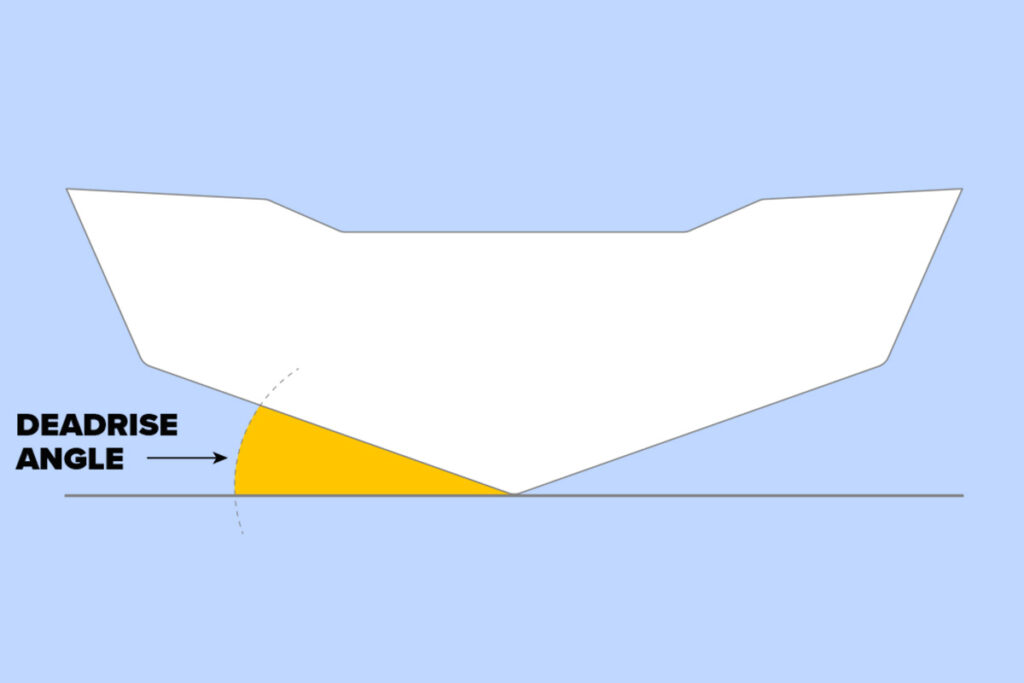

Deadrise is a critical concept to understand when it comes to selecting the right boat for your needs. As mentioned earlier, deadrise refers to the angle of a boat’s hull, measured in degrees from a flat horizontal plane. A boat with a steeper deadrise angle will have a more V-shaped hull, while a shallower angle will have a flatter hull.

The deadrise angle impacts the boat’s performance in a number of ways. A steeper deadrise angle is typically associated with better handling in choppy water, as it allows the boat to slice through waves and reduce the impact of rough seas. However, a steep deadrise angle can also reduce the boat’s stability and make it less suitable for certain types of boating activities, such as cruising or watersports.

Conversely, a shallower deadrise angle can result in better stability and a smoother ride in calmer conditions. This can make a boat with a shallow deadrise angle more suitable for activities like cruising or fishing. However, a shallow deadrise angle can also result in a harsh ride in choppy conditions and may limit the boat’s top speed .

In addition to these general considerations, it’s important to note that deadrise angles can vary widely depending on the type of boat and its intended use. For example, a high-performance offshore racing boat may have a very steep deadrise angle of 25 degrees or more, while a displacement trawler designed for long-range cruising may have a much shallower angle of 10 degrees or less.

Overall, understanding deadrise is an important part of selecting the right boat for your needs. By considering factors like the type of boating you’ll be doing, the conditions you’ll be in, and the performance you desire, you can choose a boat with the appropriate deadrise angle to ensure a safe and enjoyable experience on the water.

Why is Deadrise Important?

Deadrise is an important concept to consider when selecting a boat because it can have a significant impact on the boat’s performance, stability, and suitability for different types of boating activities.

First and foremost, deadrise is important because it affects the way the boat handles in the water. A boat with a steep deadrise angle will typically have better handling in choppy conditions, as the V-shaped hull allows the boat to slice through waves and reduce the impact of rough seas. This can make a boat with a steep deadrise angle more suitable for activities like offshore fishing or racing, where a smooth ride in choppy water is critical.

Conversely, a boat with a shallow deadrise angle will typically have better stability and a smoother ride in calmer conditions. This can make a boat with a shallow deadrise angle more suitable for activities like cruising or watersports, where comfort and stability are more important than speed or handling in rough water.

In addition to handling and stability, deadrise can also impact the boat’s top speed and fuel efficiency. A boat with a steep deadrise angle may have a higher top speed but may not be as fuel-efficient, while a boat with a shallow deadrise angle may have better fuel efficiency but may not be as fast.

