World Class Rudders, Tillers, and other Gear for Real Life Sailing

Sailboat rudders, sailboat tillers, custom rudders/ tillers, sailboat accessories, rudder repair worksheet, instructional handbook, looking for a product for your sailboat.

Can't Find your Sailboat?

Why Rudder Craft?

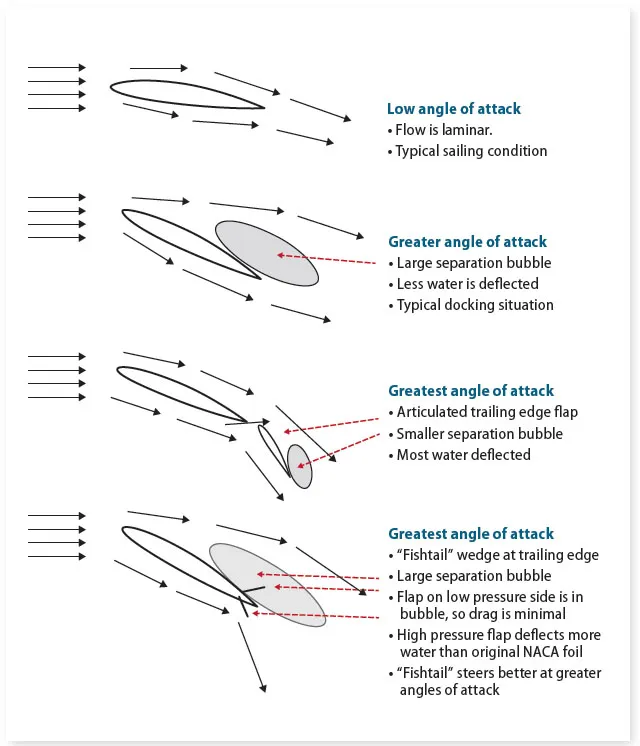

At Rudder Craft we build every sailboat rudder with the singular focus of improving your sailboat’s steering performance. In order to accomplish this our sailboat rudders incorporate a hydrofoil design, as a matter of course. Sailboats ranging from the West Wight Potter 15, all the way up to the MacGregor 36 and Catalina 42, will find a more accurate helm once a Rudder Craft hydrofoil sailboat rudder is installed.

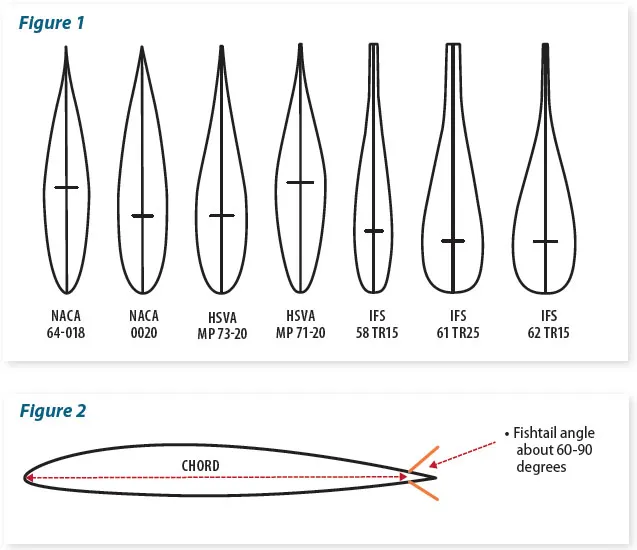

Why Hydrofoil?

Operating on principles similar to airplane wings, the foiled sailboat rudder design generates lift as the sailboat makes way. By employing the sailboat rudder to reduce drag, and increasing the force the sailboat rudder is able to exert, any sailboat will find themselves performing better: weather helm is reduced, tacking is crisper, points of sail are easier to keep, and helm effort is greatly reduced in light and moderate air.

Why Use a Kick-up Rudder?

Subscribe to our blog.

Join our mailing list to receive the latest news and updates from our team.

You have Successfully Subscribed!

No results found.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Blog Coming Soon!

Customer reviews.

What is a Sailboat Rudder?

Last Updated by

Daniel Wade

June 15, 2022

A sailboat rudder steers the boat. A rudder is a hinged fin or blade mounted on the stern of the vessel that turns side to side, and it's controlled by a tiller or a helm.

A rudder is one of the primary controls of a sailboat. When the boat moves forward through the water, the rudder causes friction on one side and changes the direction of the boat. Rudders are controlled by moving a tiller side to side or by a helm and a complex linkage system. Rudders are delicate and sometimes flush with and protected by the keel.

Table of contents

Identifying the Rudder

Rudders are connected to the sailboat using a hinge or a shaft. The rudder is always located in the water behind the boat, but some rudders have part of their structure exposed above the waterline. Rudders that aren't visible above the waterline are usually underneath the stern and controlled by a vertical shaft that descends through the bottom of the boat.

Rudder Design

Rudder design varies widely between boats. Some vessels have large, ornate rudders that are exposed above the waterline. Large rudders are common on catboats, canoe yawls, and other traditional designs.

Many modern boats use small, blade-like rudders that are hidden from view. The size of a rudder doesn't necessarily correlate with its effectiveness, but an improperly sized rudder can cause significant issues.

How Does a Sailboat Rudder Work?

Sailboat rudders are simple devices. Rudders are essentially deflectors, as they deflect water to port or starboard as the boat moves along. When the rudder is amidships or in the middle and aligned with the keel, the boat goes straight. Rudders also help keep the boat on a straight track as they increase the area of water moving down the length of the boat.

Rudders only work when the boat is moving. If there's no moving water to deflect, the rudder can do little to direct the vessel. Rudders also don't work when the boat is blown sideways. Maneuvering is only possible when the boat is moving forward.

Can a Sailboat Rudder Steer in Reverse?

But what about moving in reverse? Rudders can be used to steer the boat in reverse, but they're significantly less effective when pushed backward through the water. The distance required to make a turn in reverse is usually much higher than when moving forward, and steering input is less precise. In some cases, sailboat rudders can break off when moving too quickly in reverse.

Sailboat Steering Characteristics

Sailboats steer much differently than cars, and there aren't any brakes to slow down with. Sailboats tend to steer from the middle; picture a fan blade spinning slowly on a motor, and you'll get the picture. As a result, steering too aggressively in tight quarters can cause your bow or stern to hit something that's beside you.

Speed is generally helpful for steering, especially when you want to make precise movements quickly. However, speed is a double-edged sword, as slight rudder movement at speed can dramatically and rapidly alter the course of the boat. But remember, you can't steer without moving forward.

Tiller Steering

Sailboat rudders are often controlled by a tiller. Tillers are a long rod connected to the rudder. Sailors move the rod side to side from the cockpit to turn the rudder directly. Tillers are the simplest form or rudder control, and they're highly reliable. Tillers point in the opposite direction that the boat will travel.

Tiller steering is found most often on small boats. This is because the forces involved in steering boats of greater size can be too difficult to manage with a tiller. That said, there are some relatively large boats with cockpit configurations that allow for the use of a tiller. Sailboats with tillers range in size between 10 feet and 30 feet.

Benefits of a Tiller

Tillers have numerous benefits. Tillers offer precise control of the boat because they connect the rudder directly to the person steering the boat. Additionally, tillers are extremely simple and robust. Many blue water sailors prefer tiller steering, as it's difficult to break and easy to repair.

Over the years, sailors have developed many creative ways to make tillers more useful. Many boats feature tiller extensions that allow the sailor to steer from further away. Tillers also respond much faster than helms, which is great for racing and pushing the limits of the boat.

Tiller Self-Steering

Bluewater sailors developed an extremely useful way to multitask onboard a tiller-equipped sailboat. Self-steering is possible on vessels with a tiller, and no electronics or complex machines are necessary. Self-steering involves connecting the jib sheet to a series of pulleys and opposing bungee cord (or surgical tubing).

As the tension on the jib increases, it'll tighten the jib sheet and pull the tiller and change the course of the boat. The opposite is also true. This keeps the boat at the right angle to the wind and is useful for solo travel. GPS-guided self-steering equipment is also available for tiller-equipped sailboats, and it's relatively easy to install.

Helm Steering

A helm is essentially a large nautical steering wheel. Steering a boat with a helm is somewhat similar to driving a car, as the boat moves in the direction that you steer (unlike a tiller, which moves in the opposite direction). Sailboats equipped with tillers are usually larger. Some larger sailboats have two helms placed side-by-side in the cockpit.

The helm consists of a steering wheel and a pedestal which is mounted to the deck. Helm pedestals often feature a marine compass to make navigation possible from one location. Engine controls are often located nearby as well. Sailboat helms are often large in diameter, sometimes 30 inches or more. Large wheels make steering easy and precise.

