Become the Confident Skipper of Your Own Sailboat

Sailboat model building.

- Post author: Anns

- Post published: October 11, 2022

- Post category: Uncategorized

- Post comments: 0 Comments

Introduction

You can build a model sailboat out of wood, and it’s really easy. This blog will show you how to build a basic wooden sailboat model that’s good for beginners and more experienced modelers alike.

How to build a Sailboat: Part 1

Building a sailboat has been my dream since I was a kid. I have always wanted to build one from scratch, but never had the time or money to do so. Now that I am retired and have more time on my hands, I have decided to start building this beautiful wooden sailboat model from plans that I bought online. Here’s how you can build your own wooden sailboat:

How to build a Sailboat: Part 2

Before you can begin building a sailboat, you need to build a keel. The keel is the main part of your boat and without it, your boat would have no stability. This is what keeps the boat from tipping over when sailing in rough seas.

Next, you need to make a hull for your sailboat model by using pine wood or balsa wood strips that are glued together with sticky glue (which is sold at most craft stores). After making sure that all of the pieces fit together properly, start applying paint or stain onto each plank so they look real!

Afterwards, make sure there are no gaps between each plank so that water cannot get inside while sailing out on open waters! You’ll also want as many planks as possible because this will improve your ship’s speed! In fact…

How to Build a Sailboat: Part 3

Now that you have a hull, it’s time to turn your attention to the deck. The deck is what rests on top of the hull and provides a platform for sailing. The size, shape and placement of this part are all up to you based on what kind of ship you want to build.

Once you’ve made your decision about how big or small your deck should be, take measurements from below so that it fits snugly in place over the hull. You may need some help from someone with better eyesight than yours if parts don’t line up quite right (as they often won’t!). Then cut out some wood planks with a saw and glue them together using wood glue or waterproof epoxy (like Gorilla Glue). Afterward make sure everything fits snugly by sanding down any rough edges before painting or staining them!

At this point everything looks great with just one problem—it needs something more than just wood planks sticking out everywhere! So let’s start adding railings next….

How to Build a Sailboat: Part 4

Being able to build a sailing ship from scratch is a skill that many people never get around to learning. It’s not just hard, it’s also expensive. Not everyone can afford to go out and buy a kit where all the pieces are put together for them, nor do they want to spend hours in the garage cutting wood with their tool of choice. Here at Sailboat Model Building we’re here to help!

In this article we’ll be showing you how you can build your own sailboat from scratch using nothing more than some basic tools, maybe a table saw if you’re lucky enough, and some time on your hands (but not too much!). We’ll also teach about why building your own models is an important step towards being able to build real life sailing ships in the future!

You can make your own sailboats from wood.

You can build your own sailboat from wood. To do so, you’ll need:

- Wood for the boat’s hull and deck (about ¾ inch thick).

- Plywood for the boat’s keel and mast (about ½ inch thick).

- Fiberglass cloth to make a fiberglass hull that is stiffer than wood. It should be cut into 2-inch wide strips with an overlapping seam in the middle of each strip. The seams should run lengthwise along the sides of the boat instead of parallel with them so that they won’t show when you’re done painting it. The cloth needs to be about 6 inches longer than each side of your boat; use Velcro or duct tape at either end so that you can overlap them without getting any glue on yourself while working on this project!

- Epoxy resin glue which comes in two parts – one part hardens quickly while another part hardens slowly over several hours or days depending on how thickly they’re applied together! This makes sure everything stays put even when exposed to strong winds out there sailing around on open water!

Building a real sailboat from wood is a rewarding project that can be done with minimal tools and space. It’s also something you can do with your children as long as they’re old enough to understand safety precautions for working with sharp objects like saws or knives. I hope this blog has given you some insight into how it’s done!

You Might Also Like

Gennaker gives you a chance to get away, i love sailing because it is perfect for someone like me who is at heart a sailor. sailing could be the best way to relax especially when you are with your family and friends. it could help the kids learn about ocean animals such as whales, dolphins and other sea creatures., leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

Step-By-Step Guide: How to Build a Wooden Sailboat – Complete DIY Tutorial

Alex Morgan

Building a wooden sailboat is a rewarding and fulfilling endeavor that allows you to create your own vessel for sailing adventures. Whether you’re a seasoned sailor or a woodworking enthusiast, constructing a wooden sailboat requires careful planning, attention to detail, and a love for craftsmanship. This comprehensive guide will take you through the step-by-step process of building a wooden sailboat, from choosing the right design and gathering the necessary materials to assembling the framework, building the deck and cabin, and installing the sails and rigging. We will also discuss the finishing touches and regular maintenance required to keep your wooden sailboat in optimal condition for years of enjoyment on the water. Let’s dive into the world of wooden sailboat construction and embark on this exciting journey together.

Key takeaways:

Key takeaway:

- Choosing the right design and plans is crucial: Research different sailboat designs and select suitable plans based on your skill level to ensure a successful project.

- Gather the necessary materials and tools: Pay attention to wood selection and preparation, as well as acquiring the tools and equipment needed for building your wooden sailboat.

- Attention to detail in the construction process is important: Prepare and assemble the framework carefully, focusing on lofting, laying out the keel, constructing the ribs, and the hull structure to ensure a sturdy and reliable sailboat.

Choosing the Right Design and Plans

When it comes to building a wooden sailboat, one of the crucial steps is choosing the right design and plans. In this section, we’ll take a deep dive into the world of sailboat designs and explore the vast array of options available. From researching different sailboat designs to selecting plans that match your skill level, we’ll guide you through the exciting process of bringing your wooden sailboat dream to life. So, hop aboard and let’s set sail on this exhilarating journey of craftsmanship and adventure.

Researching Different Sailboat Designs

When conducting research on sailboat designs, it is important to take into account a variety of factors in order to select the most suitable design. One of the primary considerations is whether you prefer a monohull or a multihull sailboat. Monohulls are more commonly found and offer superior performance when sailing upwind, whereas multihulls provide both stability and speed.

Another aspect to consider is your level of sailing experience. If you are a beginner, it is advisable to seek out designs that are easier to handle and forgiving. On the other hand, experienced sailors may gravitate towards performance-oriented designs that are ideal for racing or long-distance cruising.

It is crucial to think about how you intend to use the sailboat. Are you looking for a day sailer , a cruiser , or a racing boat ? Each design comes with its own set of distinctive features and characteristics.

Determining the appropriate size of the sailboat is another crucial step, which should be based on the number of people and activities you plan to have on board. You must also decide whether you prefer an open cockpit or an enclosed cabin .

To find the perfect sailboat design that aligns with your sailing goals and preferences, it is imperative to thoroughly research various options and take into consideration all of these factors. By doing so, you will be able to make an informed decision and select the ideal sailboat design.

Selecting Suitable Plans for Your Skill Level

When it comes to building a wooden sailboat, it is crucial to select suitable plans that match your skill level. This is important as it ensures that you have the necessary knowledge and expertise to effectively complete the construction. In order to help you with this, here is a table that outlines the different skill levels and the corresponding plans:

| Skill Level | Suitable Plans |

|---|---|

| Simplified plans with detailed instructions and minimal complex techniques. | |

| Plans that require a moderate level of woodworking skills, including more intricate joinery and techniques. | |

| Advanced plans for experienced woodworkers with in-depth knowledge of boat building and complex woodworking techniques. |

Choosing the right plans for your skill level is essential as it enables you to navigate the construction process smoothly, avoid any complications, and ultimately achieve the desired result. It is crucial to honestly evaluate your woodworking skills and then select plans that align with your abilities. Keep in mind that building a wooden sailboat demands patience , attention to detail , and a willingness to learn and improve your woodworking skills.