Overall, the deadrise angle is an important factor to consider when selecting a boat because it can impact the boat’s performance in a number of ways. By choosing a boat with the appropriate deadrise angle for your needs, you can ensure a safe and enjoyable experience on the water, whether you’re fishing, racing, cruising, or enjoying watersports.

Types of Deadrise

There are generally two types of deadrise: planing and displacement.

Planing Deadrise

Planing deadrise is common in boats that are designed to ride on the water’s surface at high speeds. These boats typically have a deadrise angle of 15 degrees or less, allowing them to plane on the water’s surface. This design reduces drag and increases speed, making it ideal for water sports, fishing, and other recreational activities.

Displacement Deadrise

Displacement deadrise is common in boats designed for cruising and long-distance travel. These boats typically have a deep deadrise angle of 20 degrees or more, which allows them to cut through the water more efficiently. Displacement boats move through the water, pushing aside the water, and the hull creates a wave that travels along the length of the hull, reducing drag and increasing efficiency.

Boat Deadrise Measurements

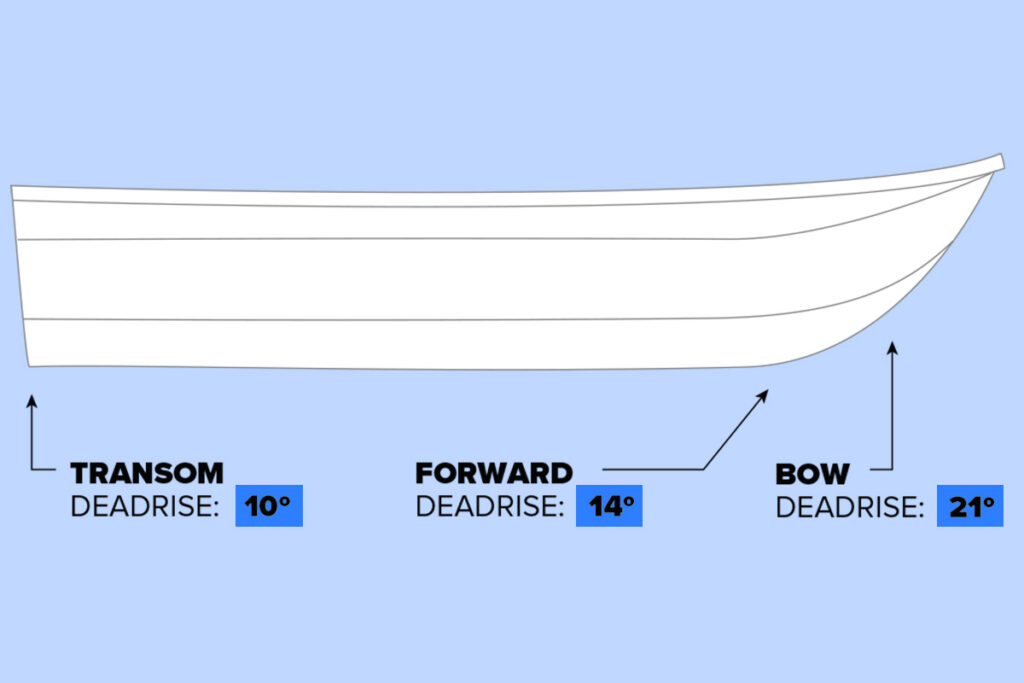

When discussing deadrise, there are three key measurements to consider: bow deadrise, forward deadrise, and transom deadrise.

Bow deadrise refers to the angle of the boat’s hull at the bow or front of the boat. This angle is typically steeper than the other two measurements, as it is designed to slice through waves and provide a smooth ride in choppy conditions. Boats with a high bow deadrise angle are often used for offshore fishing or racing, as they can handle rough seas and high speeds.

Forward deadrise refers to the angle of the boat’s hull between the bow and the mid-section of the boat. This angle is often less steep than the bow deadrise angle, but still plays an important role in the boat’s performance. A forward deadrise angle that is too shallow can result in a harsh ride in choppy conditions, while a too-steep angle can reduce speed and fuel efficiency.

Transom deadrise refers to the angle of the boat’s hull at the transom or rear of the boat. This angle is important for stability and can impact the boat’s performance in different ways. A boat with a deep transom deadrise angle will typically have a higher top speed but may not be as fuel-efficient, while a shallower angle will have better fuel efficiency but may not be as fast. Additionally, a wider transom can provide better stability and weight distribution for activities like fishing or watersports.

Overall, the combination of these three deadrise measurements plays a critical role in a boat’s performance, stability, and suitability for different types of boating activities. When selecting a boat, it’s important to consider all three measurements in order to choose the right vessel for your needs.

Deadrise and Stability

Deadrise also plays a significant role in a boat’s stability. Boats with a deep deadrise angle tend to be more stable in rough waters, while boats with a shallow deadrise angle may feel unstable or uncomfortable. However, a deep deadrise angle also means that the boat will roll more when turning, making it less stable in sharp turns.