Helm-equipped sailboats are generally 30-feet long and larger. Tillers are excellent for large boats, as they enable precise movement and require little effort to use. This is especially important at speed when the force of water rushing by a large rudder can be too difficult to overcome with a tiller.

The helm is connected to the rudder mechanically or hydraulically. Some high-end sailboats incorporate power steering, but this is unusual on most consumer vessels. Mechanical helm linkage typically utilizes a cable (or multiple cables and pulleys) that stretches from the helm to the rudder.

Hydraulic Rudder Control

Most sailboat helms are hydraulic. These helms use pressurized hydraulic fluid and small diameter lines to replicate the wheel movements at the rudder. Hydraulic systems often include a fluid reservoir and a pressure cylinder, along with mechanical parts to transfer the force at the wheel and the rudder.

Rudder Maintenance

Rudder maintenance is fairly simple and should be performed regularly. As with the hull, rudders are an ideal habitat for all kinds of unwelcome marine life. Within a year or less, your rudder can be completely encapsulated in barnacles, plants, and other organisms. Marine growth will negatively impact your speed and steering, so it must be scraped off regularly.

Maintaining the steering system is also essential. Tillers are relatively easy to maintain, as they use very few moving parts. Look for grease fittings, and make sure your tiller and rudder are fastened tightly. Helms are more complex, and the hydraulic system should be inspected, repaired, and topped off if necessary.

What to Do if the Rudder is Damaged

Rudder damage is a sailor's worst nightmare, and it's akin to a hole in the hull or losing a mast. So what should you do if your rudder gets damaged or breaks off? First, call for help! But if help isn't available, there are a few makeshift ways to steer the boat without the rudder.

If you have an outboard motor, use it to steer. If not, then a run-of-the-mill rowboat oar makes an excellent rudder substitute. Simply lash the oar to the back of the boat with the end in the water, and use it like a tiller. It's not ideal, but it worked for the Romans, and it should work for you. Some sailors have fashioned makeshift rudders from interior cabinet doors, hatches, scrap metal, and whatever else is on hand.

Losing a rudder is a worst-case-scenario, and it doesn't often happen when sailors keep up with maintenance and stay away from dangerous water. Preventative maintenance and proper navigation are the best ways to keep your rudder in good shape.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Parts

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

- Manufacturing Process

- (714) 973-2878

- (949)646-0244

- Search for:

We build rudders with passion and precision since 1963.

Ships anywhere, cost effective, satisfaction guaranteed.

In the early sixties, an innovative man named Chuck Foss developed several polyurethane foam systems useful for a variety of purposes, including the production of surfboards. His new firm, The Foss Company, soon became one of the top U.S. suppliers of foam surfboard blanks, which he sold under the name of “Foss Foam.”

Later in the sixties, one of his Foss Foam systems used to make surfboard skags was found to be an excellent material for making sailboat rudders. It was not long before The Foss Company supplied rudders to most of the boat builders in Southern California through the seventies and eighties.

The Foss Company’s former headquarters. During the eighties and nineties, the company specialized in fiberglass and foam composites. High performance sailboards and paddleboards were some of the products produced. With an extensive inventory of rudder molds, the company now specializes in supplying sailboat owners and boat repair yards with replacement rudders.

In recent years, The Foss Company has formed a strategic partnership with FinCo Fabrication, a major fiberglass manufacturing firm based in Santa Ana, California. This partnership will assure that The Foss Company’s long tradition of quality products and service will continue for years to come.

CAL 20 CAL 25 CAL 28 CAL 34 CAL 40

CATALINA YACHTS

CAPRI 18 CATALINA 22 CATALINA 25 CATALINA 250 CATALINA 30 CATALINA 45

ERICSON YACHTS

Ericson 35 Ericson 38 Ericson 41 Ericson 46

Oceanis 37 Oceanis 46.1 Beneteau 56

Manufatures A-C

Balboa Yachts B-Boats Beneteau Catalina Yachts Cal Boats Coronado Yachts Columbia Yachts Coastal Recreation Chrysler Yachts Corsair Marine C & C Yachts

Manufatures D-L

Down East Yachts Ericson Yachts Hunter Hobie Cat Irwin Yachts Islander Yachts J Boats J24 Kirby Boats Kettenburg Marine Lancer Yachts Laguna Yachts

Manufatures M-R

Merit Marine Morgan Marine MacGregor Yachts Newport Boats Olsen Boats O’Day Boats Pearson Yachts Pacific Sea Craft Ranger Yacht Reynolds Sailing

Manufatures S-Z

Sam Morse Boat Company San Juan Boats Sidelmann Tarten Marine W. D. Schock Boats Westsail Marine Westerly Marine Willard Boats

Start your rudder with us now (714) 973-2878 or (949)646-0244

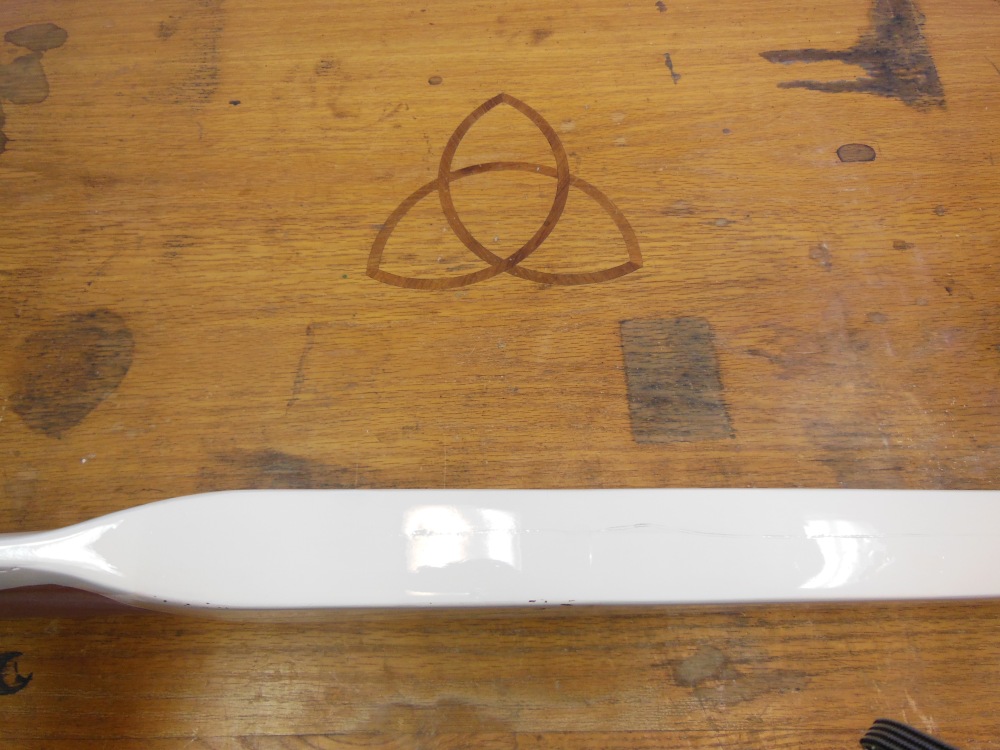

Great old boats - cal 40's new rudder, click to open video, our manufacturing process..

Working together with you the owner we select an exciting mold or sketch out a new design for a custom rudder. All based off years of experience and time tested best practices.

Prepping mold

Experienced Finco craftsmen begin the manufacturing process by sanding, polishing and waxing the rudder mold.

Gelcoat & first layer

After applying Gelcoat to the mold, they apply a layer of unidirectional fiberglass saturated with Vinylester™ resin.

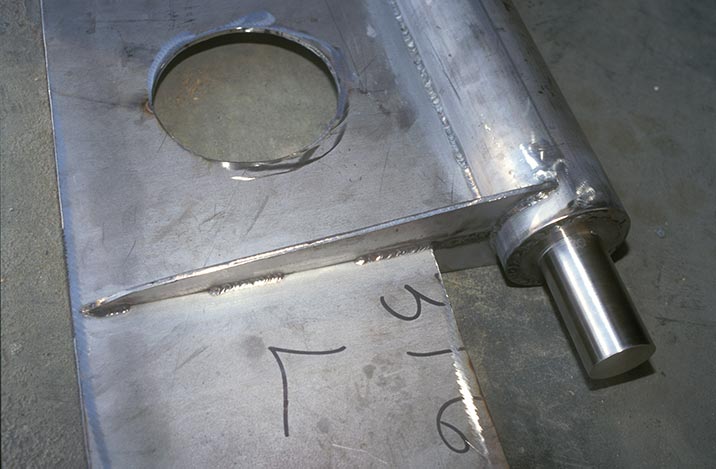

Rudder Shaft Turned

A new rudder shaft is turned from the same material as the original (or stronger.) After it is cut to length and tapered, the tangs are welded into place.