As a pro tip, if you are a beginner, it is advisable to start with simpler plans and gradually work your way up to more complex projects. This allows you to gain experience and confidence in your woodworking abilities over time. So always remember to select suitable plans for your skill level and enjoy the process of building your wooden sailboat.

Gathering the Necessary Materials and Tools

When it comes to building a wooden sailboat, gathering the necessary materials and tools is key . In this section, we’ll dive into the exciting world of selecting and preparing the right wood for your sailboat, as well as the essential tools and equipment you’ll need to bring your project to life. So, start sharpening your creativity and let’s sail away into the realm of wooden boat construction!

Wood Selection and Preparation

Incorporating the provided keywords naturally in the provided text:

1. Conduct research on the different types of wood used in boatbuilding, such as mahogany , teak , or oak . This will help you make an informed decision regarding the most suitable wood for your sailboat.

2. Determine the specific requirements of your sailboat design in order to guide your wood selection process. Each design may have different needs and preferences when it comes to the type of wood to be used.

3. Take into consideration the durability and resistance to rot of the wood options available. This is crucial to ensure the longevity and overall quality of your sailboat. Choosing a wood that can withstand exposure to water and other elements is essential.

4. Look for straight , dry , and defect-free wood. This will contribute to the structural integrity of your sailboat. Any defects or irregularities in the wood may compromise its strength and performance.

5. Calculate the amount of wood needed based on the specific design and measurements of your sailboat. This will help you estimate the quantity of wood required for the construction process.

6. Mill or cut the wood into the required dimensions and shapes as outlined in the sailboat design. This step is crucial for achieving the desired structure and appearance of your sailboat.

7. Prior to assembly, it is important to sand the wood surfaces thoroughly. This will remove any rough edges or splinters, ensuring a smooth and safe finish.

8. Apply a protective coating or sealant to the wood in order to prevent water damage. This will help preserve the wood and extend its lifespan .

By following these steps, you can ensure that the wood selected and prepared for your sailboat construction is suitable and of high quality.

Tools and Equipment Needed for the Project

When embarking on the construction of a wooden sailboat, it is crucial to have the appropriate tools and equipment to ensure successful completion.

To accurately measure and obtain precise alignment and dimensions, essential measuring tools such as a tape measure , combination square , and level are indispensable.

For shaping wooden components, cutting tools like a circular saw or table saw , jigsaw , and hand saw are necessary.

Joinery tools, including a chisel set , mallet or hammer , and drill with different-sized bits, are vital for smoothly joining parts together.

To achieve a polished finish, sanding and finishing tools such as sandpaper with varying grits, sanding blocks , and a random orbital sander are crucial.

Additionally, brushes and rollers are required for the application of finishes.

When it comes to safety, it is imperative to prioritize the use of safety goggles , ear protection , a dust mask , and work gloves to ensure personal protection during the construction process.

When selecting tools and equipment, it is essential to invest in high-quality items that are specifically designed for the tasks involved in wooden sailboat building.

By doing so, not only will efficiency be maximized, but the overall quality of the finished boat will also be greatly enhanced.

Preparing and Assembling the Framework

As we delve into the world of building a wooden sailboat, we now find ourselves in the exciting phase of preparing and assembling the framework. In this section, we’ll discover the essential steps that go into setting up the lofting and laying out the keel , as well as the intricacies of constructing the ribs and hull structure. Get ready to immerse yourself in the hands-on process of bringing this magnificent vessel to life!

Setting Up the Lofting and Laying Out the Keel

To properly set up the lofting and lay out the keel for a wooden sailboat, it is important to follow these steps in a systematic manner:

- Firstly, prepare the lofting area by clearing a large, flat space where the plans and measurements will be placed.

- Next, securely attach the keel stock to the lofting platform, making sure it is both level and aligned with the boat’s centerline.

- Using battens, rulers, and pencils, transfer the measurements and lines from the boat plans onto the lofting platform.

- Ensure the accuracy of the waterlines, buttock lines, and other reference lines on the lofting platform by drawing them according to the measurements provided in the boat plans.

- Utilizing the dimensions indicated in the plans, measure and mark the positions of the keel, stem, and transom on the lofting platform.

- Thoroughly examine and adjust all lines and measurements to guarantee their accuracy.

- Identify the locations where any additional frames, bulkheads, or structural elements will connect to the keel, by marking them accordingly.

- Prior to proceeding, double-check all marks and measurements to ensure their accuracy.

The process of setting up the lofting and laying out the keel is an integral step in the construction of a wooden sailboat. It serves as the foundation and reference points for the boat’s overall structure. It is crucial to pay close attention to detail and maintain accuracy throughout the build. By following these steps, you will be on your way to constructing your very own wooden sailboat.

Constructing the Ribs and Hull Structure

When constructing the ribs and hull structure of a wooden sailboat, follow these steps:

– Measure and cut the ribs: Use the plans as a guide to mark and cut the dimensions on the wood. Cut the ribs accurately.

– Attach the ribs to the keel: Position and attach the cut ribs evenly along the keel using marine epoxy and screws.

– Install chines and stringers: Attach the chines to the bottom edge of the boat and install the stringers along the sides for strength.

– Attach the planking: Cut and fit planks to cover the rib and stringer structure, securing them tightly.

– Reinforce the joints: Apply epoxy and fiberglass tape over the joints to strengthen the structure.

– Shape the hull: Use tools to shape and smooth the hull, paying attention to fairing for optimal hydrodynamics.

– Apply a protective finish: Coat the hull and ribs with marine-grade varnish or epoxy for durability.

– Perform a thorough inspection: Check for defects, cracks, or imperfections and make necessary repairs before moving forward.

The process of constructing wooden sailboats has evolved over time, combining traditional techniques with modern materials and tools. Craftsmanship, attention to detail, and an understanding of wood’s properties are still essential in constructing the ribs and hull structure. This blend of artistry and engineering ensures sailboats can withstand the demands of the sea while providing a smooth and enjoyable sailing experience.

Building the Deck and Cabin

Let’s dive into the exciting world of building a wooden sailboat! In this section, we’ll focus on the crucial element of constructing the deck and cabin. Get ready to explore the process of creating the deck framework and adding those essential interior features . From laying the foundation to crafting a cozy cabin space , we’ll uncover the key steps and considerations for bringing your wooden sailboat to life. So, grab your tools and let’s set sail on this exhilarating construction journey !

Creating the Deck Framework

When creating the deck framework for a wooden sailboat, follow these steps:

- Measure and mark the desired deck size and shape on the boat’s frame.

- Cut and shape the wooden planks or panels to match the marked measurements.

- Align the planks or panels horizontally across the frame, ensuring they are straight and evenly spaced.

- Secure the planks or panels to the frame using screws or nails, ensuring tight fastening.

- Add additional support beams or joists underneath the deck for added strength and stability.

- Sand the deck surface to create a smooth and even finish.

- Apply a weather-resistant sealant or paint to protect the deck from moisture and UV damage.

- Install necessary features or fixtures on the deck, such as hatches, cleats or railings.

Pro-tip: Enhance the deck’s strength and durability by adding epoxy or marine adhesive between the joints before securing the planks or panels.

Installing the Cabin and Interior Features

When building a wooden sailboat, it is important to pay attention to every step, including the installation of the cabin and interior features. To install these features, follow the following steps:

1. First, measure and cut the materials for the cabin walls, floor, and ceiling.

2. Next, securely fit the cabin walls in place.

3. Then, attach the floorboards to the cabin base using screws or nails.

4. Align and install the cabin ceiling.

5. If desired, add insulation for extra comfort.

6. Attach interior features such as cabinets, storage compartments, and seating areas.

7. Install windows and hatches to allow for natural light and ventilation.

8. Properly wire the cabin for electricity, ensuring that lights and outlets are installed and functioning.

9. Finish the interior by sanding and applying a protective coat of varnish or paint.

10. Ensure that all installations meet safety standards.

Precision and attention to detail are key when installing the cabin and interior features of a wooden sailboat. By carefully measuring, cutting, and fitting each component, you can ensure a secure fit. It is important to optimize the layout and functionality of the interior features to create a comfortable living space with ample storage. The addition of windows and hatches will enhance comfort and enjoyment by providing natural light and ventilation . If electricity is needed, proper wiring is essential to ensure necessary lighting and power outlets. Finishing the interior with a protective coat of varnish or paint will not only enhance aesthetics but also provide durability.