Deadrise and Draft

The deadrise angle also affects a boat’s draft, or how much water the boat displaces when afloat. Boats with a shallow deadrise angle typically have a shallow draft, allowing them to navigate shallow waters. Boats with a deep deadrise angle have a deeper draft, which may limit their access to certain areas with shallow water.

Deadrise and Fuel Efficiency

The deadrise angle also has an impact on a boat’s fuel efficiency. A boat with a shallow deadrise angle typically has a higher top speed but may consume more fuel. A boat with a deep deadrise angle may have a lower top speed but is more efficient at cruising speeds, making it more fuel-efficient in the long run.

Choosing the Right Deadrise

When choosing a boat, it’s essential to consider your intended use and the conditions you’ll be boating in. If you plan to use your boat for water sports or fishing in calm waters, a boat with a shallow deadrise angle may be the best option. If you plan to use your boat for cruising and long-distance travel, a boat with a deep deadrise angle may be the better choice.

Boat Deadrise Examples

Table of 10 popular boats with their deadrise measurements:

Understanding the concept of deadrise can help you choose the right boat for your needs and ensure a safe and enjoyable boating experience . Consider the type of boating you’ll be doing, the conditions you’ll be in, and the performance you desire when selecting a boat with the appropriate deadrise angle.

What is the ideal deadrise angle for a boat?

There is no one-size-fits-all answer to this question. The ideal deadrise angle depends on the intended use of the boat and the conditions it will be used in.

Can the deadrise angle be modified on a boat?

The deadrise angle is a fundamental element of a boat’s design and cannot be modified without significant structural changes to the hull.

What is the difference between a planing and displacement deadrise?

A planing deadrise is designed for high-speed performance and has a shallow deadrise angle of 15 degrees or less. A displacement deadrise is designed for cruising and has a deep deadrise angle of 20 degrees or more.

Can a boat with a deep deadrise angle handle shallow water?

Boats with a deep deadrise angle typically have a deeper draft, making them less suitable for shallow water conditions.

What is the impact of deadrise on a boat’s fuel efficiency?

A boat with a deep deadrise angle may be more fuel-efficient at cruising speeds, while a boat with a shallow deadrise angle may consume more fuel but have a higher top speed.

About the author

I worked as an officer in the deck department on various types of vessels, including oil and chemical tankers, LPG carriers, and even reefer and TSHD in the early years. Currently employed as Marine Surveyor carrying cargo, draft, bunker, and warranty survey.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

What Does a Longshoreman Do?

Longshoremen play a critical role in the global supply chain, bringing billions worth of cargo into the country. So what does a longshoreman do exactly?

The Ocean Warming Effects on Marine Life

The last few decades have seen ocean temperatures rise as climate change begins to affect maritime industries worldwide. Here are the ocean warming effects on marine life seen so far.

How Do Cruise Ships Handle Hurricane Season Cruises?

Thankfully, modern cruise ships can handle a hurricane season cruise. Due to past experiences and new advancements, crews prove these boats operate well no matter the weather.

What is a Sailboat Transom?

Last Updated by

Daniel Wade

June 15, 2022

In sailing terms, a transom is the flat vertical section at the back of the boat. Outboard motors are mounted to the transom.

The transom is a structural and stylistic part of the sailboat. Additionally, most of the transom is visible from above the waterline. Outboard motors are almost always mounted to the transom. Powerboats, such as runabouts and ski boats, usually also have a transom.

Table of contents

What is the Transom Used For?

Transoms are an integral part of a sailboat's hull, and they also happen to be a very useful mounting point for all kinds of equipment. Transoms are used to mount outboard motors, antennas, and sometimes the rudder.

What Kind of Boat has a Transom?

Virtually every kind of modern vessel has a transom. Watercraft that utilize this design feature include speedboats, houseboats, fishing vessels, cargo ships, warships, and (of course) sailboats. Transoms are common because they simplify the construction process of boats and ships. The transom design commonly found on sailboats became popular during the 20th century.