Shaft set & foam+

Once the fiberglass has cured, the tapered stainless steel shaft is set into the mold. After the shaft is aligned, the halves are mated, clamped and sealed, and liquid foam is poured into the mold.

Sand to Smooth

When the foam has cured, the rudder is removed and the seams sanded smooth. Most OEM rudder fabrication stops here; we go farther .

Taped and cured

Fiberglass tape is laminated to the seams. After the tape has cured and has been sanded smooth, the rudder gets a final coat of gelcoat.

Faired & prepped

In the last step, the entire rudder is faired and sanded in preparation for you to apply a coat of bottom paint.

Packed in custom box

The finished rudder is packed in a purpose-built crate suitable for shipping to you anywhere in the world.

Why Select Us?

We have many of the original molds and tooling for production boats made over the mast 60+ years in our inventory and can replace damaged rudders with the exact factory replacement. If you would like a custom rudder, we can modify or design from scratch a rudder that meets your exact needs.

The original rudders originally were manufactured by “clam-shell” method and our exact replacements use the same tooling. Plus over the years there have been advances in glass cloth and in laminating resins making them stronger and more reliable. The closed cell foam core of the rudder remains the same, but the selective addition of unidirectional fibers has increased the strength of our rudders, and the use of Vinylester™ resins has eliminated blisters and the need for expensive barrier coats.

Newer designs to improve handling and directional control. This is most important when sailing very fast and can help prevent broaching and spin-outs. Most boats can use upgraded rudders without incurring a rating penalty. Some local PHRF boards will hit some designs with a 3 seconds-per-mile penalty so you should check with your local board before making your change.

Get in Touch

Here for you.

Phone: (714) 973-2878 (949) 646-0244 Email: [email protected]

Foss Rudders fondued in 1963 has partnered with FinCo Fabrication, a major fiberglass manufacturing firm in Santa Ana, California. We make precision rudders for you.

Where to find us

2520 South Broadway, Santa Ana CA 92707

The Types of Sailboat Rudders

- Snowboarding

- Scuba Diving & Snorkeling

Full Keel Rudder

On a sailboat , as the rudder is moved to one side by means of the tiller or steering wheel, the force of the water striking one edge of the rudder turns the stern in the other direction to turn the boat. Different types of rudders have different advantages and disadvantages. The type of rudder is often related to the boat’s type of keel.

Rudder on Full-Keel Sailboat

As shown in this photo, the rudder of a full-keel boat is usually hinged to the aft edge of the keel, making a continuous surface. The engine’s propeller is usually positioned in an aperture between the keel and rudder.

Advantages of Full Keel Rudder

The primary benefit of this rudder configuration is the strength and protection provided to the rudder. It is hinged at top and bottom, well distributing the forces on the rudder. Rope (such as lobster pot warps) or debris in the water cannot snag on the rudder.

Disadvantage of Full Keel Rudder

Because the sideways force of the water on the rudder is entirely behind the rudder’s pivoting point at its leading edge, putting all the force on one side of the rudder, it takes more energy to move the rudder. This is one reason why larger boats seldom have tillers—because it can require much force to “push” the rudder out against the water streaming past the keel.

Spade Rudder

Most fin keel boats have a spade rudder, which extends straight down from the aft hull section. The rudder post comes down through the hull into the rudder itself, allowing the entire rudder to rotate to either side, pivoting around the post.

Advantages of Spade Rudder

The spade rudder is self-standing and does not require a full keel or skeg for its mounting. The rudder post inside the rudder can be moved aft from the leading edge (see next page on Balanced Rudder) so that the force of the water is not all on one side when the rudder is turned. This requires less energy to steer than with a keel- or skeg-mounted rudder.

Disadvantage of Spade Rudder

A spade rudder is more vulnerable to debris or objects in the water, which may strike the rudder and exert a force on the rudder post, the only structure supporting the whole rudder. Even the force of water when the boat “falls” off a wave can exert damaging stress on a spade rudder. If the rudder post is bent, the rudder may jam and become useless.

Balanced Spade Rudder

Note the clear air space at the top of the leading edge of this balanced spade rudder. The rudder post is several inches back from the front of the rudder. When the rudder is turned, the leading edge rotates to one side of the boat while the trailing edge rotates to the other side. While the turning action on the boat is the same, the forces on the helm are more nearly balanced, making it very easy to steer.

Skeg-Mounted Rudder

Some fin keel sailboats have a skeg-mounted rudder like the one shown. The skeg offers the same advantages as a keel mounted rudder: the rudder is protected from objects in the water and has more structural strength than a rudder mounted only on the rudder post.

It also has the same disadvantage: because it is not “balanced” as a spade rudder may be, with water forces distributed on both sides, it requires more force to turn the rudder.

Outboard Rudder

An outboard rudder is mounted outside the hull on the boat’s stern, such as shown in this photo, rather than below the hull using a rudder post or hinges to the keel or skeg. Most outboard rudders are turned with a tiller rather than a steering wheel since there is no rudder post to which to gear a wheel.

Advantages of Outboard Rudder

An outboard rudder does not require a hole through the hull for a rudder post and thus is less likely to cause trouble if damaged. The rudder can often be removed or serviced while the boat is still in the water. Hinges at the top and bottom of the rudder section may provide more strength than a single rudder post.

Disadvantages of Outboard Rudder

Like a spade rudder, an outboard rudder is vulnerable to being struck by or caught in objects or rope in the water. Unlike a spade rudder it cannot be balanced in the water flow, so the force of water is always on one side of the pivot point, requiring more energy for turning the rudder.

A rudder is often related to keel shape .

- Learn How to Sail a Small Sailboat – 1. The Parts of the Boat

- Choosing a Centerboard or Fixed Keel Sailboat

- How to Heave To a Sailboat

- Control Your Tiller Without a Tiller-Tamer

- 6 Types of Boat Engines

- Choosing an Inboard or Outboard Engine

- How to Tow a Dinghy Behind a Sailboat

- The What, Why, and How of Wheel Balancing

- Using AIS on Your Sailboat

- The Sunfish: A Perfect Lake or Urban Sailboat

- Mount Shasta Climbing Facts

- Inline Skate Wheels 101

- How to Anchor a Sailboat

- How to Not Damage Your Wheels

- Do It Yourself Boat Trailer Tongue Extension

- How Cambered Tires Work

The Foss Company can ship replacement sailboat rudders anywhere in the world from our headquarters in Newport Beach, California. Our company has manufactured high density, "closed cell" foam rudders for more than 35 years. Our first "Foss Foam" rudders were created for the famous Cal 40 yacht during the sixties, and most of those vessels--and rudders--are still in service today.

We now make rudders and dagger boards for most sailboats, all in a timely and cost-effective manner. By working with existing molds of a more modern design, we can also supply rudders for older boats that will improve their performance and handling--all for a very reasonable price. Our special manufacturing process assures that our rudders are strong, light and dependable, ready for a lifetime of sailing pleasure.

We have also created rudders from many other sailboats around the world, including those from the following manufacturers:

For more information about our line of Foss Foam replacement rudders, please call (949) 646-0244 or contact us at our office in Newport Beach, California.

The $tingy Sailor

Diy trailerable sailboat restoration and improvement without throwing your budget overboard.

How To Repair a Rudder

Rudders damage easily. Although they work similar to a keel, they aren’t nearly as tough. If you dry sail, the edges can accumulate nicks and dings in the fiberglass from loading and unloading. The rudders of some sailboats can hit the outboard motor’s propeller if you’re not careful. Add in accidental groundings, storage damage, and stress cracks and it doesn’t take much time in water to make the wooden core swell and damage the rudder even more. Without repairs, a weakened rudder can even break into pieces under stress. It pays to protect your rudder.

Before I continue, a bit of legal housekeeping. This post contains affiliate links. That means I receive a small commission if you make a purchase using those links. Those commissions help to pay the costs associated with running this site so that it stays free for everyone to enjoy. For a complete explanation of why I’m telling you this and how you can support this blog without paying more, please read my full disclosure .

If your rudder is showing any bare wood, has deep nicks in the edges, or has swelled and cracked the fiberglass at the edges, you should repair it while you still can. All of these kinds of damage are easily repairable by the do-it-yourselfer for a small fraction of the cost of a new rudder.

It’s just like doing auto body work

If you’ve ever done any auto body work, you know the goal is to build up and restore a smooth shape to damaged surfaces. It’s the same with your rudder but the finish quality doesn’t have to be as perfect.