Remember, the goal is to create a cozy retreat for sailors, so it is important to put in the necessary effort to install the cabin and interior features correctly.

Installing the Sails and Rigging

Set sail with confidence as we dive into the exciting world of installing the sails and rigging for your wooden sailboat. Discover the key considerations in choosing the perfect sails and master the art of setting up and adjusting the rigging. With expert tips and tricks , this section will equip you with the knowledge to navigate the waters with ease and experience the thrill of sailing your wooden masterpiece .

Choosing the Right Sails

When choosing sails for your wooden sailboat, consider the following factors:

– Type of sailing: Determine if you plan to cruise , race , or do both. Different sails are designed for specific purposes.

– Boat size: The size of your sailboat determines the size and number of sails you need. Larger boats require bigger sails , while smaller boats may need fewer and smaller sails .

– Wind conditions: Consider the typical wind conditions in your sailing areas. Different sails perform better in light winds , heavy winds , or various wind conditions.

– Sail material: The material of the sails affects durability and performance. Material choices include Dacron , laminate , and nylon . Each material has different trade-offs between longevity, performance, and cost.

– Reefing options: If you sail in varied or unpredictable wind conditions, choose sails with reefing options. Reefing allows you to adjust the sail area for stronger winds, improving control and safety.

– Manufacturer reputation: Research sail manufacturers for their reputation and reliability. Read reviews, seek recommendations, and consider warranty and customer support.

By considering these factors, you can make an informed decision when choosing sails for your wooden sailboat. Remember, the right sails greatly impact your sailing experience, so take your time and choose wisely.

Setting Up and Adjusting the Rigging

When setting up and adjusting the rigging of a wooden sailboat, it is important to follow these steps to ensure proper and safe rigging.

To start, attach the mast to the deck using a mast step or mast partner for stability and support. This will provide the foundation for the rigging.

Next, secure the standing rigging , which includes the shrouds and stays , to the mast. This will help distribute the forces from the sails and ensure the stability of the mast.

Connect the forestay to the bow of the sailboat. This will keep the mast in line and control the position of the headsail.

To counteract forces from the headsail and maintain rigging tension, attach the backstay to the stern of the boat.

Use turnbuckles or rigging screws to adjust the tension in the standing rigging. This will ensure proper alignment and support of the mast.

Install the running rigging , including halyards and sheets , to control the position and tension of the sails.

Before and during sailing, it is important to regularly check the tension in the rigging to ensure performance and safety.

Make any necessary adjustments to the rigging during sailing in order to optimize the shape of the sails and enhance the performance of the boat.

By following these steps, you will be able to properly set up and adjust the rigging of your wooden sailboat, allowing for safe and enjoyable sailing experiences.

Finishing Touches and Maintenance

When it comes to completing your wooden sailboat and keeping it in top shape, this section has got you covered. We’ll dive into the art of applying exquisite finishes to the hull and deck, giving your sailboat a stunning appearance. And don’t worry, we won’t neglect the nitty-gritty details of regular maintenance and care, ensuring your wooden vessel remains seaworthy for years to come. So, let’s get ready to add those finishing touches and keep your sailboat sailing smoothly !

Applying Finishes to the Hull and Deck

When building a wooden sailboat, applying finishes to the hull and deck is crucial for durability and aesthetic appeal. Here are the steps to follow:

1. Prepare the surfaces: Sand down rough spots, fill in cracks and imperfections, and ensure a smooth and clean surface.

2. Choose the right finish: Consider the type of wood and desired look. Varnish provides a glossy and traditional appearance, while paint offers different colors and styles.

3. Apply the primer: Enhance adherence and create an even surface for the final coat by applying a primer.

4. Apply the finish: Use a brush or roller to apply the chosen finish coat to the hull and deck. Follow the manufacturer’s instructions for drying times and application techniques.

5. Allow for drying and curing: Follow the manufacturer’s instructions for drying and curing to ensure the finish is fully set and provides maximum protection.

6. Inspect and touch up: After drying, inspect the hull and deck for missed spots or imperfections. Touch up any areas that require additional finish for a seamless and polished look.

By following these steps and applying finishes properly, you can protect and enhance the hull and deck of your wooden sailboat, ensuring it looks beautiful and lasts for many years.

Regular Maintenance and Care for Your Wooden Sailboat

Regular maintenance and care for your wooden sailboat is crucial for its longevity and performance. Here are the steps to follow:

1. Inspect the hull and deck for damage like cracks or rot. Promptly repair any issues to prevent further damage.

2. Clean the boat regularly with mild detergent and freshwater to remove dirt, salt, and grime that can accumulate over time.

3. Apply a protective coating to the hull and deck using marine-grade varnish or paint to prevent water penetration and protect against UV damage.

4. Check the rigging and sails for wear or damage. Replace worn-out lines or rigging components for safe sailing.

5. Inspect wooden components such as the mast, boom, and rudder for rot or decay. Replace or repair as necessary to maintain structural integrity.

6. Keep the interior of the sailboat clean and dry to prevent mold and mildew growth. Use a dehumidifier if needed.

7. Regularly check and maintain the boat’s systems , including electrical, plumbing, and navigation equipment. Address any issues promptly.

8. Store the wooden sailboat in a suitable location, such as a covered boat dock or boatyard, when not in use. Protect it from extreme weather conditions.

Pro-tip: Establish a regular maintenance schedule and keep a detailed record of all maintenance and repairs. This will help you stay organized and ensure your wooden sailboat remains in optimal condition.

Some Facts About How To Build A Wooden Sailboat:

- ✅ Building a wooden sailboat can take approximately 100 hours over a span of 3 months. (Source: Instructables)

- ✅ A wooden sailboat can cost around $1,000 to build. (Source: Instructables)

- ✅ The boat is typically built from 4×8 sheets of plywood and measures 8 feet in length. (Source: Instructables)

- ✅ Various tools such as a pull-saw, table saw, router, sander, and drill are needed for building a wooden sailboat. (Source: Instructables)

- ✅ Fiberglass cloth, epoxy resin, screws, and other materials are used to reinforce and waterproof the wooden sailboat. (Source: Instructables)

Frequently Asked Questions

1. how long does it take to build a wooden sailboat.

Building a wooden sailboat typically takes about 100 hours spread over approximately 3 months.

2. What materials are needed to build a wooden sailboat?

To build a wooden sailboat, you will need 4×8 sheets of plywood, epoxy resin, oak plywood, various tools (such as a pull-saw, table saw, router, etc.), fiberglass cloth, screws, fasteners, and other supplies like glue, clamps, and mixing cups.

3. How much does it cost to build a wooden sailboat?

The estimated cost of building a wooden sailboat is around $1,000, including the materials and tools needed for the project.

4. Can I learn to build a wooden sailboat if I have no prior experience?

Yes, building skills can be learned gradually, and mistakes can be avoided along the way. With patience and guidance from boat building plans, even beginners can successfully build a wooden sailboat.

5. How long is the wooden sailboat described in the reference?

The wooden sailboat described in the reference is an 8-foot long pram, featuring classic lines and made from 4×8 sheets of plywood.