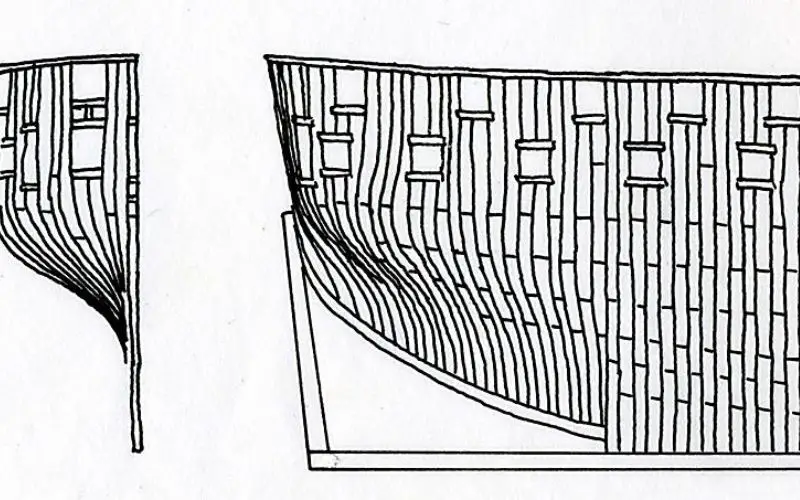

Previously, shipbuilders utilized complex and attractive lines on the vessel's stern. These lines made watercraft more aesthetically pleasing, but they required complex framing and a highly skilled workforce. The introduction of the flat transom design greatly reduced boat construction cost, time, and complexity.

How to Identify a Sailboat Transom

Locating and identifying the transom of a sailboat is easy. The transom is located at the rear of the vessel and is sometimes referred to as the "stern" of the boat. Using this terminology for the transom is only half correct, as the transom itself is just one piece of the stern.

What does the Transom of a Sailboat Look Like?

The transom of a sailboat is often a wide, flat surface located on the outside of the vessel's stern. It's the place where you'll often find the name and home port of the vessel, along with a number of stern-mounted utilities.

Transoms come in all shapes and sizes, depending on the design and purpose of the boat. They can be square, round, small, large, and shaped like virtually anything. However, most modern sailing vessels use relatively simple rounded-rectangle transoms.

Is the Transom located Above the Waterline?

Yes, the majority of the transom is located above the waterline (assuming the sailboat is still afloat). Some transoms, especially on more elegant yachts, are smaller and preceded by a dramatic upward-sloping stern.

Some sailboats, such as schooners, often utilize more elegant transom designs. Early yachts of the Edwardian period are known for their dramatic sterns and elegant transoms.

Sailboat Transom Styling

Sailboat transoms vary significantly in styling, though the simplest designs are usually more common. Many sailboat transoms are not completely flat. Instead, they often sport a slight outward bow or curve.

Additionally, sailboat transoms do not always have a perfect 90-degree vertical orientation. Instead, they often slope backward or forwards. This design feature has many names, including the 'launch-style' stern.

Types of Sailboat Sterns

The primary types of sailboat sterns are the transom stern (as described above) and the canoe stern. Transom stern sailboats are far more common today due to their simplicity, utility, and relative ease of construction.

Canoe-stern sailboats don't have what most people would consider a transom. Instead, these vessels are pointed on both ends—bow, and stern. And while there are some advantages to canoe-stern designs, they lack the simple utility of a flat stern.

Advantages of a Transom Stern Sailboat

The transom stern is the most popular sailboat configuration today, and for a good reason—as we mentioned earlier, there's a lot to be said about utilizing a clean, flat surface at the rear of the boat.

Given the proliferation of outboard motors, it's extremely useful to have a flat and strong surface to work with. This is especially important on larger sailboats that don't come equipped with inboard motors.

The transom adds an increased layer of strength and structural rigidity to the hull. Additionally, the transom stern opens up numerous hull design possibilities and allows designers to focus on stability, experiment with new materials, and utilize modern hull forms.

A sailboat with a transom is much easier to construct than a canoe-type vessel, especially when using traditional materials. What once took weeks of careful lofting, planing, cutting, and steaming is now accomplished with a laser cutter and a single piece of heavy-duty plywood.

Transom-Mounted Outboard Motors

Outboard motors are tricky to mount on canoe-stern vessels, as there's no flat place to put the motor. A sailboat transom negates this issue entirely. Many sailboats between 20 and 30 feet in length have one (or more) outboard motors mounted to the stern.

Outboard Placement

When under sail, many sailboat owners retract their outboard from the water to avoid creating drag and throwing the boat off course. This is especially true on boats with a transom-mounted rudder, as the outboard can never be placed in the middle of the transom.

Outboard placement doesn't matter very much on a transom sailboat, as sailors can steer with the vessel's rudder while under power. Many sailboat outboards aren't designed to move side to side—instead, they're mounted in a fixed position on a retractable bracket.

Retractable Brackets

Maritime engineers spent decades devising all kinds of sailboat outboard motor brackets. Today, you can find virtually any kind of bracket to mount an outboard to your transom. Some brackets allow you to steer from the outboard, but many do not.

Brackets for larger sailboats often swing out and up rather than hinging on a single point. This allows sailors to move the outboard completely out of the way and elevate it, which keeps the equipment dry while underway.

Other transom-mounted outboard motor brackets are typically manually-operated, and sometimes utilize levers, gears, or hydraulics to reduce the strength required to lift the motor out of the water. On high-end boats, electrically-operated outboard brackets take the weight off entirely.

Sailboat Transom Structure

The structural significance of sailboat transoms cannot be overstated. These mostly flat sections of material are often one of the thickest parts of the boat. This is especially true on powerboats, where much of the engine force is transmitted to the hull through the transom.