Follow these steps to make your rudder smooth and watertight again:

1. Start with a 4″ handheld grinder or similar power tool to remove all of the rough and damaged fiberglass down to solid material. Also remove all damaged wood core material. This might seem overly aggressive but the repair won’t last unless it’s built on a solid foundation and a grinder will get you there fast. By removing the rudder’s skin, it will dry out faster.

2. Let the wooden core dry out as much as possible. You don’t want to trap moisture in the core where it will dry rot. If you lay up your sailboat for the off-season, that’s a good time to dry out your rudder. Finish the repair before the start of the next sailing season.

3. After the core has dried thoroughly, use a random orbital or similar power sander to feather the ground edges back a couple of inches all around and to remove any paint so that an epoxy patch will stick properly to the original fiberglass.

4. Mix some thickened West System or an equivalent epoxy and build up the ground and sanded areas to their original shape. Colloidal silica is a good thickener for this application.

5. With a power sander or sanding block, carefully smooth the patched areas to match the surrounding surfaces and edges.

7. Apply a barrier coat of one-part polyurethane or two-part (preferred) epoxy paint over the repaired areas.

6. Fill small cracks above the water line with Capt. Tolley’s Creeping Crack Cure .

7. Last, re-apply ablative paint or a polyurethane topcoat to match the rest of the rudder or hull. If you keep your sailboat in the water, ablative paint can minimize algae growth. If you dry sail or remove your rudder when you’re not sailing, ablative paint gives no benefit and will just transfer to everywhere you don’t want it. I reapplied ablative paint to this rudder but I sanded it off a year later and applied a gloss white polyurethane when Summer Dance got a different color bottom paint job .

8. Now is a good time to remove, clean, polish, and rebed all of the rudder hardware with butyl tape . If the tiller bushings are worn, read How to Replace Worn Tiller Bushings .

Now that you have a restored and sealed rudder, take good care of it and it will take good care of you!

Would you like to be notified when I publish more posts like this? Enter your email address below to subscribe to this blog and receive notifications of new posts by email. You will also receive occasional newsletters with exclusive info and deals only for subscribers and the password to the Downloads page. It’s free and you can unsubscribe at any time but almost nobody does!

Share this:

21 thoughts on “ how to repair a rudder ”.

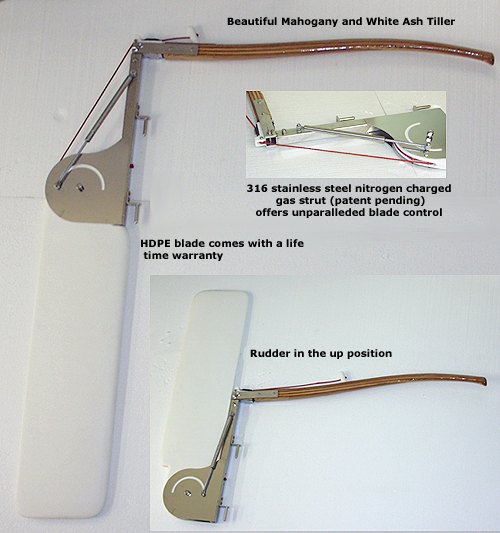

Hello from the UK! The rudder on my Jaguar 22 is the pivoted type to cope with grounding when the keel is lifted. It’s made from dense dark wood (mahogany I think) and it weighs a TON! It worries me having all that weight hanging off the f/g transom plus the outboard – it flexes the hull… I’ve seen some of the Gucci lightweight racing replacements available in the States for mega-bucks, but I wondered if you’d ever considered making a replacement lightweight rudder $tingy-style from (say) stainless or aluminum frame,with glass fibre coverng over foam, or similar? It would be a fascinating project!

Keep up the good work!

Mike (Tamariu) Jag 22

Your description makes me wonder if a previous owner made your kick-up rudder blade himself. No factory C-22 rudder that I’ve ever heard of was made of hardwood. I can’t imagine why the UK builder would go to that expense and being a licensee of Catalina Yachts, they would be legally bound to stick to the factory designs, materials, and methods.

As a matter of fact, I do have tentative plans to make a balanced rudder similar to what you describe or possibly of solid, lightweight cedar, so stay tuned! $tingy

Sounds good – I’ll keep watching!

Great informative article. Enjoy all your postings, have learned a lot.

Has anyone ever made a new rudder solely out of wood?

I’ve seen one fella’s rudder that he made out of mahogany and it weighed a ton. Others have attempted to make balanced rudders to replace the stock one. Rudder Craft makes high performance replacement rudders but they’re pricey and they also aren’t class legal for racing. Building a balanced rudder with conventional techniques is on my to-do list so you might see it here someday!

Well, I am a novice sailer at best. I won’t be racing, so a little extra weight won’t hurt much. From the looks of the rudder I have, it is has a wooden core in it. I just aquired the sailboat with some restoration needed. The rudders bottom has the fiberglass rubbed off. I have access to some cedar planks the same size as current rudder, so I was thinking of a nice winter project. Boat stays trailered when not in use.

Cedar would be strong, lightweight, and rot resistant. Go for it and send me some pictures when you’re finished and I’ll add them to the Reader’s Gallery.

Here is a link that I hope will take you to my pictures of the Sage 17’s rudder system in the Google ‘Photos’ cloud: https://goo.gl/photos/ttvihZ2zxm5xsz58A (I prepared some comments before I searched for the photos and the text disappeared when I returned…maybe they got posted…)

I really appreciated and look forward to the clear and concise project posts!

Very nice. Can you describe how it works here? It looks like when you raise the tiller handle, the rod rotates the blade up and the bungee holds it in position. What did you make the blade out of, mahogany?

I think you understand it better than I do…and as described here:

http://sagemarine.us/sage_17.html (see tab on stern & rudder features)

As I recall, the Sage rep said it took some experimentation to get the balance just right for the length of and attachment points for the rod on blade and tiller. You will see the rudder is outsourced to another manufacturer…I wonder if they have branched out to other boats?! The blade is mahogany, they note…

It doesn’t look to like it would be that hard to replicated, if you have the capability to fabricate/locate stainless parts. I’ll be interested to read how you’d do it, when you’ve replicated a similar designed for your boat!

Ah, I understand now with your link to Sage Marine. I thought you made the rudder yourself.

I was planning to make a balanced, fixed-style rudder but now after seeing how yours is made, I just might make a kick-up rudder instead that will lock up for trailering!

You bet. Just a little payback for all your great info. If I hear back that J O Boatworks will customize the design to meet other boats, I’ll let you know!

Well, we are almost finished with the rudder out of cedar. Instead of one solid piece we had to use 3 pieces thick of varying lengths that we planed and glued together then molded and sanded then applied more that 10 coats of marine varnish. Hardware is basically all we have left. Only thing, we we got involved and forgot to take very many pictures until the almost the finished product…sorry I can’t figure out how to post a picture here…

Sounds fun, Jeff. Take the best pictures you can and enter the 2017 Stingy Sailor DIY Project Contest coming soon!

If you want to have a balanced kick-up rudder like JO Woodworking fabricates for the Sage, contact him from his website.

http://www.jowoodworks.com/archives/category/boat-parts/holder

We emailed numerous times to confirm he could get the system to work for my setup and pricing seems fair! I am hoping my tax refund can pay for one for my Venture 21!

Happy sailing in 2017!

Hey Stingy, another helpful post, thank you. I had my rudder snap off sailing day before yesterday thanks to rusted hardware.. Anyway you mentioned that you ended up sanding off the anti fouling paint, and as you know it is quite pricey and sold in quarts (way more than needed for rudder bottom half) so would you say that using it is a little overkill? Do you think the growth would be much more uncontrollable without using it? I’d rather save the $50 and skip the anti fouling paint if it’s not a massive difference in growth/cleaning. Thanks

Hi, Christian

If you leave your rudder in the water all the time, then antifoul paint will make it easier to keep clean of marine growth. If you have a kick-up rudder and retract it when not sailing or, like I do, take the standard rudder off unless you’re sailing, then the extra paint is overkill. I connect my tiller with a quick release pin so it takes less than a minute to mount and dismount. This way, I’m able to keep my rudder clean and drag-free. I just wipe it down occasionally. It also minimizes the amount of water that can penetrate into the core through pintle holes and cracks and weaken it, which can result in catastrophic failure like you’ve experienced.

If your rudder wasn’t badly softened from water intrusion, then you should carefully question why it broke. If you weren’t in a dangerously rough sea state but had extreme, prolonged weather helm in normal conditions, then you might not have balanced the sail trim properly. When properly trimmed, you should be able to steer with minimal effort in all but the worst conditions.

Hope that helps, $tingy

Hi there, I have a C-lark with an all-wood rudder that is starting to crack around the gudgeon (I think that is the correct term). The cracks are starting at the top and running parallel to the long axis of the rudder. I haven’t been successful finding an appropriate used replacement, so am thinking about trying to fix this one. With a few of the cracks full width (not length) at the top is it worth trying to re-work this one, or would it be better to start fresh using this one as a blue print? If so, any resources you could recommend on materials and considerations? Thanks!