6. Can I launch the wooden sailboat in any body of water?

Yes, the wooden sailboat is designed to be light enough to fit in a small pickup truck or be rolled to a local lake on a dolly, making it suitable for various bodies of water.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

Refastening a Wooden Hull - Season 4, Episode 1 Now Available!

How to Build Half Models, Part 1

Watch trailer.

Episode Summary

There are few products of woodworking as exciting to behold as a well-crafted half model. It reveals the character of the boat it represents at a scale that can be admired at a glance and appreciated for a lifetime. In this episode, boatbuilder and modelmaker Eric Dow introduces viewers to half-hull modeling and demonstrate how it can be both a practical way to enjoy woodworking with limited time and tools, and a tangible way to grasp the intricacies of boat plans.

This episode opens with WoodenBoat Publications founder Jon Wilson describing how half models have played an important part in both his personal and professional lives, and offers a fascinating glimpse of a number of well-known boat designs and designers. Eric Dow follows with an explanation of the shape and composition of a half model and how to build one from a lines plan. He shares what tools are needed, which woods are most suitable for the task, and the best glues to use. Using the example of the legendary Herreshoff yacht GLORIANA, he transfers the lines to the stock and cuts out the pieces. The episode ends with a demonstration of proper gluing and clamping techniques.

learn from the masters

Already a member? log in

A Blacksmithing Primer

The backbone: stem, rabbet, and frame sockets, painting symra, more from season one, reading boat plans, creating station molds, laying out and cutting a stem rabbet, steam bending, making homemade boatbuilding tools, a simple method for spiling planks, fitting thwarts, the abcs of wooden spar construction, interior joinery, scarf joints, how to build half models, part 2, subscribe for full access.

Flipbooks are available to paid subscribers only. Subscribe now or log in for access.

- PRO Courses Guides New Tech Help Pro Expert Videos About wikiHow Pro Upgrade Sign In

- EDIT Edit this Article

- EXPLORE Tech Help Pro About Us Random Article Quizzes Request a New Article Community Dashboard This Or That Game Popular Categories Arts and Entertainment Artwork Books Movies Computers and Electronics Computers Phone Skills Technology Hacks Health Men's Health Mental Health Women's Health Relationships Dating Love Relationship Issues Hobbies and Crafts Crafts Drawing Games Education & Communication Communication Skills Personal Development Studying Personal Care and Style Fashion Hair Care Personal Hygiene Youth Personal Care School Stuff Dating All Categories Arts and Entertainment Finance and Business Home and Garden Relationship Quizzes Cars & Other Vehicles Food and Entertaining Personal Care and Style Sports and Fitness Computers and Electronics Health Pets and Animals Travel Education & Communication Hobbies and Crafts Philosophy and Religion Work World Family Life Holidays and Traditions Relationships Youth

- Browse Articles

- Learn Something New

- Quizzes Hot

- This Or That Game

- Train Your Brain

- Explore More

- Support wikiHow

- About wikiHow

- Log in / Sign up

- Hobbies and Crafts

- Model Making

How to Build a Model Ship

Last Updated: January 22, 2024 References

This article was co-authored by wikiHow Staff . Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards. This article has been viewed 247,739 times. Learn more...

Model ship building is an interesting hobby that many people enjoy. It can be a lot of fun to see your model ship come together as you build it. Most model ships are accurate representations of actual ships and even share some things in common with their construction processes. If you've never built a model ship before, don't worry. There are plenty of model kits that have all the pieces you'll need to build your own model ship.

Buying a Model Boat Kit

- Your local hobby shops will likely have model boat kits available to buy.

- Many on-line hobby shops can send a model boat kit to your home.

- There are many different model boat kit styles that you can buy. Many of these will have a differing levels of difficulty and challenge.

- If this is your first time building a model boat, try to select a simple model for beginners.

- Do some research on the type of boat you are building to help you get an idea of what it will look like when finished. [1] X Research source

- You will likely want a wood plane or sandpaper.

- Small pliers can help when assembling the model.

- You may find a complete ship model tool kit that will provide everything you need to get started.

- Each model boat will have its own instructions.

- Always consult your instruction manual every step.

Building the Body of a Model Ship

- Make sure all the parts are accounted for.

- Make sure none of the parts are damaged.

- Find your instructions manual and review it.

- You may need additional tools or materials. Check your instructions to see if you need to buy anything else before getting started.

- Slide the bulkhead frames into the keel. The keel will be the long piece of the frame, running the length of the boat. The bulkheads will slide into slots found on the keel. Bulkheads will help shape the planks of your boat when it's time to apply them.

- Once you're sure everything fits, you can glue the bulkhead frames into the keel.

- Make sure everything is level and flat on the top of the frame. If any bulkheads or areas of the keel are higher than others, use sandpaper to level them off.

- Place a plank over the bulkheads.

- If there is a space where the plank doesn't touch a bulkhead, sand the bulkheads down until the plank rests flatly against each bulkhead.

- Take your time and make sure each plank will lay flatly against the bulkheads.

- Make sure to test both sides of the bulkheads.

- If you sand one area down too much, you can add tiny slivers of wood later on to level off the plank.

- You will likely place the first plank at deck level.

- Planks run the length of the boat, from fore to aft.

- Each plank will be glued to the bulkheads that it is meant to touch.

- Check your model's instructions to learn where you should place your first plank.

- Add planks in pairs to ensure they are even and level with one another. Your first planks should mirror images of one another.

- Soaking planks in water can help them become more flexible.

- If there are any gaps, you can use wood filler or small pieces of wood to fill them in.

- Your model may have you add additional layers of planking. Follow your model's unique instructions when adding planks to ensure the best results.

- Additional layers of planking are often decorative.

- You may need to taper some planks to close up gaps.

- Your model boat's hull should look completely smooth after sanding it.

- Each plank will look like it was naturally blended or attached to the next.

- No one plank should stick out further than another.

- Double check your model before adding any finishing touches.

- You may need to use wood filler or small pieces of wood to make the deck piece lay level.

- Take a moment to sand down any rough areas that you might notice.

- Your model will likely have specific instructions for attaching the deck piece. Always check your instructions to make sure your model will be successfully completed.

Finishing the Model Boat

- Most wooden model boats will require some kind of wood stain and sealant to protect the wood.

- Some models can be decoratively painted to look like their real life counter parts.

- Matte or stain polyurethane finishes can be a great addition to your model boat.

- Figurehead.

- The boat's wheel.

- Quarterdeck.

- You can buy model boat displays at many hobby stores.

- You shouldn't have any leftover parts from your model. If you do, try to figure out where it was supposed to go and add it if possible.

- Be careful with your finished model boat as it will be fragile.

Community Q&A

- You could also try buying a plastic kit. Most plastic kits come with pre-made sections that can be snapped or glued together easily. Thanks Helpful 0 Not Helpful 0

- Don't be in a rush to assemble your model boat. Take your time with each step to make sure everything is correct. Thanks Helpful 1 Not Helpful 0

- All models will have their own instructions. Try to follow these as closely as you can to ensure great results. Thanks Helpful 0 Not Helpful 0

Things You'll Need

- A model boat kit of your choosing.

- Tools required by the kit.

- A clean and well lit space to build the model in.

You Might Also Like

- ↑ http://www.intothings.com/reality.html

- ↑ https://www.youtube.com/watch?v=GulqnmgkPpQ

- ↑ https://daveifm.wordpress.com/

- ↑ http://www.building-model-boats.com/boat-hull-design.html

- ↑ https://www.youtube.com/watch?v=bSyVTYBwOmc

- Videos provided by Gary Brinker

About This Article

If you want to build a model ship, buy a boat kit that will have all of the pieces you’ll need for your new hobby. Most kits require some basic tools to assemble, like a wood plane or sander and small pliers, so make sure to check the requirements before you start building. When you’re ready to start, begin by building the frame, including the bulkheads, deck, and hull. Once the frame is done, stain, paint, or seal your boat to give it a more finished look. Then, add details, like sails, masts, wheels, and rigging. When you're done with your project, buy a model boat display at a hobby store to proudly show all of your hard work. To learn how to sand your model boat, keep reading! Did this summary help you? Yes No

- Send fan mail to authors

Reader Success Stories

Muftah Shahob

Dec 19, 2017

Did this article help you?