An easy way to understand this concept is to examine the transom of a typical aluminum 'John Boat.' Most of these boats have additional support brackets at the base of the transom, along with a thick piece of oak or mahogany located around the motor mounts.

What is a Sailboat Transom Transom Made Of?

Sailboat transoms are usually made out of a thicker piece of its hull material . Wooden sailboats often use two or three layers of thick plywood to make the transom, as it's also the rearmost mounting point for hull frames and planks.

Fiberglass sailboat transoms are, as you would expect, made of fiberglass. However, fiberglass boats often incorporate a structural form beneath the glass and resin. Form materials are usually either balsa wood, plywood, or another composite. Layered fiberglass transoms are strong and long-lasting.

However, fiberglass transoms are not impervious, especially when water finds its way into the wooden core. This usually happens due to cracks, accidents, and neglect. If the wood behind the fiberglass rots, it compromises the structural integrity of the transom.

Is a Cracked Transom a Big Deal?

Yes, a cracked transom can be a very big deal on sailboats and powerboats alike. A crack in the transom is usually formed by stress or manufacturing defects, and it's akin to a crack in any other structural part of the boat.

It's essential to ensure that the transom of your sailboat is structurally sound, regardless of its build material. Check the transom for cracks, soft spots, deformities, and rot before purchasing a sailboat or venturing out on the water.

Sailboat Transom Repairs

So, your transom needs some work. Is it worth scrapping the boat, or can it be saved? Generally speaking, a sailboat with a damaged transom isn't automatically relegated to the scrap heap.

Transom repair cost and procedure vary depending on what the boat is made of. Wooden, steel, and aluminum sailboat transom repairs generally require a higher skill level than fiberglass boats.

Most boatyards can repair virtually any kind of damage to a fiberglass sailboat transom as long as you're willing to pay for it. Remember, the cheapest way to repair your transom is to maintain it before it leaks, cracks, or rots.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Parts

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

My Cruiser Life Magazine

What Is the Transom on a Boat? EXPLAINED

Transom is an old word deeply rooted in tradition, like many nautical terms. The word is also used in architecture in a similar function. So what is the boat transom, and why are they important?

The backend of a boat is called the transom. The boat’s backend has a fancy name just like all other things nautical and on boats. This definition is important to understanding the transom in boat design since it’s usually a vertical panel of the boat’s hull set crosswise to the sides.

Here’s a quick look at the origins of the word and the different types of derrieres sported by all the sorts of vessels on the Seven Seas.

Table of Contents

Why is the transom important, what is the transom made of, small boats (e.g., dinghies, small fishing boats), medium boats (e.g., recreational runabouts, center consoles), large boats (e.g., yachts, sailboats), specific measurements, factors influencing transom size, canoe sterns or double enders, raked – classic transom stern with overhangs, flat transom sailboats, reverse transom designs, other boat transom features, flat transom powerboats, outboard motor transom, how to measure transom height, what is transom height, boat transom angle, outboard motor transom height, 1. assess the damage, 2. decide on diy vs. professional repair, 3. prepare for repair, 4. repair process for minor damage, 5. major structural repair or replacement, 6. waterproofing and sealing, 7. inspection and testing, 8. regular maintenance and inspection, is transom the same as the poop deck, the boat’s transom – demystified, faqs (frequently asked questions), what is the transom.

Like all other things nautical and on boats, the boat’s backend has a fancy name. It’s called the boat transom. The word derives from as far back as 1300s Middle English and can trace its roots even further back to Latin and Old French words that meant transverse or crosswise.

This definition is important to understanding the transom in boat design since it’s usually a vertical panel of the boat’s hull set crosswise to the sides.

A similar word in nautical lingo is “stern.” Stern is more of a direction, though, as in setting the “stern lines” when docking or “powering astern” when driving in reverse. In contrast, the boat transom is a part of the boat located on the stern.

Depending on the type of boat in question, whether it is a small boat or a large boat, the boat transom might support some important gear. For example, small powerboats often have their outboard motors mounted on their transoms. Many sailboats mount rudders on the transom. Larger vessels may support swim platforms back there.

What is the transom for? Well, the transom serves several important functions:

- Structural support – The transom provides critical structural reinforcement and helps support the shape and integrity of the stern. It braces the sides of the hull.

- Mounting platform – The transom provides a mounting location for the engine(s), rudder(s), steering gear, and other hardware that needs to be positioned at the stern. Holes and hardware can be mounted into/onto the transom.

- Lift point – Lifting slings are often attached to the transom to allow lifting the boat. The transom safely distributes the lifting forces across its width.

- Work platform – On smaller boats, the transom can provide a work platform for tasks like removing/storing gear, boarding, washing, maintenance, etc.

- Drainage – Scuppers and drain holes are often built into the transom to allow water to safely drain off the deck from the stern.