I very nearly got a derelict C-Lark for free so I know what a fun little boat that is. I’m a little confused about the cracks you describe as running along the long axis of the rudder but also full width. At any rate, I’m a big proponent of fixing anything that can be fixed. Your rudder might take some creative joinery to make it solid again but you have nothing to lose by trying, right? Depending on the extent of the cracks, I would either use waterproof glue and clamp the cracks or cut the rudder along the cracks, square the pieces up on a joiner, and then glue and clamp it together again, possibly using dowels or biscuits for additional strength.

If the damage is too extensive to repair, there are lots of materials that make a good rudder. Probably the easiest is either a solid piece of HDPE, which would be impervious to moisture and should last forever but require a lot of hand shaping or clear grain cedar with a fiberglass shell, which would be strong and lightweight and easier to fabricate.

It would make a great DIY project, so keep us updated on your progress, $tingy

Thanks, I think I am going to give a go at making a new rudder with cedar and fiberglass as you suggested. I have a friend with some skills who is going to lend a hand, but I will take photos and post our progress. Thanks!

Leave a comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

- Paddle Board

What Is a Sailboat Rudder? An Overview of Its Function and Design

Sailboats have been used for thousands of years to traverse water. They have undergone many changes and improvements over the years, and one of the essential components of a sailboat is the rudder.

Quick Facts

Understanding the sailboat rudder.

The rudder is a vital component of a sailboat that plays a crucial role in steering and maneuvering the vessel. The rudder works by changing the direction of the water flow around it, which moves the boat in the opposite direction. Without a rudder, it would be impossible to navigate a sailboat effectively, especially in different water and wind conditions.

Components of a Sailboat Rudder

A sailboat rudder comprises several components, each with a unique function that contributes to the rudder’s overall effectiveness. The stock is the main vertical shaft that connects the rudder blade to the boat’s helm. It is usually made of stainless steel or aluminum alloy and is designed to withstand the forces exerted on the rudder during navigation.

The blade is the flat portion of the rudder that faces the water current and directs the water flow in the opposite direction to steer the boat. The blade is typically made of fiberglass-reinforced plastic or aluminum alloy and is designed to be lightweight and durable. Pintles and gudgeons are the two connections between the rudder and stern that allow for easy installation and removal of the rudder. Pintles are the vertical metal pins that fit into the gudgeons, which are the horizontal metal brackets attached to the boat’s stern.

Different Types of Rudders

There are several types of rudders used in sailboats, each with its advantages and disadvantages. Transom-mounted rudders are the most common type of rudder, and they are mounted on the stern of the boat. Skeg-mounted rudders are attached to a fixed fin called a skeg, which provides additional stability to the rudder.

Keel-mounted rudders are attached to the boat’s keel, which is the central structural element that runs along the bottom of the hull. Spade rudders are free-standing rudders that are not attached to any part of the boat and are commonly used in racing sailboats. The type of rudder used depends on the boat’s size, design, and intended use.

Materials Used in Rudder Construction

Rudders can be made from various materials, each with its advantages and disadvantages. Wooden rudders are the traditional choice and are still used in some sailboats today. However, they are relatively heavy and require regular maintenance to prevent rot and decay.

Aluminum alloy rudders are lightweight and durable, making them an excellent choice for racing sailboats. Stainless steel rudders are also durable but are heavier than aluminum alloy rudders. Fiberglass-reinforced plastic rudders are the most common type of rudder used today, as they are lightweight, durable, and require minimal maintenance.

The sailboat rudder is an essential component that plays a crucial role in steering and maneuvering a sailboat. Understanding the different types of rudders, their components, and the materials used in their construction can help sailors choose the right rudder for their boat and navigate more effectively in different water and wind conditions.

The Function of a Sailboat Rudder

Steering and maneuvering.

The primary function of a sailboat rudder is to steer and maneuver the boat. The rudder’s blade directing the flow of water in a specific direction allows for the steering of the boat as the blade changes direction. Sailors can use the rudder to turn the boat in any direction they choose, allowing them to navigate through narrow channels or around obstacles in the water. It is essential to note that the rudder works in conjunction with the sails to control the boat’s direction and speed.

Balancing the Sailboat

The balance of the sailboat is critical to ensure safe maneuvering, and the rudder plays a crucial role in achieving this. A balanced rudder helps in keeping the boat steady, reducing drag, and preventing unwanted turning. Sailors can adjust the rudder’s angle to keep the boat balanced and on course, especially in rough water conditions. A well-balanced rudder also helps to reduce the risk of capsizing or losing control of the boat .

Rudder Effectiveness in Different Conditions

Rudder effectiveness varies depending on the boat’s size, weight, and water and wind conditions. A larger boat may require a bigger rudder for proper maneuvering, while a smaller boat can work with a smaller rudder. Sailors must also consider the water and wind conditions when choosing the right rudder for their boat. In calm waters, a smaller rudder may be sufficient, but in rough water, a larger rudder may be necessary to maintain control of the boat. Additionally, the rudder’s effectiveness can be affected by the boat’s speed, with higher speeds requiring more significant rudders to maintain control.

It is also important to note that the rudder’s effectiveness can be impacted by external factors such as weeds or debris in the water. These factors can reduce the rudder’s ability to steer the boat and require sailors to make adjustments to maintain control. Additionally, the rudder’s effectiveness can be impacted by the sailor’s skill level, with more experienced sailors able to make more precise adjustments to the rudder to control the boat’s direction and speed.

Design Considerations for Sailboat Rudders

Sailboat rudders are an essential component of a boat’s steering and maneuvering system. A well-designed rudder can make all the difference in a boat’s performance , especially in challenging weather conditions. In this article, we will explore some of the key design considerations for sailboat rudders.

Rudder Size and Shape

The size and shape of a rudder play a crucial role in determining its effectiveness in steering and maneuvering a boat. A larger rudder provides more leverage and maneuverability, allowing the boat to turn more sharply. However, a larger rudder may also produce more drag, which can slow down the boat’s speed.

The shape of the rudder is also important. A well-designed rudder should be streamlined to reduce drag and turbulence. The thickness of the rudder should be carefully considered to ensure that it is strong enough to withstand the forces exerted on it while remaining lightweight.

Rudder Placement and Configuration

The placement of the rudder on the boat can significantly affect its performance. A rudder that is too far forward can cause the boat to become unstable, while a rudder that is too far aft can make it difficult to steer. The location of the rudder must also take into account factors such as the propeller’s placement and the boat’s shape.

The configuration of the rudder can also determine its effectiveness and balance. A single rudder is the most common configuration, but some boats have twin rudders to provide more steering control. The angle of the rudder blade can also be adjusted to optimize its performance.

Hydrodynamic and Aerodynamic Factors

The design of a rudder must take into consideration the hydrodynamic and aerodynamic factors affecting the boat’s performance. Hydrodynamic factors include water flow, pressure, and turbulence, which can significantly affect the rudder’s performance. The shape and placement of the rudder must be carefully designed to minimize these effects.

Aerodynamic factors consider the wind and air resistance’s impact on the boat’s performance. The rudder’s size and shape must be designed to minimize the wind’s effect on the boat while providing sufficient steering control.

The design of a sailboat rudder is a complex process that requires careful consideration of many factors. The size and shape of the rudder, its placement on the boat, and its configuration must be optimized to provide effective steering and maneuverability. By taking into account the hydrodynamic and aerodynamic factors affecting the boat’s performance, a well-designed rudder can significantly improve a sailboat’s overall performance.

Rudder Maintenance and Repair

The rudder is a crucial component of any sailboat, providing steering and control. As such, it’s essential to keep it in good working order through regular maintenance and inspections.

Inspecting Your Rudder

Regular inspection of the rudder is essential to ensure its continued performance and longevity. A thorough inspection includes checking for cracks, wear and tear, and loose components such as hinges, pins, and screws. It’s also important to check the rudder’s alignment and ensure it moves smoothly and without any obstructions.

During your inspection, be sure to check for signs of corrosion, particularly on metal components. Corrosion can weaken the rudder and cause it to fail, so regular cleaning and maintenance are essential to prevent this.

If you notice any issues during your inspection, it’s important to address them promptly. Small cracks or damage can often be repaired, but if the damage is extensive, it may be necessary to replace the rudder entirely.

Common Rudder Issues and Solutions

One common issue with rudders is corrosion, particularly on metal components. Regular cleaning and maintenance help prevent corrosion and ensure the rudder’s longevity. If you do notice signs of corrosion, it’s important to address it promptly to prevent further damage.