Featured Articles

Trending Articles

Watch Articles

- Terms of Use

- Privacy Policy

- Do Not Sell or Share My Info

- Not Selling Info

Don’t miss out! Sign up for

wikiHow’s newsletter

POPULAR SEARCHES:

- Raspberry Pi

- Woodworking

- 3D Printing

- Maker Faire

- All Stories

- Magazine Projects

- Board Guide

- Magazine Issues

Projects from Make: Magazine

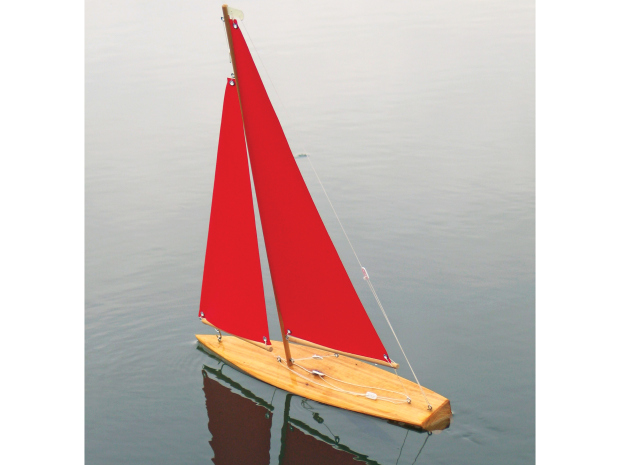

Wooden mini yacht.

Build a Wooden Mini Yacht this weekend.

- Time Required!: A weekend

- Print this Project

By Thomas Martin

Thomas martin.

When my son was 3 years old, I made a small bathtub boat with him, using scrap wood and a piece of dowel. It lasted much longer and got more of his attention than any dollar-store bath toy, and about six years later we decided to try building a larger boat for the pool and local ponds we fished.

Here’s the result of our experimentation: a simple and worthy pond sailer that’s rigged and scaled like a real yacht. You can build it in a weekend using readily available materials and tools.

Project Steps

Prepare the sailcloth..

It’s hard to find waterproof fabric that’s easy to cut and won’t fray. You can make your own by stretching ripstop nylon loosely over a frame or 2 hangers, and spraying it lightly (in a well-ventilated area) with polyurethane.

First spray up and down, and then back and forth, until the fabric is well coated but not saturated.

Let dry overnight.

Mark and cut the parts.

Download the project plan and print it at full size. Following the plan, measure and mark the mast, jib boom, and mainsail boom lengths on the ¼” dowel. Trace the hull from the printed pattern onto the top and 2 ends of the cedar block; cut templates or use carbon paper. Draw the keel and masthead crane patterns on the brass strips, and draw the bowser (rigging clip) pattern 8 times on the thin plastic.

Cut and drill all the parts. Any fine-tooth saw will cut the dowel, or you can roll it under an X-Acto blade and snap the score. Heavy-duty shears or a hacksaw will cut the brass; be sure to file away the sharp edges afterward. You can saw or file down the hull’s shape, then use a hobby knife or thin chisel to excavate the slot for the keel. Drill all holes, plus pilot holes for the screw eyes (in the hull, just poke pilot holes in by hand with a thumbtack).

Finally, file, sand, and smooth all parts. The more time you spend here, the better — especially if you plan to use a clear finish over the wood.

Mount the keel.

On the underside of the hull, mask both sides of the keel’s slot with tape. Wearing gloves, and in a well ventilated location, mix and spread some 5-minute epoxy into the slot using a scrap stick or wooden match.

Slide the keel into position and hold it there while the epoxy cures. You can square it up using a business card on each side.

Use a gloved finger to smooth the epoxy along the joint line, and fill any voids with more epoxy.

Finish the wood.

Finish the hull uniformly, or for a big-boat look, paint the outside of the hull and stain the deck.

Sand the hull with 100-grit paper over a sanding block, and again with 150-grit. Apply a first coat of paint or varnish, and re-sand with 180-grit before each subsequent coat.

For a stained deck, first paint the hull upside down, then re-sand the top perimeter to remove any overspray. Rub stain into the deck and edge, let dry, and coat with varnish or polyurethane.

For the mast and boom pieces, bevel the cut edges for a more finished look, then sand with fine grit to remove any fuzz. Stain if desired, and cover with at least 2 coats of varnish or polyurethane sealer, sanding lightly between coats.

Assemble the mast and booms.

Cut a slot in the top of the mast and glue in the masthead crane. Once that’s secure, follow the plan to install all screw eyes: 4 to the mast, 1 on the fore end of each boom, 1 more on the mainsail boom (for the boom vang), and 4 to the deck. Screw these in until the shank of the screw is completely into the wood.

Insert the brass brad down through the hole in the jib boom and bend it into a clew hook.

Use needle nose pliers to open the mainsail boom eye, hook it onto the eye on the mast, and close it. This forms the gooseneck, the joint that lets the boom swing from side to side (far left in the photo). Press the mast down into the hole in the deck with the masthead crane centered afterward, and tap it gently down into its hole with a hammer.

Add the sails.

After the sail material is dry, trace and cut it to the plan patterns. Lay the boat on its side on a hard surface with the masts and booms in place and fit the sails to the areas for rigging. For the grommets, cut a small X at each sail corner, insert a grommet up through the hole, press the cloth down around it, and tap the grommet flat with the eyelet tool until it firmly grips the cloth.

NOTE: It’s a good idea to practice setting grommets first with a couple of sailcloth scraps and extra grommets. It’s time for rigging. Knot and cut a short length of dacron line, thread it through a bowser, and string the boom vang. For these and all other knots, add a tiny drop of cyanoacrylate glue immediately after tying; the line is slippery and won’t hold knots otherwise.

Use 5″ lengths of line to tie each sail grommet to its corresponding screw eyelet or drilled hole with a square knot. You’ll need about 10″ for the top of the jib sail, which threads through 2 eyelets before tying off to the uphaul bowser.

Referring to the plans, tie the 4 lower connections on the booms first, and then add the upper lines for tension, so there are no wrinkles in the sails along the booms. Thread a bowser onto the jib uphaul as indicated: for their final tensions, you’ll adjust the jib using the uphaul at the top, and the mainsail using the boom vang.

For the backstay, tie in a long length of line at the masthead crane and install a bowser, routing the line through the eyelet at the stern.

Tighten the backstay and the sails so that they’re fairly tight but the mast is not bowed forward or aft. Finally, add the 2 lines called sheets. For these, cut two 15″ lines. Tie each one through the hole in the aft end of a boom, thread it through the sheet eyelet on the deck just underneath, then through 2 holes in a bowser, through the other sheet’s eyelet, and finally through the last hole in the bowser, doubleknotting the line.

NOTE: It’s important to tie the bowsers exactly as shown on the plan to make them work. The sheets let you adjust the angle (trim) of the sails — slack for downwind sailing or tight for crosswind — letting you cross a pond or pool in any direction that isn’t too close to directly upwind.

This project first appeared in MAKE Volume 20 , page 56.

From the Shed: New Arrivals

DIY Arcade Joystick Kit

Make: Arduino Electronics Starter Pack

Maker's Notebook - Hardcover 3rd Edition

Transistor Cat Kit

Our websites use cookies to improve your browsing experience. Some of these are essential for the basic functionalities of our websites. In addition, we use third-party cookies to help us analyze and understand usage. These will be stored in your browser only with your consent and you have the option to opt-out. Your choice here will be recorded for all Make.co Websites.