On most boats, the design and engineering of the transom is absolutely essential.

Boat transoms are typically constructed out of the following materials:

- Wood – Usually marine-grade plywood or teak, this was historically the most common material for transoms. It’s easy to cut and shape, provides good support, and allows for mounting hardware. However, wood requires a lot of maintenance to prevent rot over time.

- Fiberglass – Now the most popular choice for transom construction. It’s durable and waterproof, providing excellent structural support. Fiberglass doesn’t rot and requires little maintenance. It can be molded with built-in contours. Gelcoat provides a nice finish.

- Aluminum – Aluminum transoms offer the strength of metal with the corrosion resistance that’s essential around water and salt. They need very little maintenance and hold up well to impacts. However, they require specialized fabrication and are difficult to repair if bent or damaged.

- Composites – Some modern transoms use advanced composite materials like carbon fiber or other epoxy resins for very high strength weight ratios. These require specialized construction methods and repairs can be difficult and expensive.

The transom material is chosen based on considerations like cost, weight, strength needs, corrosion resistance, ease of fabrication, and repair-ability. High performance offshore power boats may use exotic composite transoms, while small recreational and fishing boats still often rely on versatile and repairable wood or fiberglass transoms.

How Big is the Boat Transom?

The size of a transom on a boat varies widely depending on the type and size of the boat itself. There’s no one-size-fits-all measurement, as the transom must be proportionate to the vessel’s dimensions, intended use, and the type of propulsion system it accommodates.

- Width: Can range from a few feet to the full width of the boat, typically up to 6 feet for very small boats.

- Height: The height above the waterline can be as low as a few inches to about a foot, depending on the boat design and the need to prevent water ingress.

- Width: Generally follows the beam (width) of the boat at its stern, which can be anywhere from 6 to 12 feet.

- Height: The transom height from the deck to the bottom of the boat (not including the motor) might range from 1 to 3 feet, with variations for specific uses (e.g., fishing, watersports).

- Width: For larger vessels, the transom can be quite wide, matching the beam at the stern, which could exceed 15 feet or more.

- Height: Height can vary significantly, with some transoms extending two stories or more, incorporating features like swim platforms, boarding areas, or even garages for smaller watercraft.

- Short Shaft: About 15 inches

- Long Shaft: About 20 inches

- Extra-Long Shaft: 25 inches or more

- These measurements are important for matching the motor shaft length to ensure optimal performance and prevent damage.

- Purpose of the Boat: Fishing boats, for example, may have lower transoms for easy access to the water, while speedboats might have higher transoms to accommodate powerful engines and enhance performance.

- Type of Waters: Boats designed for calm waters can have differently designed transoms compared to those intended for rough seas, where a higher transom may prevent water ingress.

- Aesthetics and Design: The overall design ethos of the boat will influence transom dimensions, balancing functionality with the desired appearance.

Sailboat Transom Designs

Nothing brings a sailboat design together quite like the boat transom does. Of course, there are many different designs out there, but to some extent, the boat transom is a trendsetter.

For example, in the 1970s, it was fashionable for bluewater cruising sailboats to have canoe-style sterns. Sometimes called double-enders, these boats were sturdy and solid. They’re trademarks of the Valiants and Hans Christian fleets.

Today, the sleeker looks of the reverse or flat transom have taken over. This is mostly due to the changes in yacht design over the last few decades. Today, emphasis is placed on wide cockpits with walk-through transoms and big swim steps.

The boat transom is just one feature in the overall design of a yacht. Therefore, it’s impossible to draw any big conclusions from this one feature. It’s even impossible to declare one better than the other.

What we can say with confidence is what we like. Some love the salty looks of those canoe sterns, while others find them cramped and dated. Some sailors want sugar scoop-style boat transoms with a big swim platform, and others want the curvy lines of a heart or champagne flute-shaped rear end.

Bringing the stern of a sailboat (and sometimes a powerboat) back to a point like a canoe lends a salty and traditional look to any vessel. Canoe sterns are often compared to transom stern sailboats. It implies seaworthiness, although whether or not it provides any real benefits is up for much debate.

Canoe sterns are common on many of the cutters from the 1960s and 1970s, including famous designs like the Westsail 32, Valiant 40, or Hans Christian 32. On smaller vessels, it’s also often combined with a hung rudder, such as on the Bristol Channel Cutter, Pacific Seacraft Moriah, or the Morris Francis.

The rake of the transom refers to the angle at which it extends afterward. If a transom is raked, it angles away from the vessel. If it is flat, it is vertical. And if it angles in toward the boat, the boat transom is said to be reversed.

Raked transoms, combined with long overhangs, were popular on racing boats for most of the 20th century. This resulted from limits on waterline length placed by racing rule committees. So designers added long overhangs that would add to the waterline as the boat healed.