Another common issue is damage to the blade or stock. This can be caused by impact with debris or other boats, or simply wear and tear over time. If the damage is minor, it may be possible to repair the rudder. However, if the damage is extensive or compromises the rudder’s structural integrity, it may be necessary to replace it entirely.

Loose components such as hinges, pins, and screws can also cause issues with the rudder. These should be checked regularly and tightened or replaced as needed.

When to Replace or Upgrade Your Rudder

Sailboat rudders can last for many years, but at some point, replacement or upgrade may be necessary. This includes upgrading to a newer design or larger rudder to improve the boat’s performance or replacing a damaged or worn-out rudder that is beyond repair.

If you’re considering upgrading your rudder, it’s important to consult with a professional to ensure that the new rudder is compatible with your boat and will provide the desired performance improvements.

Regular maintenance and inspections are essential to ensure the continued performance and longevity of your sailboat’s rudder. By staying on top of any issues and addressing them promptly, you can ensure that your rudder will continue to provide reliable steering and control for many years to come.

A sailboat’s rudder is a crucial component that helps steer and maneuver the boat safely. The size, shape, placement, and construction materials must all be taken into consideration when designing or replacing a rudder. Regular maintenance and inspection help ensure its continued performance and longevity.

Rudder FAQS

How does a sailboat rudder work.

A sailboat rudder works by changing the direction of the water flow past the boat’s hull, which in turn changes the direction of the boat. The rudder is attached to the stern of the boat and can be turned left or right. When the rudder is turned, it creates a force that pushes the stern in the opposite direction and turns the bow towards the direction the rudder is turned. This is how a rudder steers a boat.

What is a rudder and its purpose?

A rudder is a flat piece, usually made of metal or wood, attached to the stern of a vessel such as a boat or ship. The main purpose of the rudder is to control the direction of the vessel. It does this by deflecting water flow, creating a force that turns the vessel. Without a rudder, steering a vessel would be significantly more challenging.

Can you steer a sailboat without a rudder?

Steering a sailboat without a rudder is challenging but not impossible. Sailors can use the sails and the keel to influence the direction of the boat. By trimming the sails and shifting weight, it’s possible to cause the boat to turn. However, this is a difficult technique that requires a deep understanding of sailing dynamics and is usually considered a last resort if the rudder fails.

What controls the rudder on a sailboat?

The rudder on a sailboat is typically controlled by a steering mechanism, like a tiller or a wheel. The tiller is a lever that is directly connected to the top of the rudder post. Pushing the tiller to one side causes the rudder to turn to the opposite side. On larger boats, a wheel is often used. The wheel is connected to the rudder through a series of cables, pulleys, or hydraulic systems, which turn the rudder as the wheel is turned.

How do you steer a sailboat with a rudder?

To steer a sailboat with a rudder, you use the tiller or wheel. If your sailboat has a tiller, you’ll push it in the opposite direction of where you want to go – pushing the tiller to the right will turn the boat to the left and vice versa. If your sailboat has a wheel, it operates like a car steering wheel – turning it to the right steers the boat to the right and turning it to the left steers the boat to the left.

How do you steer a sailboat against the wind?

Steering a sailboat against the wind, also known as tacking, involves a maneuver where the bow of the boat is turned through the wind. Initially, the sails are let out, and then the boat is steered so that the wind comes from the opposite side. As the boat turns, the sails are rapidly pulled in and filled with wind from the new direction. This maneuver allows the boat to zigzag its way upwind, a technique known as “beating.” It requires skill and understanding of sailing dynamics to execute effectively.

John is an experienced journalist and veteran boater. He heads up the content team at BoatingBeast and aims to share his many years experience of the marine world with our readers.

What to Do If Your Boat Engine Won’t Start? Common Problems & How to Fix Them

How to launch a boat by yourself: complete beginner’s guide, how to surf: complete beginner’s guide to get you started.

Comments are closed.

Type above and press Enter to search. Press Esc to cancel.

My Cruiser Life Magazine

All About the Rudder on a Sailboat

The rudder on a sailboat is one of those important parts that often gets overlooked. It’s hidden underwater most of the time and usually performs as expected when we ask something of it.

But when was the last time you seriously considered your sailboat rudder? Do you have a plan if it fails? Here’s a look at various designs of sail rudder, along with the basics of how it works and why it’s there.

Table of Contents

How are sailboat rudders different than keels, how does the rudder work, wheel steering vs. tiller steering, full keel rudder sailboat, skeg-hung rudders, spade rudder, variations on designs, emergency outboard rudder options, looking to sail into the sunset grab the wheel, steer your sail boat rudder, and get out there, sail boat rudder faqs.

What Is a Boat Rudder?

The rudder is the underwater part of the boat that helps it turn and change direction. It’s mounted on the rear of the boat. When the wheel or tiller in the cockpit is turned, the rudder moves to one side or another. That, in turn, moves the boat’s bow left or right.

When it comes to sailing, rudders also offer a counterbalance to the underwater resistance caused by the keel. This enables the boat to sail in a straight line instead of just spinning around the keel.

Sailboat hull designs vary widely when you view them out of the water. But while the actual shape and sizes change, they all have two underwater features that enable them to sail–a rudder and a keel.

The rudder is mounted at the back of the boat and controls the boat’s heading or direction as indicated by the compass .

The keel is mounted around the center of the boat. Its job is to provide a counterbalance to the sails. In other words, as the wind presses on the sails, the weight of the ballast in the keel and the water pressure on the sides of the keel keeps the boat upright and stable.

When sailing, the keel makes a dynamic force as water moves over it. This force counters the leeway made by air pressure on the sails and enables the boat to sail windward instead of only blowing downwind like a leaf on the surface.

The rudder is a fundamental feature of all boats. Early sailing vessels used a simple steering oar to get the job done. Over the years, this morphed into the rudder we know today.

However, thinking about a rudder in terms of a steering oar is still useful in understanding its operation. All it is is an underwater panel that the helmsperson can control. You can maintain a course by trailing the oar behind the boat while sailing. You can also change the boat’s heading by moving it to one side or the other.

The rudders on modern sailboats are a little slicker than simple oars, of course. They are permanently mounted and designed for maximum effectiveness and efficiency.

But their operating principle is much the same. Rudders work by controlling the way water that flows over them. When they move to one side, the water’s flow rate increases on the side opposite the turn. This faster water makes less pressure and results in a lifting force. That pulls the stern in the direction opposite the turn, moving the bow into the turn.

Nearly all boats have a rudder that works exactly the same. From 1,000-foot-long oil tankers to tiny 8-foot sailing dinghies, a rudder is a rudder. The only boats that don’t need one are powered by oars or have an engine whose thrust serves the same purpose, as is the case with an outboard motor.

Operating the Rudder on a Sailboat

Rudders are operated in one of two ways–with a wheel or a tiller. The position where the rudder is operated is called the helm of a boat .

Ever wonder, “ What is the steering wheel called on a boat ?” Boat wheels come in all shapes and sizes, but they work a lot like the wheel in an automobile. Turn it one way, and the boat turns that way by turning the rudder.

A mechanically simpler method is the tiller. You’ll find tiller steering on small sailboats and dinghies. Some small outboard powerboats also have tiller steering. Instead of a wheel, the tiller is a long pole extending forward from the rudder shaft’s top. The helmsperson moves the tiller to the port or starboard, and the bow moves in the opposite direction. It sounds much more complicated on paper than it is in reality.

Even large sailboats will often be equipped with an emergency tiller. It can be attached quickly to the rudder shaft if any of the fancy linkages that make the wheel work should fail.

Various Sail Boat Rudder Designs

Now, let’s look at the various types of rudders you might see if you took a virtual walk around a boatyard. Since rudders are mostly underwater on the boat’s hull, it’s impossible to compare designs when boats are in the water.

Keep in mind that these rudders work the same way and achieve the same results. Designs may have their pluses and minuses, but from the point of view of the helmsperson, the differences are negligible. The overall controllability and stability of the boat are designed from many factors, and the type of rudder it has is only one of those.

You’ll notice that rudder design is closely tied to keel design. These two underwater features work together to give the boat the sailing characteristics the designer intended.

The classic, robust offshore sailboat is designed with a full keel that runs from stem to stern. With this sort of underwater profile, it only makes sense that the rudder would be attached to the trailing edge of that enormous keel. On inboard-powered sailboats, the propeller is usually mounted inside an opening called the aperture between the keel and rudder.

The advantages of this design are simplicity and robustness. The keel is integrated into the hull and protects the rudder’s entire length. Beyond reversing into an obstacle, anything the boat might strike would hit the keel first and would be highly unlikely to damage the rudder. Not only does the keel protect it, but it also provides a very strong connection point for it to be attached to.