WOODEN BOW TIES

How to build a wooden sailboat: a beginner's guide.

Are you interested in building your own sailboat? If so, building a wooden sailboat can be a rewarding and fulfilling experience. Not only will you have a unique vessel to call your own, but you’ll also learn valuable woodworking skills along the way.

To get started, you’ll need to gather the necessary materials and tools. This may include oak plywood, epoxy resin and hardener, thickener, brad nails, masking tape, a pull-saw, and a table saw. Once you have everything you need, you can begin the process of building your sailboat. From creating a jig and frame assembly to making the mast, there are many steps involved in building a wooden sailboat. But with patience and attention to detail, you can create a beautiful and functional vessel that will bring you joy for years to come.

Understanding the Basics of a Wooden Sailboat

If you are interested in building a wooden sailboat, it’s important to understand the basics of how a sailboat is constructed. In this section, we’ll cover the parts of a wooden sailboat and the different types of wooden sailboats.

Parts of a Wooden Sailboat

A wooden sailboat is made up of several parts, each with its own unique function. Here are some of the most important parts:

- Hull : The hull is the main body of the boat. It is the part of the boat that sits in the water and provides buoyancy.

- Keel : The keel is a long, narrow fin that extends down from the bottom of the hull. It helps to keep the boat from capsizing by providing stability.

- Rudder : The rudder is a flat piece of wood or metal that is attached to the back of the boat. It helps to steer the boat.

- Mast : The mast is a tall, vertical pole that supports the sails.

- Sails : The sails are large pieces of fabric that are attached to the mast and other parts of the boat. They catch the wind and propel the boat forward.

- Boom : The boom is a horizontal pole that is attached to the bottom of the mast. It helps to control the shape of the sail.

Types of Wooden Sailboats

There are many different types of wooden sailboats, each with its own unique characteristics. Here are some of the most common types:

- Dinghy : A dinghy is a small sailboat that is typically used for recreational sailing or racing.

- Sloop : A sloop is a sailboat with a single mast and a fore-and-aft rig.

- Ketch : A ketch is a sailboat with two masts, with the main mast taller than the mizzen mast.

- Yawl : A yawl is a sailboat with two masts, with the mizzen mast located aft of the rudder post.

When choosing a type of wooden sailboat to build, it’s important to consider your needs and experience level. A dinghy is a good choice for beginners, while a ketch or yawl may be more suitable for experienced sailors.

By understanding the basics of a wooden sailboat and the different types available, you can make an informed decision about which type of boat to build.

Choosing the Right Materials

When building a wooden sailboat, choosing the right materials is crucial to ensure the boat’s durability and performance. In this section, we will discuss the two most important materials you’ll need to choose: wood and sails/rigging materials.

Selecting the Right Wood

Choosing the right type of wood for your sailboat is critical. You want a wood that is strong, lightweight, and resistant to rot and decay. Some of the most popular types of wood used in sailboat building include:

- Cedar: Lightweight and easy to work with, cedar is an excellent choice for planking and decking.

- Mahogany: Strong and durable, mahogany is often used for building frames and keels.

- Oak: A dense and hard wood, oak is commonly used for building frames and planking.

When selecting your wood, make sure it is free of knots, cracks, and other defects that could weaken the boat’s structure. You should also consider the wood’s grain pattern, as this can affect the boat’s strength and appearance.

Choosing Sails and Rigging Materials

The type of sails and rigging materials you choose will depend on the type of sailboat you’re building and your sailing needs. Some of the most common materials used in sail and rigging construction include:

- Dacron: A strong and durable synthetic material, dacron is commonly used for sailcloth.

- Nylon: Lightweight and flexible, nylon is often used for spinnaker sails.

- Stainless Steel: Strong and corrosion-resistant, stainless steel is commonly used for rigging hardware.

When selecting your sails and rigging materials, consider the conditions you’ll be sailing in and the type of sailing you’ll be doing. For example, if you’ll be racing, you may want to choose lightweight sails and rigging materials that will help you achieve maximum speed. On the other hand, if you’ll be cruising, you may want to choose more durable materials that can withstand rougher conditions.

By choosing the right materials for your wooden sailboat, you can ensure that your boat is strong, durable, and performs well on the water.

Designing Your Sailboat

Before you start building your wooden sailboat, you need to design it. This will involve creating a blueprint and determining the size and shape of your boat.

Creating a Blueprint

Creating a blueprint is an essential step in designing your sailboat. It will help you visualize your boat and ensure that you have all the necessary components in place. You can create a blueprint using software such as AutoCAD or SketchUp, or you can draw it by hand.

When creating your blueprint, consider the following:

- The length, width, and height of your boat

- The position of the mast and sails

- The location of the rudder and keel

- The number of cabins and their layout

- The placement of any storage compartments or equipment

Determining the Size and Shape

The size and shape of your sailboat will depend on several factors, including your budget, the type of sailing you plan to do, and the number of people who will be on board.

Consider the following when determining the size and shape of your sailboat:

- The type of sailing you plan to do (coastal cruising, racing, etc.)

- The number of people who will be on board

- The amount of storage space you will need

- The amount of deck space you will need

- Your budget

Once you have determined the size and shape of your sailboat, you can start gathering materials and building your boat.

Building the Hull

When building a wooden sailboat, the hull is the most important part of the boat. It is the main structure that holds everything together and keeps the boat afloat. Building the hull requires cutting and assembling the wooden frame.

Cutting the Wood

To begin building the hull, you will need to cut the wood into the appropriate sizes and shapes. The wood should be cut according to the plans or blueprints that you have created. You can use a saw or a jigsaw to make the cuts.

It is important to use high-quality wood that is free of knots or other defects. The wood should be strong enough to withstand the pressure and weight of the water. Common types of wood used for building a wooden sailboat include cedar, oak, and mahogany.

Assembling the Frame

Once you have cut the wood, you can begin assembling the frame of the hull. The frame is made up of vertical pieces of wood called frames, which hold the shape of the boat. The frames are attached to the keel, which is the main structure that runs down the center of the boat.

To assemble the frame, you will need to use a sawhorse or other support to hold the lumber in place. You can then use screws or bolts to attach the frames to the keel. It is important to ensure that the frames are level and straight.

After the frames are attached to the keel, you can add the planks to the hull. The planks are attached to the frames and keel using screws or nails. It is important to ensure that the planks are properly aligned and spaced.

Once the planks are attached, you can sand and finish the hull to give it a smooth and polished look. This will also help to protect the wood from the elements.

Building the hull of a wooden sailboat requires patience and attention to detail. With the right tools and materials, you can create a strong and beautiful hull that will last for years to come.

Installing the Deck and Cabin

Installing the deck and cabin of your wooden sailboat is a crucial step in the construction process. It not only adds to the aesthetics of your boat but also provides structural support. Here are some tips to help you through the process.

Deck Installation

The deck of your wooden sailboat should be installed after the hull has been completed and before the cabin is built. It is important to ensure that the deck is watertight to prevent any leaks. Here are the steps to follow when installing the deck:

- Cut the deck to fit the hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the hull and deck joint to seal it.

- Secure the deck to the hull using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the deck to make it watertight.

- Sand the surface of the deck to prepare it for painting or varnishing.

Cabin Installation

The cabin of your wooden sailboat provides shelter and storage space. It is important to ensure that it is properly installed to prevent any leaks. Here are the steps to follow when installing the cabin:

- Build the cabin on a flat surface using marine-grade plywood.

- Cut the cabin to fit the deck and hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the cabin and deck joint to seal it.

- Secure the cabin to the deck using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the cabin to make it watertight.