View this post on Instagram A post shared by Clay Burkhalter (@burkhalterphotos)

Flat transoms have a distinctive look and allow a boat to carry the boat beam farther aft. This is great for having bigger cockpits and more hull volume in the rear of the boat.

Flat transoms are an iconic feature of Island Packet sailboats, which is a great sailboat to live in , but they’ve been used in many others as well. The Passport 40, a well-regarded Bob Perry design, has a particularly graceful one.

Flat transoms are very popular in modern yacht design, with Beneteau , Catalina , and Jeanneau offering yachts or sailboats with wide, flat transoms with rear door fold-down swim steps.

Reverse transoms angle forward toward the bow of the boat. Several famous designs carried reverse transoms, like Sabres and Hylas yachts.

Sugar Scoop Transom

Sugar scoops are reverse transoms that are hollow in the center line, allowing space to design in a built-in swim platform and stairs. This is very popular on catamarans.

Transom-Hung Rudders

Many boats include an externally mounted or transom-hung rudder.

Wineglass or Heart-Shaped Transom

One unique and eye-catching transom design is the heart-shaped transom, which is usually raked and sometimes includes a prominent overhang.

A few examples of boats with beautiful behinds like this include the Shannon 38 and the Cabo Rico 38 and 42.

View this post on Instagram A post shared by Freya (@seafreyaafloat)

Power Yacht Transom Designs

Enough about sailboats of all types , it’s time to get somewhere already. Power vessels have transoms too, and they’re just as valid and appreciated.

Flat transoms are likely the most common powerboat feature. For one thing, this suits the planning hull form well. Where sailboats come to a fine exit at the rear, a planning boat will need a broad wetted surface to support the boat’s weight at speed. The result is a flat and broad transom sported by all sorts of vessels.

Flat transoms often support an added-on swim platform. Many smaller boats have a flat transom where outboard motors are mounted. An outboard bracket is used if the motor doesn’t attach directly to the transom.

View this post on Instagram A post shared by HMY Yachts (@hmyyachts)

A fantail is a semi-circular aft deck, so the transom is curved. It’s a classic look that you’d find on the back end of the HMS Titanic or other classic wooden yachts of the early 1900s.

View this post on Instagram A post shared by Seattle Ship Canal Spotter (@seattleshipcanalspotter)

Powerboats and fishing vessels with outboard motors will hang them on the boat transom.

The traditional and simplest way to do so is to mount them directly on the boat transom. An outboard transom will usually have a notch cut out of the top of it, which will allow space for the motor to be mounted. Unfortunately, this reduces the freeboard of the boat transom itself and could present a problem in following seas or when operating astern. Some offshore designs combine the cutout with a self-bailing well to keep the rest of the boat dry.

The molded outboard bracket is a modern method of preserving transom height while allowing outboards to be mounted low. These are mounted onto boat transoms and allow for standard outboard shaft lengths to be used, no matter the boat’s size or the actual boat transom height.

Outboard Transom Mounting

Sizing your outboard correctly is critical to getting your boat’s performance right. The goal is to get the anti-cavitation plate, located just above the propeller, roughly in line with the bottom of the boat. It needs to be the right height, not too far above the keel and not too far below. It also needs to match the hull’s angle so that the thrust from the engine propels the boat forward at the most efficient angle.

While the transom is an important structural integrity component in any boat, a transom that supports an outboard needs to be extremely strong and structurally sound.

As described above, the entire transom height can describe two things; one is the actual freeboard provided, and another is the outboard mounting height. The boat’s design will dictate what length of outboard motor shaft you should use.

The boat transom height is measured from the lowest point on the keel along the center line to the spot where the outboard motor’s mounting holes bracket rests. In the case of a dinghy or johnboat, this point may be the top of the transom. In the case of a larger offshore boat, it may be to the top of a cutout on the transom. If the boat has a bracket, the measurement is made from the bottom of the keel to the top of the bracket.

Depending on the design, this number may or may not represent the freeboard available from the transom. The freeboard is the height of the sides of the boat above the water. Generally, the more freeboard you have, the better. Extra freeboard provides a drier ride and keeps waves and splashes out.

Height isn’t the only consideration when measuring a boat’s transom for an outboard motor. You’ll also want to consider the transom angle. A flat transom will be vertical when the boat is at rest. Many powerboats have transoms that angle aft, meaning that the outboard needs to be trimmed up slightly to sit correctly.

Outboard brackets allow for adjusting their mounting angle to neutralize the effects of an angled transom. But the brackets can only correct for so much, so in some cases, you may have to use an angled backing block when you mount the motor.

Motor manufacturers have standardized a few basic lengths for their outboard motors. Of course, the precise measurements will depend on the engine’s power rating. But outboard or inboard motors are usually available in short, long, and extra-long shaft lengths.