Full keel boats are known for being slow, although there are modern derivatives of these designs that have no slow pokes. Their rudders are often large and effective. They may not be the most efficient design, but they are safe and full keels ride more comfortably offshore than fin-keeled boats.

Plenty of stout offshore designs sport full keel rudders. The Westsail 38s, Lord Nelsons, Cape Georges, Bristol/Falmouth Cutters, or Tayana 37s feature a full keel design.

A modified full keel, like one with a cutaway forefoot, also has a full keel-style rudder. These are more common on newer designs, like the Albergs, Bristols, Cape Dorys, Cabo Ricos, Island Packets, or the older Hallberg-Rassys.

A design progression was made from full keel boats to long-fin keelboats, and the rudder design changed with it. Designers used a skeg as the rudder became more isolated from the keel. The skeg is a fixed structure from which you can mount the rudder. This enables the rudder to look and function like a full keel rudder but is separated from the keel for better performance.

The skeg-hung rudder has a few of the same benefits as a full keel rudder. It is protected well and designed robustly. But, the cutaways in the keel provide a reduced wetted surface area and less drag underwater, resulting in improved sailing performance overall.

Larger boats featuring skeg-mounted rudders include the Valiant 40, Pacific Seacraft 34, 37, and 40, newer Hallberg-Rassys, Amels, or the Passport 40.

It’s worth noting that not all skegs protect the entire rudder. A partial skeg extends approximately half the rudder’s length, allowing designers to make a balanced rudder.

With higher-performance designs, keels have become smaller and thinner. Fin keel boats use more hydrodynamic forces instead of underwater area to counter the sail’s pressure. With the increased performance, skegs have gone the way of the dinosaurs. Nowadays, rudders are sleek, high aspect ratio spade designs that make very little drag. They can be combined with a number of different keel types, including fin, wing keels , swing keels, or bulb keels.

The common argument made against spade rudders is that they are connected to the boat by only the rudder shaft. As a result, an underwater collision can easily bend the shaft or render the rudder unusable. In addition, these rudders put a high load on the steering components, like the bearings, which are also more prone to failure than skeg or full keel designs. For these reasons, long-distance cruisers have traditionally chosen more robust designs for the best bluewater cruising sailboats .

But, on the other hand, spade rudders are very efficient. They turn the boat quickly and easily while contributing little to drag underwater.

Spade rudders are common now on any boat known for performance. All racing boats have a spade rudder, like most production boats used for club racing. Pick any modern fin keel boat from Beneteau, Jeanneau, Catalina, or Hunter, and you will find a spade rudder. Spade rudders are common on all modern cruising catamarans, from the Geminis to the Lagoons, Leopards, and Fountaine Pajots favored by cruisers and charter companies.

Here are two alternative designs you might see out on the water.

Transom-Hung or Outboard Rudders

An outboard rudder is hung off the boat’s transom and visible while the boat is in the water. Most often, this design is controlled by a tiller. They are common on small sailing dingies, where the rudder and tiller are removable for storage and transport. The rudder is mounted with a set of hardware called the pintle and gudgeon.

Most outboard rudders are found on small daysailers and dinghies. There are a few classic big-boat designs that feature a transom-hung rudder, however. For example, the Westsail 38, Alajuela, Bristol/Falmouth Cutters, Cape George 36, and some smaller Pacific Seacrafts (Dana, Flicka) have outboard rudders.

Twin Sailing Rudder Designs

A modern twist that is becoming more common on spade rudder boats is the twin sailboat rudder. Twin rudders feature two separate spade rudders mounted in a vee-shaped arrangement. So instead of having one rudder pointed down, each rudder is mounted at an angle.

Like many things that trickle down to cruising boats, the twin rudder came from high-performance racing boats. By mounting the rudders at an angle, they are more directly aligned in the water’s flow when the boat is healed over for sailing. Plus, two rudders provide some redundancy should one have a problem. The twin rudder design is favored by designers looking to make wide transom boats.

There are other, less obvious benefits of twin rudders as well. These designs are easier to control when maneuvering in reverse. They are also used on boats that can be “dried out” or left standing on their keel at low tide. These boats typically combine the twin rudders with a swing keel, like Southerly or Sirius Yachts do. Finally, twin rudders provide much better control on fast-sailing hulls when surfing downwind.

Unbalanced vs. Balanced Rudders

Rudders can be designed to be unbalanced or balanced. The difference is all in how they feel at the helm. The rudder on a bigger boat can experience a tremendous amount of force. That makes turning the wheel or tiller a big job and puts a lot of strain on the helmsperson and all of the steering components.

A balanced rudder is designed to minimize these effects and make turning easier. To accomplish this, the rudder post is mounted slightly aft of the rudder’s forward edge. As a result, when it turns, a portion of the leading edge of the rudder protrudes on the opposite side of the centerline. Water pressure on that side then helps move the rudder.

Balanced rudders are most common in spade or semi-skeg rudders.

Sail Rudder Failures

Obviously, the rudder is a pretty important part of a sailboat. Without it, the boat cannot counter the forces put into the sails and cannot steer in a straight line. It also cannot control its direction, even under power.

A rudder failure of any kind is a serious emergency at sea. Should the rudder be lost–post and all–there’s a real possibility of sinking. But assuming the leak can be stopped, coming up with a makeshift rudder is the only way you’ll be able to continue to a safe port.

Rudder preventative maintenance is some of the most important maintenance an owner can do. This includes basic things that can be done regularly, like checking for frayed wires or loose bolts in the steering linkage system. It also requires occasionally hauling the boat out of the water to inspect the rudder bearings and fiberglass structure.

Many serious offshore cruisers install systems that can work as an emergency rudder in extreme circumstances. For example, the Hydrovane wind vane system can be used as an emergency rudder. Many other wind vane systems have similar abilities. This is one reason why these systems are so popular with long-distance cruisers.

There are also many ways to jury rig a rudder. Sea stories abound with makeshift rudders from cabinet doors or chopped-up sails. Sail Magazine featured a few great ideas for rigging emergency rudders .

Understanding your sail rudder and its limitations is important in planning for serious cruising. Every experienced sailor will tell you the trick to having a good passage is anticipating problems you might have before you have them. That way, you can be prepared, take preventative measures, and hopefully never deal with those issues on the water.

What is the rudder on a sailboat?

The rudder is an underwater component that both helps the sailboat steer in a straight line when sailing and turn left or right when needed.

What is the difference between a rudder and a keel?

The rudder and the keel are parts of a sailboat mounted underwater on the hull. The rudder is used to turn the boat left or right, while the keel is fixed in place and counters the effects of the wind on the sails.

What is a rudder used for on a boat?

The rudder is the part of the boat that turns it left or right

Matt has been boating around Florida for over 25 years in everything from small powerboats to large cruising catamarans. He currently lives aboard a 38-foot Cabo Rico sailboat with his wife Lucy and adventure dog Chelsea. Together, they cruise between winters in The Bahamas and summers in the Chesapeake Bay.

Leave a comment

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Jordan Yacht Brokerage

We Never Underestimate Your Dreams

Sailboat rudder types – full, spade, skeg, outboard.

The four rudder types are: full, spade, skeg, and outboard. This article discusses the advantages and disadvantages of each.

Full The full or full keel rudder lies at the aft end of a full length keel. The keel-rudder streches along the entire length of the bottom of the hull. The full rudder is safe and nearly invulnerable to damage. The leading edge of the keel protects the rudder from flotsam. The full rudder is quintessential of offshore cruisers like Wetsails and Cabo Ricos. Even grounding may not cause damage. The boat will sit comfortable on its side until the tide returns and floats the boat back up.

Spade The spade rudder lies at the aft separate from the keel. A spade rudder is easy to turn because the water rushes both against its fore and aft edges – great for using a tiller. A spade rudder is also fast as the wet area less than a full keel. The boat racing along with less resistance. Spade and partial spades are becoming the most popular rudder type. The Hylas 70 has a partial spade rudder as well as early 54’s.

Skeg A skeg rudder is more modern in performance and safety. It is the most popular and common type of rudder on production boats these days. The rudder is fast and looks like a spade keel. Except, the skeg rudder has a fake keel which extends from the hulls aft and protects the fore edge. Most Hylas yachts have skeg rudders.

Outboard Outboard rudders are seen on smaller boats. They simply hang over the stern of the boat. For example, racing prams use outboard rudders. They are easy to fasion as emergency rudders. You can make one out of a handlerail and cabin door.

Conclusion A rudder is either full, spade, skeg, or outboard. Each type has its benefits. The most important part is make sure she is in good condition and have a spare.

4 Replies to “Sailboat Rudder Types – Full, Spade, Skeg, Outboard”

Ahoy Mateys, it’s Fox Axel the Pirate. I’ve got a swashbuckling yarn to tell ye. Me was drifting along way out at sea. Me had lost me steering while pillaging a friendly ship. The knaves canon knocked me rudder off. Me had nought to to turn to. The authorities would hang me, the villainous lot. But, me was getting desperate out of grub and rum, nothing to sage me drunken pirate ways. I had lost me last vestige of sanity.

Finally, me saw in the distance a giant whaler coming. The big ship sailed straight at me. “Ahoy mateys!” me spake. The freighter came near, too near. Shiver me timbers. The goulish crew must be drunk out of thee minds. Me could not steer away. She rammed straight slicing me ship in twain. Down to Davy Jones’ locker we went. Take care with ye rudders mateys – the Pirate of Monkey Isle.

Ok ye swabs ave a told me to finish me story. Ere dis da rest. As the freighter tore away leaving me to perish in the sea. I climbed on a board of driftwood from me sinkin’ ship. I passed out adrift, alone. When I came to, I found meself shipwrecked on a deserted island. I stumbled around and ran into, who of all? Big Red, me pirate enemy! Aye, I’m shipping as mate with his goulish fleet until I can betray and kill him. Aye, hope Big Red ain’t reading dis here blog. Black Fox the Pirate.

I am ye swab. I am too sharp for some ere fool like ye. I ain’t gots no book learning, but me hast carniving ways from many years below the mast. Iffen ye be trying to betray me, I am a gonna get ye.

Thank you for sharing this article.It’s quite easy to understand the difference.

Leave a Reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Professional BoatBuilder Magazine

The rudimentaries of rudders.

By Steve D'Antonio , Jul 12, 2018

Even stoutly constructed rudders are vulnerable to deterioration over time, especially when mild steel or high-carbon-stainless steel is buried in composite foil sections, which inevitably become saturated with seawater.

Like other systems and gear aboard cruising and commercial vessels, rudders have terms to identify their parts and functions. When measuring a rudder, the span and chord are the vertical height and fore-and-aft width, respectively, while the top of portion closest to the hull is referred to as the root , and the bottom is called the tip . Another term frequently used when discussing rudder design, particularly for sailing vessels, is aspect ratio —simply the square of the rudder’s span divided by the rudder’s area. As a rule of thumb, longer, narrower rudders are more efficient than short, wide rudders, and the aspect ratio describes precisely this relationship. Thus, rudders on high-performance sailing vessels are said to have a high-aspect ratio. Walking around a boatyard one day and measuring a few cruising sailboat rudders, I came up with aspect ratios of between 1.7 and 2.1, while one high-performance sailing vessel’s rudder came in at 3.5. The 20-knot semi-displacement lobster yacht’s rudder I measured yielded an even 2.0 aspect ratio, which is considered respectable for this application.

More identifiable rudder components include the stock ; web or armature ; rudderport or log ; stuffing box or compression tube ; bearing ; gudgeon ; and pintle . Not every rudder has all these components.

Rudderstocks

The rudderstock is essentially a shaft or tube that protrudes from the top and sometimes the bottom, depending upon type, of many rudder designs. Because this component provides the primary connection between the rudder’s blade (the flat section that imparts the steering force) and the vessel’s steering system, its design, construction, and material are consequential.

Most stocks are made of stainless steel, bronze, or aluminum, while some are carbon fiber, and they may be solid or hollow. Stainless steel is by far the most common, but it has a penchant for crevice corrosion when exposed to oxygen-depleted water. Insidiously, corrosion nearly always occurs in places where it cannot easily be seen—such as inside many composite (fiberglass and core material) rudder blades and beneath flax-type stuffing-box packing (the problem is exacerbated when the vessel is used infrequently).

This all-stainless rudderstock and webbing is well crafted and ready to be covered with its composite shell.

Of the stainless steel alloys, some resist this corrosion better than others. Stainless-steel rudderstocks should be manufactured with strong, highly corrosion-resistant proprietary shafting alloys such as A22. The next best choice is 316L stainless steel, which also resists crevice corrosion well. Critically important is the L suffix, meaning “low carbon,” a requirement if it is to be welded, as nearly every rudderstock must be, to the support within composite rudders, or to all-metallic plate-steel rudders. Failure to source low-carbon stainless steel for the stock or the web leads to weld decay, sometimes referred to as carbide precipitation, where the region around the weld loses its resistance to corrosion and rusts when exposed to water.

Aluminum rudderstocks are nearly always tubular. Common on aluminum vessels to reduce the likelihood of galvanic corrosion, aluminum stocks are also relatively common on fiber reinforced plastic (FRP) vessels, particularly large ones. Rudder blades, particularly on aluminum vessels, are often fabricated from aluminum. Of the various aluminum alloys, only a few possess the necessary corrosion-resistance and strength necessary for use as rudderstocks. Of these, the 6000 series, and 6082 in particular—an alloy of aluminum, manganese, and silicon—are popular for this application.

Because aluminum, like stainless steel, suffers from corrosion, it should not be used as stock or web material in composite rudders. Referred to as poultice corrosion, it occurs when aluminum is exposed to oxygen-depleted water. Because oxygen is what allows aluminum to form its tough, corrosion-resistant oxide coating, the metal should never be allowed to remain wet and starved of air as it would be inside a composite rudder blade after water makes its way in around the stock and pintle.

Rudderstock material can corrode in way of the oxygen-starved environment around the packing in a stuffing box.

Bronze, a once popular rudderstock material, is no longer common in today’s production vessels. Although strong and exceptionally corrosion resistant (immune to crevice corrosion), bronze is not easily welded to attach to a rudder’s internal structural webbing, and has thus been supplanted by stainless alloys. Bronze rudderstocks, particularly those that have seen many sea miles, are also known for wearing, or hourglassing, within stuffing boxes, where the flax rides against the stock. If a bronze stock rudder is chronically leaky, disassemble the stuffing box and check for excessive wear. The same is true for stainless and aluminum stocks: chronic leakage is often an indication of corrosion at the packing. Finally, because of their galvanic incompatibility, neither bronze nor copper alloys should be used aboard aluminum vessels for rudderstocks or any other rudder or stuffing box components.

Mild-steel webbing welded to a stainless-steel rudderstock is a recipe for eventual corrosion and failure.

The webbing, or internal metallic support system, in most composite rudders must be strong enough to carry the loads of service and be made of the appropriate material. At one time, many rudders were built using stainless-steel stocks and ordinary, rust-prone mild or carbon-steel webbing. Inadvisably, some still are. The union between a stainless stock and FRP rudder blade is tenuous at best (the two materials expand and contract at different rates) and stainless steel’s slippery surface makes adhesion to the laminate resin a short-lived affair. Once water enters the gap between these two materials, it will reach the webbing and associated welds. Thus, all the materials within this structure must be as corrosion- and water-resistant as possible, and the core material must be closed-cell—often foam—and nonhygroscopic.

This destroyed foam-core and stainless-steel rudder reveals the conventional construction of such appendages.

Additionally, where possible, the stock should consist of a single section of solid or tubular material; i.e., it should not be sleeved, reduced, or otherwise modified or welded unless done so in an exceptionally robust manner. The webbing must be welded to the stock, but the structure of the stock should not rely on a weld that would experience cyclical, torsional loading.

The webbing in the form of a plate or grid should be welded to the stock with ample horizontal gussets (small wedges welded where the stock and webbing interface), which will reinforce welds 90° to the primary web attachment.

Whether the rudder is spade (supported only at the top) or skeg hung (supported at the top and the bottom), the stock must pass through and be supported by the hull. This is usually accomplished by a component known as a rudder log, or port. In its simplest form it’s a tube or pipe through which the stock passes. Nearly all logs incorporate two other components—a bearing and a stuffing box. The bearing may be as simple as a bronze or nonmetallic bushing or tube inside of which the stock turns; or it may be as complex as a self-aligning roller-bearing carrier that absorbs rudder deflection and prevents binding.

This rudder log is leaking, corroded, and poorly supported, with washers compressing into the backing plate and gelcoat cracking off.

The log transfers tremendous loads and must be exceptionally strong and well bonded to the hull. Fiberglass vessels should rely on a well-tabbed-in purpose-made tube (its filaments are wound and crisscrossed and thus quite strong) that is supported with a series of vertical gussets that distribute the load to the hull’s surrounding structure. On some spade rudder installations, particularly where the log is not, or could not, be long enough, an additional bearing is used at the top of the stock, above the quadrant, where it is supported by the vessel’s deck.

On metal boats the design is similar but with a metal tube welded in place, supported by substantial gussets. For vessels with skeg-hung rudders, the strength of the rudder log is still important. However, because the loads are not imparted by a cantilevered structure, logs used in these applications may be less substantially supported.

Stuffing Box