- Install any windows, hatches, or doors in the cabin.

- Sand the surface of the cabin to prepare it for painting or varnishing.

By following these steps, you can ensure that your wooden sailboat’s deck and cabin are properly installed and watertight. This will not only make your boat look great but also ensure that you have a safe and enjoyable sailing experience.

Setting Up the Mast and Sails

Now that you have built your wooden sailboat, it is time to set up the mast and sails. This process may seem daunting, but with a little patience and attention to detail, you can have your boat ready to sail in no time.

Step 1: Install the Mast

The first step is to install the mast. Depending on the design of your boat, the mast may be a single piece or assembled from multiple sections. Make sure the mast is secured properly and is straight. Use a level to ensure the mast is vertical in both directions.

Step 2: Prepare the Sails

Next, prepare the sails. Make sure the sails are clean and free of any debris or damage. Attach the sail to the mast using the halyard, which is a rope used to raise and lower the sail. Make sure the sail is hoisted all the way to the top of the mast.

Step 3: Attach the Boom

Attach the boom to the mast and secure it with a boom vang, which is a rope used to control the angle of the boom. The boom is the horizontal spar that holds the bottom edge of the sail.

Step 4: Set the Sail

Once the boom is attached, set the sail. Adjust the angle of the boom and the sail to catch the wind and start moving. You can use the main sheet to control the angle of the sail and the boat’s speed.

Step 5: Trim the Sail

Finally, trim the sail to optimize its performance. This involves adjusting the sail’s shape and position to maximize its power and minimize drag. Use the sail controls, such as the cunningham and outhaul, to adjust the sail’s shape. Use the main sheet to control the sail’s position relative to the wind.

Congratulations! You have successfully set up the mast and sails of your wooden sailboat. Now it’s time to hit the water and enjoy the thrill of sailing.

Applying Finishing Touches

When it comes to building a wooden sailboat, applying the finishing touches is a crucial step that can make all the difference in the final product. Here are some tips and tricks to help you get the perfect finish.

Sanding and Finishing

Before you can apply any finish, you need to make sure the surface is smooth and free of imperfections. This means sanding the wood with progressively finer grits of sandpaper until you achieve the desired smoothness. Once you’ve finished sanding, you can apply a wood conditioner to help the wood absorb the finish more evenly.

When it comes to choosing a finish, you have several options. Some popular choices include varnish, paint, and oil. Varnish is a popular choice for wooden boats because it provides a durable, glossy finish that can withstand the harsh marine environment. Paint is another option, but it requires more maintenance than varnish and may not provide as much protection against the elements. Oil is a good choice if you want a more natural look, but it may not provide as much protection as varnish or paint.

Painting and Varnishing

If you decide to go with paint or varnish, there are a few things to keep in mind. First, make sure you apply the finish in a well-ventilated area to avoid inhaling fumes. Second, make sure you apply thin, even coats and allow each coat to dry completely before applying the next. This will help prevent drips and ensure a smooth finish.

When it comes to varnishing, it’s important to use a high-quality brush and work quickly to avoid brush marks. You may also want to consider using a foam brush for hard-to-reach areas. Once you’ve applied the final coat of varnish, you can buff the surface with a soft cloth to achieve a high-gloss finish.

Painting requires a different approach. You’ll need to choose the right type of paint for your boat and make sure you apply it evenly. If you’re painting a large area, you may want to consider using a paint sprayer to achieve a smooth, even finish. Once the paint has dried, you can apply a clear coat to protect the paint and give it a glossy finish.

In conclusion, applying the finishing touches to your wooden sailboat is an important step that requires careful attention to detail. By following these tips and using the right tools and materials, you can achieve a beautiful, long-lasting finish that will protect your boat and make it stand out on the water.

Safety Measures

When building a wooden sailboat, safety should always be your top priority. Here are some safety measures you should take to ensure a safe and successful build.

Installing Safety Equipment

Before you start building, make sure you have all the necessary safety equipment installed in your workshop. This includes fire extinguishers, smoke detectors, and first aid kits. You should also have a clear and unobstructed path to the exit in case of an emergency.

When working with power tools, always wear eye and ear protection, as well as a dust mask to protect your lungs. If you are using chemicals, make sure you are working in a well-ventilated area and wear gloves and a respirator if necessary.

Conducting a Safety Check

Before you start working on your sailboat, conduct a safety check to make sure everything is in order. Check that all tools and equipment are in good working order and that there are no loose or damaged parts. Make sure your work area is clean and free of clutter, and that all cords and cables are properly secured.

When working with wood, be aware of any knots or cracks in the wood that could weaken the structure of your sailboat. Use only high-quality marine-grade wood and be sure to follow the plans carefully to ensure a strong and safe boat.

By following these safety measures, you can ensure that your wooden sailboat build is a safe and enjoyable experience.

Maintaining Your Wooden Sailboat

Congratulations on building your own wooden sailboat! Now that you have a beautiful vessel, it’s important to keep it well-maintained to ensure its longevity and safety on the water.

Regular Maintenance

Regular maintenance is essential to keep your wooden sailboat in top condition. Here are some tips to keep in mind:

- Clean your boat regularly with a mild soap and water to prevent dirt and grime buildup.

- Check for any signs of damage, such as cracks, rot, or loose fittings, and address them promptly.

- Apply a fresh coat of varnish or paint every few years to protect the wood from the elements.

- Keep your boat covered when not in use to protect it from the sun and rain.

Seasonal Maintenance

In addition to regular maintenance, there are also some seasonal tasks that you should perform to keep your wooden sailboat in top condition:

- At the beginning of the season, inspect the hull for any damage or wear and make any necessary repairs.

- Check the rigging and sails to make sure they are in good condition and make any necessary repairs or replacements.

- Before storing your boat for the winter, make sure to properly winterize it to protect it from the cold and moisture.

Additional Tips

Here are some additional tips to keep in mind when maintaining your wooden sailboat:

- Use high-quality marine-grade products when cleaning and maintaining your boat.

- Avoid using harsh chemicals or abrasive materials that can damage the wood.

- Regularly check the bilge for any water buildup and pump it out as needed.

- Keep your boat well-ventilated to prevent moisture buildup and mold growth.

By following these tips, you can keep your wooden sailboat in top condition and enjoy many years of safe and fun sailing.

Leave a Reply Cancel reply

You must be logged in to post a comment.

Building model boats - Introduction

An introduction to model boat building – here is how to get started making your own rc or static model ship from kit or scratch..

When starting building model boats for the first time, I find the hardest part being able to help people choosing a model that correspond with their particular situation, be it their skills, tools, interests or place of construction. This page is meant as an overview to help you find your corner of this great hobby.

Most people seem to think building model boats from kits is a lot easier than building from scratch. I'm not sure if that is true. The most important advantage a kit has is that some parts are preformed and that it comes with instructions.

Some wooden model boat kits are of low quality, both in terms of material and instructions. A measly kit like that is a waste of time and will hinder you more than help.

Many model boats have been build from scratch as a first model. You just have to figure out what building method suits you best. A good way to start is with strip or sheet planked plank-on-bulkhead model boats. I'd recommend using balsa or basswood to limit the need for power tools.

If you happen to be an experienced woodworker with a shop area and some power tools, building bread-and-butter model boats may be a good option. It is a lot faster than strip planking in most cases.

Both methods discussed above will work if you are building a radio controlled model boat. One thing to consider is how quickly you want to get to sail it. If you are in hurry, consider a kit with a preformed hull from ABS or fiberglass.

If you’re just starting out, you may want to choose a relatively simple project. The quickest way to kill all enthusiasm is to get in way over your head. A sensible approach is to conquer a few skills with each successive model. This way you learn to tackle more and more difficult projects as your skills develop. At the same time you'll keep the cost down in the event you decide to abandon a project.

Static or Working Model

There are many purposes of building model boats. For the hobbyist it typically boils down to two categories:

Static Model Boats

The majority of model boats are built as static models. In essence that means they are for display only. They are typically more or less successful attempts at depicting a historic or fictitious vessel (such as from a movie). The majority of kits, regardless of material used, are for static display only. Oftentimes builders wish to convert a static kit to a working model to save time. Often, this is a mistake. Not only is the time and effort required often underestimated - static models are more often than not too heavy to do well as working models.

Working Model Boats

A working model boat is built to be run in water as its main purpose. To accomplish this, some compromises may have been made in scale detail or accuracy. There is an underlying tolerance in the model boat community for "semi scale" models as long as they are working models. In fact, most ready-made RC boats are entirely fictional.

Model Building Materials

Just about all model building materials you can think of has been used for model boats hull construction by now, anything from whale teeth to carbon fiber. The exotics aside, the most commonly used materials for building model boats include:

- Plastic or resin

- Fiberglass (GRP, polyester or epoxy)

- Paper (kraftpaper, cardstock)

Model Boat Hull Design and Construction

The hull is probably the most important aspect of model boat building – and, in my opinion, the most fun to build! There are many methods and materials that can be used. For more, click the heading above.

Half Hull Model

If building model boats from a plan for the first time, a half hull model can be a good start. Essentially, it is half of a hull split down the middle, sometimes with wheel house and stumps for masts when relevant. It is then mounted on a board and hung on the wall for display.

This type of models was originally made by yacht, boat and ship builders and designers that didn’t have the expertise to design directly on the drawing board. It became their "master" from which plans were drawn up. Herreshoff, the famous American yacht designer, apparently designed all his boats this way.

Solid or laminated hardwood is the most common material, although planked or "crow's nest models" (bulkheads and incomplete planking) happen as well. One obvious benefit is that symmetry is a non-issue!

Radio Controlled Boats

Building RC boats gives the building a purpose beyond the building in itself. What sets radio controlled boat hulls apart is they have to be:

- Water proofed and sealed (obviously!)

- Built tough for transport and operation

- Be large (buoyant) enough to house RC gear, motors, steam plant etc.

It seems model boat fiberglass hulls are gaining more and more at the expense of vacuum formed ABS hulls among kit manufacturers. You can also make them yourself. This may make the most sense if you need several hulls of the same mold. There are some vendors who specialize in making hulls only, as opposed to a complete kit. This is typically a less expensive option than getting a full blown kit.

Toy Boat Building

Building toy model boats can be as involved as you want it to be. With the goal of building a toy as opposed to a scale model can take some of the pressure off for the result to be 100% realistic and allows infinite artistic license.

Return from Building Model Boats Intro to Homepage

| Facebook Twitter |

Would you prefer to share this page with others by linking to it?

- Click on the HTML link code below.

- Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, your Facebook account, or anywhere that someone would find this page valuable.

- Plans Store

- Model Boat Books

- Model Boats Intro

- Building Materials

- Make a Hull

- Plastic Kits

Radio Control

- US Battleships

- Torpedo Boats

- Model Boats Q&A

- Model Ship Gallery

- What's New?

- Privacy Policy

By Petter Blix

Copyright 2009-2018 Building-Model-Boats.com

Trademarks belong to their respective owners

All Rights Reserved

Wooden Boat Model Hull Under $10

Introduction: Wooden Boat Model Hull Under $10

This is the first boat I've ever made. This boat is supposed to represent a small cutter. I wanted to make this project complete but for showing people, I only wanted to show how to make the hull because after all its going to be your boat, put your twist on it. No boat is ever the same.

Wooden Board: 1"x4"x6 ft for 5 dollars Wood Glue: Titebond for 3 dollars

Pencil (for drawing and putting on the profiles)

Paper and cardstock (for drawing the profiles)

Some type of saw (for cutting)

Chisel (for pairing)

Clamps (for clamping)(many, you can never have too many clamps)

Ruler (for measuring and marking straight lines)

Hammer/ mallet (to work with chisel for those knots)

Spokeshave/ hand plane (shaving and getting the wood smoother)

Sandpaper (for making the wood very smooth)

table vice (holding it in place)

File Raspe (for smoothing and for finding high spots)

Step 1: Cut Your Plank

Get your plank of wood and measure cut out 4 10" pieces.

Step 2: Gluing

Glue your 4 10" pieces together one on top of the other.

Step 3: Clamp

Clamp your wooden pieces together in different places and on both sides, no need to clamp the edges with glue seeming out. Follow glue instructions for preparation, time and clean up.

Step 4: Make Profiles

Find a ship online that you like (I choose a cutter) and make profile cards for the hull for every inch. You should have 10 cards done.

Step 5: Profiling Top Down

Make a profile for the top part of your boat, again this is your boat, do as you please. And then cut the center of it out so you have the outline.

Step 6: Cutting Out the Profile

To do this you need to put your half profile on top and make sure that the width can fit in one size (half of the block). To do this simply measure your block and mark the center line down the entire thing. Then put your profile up to it and mark the profile using a marking device. Flip the profile over and mark the other side next to it so it lines up.

To make the next step easier all you need to do is do the exact same thing but on the bottom.

Step 7: Clamp and Cut

You will then want to Clamp the block to make sure it doesn't slip when cutting.

You will then want to follow the line and cut a little bit away from the line using a saw. This way you can edit your boat easier.

Also when cutting, it's very IMPORTANT to check the bottom periodically and make you haven't gone over the line.

Step 8: Clean Up

Now its time to just smooth the edges down by using a chisel. When doing this, you want to just smooth out the lines not get down to the line.

Don't get to carried away as this is just to make it cleaner and not rough to hold.

Step 9: Shaping

Now you want to draw the hull out, the easiest way, in my opinion, is to shape the bow. So you need to draw you bow on both sides and make sure they are the same shape.

I recommend making a curved line similar to mine, easiest curve.

This is your boat, so your design is up to you.

Step 10: Cutting

Using a saw, cut along the lines and make sure you don't get too close to the lines.

Step 11: Shaping

Using a chisel, shape the bow down to a flat surface then starting from the sides, chisel down until its a finer blade. Using your profile cards you made earlier, shape the bow.

IMPORTANT: If you happened to stumble across a knot, use your chisel carefully as it could pop out or crack. If needed, use your mallet to cut it use the chisel if you cant pair it out.

Step 12: Shaping the Hull

Using all your profiles shape the hull . down using a chisel, try not to use long strokes and try to cut with the grain. The reason, why you want smaller cuts, is to reduce the chance of messing up. Never cut against the grain, because you could cut deeper then you wanted due to the flaking (flaking is when it doesn't cut it brakes).

When shaping the keel mark it out how thick you want it to be and cut it very carefully using a saw until you're desired length.

REMEMBER to always check your hull with profile cards.

Step 13: Planing and Sanding

Now you should have your hull shape, its time to smooth it out and get the chisel's leftover hills out.

Using a plane or a spokeshave start shaving everywhere. Get rid of pencil marks, and clamp indents by shaving it down. When you hit think you're done start sanding out the boat, when sanding try to start with higher grit and slowly get into the finer sandpaper. If you don't have multiple types then just use what you have to finish off any unsmooth surfaces.

Step 14: Cutting Down the Boat's Depth

If you want to cut down your boat's depth then do this step, if you are fine with what you have then skip it, but read this step first.

Look at your boat and determine how deep you want to cut it. For me, it was 3/16 of an inch.

When doing this step you want to make sure that you have a curve on the boat. SO when drawing, start at the back with your desired length. As you go down the sides make it lower than the stern and come up towards the bow, making a curved effect. The bow should be the highest part. Do this on both sides.

When cutting, use a saw and make sure to cut away from the line.