When looking for what size transom for a short shaft motor, you’ll need to consider a few things. Don’t just assume that a “short shaft motor” means the same thing for every engine–one manufacturer may believe short means 15 while another uses 17. Some may have an XS extra-small shaft option available.

Additionally, a short shaft five hp engine may be 15 inches, while a short shaft 300 hp engine may be 25 inches. While 15, 20, and 25 inches are the industry standard, you should double-check the specifics of your engine before making such a big commitment.

Here are some of the standards, but remember to double-check these numbers for your make and outboard model.

Outboard Height on Transom

What to do about a damaged transom.

A damaged transom can compromise the structural integrity and safety of your boat, so it’s important to address the issue promptly. Repairing a damaged transom involves several steps and might require professional help, especially if you’re not experienced in boat repair. Here’s what you can do:

- Extent and Type: Determine the extent and type of damage. Is it superficial, like paint or gelcoat damage, or structural, affecting the wood or fiberglass core?

- Water Intrusion: Check for signs of water intrusion in wooden cores, a common issue that can lead to rot and weaken the structure.

- DIY: If the damage is superficial or you have experience with fiberglass or woodworking, you might opt to repair it yourself.

- Professional Help: For structural damage, especially if fiberglass work or complete transom replacement is needed, seek professional assistance. Boat repair specialists can ensure the repair is done correctly and safely.

If you’re attempting DIY repairs for minor damage:

- Gather Materials: You’ll need materials like marine-grade plywood (for wooden transoms), fiberglass cloth, resin, and possibly gelcoat for finishing.

- Safety Gear: Use appropriate safety gear, including gloves, masks, and eye protection.

- Clean and Dry: Ensure the area is clean, dry, and free of debris.

- Fill and Seal: Fill small cracks or holes with epoxy resin or a fiberglass repair kit. For wooden transoms, ensure the wood is dry and treat with a wood hardener if necessary before filling.

- Sand and Finish: Once the repair material has cured, sand the area smooth and apply paint or gelcoat to match the surrounding area.

- Remove Damaged Material: For major repairs, the damaged portion of the transom, including any rotted wood or delaminated fiberglass, must be completely removed.

- Replace Core Material: Install new marine-grade plywood or an alternative core material, ensuring it’s properly sealed and bonded to the hull.

- Rebuild Fiberglass Layers: Apply new layers of fiberglass cloth and resin over the core, building up to the original thickness.

- Finishing Touches: Sand the repaired area smooth, and apply paint or gelcoat to match the boat’s finish.

Ensure that all repairs are properly sealed and waterproofed to prevent future water intrusion, paying special attention to any areas where hardware is reattached to the transom.

After the repair:

- Inspect: Thoroughly inspect the repair area and surrounding transom for any signs of missed damage or potential weak spots.

- Test: It’s advisable to perform a water test in a controlled environment to ensure the repair holds up under real conditions.

- Prevent future damage by regularly inspecting the transom and entire hull for signs of wear, damage, or water intrusion, especially if the boat is older or frequently used in harsh conditions.

Is Transom the Same as a Stern?

while the transom is part of the stern, they are not the same. The stern refers to the whole back end of the vessel, and the transom is a specific structural element within that area. Understanding the distinction helps in appreciating the design and functionality of boats and ships.

In essence, while the transom is a structural component that helps define the shape and function of the stern, the poop deck is an elevated platform or deck located at the ship’s stern, offering a distinct functional space. These terms are not interchangeable and refer to different aspects of a ship’s anatomy and design.

And there you have it! I tried covering all I could about boat transoms, but let me know if I missed anything and if you have other questions.

What is an engine transom?

The transom is the vertical section of a boat’s hull that is perpendicular to the sides of the hull and located at the back. For example, an engine transom is designed to hold an outboard motor.

Do all boats have a transom?

Yes, although various boat transoms can look different from one another. The transom is an integral part of the boat’s hull and an important part of the overall design. It serves both aesthetic and functional purposes. The only exception to this rule is vessels designed with a canoe stern, sometimes called a double-ender. Instead of terminating in a flat transom, these vessels feature a rounded stern with no vertical surface.

Why is the transom important?

The transom of the boat is an important design feature of its hull. In sailboats, the type of stern a boat has will dictate some of its design and performance characteristics, but the type of transom alone will make little difference. In general, the greatest advantages in performance come from out-of-sight below-the-watertight design qualities. The transom is, more often than not, designed for aesthetic appeal. The transom will belay what sort of boat you are looking at in powerboats. Outboard motor transoms are functional. Planing hulls will tend to have broad, flat transoms. And finally, displacement hulls will have a variety of transoms, much like sailing vessels.

Matt has been boating around Florida for over 25 years in everything from small powerboats to large cruising catamarans. He currently lives aboard a 38-foot Cabo Rico sailboat with his wife Lucy and adventure dog Chelsea. Together, they cruise between winters in The Bahamas and summers in the Chesapeake Bay.

Leave a comment

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium