- Cars, Jets & Yachts

How Much Does a Yacht Cost to Build?

The cost to build the world's largest superyachts is a closely guarded secret.

By Kim Ayling

The freedom that comes with owning your own yacht is unrivaled and, if you have the funds to do so, the joy of building your own is even better. However, with prices easily creeping up into the hundreds of millions, and even billions, we ask the all-important question: how much does a yacht cost to build?

Unsurprisingly, the total cost to build the world’s most famous yachts is a closely guarded secret, but there are a few fairly reliable estimations sailing around the industry. One standard way to work out how much a yacht will cost to build is price per gross weight. However, while this can be a helpful guide in valuing yachts, it doesn’t always correlate.

For example, it is thought that Lurssen’s 590-ft Azzam , which features a bulletproof owner’s cabin, an onboard golf practice suite and a submarine, cost in the region of $600m to build. At approximately 13,136 gross tons (GT), that would have made her around $45,676 per GT.

REV , on the other hand, which while still in construction is set to surpass Azzam as the largest yacht in the world at an impressive 602ft, is estimated to be costing around $350m to build. Her weight is thought to be around 17,440 GT, putting her at $20,069 per GT. Clearly, biggest doesn’t always mean most expensive. So what does affect the cost of a yacht build?

[See also: How Much Does it Cost to Charter a Yacht?]

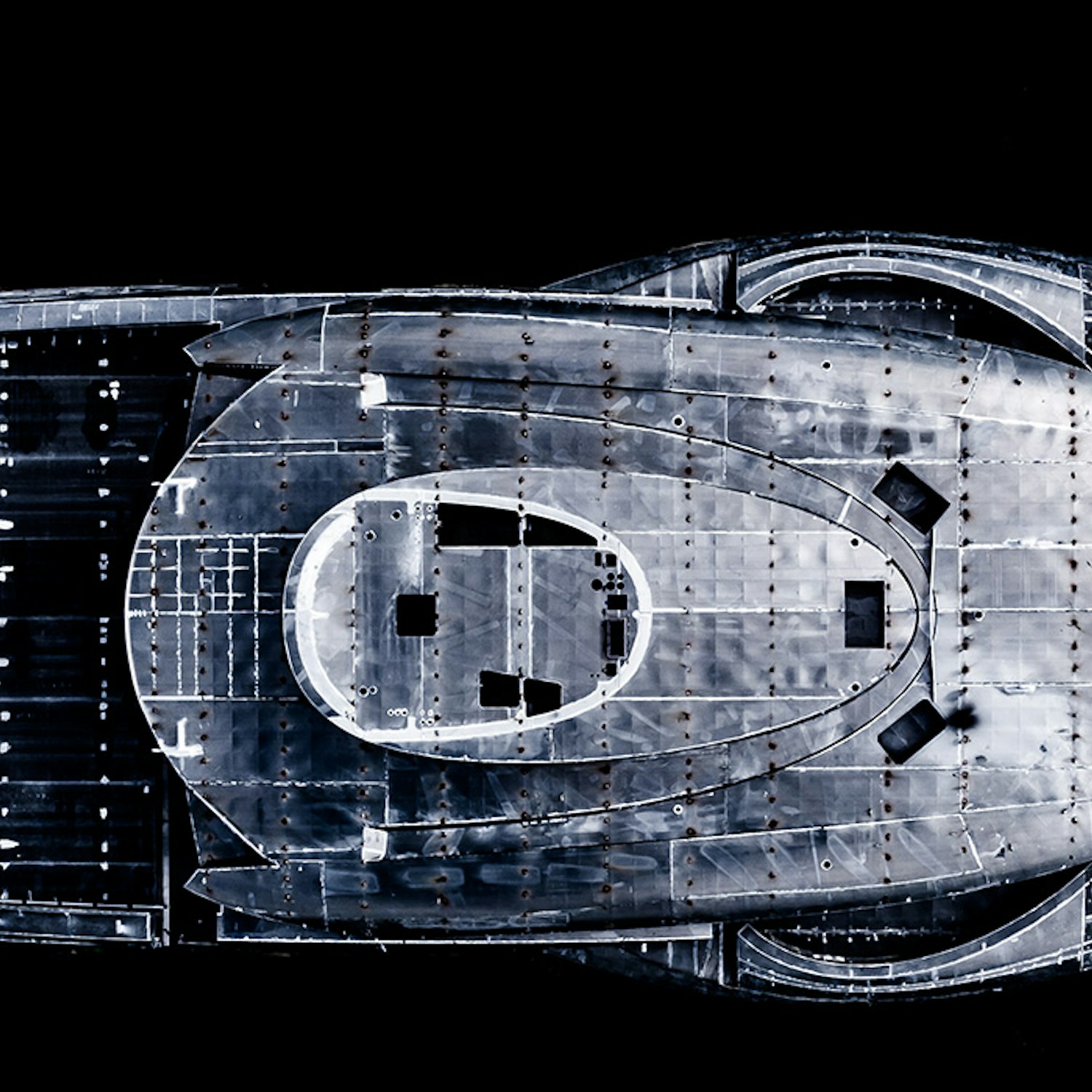

REV is thought to be costing around $350m / ©REV Ocean

Custom vs pre-designed yachts

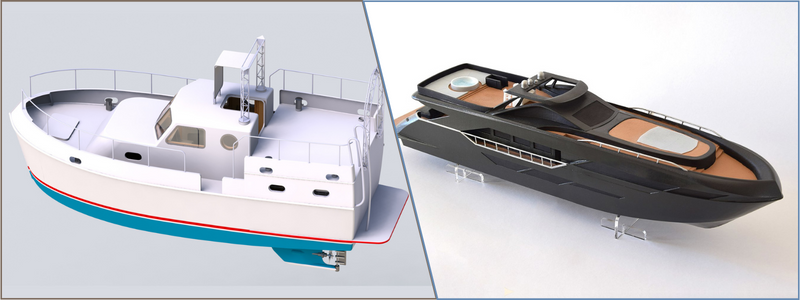

Firstly, you need to decide the kind of yacht you want: custom or pre-design. Naturally, a custom yacht build will be more expensive. But, for that extra cost, you will get full control over the design, the finish and everything in between.

The Ultimate Tenders to Pair With Your Superyacht

Sea Change: The Sunreef 88 Ultima Yacht

Four Seasons Yachts Announces its First Luxury Itineraries

A pre-designed yacht on the other hand will save you both money and time. This category of yacht is built based on an existing model, with finishing touches such as interiors, tenders and layout completed when she’s bought. Obviously, this leaves owners with a lot less freedom over their yacht, but it is considerably cheaper and can be delivered in a matter of months instead of years.

Choosing a yacht builder

The world of shipbuilding is dominated by a few key players. For a fully custom build, the likes of Lurssen, Feadship, Oceanco and Royal Huisman (among several others) rule the roost. With builders like this, you can expect to pay a higher price, but for that, you’ll receive years of experience, industry prestige, and cutting-edge technology and techniques.

The most prestigious shipyards will also inevitably have the most skilled team. The team involved in building a yacht is, to put it simply, vast. From start to finish, hundreds of pairs of hands will be involved in the process, with the key players including a yacht designer (interior and exterior), a naval architect and an engineer, as well as a huge team of skilled laborers. There will also be an owner representative working closely with the shipbuilder to ensure the project is delivered in time and to the buyer’s exacting standards.

Content from our partners

Sky High Gourmet: Qatar Executive’s Impressive Dining

The Best Family-friendly Vacation Destinations in Spain

W New York – Times Square: “We Do Things Differently”

The cost of your yacht build will of course include the wages of each of the experienced people involved in making it, so if you want the best, expect to pay for it.

[See also: Discovering the World’s Most Exciting Superyacht Concepts]

Viva by Dutch shipyard Feadship / ©Feadship

What affects the cost of building a yacht?

Naturally, a huge variety of factors will impact the total cost of building a yacht. Size is of course one of the main considerations, but materials are another key factor that will dramatically impact cost. Aluminum, for example, is favored for being an impressively lightweight hull material but ton for ton, it is far more expensive than steel.

Onboard technology will also see the final cost creep up rapidly. Demand for smart yacht technology, for example, is continuing to grow, with more owners wanting to replicate the ease of voice control tools that they enjoy in their home, onboard their yacht.

And things that we might take for granted on land such as high-speed WiFi become more complicated – and more expensive – on the water. Kitting your yacht out with a satellite dish can set you back anywhere up to $50,000 which while doesn’t sound much in the grand scheme of a multi-million-dollar ship build, is just one of many hidden costs.

How much do yacht toys and tenders cost?

The yacht itself is just the start of the story when it comes to working out costs. On top of the build, potential owners will need to kit out their boat with all the latest toys and tenders – from submarines to helicopters – which can add a serious amount to your total.

For example, a self-drive submersible by Triton Submarines , which will allow owners to see the underwater world in a completely new way, will start at around $15m. Similarly, while you can pick up a low-grade, second-hand tender for a few thousand dollars, a top-of-the-range option will easily creep into the millions.

Ultimately, the only way to work out exactly how much a yacht will cost to build is to make a serious inquiry with a broker, who will be able to connect you with a yacht builder. From here, you can collaboratively work together to ascertain your budget and exactly how much your perfect yacht will cost.

[See also: The Most Innovative Yachts of the 21st Century]

Oceanco, who made the sleek Esquel, is one of the best yacht builders in the world / ©Oceanco

Latest in Luxury

The explorer.

Thank you for subscribing to Elite Traveler.

Page Loading

- Vessel ltinerary

- Administration

- Dockage & Fuel

- Maintenance

- Capital Repairs & Reserves

- Total Expenses =

- Name Length Build

- # Total Expenses Date Saved

Advanced functionality coming soon.

Us flagged vessel, health insurance costs per crew, uniform cost per crew, training cost per crew, food cost per crew, crew turnover, hires using a professional crew agency.

- Restore Default

- $ | € | £

Costs of food provisions will vary dependent upon how eloborate food Preferenaces are

Location will play huge factor in food provisons and thing may have to be folws into remorte locations.

Crew is one of the largest expenses on a superyacht and critical to the owner’s enjoyment of their vessel. As the largest crew agency in the world, we know crew. Our cost calculator contains customized crew lists for yachts ranging from 80ft to 600ft with salary information based on our reference verified salary data.

Our users also have the ability to completely tailor the crew list to the specific needs, schedule and requirements of their vessel. Each yacht is unique and may have specific owner requests in addition to the yacht’s safe manning requirements.

Management of the supplemental crew costs and strategic budgeting can help avoid significant overspend on categories such as food and uniform. This tool contains default values based on our industry expertise and recommended budget for an efficiently and safely run superyacht.

To learn more about each crew position in detail, including salary ranges, please visit our yacht department directory .

Drag the sliders to modify your results. These are not linear scales and we expect most yachts to operate within the 20-80% window. Above 80% and below 20% costs increase or decrease at exaggerated levels and we only see numbers in these levels in very rare circumstances.

This sunburst diagram is interactive. You can click into each block to see the expense break down and mouse over each block for more details.

Our chart of accounts displays seven major categories, 20 sub-categories plus a further 80 detail categories for a total of 107.

Our yacht operating cost calculator is now on it’s third major revision. We start with actual yacht expense data from our yacht management accountants and then generate formulas to extrapolate out the budget for a wide range of yachts. We have been providing accounting services to large yachts for the past 18 years.

Our operating cost calculator is tuned for yachts from 80 to 600 feet. We find operating variables create the largest variances for yachts smaller than 100 feet and larger than 250 feet. We have tested the numbers the most in the range from 100 to 250 feet.

Our budget calculator factors in the fuel burn for a range of engine sizes typically seen installed on yachts by length. By dragging the green “fuel dockage” slider to the right you will increase the projected fuel burn rate and therefore the budget cost for fuel. Our default position would be for a typical displacement fuel burn. Position the slider in the 60-80% range for fuel projections for planning hulls.

Our default values produce a budget number that we believe is generous to run a yacht to a high standard. Perfect is a very expensive word to use in the yachting industry where standards are already high. Moving the crew and maintenance sliders to 80% will provide an “industry best” quality of crew and give them the maintenance budget to operate to a very high standard. If you need to go over the 80% area then you may have unusually labor intensive equipment on the yacht.

Yes, our yacht operating cost calculator can output a budget suitable for this situation. Adjust the owner use to 2 (minimum value), owner slider to 0, crew slider to 10%, Administration to 10%, Fuel and Dockage to 0, Maintenance to 10% and then Capital Repairs to 0. This will remove all of the large charges associated with owner use and vessel movement but leave the essential base maintenance and insurance in place.

Lift on and float in yacht transport is a popular way to transport yachts across large ocean passage. The yachts that this service certainly applies to are ones that may not have the motoring range or structural integrity for blue ocean cruising. The cost of transporting a yacht twice per year is put into our budget once the “Fuel Dockage” slider hits 75%. If your yacht has the range we recommend self-sufficient ocean passages whenever possible. Whilst the transport companies sell their services based upon reportedly well oiled operated schedules the reality is that your yacht may stay waiting for pickup for a week or more with no compensation due. When factoring in all secondary factors of self-sufficient passages (increased fuel, maintenance, potential storm damage, crew time off, extra delivery crew) compared with transporting your yacht (insurance, potential loading / unloading damage, loss of schedule control, no work whilst underway, crew flights, crew accommodation) we believe that there is a 100% premium associated with float in transport and a 75% premium with lift on transport compared with self-powered.

Abandoned yachts crash in value. We recommend that even if you are trying to sell your yacht that you use the yacht for a minimum of two weeks per year so that systems are tested and working every six months. There is nothing worse for a yacht than not being used. If you truly are not going to use the yacht then you should sell it immediately for the first genuine offer as every dollar you put into maintenance will not be recovered at the time of the sale.

We did not build this version with sailing yachts in mind. Early in our development of this version we decided to exclude sailing yachts as a few of the major cost drivers scale very differently for sailing yachts compared with motor yachts. For example: To calculate paint costs we reviewed the surface area of over 100 large yachts and created a formula for painted surface area to length. Sailing yachts just don’t scale in a consistent way. Similarly crew numbers don’t scale in the same manner that they do for motor yachts. If there is sufficient demand we may build a sailing selector switch into a future version of this tool.

We hate to hear when yacht owners were told by their broker to factor in 10% of the purchase price to operate the yacht. This over used saying is sadly right occasionally (particularly for newer yachts in the $20-30M range)… but just because a broken watch tells the right time twice a day you shouldn’t rely upon it to tell the time. As yachts get older their capital value decreases but their maintenance costs increase. There is no way that a fixed 10% of purchase cost rule can be true… if your broker told you this rule then you need a new yacht broker… we know some good ones. 😊

Advanced functionality coming soon…

We are building advanced tools to allow you even greater control over our operating cost calculator. Please enter your email address below to be advised when it is available.

Save this version

Share your calculations, please save version before sharing luxyacht - calculator, you must be logged in to save this version of the cost calculator that you have customized for your yacht..

Your Vision. Your Burger.

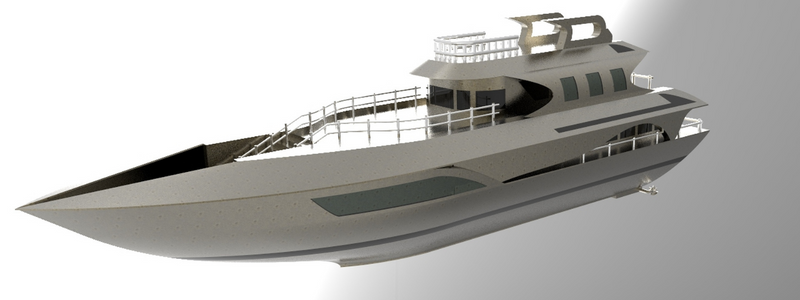

Creating a custom-built yacht is a journey unlike any other. Conceiving your yacht alongside Burger’s engineers and design team is a remarkable experience: developing the specifics, reviewing the plans and making decisions as you watch your dreams materialize before your eyes. Burger welcomes all clients to enjoy the progression of their journey while your custom creation evolves.

The first step in delivering the yacht of your dreams is to share your vision with the Burger design team and engineering staff. Our in-depth design brief helps define your priorities for a yacht. We recommend touring the Burger shipyard where you can meet our exceptional team, learn how your yacht will be constructed and to witness the true value of Burger’s experience and craftsmanship.

After defining your vision, your dreams will begin to take shape in dramatic conceptual designs, renderings and cost estimates, presented for your direction and approval before moving forward.

Conceptual designs and renderings include:

- Hull designs

- Exterior styling and interior floor plans

- Interior elevation renderings

- Engines, propulsion and electric generation equipment selection

- Special requirements, including recreational and/or shore tenders and storage options

- Navigation electronics and entertainment system descriptions

Once you’ve approved the design, Burger will prepare a detailed design and specification breakdown with descriptions of every step in your yacht’s construction; from its development milestones to key points of approval. With a finalized and signed contract, your yacht is on the way to fruition. Each step of the build is documented before work begins, with a detailed timeline that describes each step of the process, so that you remain involved and aware of our progress, every step of the way.

Months of careful planning and construction culminate when it’s time to launch your new Burger yacht. Along with the Burger team, you and/or your captain take your new Burger yacht through various sea trials, including at-sea observations and detailed walk-through inspections. At this stage, final modifications and refinements are made.

Congratulations; owning a Burger built for you also means you’ve joined the most exclusive fleet of yachts in the world. Our craftsmen share your pride in seeing your new yacht launched, and value each customer relationship that endures long after delivery. Bringing your dreams to reality is what makes every Burger yacht unique and extraordinary.

With your Burger set out into open waters, a new journey begins.

Custom Yachts

View Burger's full fleet of custom yachts, uniquely crafted to each owner's vision of limitless luxury.

Design Concepts

Explore Burger's newest design concepts and yachts under construction — and bring your ideas to their design.

Our knowledge & expertise. It’s a smart investment

Yacht Construction & Build

With an experienced luxury yacht construction team comprised of former superyacht captains, engineers, and project management specialists, Moran Yacht & Ship has successfully negotiated, managed, and completed over $3 billion in new yacht-build projects. This incredible statistic is unmatched by any other brokerage company in the world.

- Luxury Yacht Construction

- Yachts Under Construction

- Completed Custom Yachts

Luxury Yacht Builders

- Contact Build Team

Why build with Moran Yacht & Ship?

Over the past 36 years, Moran’s yacht construction management team has been actively involved in successfully building over 60 of the finest quality new superyacht construction projects globally. Contact our new build project management team today to learn how we can help you build your next custom luxury yacht in partnership with the leading megayacht builders in the industry.

Discover how our yacht build process is different

Before the keel is even laid, our yacht project management team compiles an all-encompassing marine specification. We then negotiate a comprehensive yacht-building contract that protects our clients from delays and additional costs. We assemble an experienced yacht build team that includes only the best naval architects, interior and exterior designers, and project managers to bring your dream yacht to life.

Unlike many of our competitors, who disappear as soon as the yacht build contract is signed, our accomplished team will remain in place through final delivery to ensure a smooth yacht construction process and complete satisfaction. As a further courtesy to our clients, we remain with the vessel in a yacht management capacity to take care of any warranty items and ensure hassle-free day-to-day operations.

Completed Custom Yacht Construction Projects

BLACK PEARL

LADY KATHRYN V

TOP FIVE II

View 47+ more Completed Projects

Our results speak for themselves.

Whether you are looking to build a semi-custom motor yacht or build a custom superyacht, you can be certain that the new yacht construction team at Moran Yacht & Ship has the experience, knowledge, and capability to deliver the boat build of your dreams. Our experience ensures that you will take delivery of your vessel on time, within budget, and to the highest quality standards.

Yachts Currently Under Construction

View 5+ more Projects under construction

Choosing the right yacht builder and shipyard is imperative for a successful new yacht construction project. Learn more about some of the builders our yacht project management team works with and recommends.

Yacht Construction FAQs

What support will moran yacht & ship offer me during my yacht construction.

The experts and brokers at Moran Yacht & Ship have been in the industry for a long time and oversee many superyacht construction projects. Their expertise will support you at every stage of the new build process, ensuring your exact requirements are met. This includes:

- Informed selection of builder and shipyard

- Choice of interior and exterior designer

- Development and negotiation of the technical specification

- Negotiation of the build contract and price

- Project management throughout the build process

What does it cost to build a yacht?

The cost of building a yacht from scratch is based on multiple factors, including the size of the vessel, materials used, the complexity of the design, technology, propulsion systems, interior design features, onboard amenities, and the shipyard and designers used. Expect building a luxury boat to cost anywhere from $2 million to more than $300 million. Working with an experienced new build project management team, such as the experts at Moran Yacht & Ship, offers a cost-effective solution by ensuring builds remain within budget.

What are the benefits of building a yacht as opposed to buying a used yacht?

There are multiple benefits to building a yacht as opposed to buying a pre-owned yacht. When you build your own yacht, you enjoy the benefits of a fully customized vessel to meet your precise requirements, from its naval architecture and size to its cruising capabilities, layout, onboard technology, amenities, and interior design. A custom yacht will be tailored to suit your lifestyle and desired experiences.

Also, when you build your yacht, you won’t have to worry about pre-existing conditions. A new build yacht will come fully warranted, providing protection from future mechanical repairs and providing complete peace of mind.

Finally, Moran Yacht & Ship ensures that building a yacht is indulgently fun. You will have the opportunity to collaborate with a team of highly experienced boat-building professionals to create something truly extraordinary, from sketch board to on the water. Nothing matches the thrill of building your own yacht with even the smallest details tailored to your precise requirements. Indeed, a custom yacht offers the ultimate lifestyle purchase.

What are the pedigree shipyards that Moran has built with?

- Lurssen Since 1875, the northern German shipyard has produced some of the finest vessels on the superyacht market. This pedigree shipyard is known for innovating and utilizing cutting-edge technology. Lurssen continually breaks records, including developing both the longest superyacht in the world (AZZAM) and the biggest luxury superyacht in the world (DILBAR).

- Amels This Dutch shipyard officially entered the yachting sphere with the superyacht KATALINA, now named LADY GEORGINA, in 1982. The luxury boat builder specializes in motor boats, constructing both full custom as well as their highly sought-after semi-custom Limited Editions yacht series.

- Oceanco Oceanco is a pedigree boat builder and industry pioneer based in the Netherlands. The shipbuilder is renowned for building award-winning custom vessels up to 200 meters, both motor yachts and sailing vessels. The Dutch shipyard specializes in building innovative, high-quality superyachts that push the boundaries of shipbuilding.

- Feadship Also among the world’s most notable superyacht manufacturers is Feadship, a full custom motor yacht builder known for its uncompromising pursuit of perfection. The pedigree shipbuilder is located in Holland and boasts a long history stretching back to 1949.

Moran Yacht & Ship boasts strong relationships with the world’s leading shipyards and has project managed some of the world’s most luxurious custom superyachts. Contact us today if you want to build a luxury boat.

What countries are known to have the best shipyards?

European countries, including the Netherlands, Italy, France, and Germany, dominate when it comes to the best shipyards, thanks to their rich maritime heritage, skilled craftsmanship, and use of exceptionally high-quality materials.

What are the current waiting times to build a yacht with the best shipyards?

Overall, the more prestigious the shipyard, the longer the waiting time will be. Current waiting times for some of the most prestigious builders are around 4 to 5 years.

How long does it take to build a yacht?

The build time for a yacht can vary significantly depending on the project’s size, specifications, and complexity. Generally, superyacht construction times at pedigree shipyards range from 36 to 39 months.

Our new construction team is known for delivering our client’s projects on time and within budget.

What are mega yacht hulls made from?

Megayacht hulls are typically made from fiberglass, aluminum, or steel, and the choice of material will depend on the budget, yacht design, and how the owner wishes the vessel to perform.

A fiberglass hull is known for its excellent sea-keeping capabilities and ease of maintenance.

Aluminum offers excellent strength and durability. As a relatively lightweight material, it also provides better fuel economy and enables a yacht to reach higher speeds.

Steel is an exceptionally strong and durable material with high resistance to abrasion, making it popular with ocean-cruising yachts, especially expedition vessels. However, it is heavier than fiberglass or aluminum, making it less popular with owners wishing to build a yacht where speed is a priority.

What makes a boat considered a yacht?

Overall, there is no standardized definition of what makes a yacht. Mostly, the term yacht applies to vessels over 24 meters, where regulations for ownership change as well. The term yacht can equally define a motor boat or sailing vessel. Additionally, terms like superyacht, megayacht, or gigayacht are often used to describe the most luxurious and largest ocean-going vessels.

Do I have to pay VAT on a new yacht?

As a moveable asset, whether you have to pay VAT – Value Added Tax – can be complex. Generally speaking, whether you have to pay VAT will depend on the country the owner is acquiring the yacht from and their country of residence. The VAT may also depend on the intended use of the vessel. Every country has different VAT rules and regulations. It is always a good idea to consult with a local tax professional with expert knowledge of the yachting industry to mitigate any potential tax liabilities.

What are financing options for yacht construction?

Building a new luxury boat can be an expensive endeavor and is a significant investment. Various financing options are available to those interested in purchasing or building a yacht. Financing typically involves one of three different solutions:

- Portfolio loans

- Private lenders

Bank loans are a popular option for financing a yacht construction. Many banks offer boat loans, which are similar to auto loans in terms of loan structure and required collateral.

Portfolio loans have become more popular for financing new construction projects. A number of institutions offer these and often have very favorable rates.

Private lenders also offer funding for boat construction. These lenders typically offer more lenient terms compared to banks. However, interest rates can be higher, and a larger down payment is often required.

How much does it cost to run a yacht per year?

The cost of running a yacht depends on many factors, including:

- Maintenance needs : they will also grow with the age of the yacht

- Size : the larger the yacht, the more crew is required

- Time spent cruising : fuel expenses increase with the cruising range

- Insurance costs

- Location : dockage and mooring fees will vary

Overall, a rule of thumb is that luxury yachts cost around 10% of their purchase price per year. This percentage is typically reduced slightly as the size of the boat increases.

Contact our New Yacht Construction Team

Are you considering building a new yacht? Contact our team today to learn how we will set you up for success.

Build a Yacht

Do you plan to build a yacht of your own.

If yes, read this guide on new yacht construction.

We will go through stages of a superyacht new build and discuss important points that every yacht owner or owner representative needs to know when commissioning custom yacht construction.

New Yacht Construction in a nutshell

Why build a yacht? The answer to this question is slightly different for every superyacht owner. One aspect is true for all: only a fully customized superyacht which was made specifically for you will perfectly fit all of your requirements and tastes.

If you are not satisfied with serial production yachts and seek that unique superyacht to call truly yours – then building a yacht is for you.

Superyacht build is an exciting process which only a handful of people in the world are lucky to experience.

There is nothing like seeing your own superyacht coming to life, first on paper in form of superyacht designer drawings, and then for real at the superyacht shipyard.

New yacht construction is a lengthly and sophisticated process which can take several years to complete. Thus it is very important for every superyacht owner to understand ins and outs to prevent unnecessary mistakes.

We at Yachtowner.co prepared a guide through superyacht build process for you. Let’s dive right in!

Build a yacht. Where to start

Why build a yacht.

Always start your superyacht new build process with why. The better you understand yourself, the easier it will be for superyacht professionals to satisfy your needs.

Why do you want to commission new superyacht construction? What drives you? How are you going to use your boat? What are your requirements? Sit down and make a list of things you would like to see at your new superyacht. Let your dreams flow and capture them on paper.

Look at your requirements and rate them. Group all your requirements into groups: “absolute must have”, “desirable”, “nice to have”. This grading will help yacht designers and shipyard understand your priorities and focus on the right things. Add information about numbers of cabins, speed, cruising range of your yacht, maximum noise and vibrations levels, and anything else which comes to your mind.

Save photos and descriptions of other yachts you like, including finishings type and quality. They will later serve as benchmark for a superyacht designer.

Try to describe the use of your boat in 1 or 2 sentences. A “floating home for my family”, a “fast and furious party boat”, or “an expedition vessel to explore arctic regions”? Give your new luxury boat your personal twist!

Successful yacht build starts with clear communication

By the time you decide build your own yacht, you should already have tried out chartering different yachts or owned some of second hand yachts.

As with anything else, in yachting it is also better to gain maximum experience, yachting knowledge and understanding of your needs, before you start your first large project.

How can you know what you want, if you don’t know which options are available? If you are just starting out in yachting, read our article How to Buy a Yacht .

Yacht design is all about compromises. Aiming to build the fastest boat, for example, implies limiting its overall weight. It means less additional lifestyle appliances on board.

To maintain the speed, a stronger engine is required, which means more fuel storage and less inside space. There are many examples of compromises like this.

Due to its high quality and sophisticated finishings, superyacht construction is much more labour intense than construction of any other type of vessel. Executing change requests gets expensive very soon.

Also, unlike in serial production of planes or cars and due to uniqueness of your boat, the shipyard does not have possibility to fully standardize the production process. Solutions can not be tested for various hundreds of times before the building begins. The shipyard just has one shot to get things right.

The more specific and detailed your understanding of your own preferences, the clearer and faster your communication about them, the better job your superyacht designer, architect and shipyard will be able to execute.

Superyacht Build: Choose the Right Team

You are about to sign a superyacht construction contract which will tie you into working with a shipyard for the next couple of years. Make sure you choose the right people! Superyacht building team can make or break the project.

In general, you will be working with a number of different experts from the superyacht industry during the next couple of years. They will surely have deep knowledge in their specific spheres of expertise.

Surrounding yourself with experienced professionals with no conflict of interest and simultaneously educating yourself on yacht building process will make you feel confident and comfortable in such a specific setting.

Always ask questions, clarify things you might not understand. Maritime industry is full of jargon. It’s ok not to know specific terms. It is much better to ask rather than to not be able to follow a discussion.

Professionals build the yacht for you, but in the end, it is your yacht. You want to make sure that you get the boat of your dreams and have enough knowledge on how it functions.

As a future superyacht owner, you probably already have your favorite yacht designers, naval architects and superyacht brands. If not yet, then check out our Comprehensive list of 195 Superyacht Brands to discover some of the world’s best superyacht builders.

How to Build a Yacht: Design Phase

Now when you already have put your first thoughts on paper, it’s time to make first contact with a superyacht designer and/or a naval architect.

A superyacht designer is responsible for creating an attractive and practical design for your future yacht. A naval architect is typically a professional engineer in charge of construction, design and repair of yachts.

If optical appearance and interior design is your focus, yacht designer might be appropriate to hire. If instead you want to incorporate non-traditional and sophisticated technical elements into your yacht, a naval architect is the right person to contact.

Take the list of your preferences that we discussed in the beginning of this guide and visit several superyacht designers and architects. Browse through previous yacht projects in their portfolios. Make sure that he or she has enough experience in designing similar types of yachts.

Choose two or three best companies. Ask them for preliminary drawings and estimates of fees, and compare. Choose the one who suits you best.

Then visit a superyacht insurance agent and a classification society surveyor . Yacht insurance decides whether the yacht is ready to launch. Classification society is an entity which monitors that the yacht is built according to highest standards and quality.

The surveyor checks if the shipyard builds your yacht to the best quality. It is in your interest to involve these two stakeholders already in the beginning of the process, to avoid unnecessary hassle from the start. Show them the first drawings and specifications of the new yacht that you got from the designer/architect, and ask how they work and what else they need.

Clarify yacht financing . The majority of privately owned superyachts are financed by some kind of a bank loan. It is a savvy financial decision to finance your superyacht by a bank loan.

By negotiating good loan conditions, you can keep your own cash and invest it into a better performing asset classes with higher returns. There is a number of financial institutions worldwide which specialize in superyacht financing.

Think about the flag of your future superyacht . In which country will it be registered? Will it be a Red Ensign Flag ? Choice of the country of registration will affect legal status of your superyacht, so choose carefully.

We cannot stress enough how a well-executed and detailed yacht design is crucial for the following yacht construction! Before starting to build a yacht, one needs to run a full check of all documents, specifications and plans. The better you prepare on this stage, the smoother the yacht building process will be.

Build a Yacht: Shipyard & Construction

The big decision alongside the choice of yacht designer and naval architect, is undoubtedly, the choice of shipyard . This is the manufacturer of your future custom superyacht. The shipyard plays an immense role and has responsibility to deliver your new yacht the way you want it.

Once the preliminary design of your yacht is ready, you can start looking for a suitable shipyard to build your yacht.

How to choose a shipyard to biuld a yacht? Which yacht brand is the best for you? Look out for the following points:

- Shipyard size

- Shipyard’s preferred size of yachts

- Years on the market

- Previous experience in building similar yachts as yours

- Delivery schedule

- Own design team

- Reviews of previous clients

- Resale value of yard’s previous yachts

- Project management skills

- Who is the project manager? Do our personalities fit well?

- Are processes in place?

- ISO standards & compliance

- Procurement department & policies in place

- Financial stability of the shipyard

- Do I have a good feeling with the shipyard?

There is quite a variety of shipyards in the world and it can become a daunting task to choose the best one for you. Send your inquiry to several shipyards, and narrow down your choice to 3-4 best ones based on their answers. Get more details and specifications from them and choose the best shipyard.

The shipyard will assign a project manager and a team to run the building of your new custom superyacht.

The project manager is an employee of the shipyard and is the key person who runs the construction of your yacht. His task is to project manage the build, to make sure everything sticks to schedule and there is no significant cost overrun, and to maintain communication with the owner’s representative.

Cooperation between project manager and owner’s representative is key in successful superyacht construction. Whereas the owner’s representative has power to act on owner’s behalf, the shipyard’s project manager is the one who runs the show on shipyard floor.

Visit the shipyard personally and talk to the general manager and the potential project manager (the latter reports to the former).

Take a look at the facilities. Try to find out how the processes at the shipyard are managed. Are proper project management procedures established? Are processes structured and responsibilities clear?

The better the organization of shipyard’s work, the more likely is your new custom yacht to be completed up to your expectations. One of the ways of finding it out is asking for previous client’s opinions. Ask the shipyard if they can share such contacts with you.

The team will prepare a project plan and a project schedule. After that the execution will start. This is a long, sophisticated but a very exciting process, when you will finally see your yacht materializing.

It is good practise to have a yacht engineer or captain who will be working on the yacht after completion to be part of the team during construction. His detailed knowledge of the new yacht will be invaluable for its daily operation after the handover.

Visit the shipyard once in a while and take photos of different stages on construction. What exciting memories to look back at!

During the yacht construction phase, you are likely to submit some changes. Some issues might arise. But don’t get demotivated, it is normal with a project of such scale.

Proper execution control mechanisms and processes will allow your team to identify potential issues at early stages, while it is still relatively easy and cheap to fix them.

Build a Yacht: Sea Trials & Closing

Finally the construction of your custom superyacht is completed. We know you can’t wait to see your beauty on water!

Launching is the day when your new yacht is put in the water for the first time. It is an exciting and very important moment, which needs to be carefully planned by the shipyard.

Now the yacht needs to be tested in action. This is a period of sea trials . For several weeks, all systems of your new yacht will be tested in operation. This is the final complete technical check of your new luxury boat. Some fixes might be done during this period.

As with a brand new car, some systems on the yacht will take longer time to be fully tested in action. Some fine tunings will surely also be done during the first and second years of your superyacht’s lifetime. It is absolutely normal.

Handover is the final stage of yacht construction project. This is when you sign the final acceptance of the yacht, probably with a list of things which still need to be fixed in the upcoming weeks.

With the handover of the yacht, also all its documentation has to be handed over to you or your team. This includes all the plans, drawings, sea trials results, manuals to all the systems and appliances on board.

Your crew has to have access to all these documents to be able to comfortably transition to the new build yacht.

Give your captain and crew some time to accommodate onboard and get accustomed to the new yacht.

Now you are finally ready to make the first voyage on your new custom superyacht , the moment you have been waiting for so long.

Congratulations!

Build a Yacht: Contract is King

Yacht construction documentation.

When it comes to building a yacht, paperwork matters. With such a large project, all the parties involved are interested in having everything clarified on paper before yacht construction starts.

Unclear or conflicting conditions, missing clauses, mess in communications and emails can substantially complicate building of your yacht. As well as make it much longer and more expensive.

Work with lawyers that have been working with yacht building projects before. They will advice on how to setup contracts, which paragraphs and attachments to include.

You should have the following documentation package: contract, scope of work, technical specifications, terms and conditions, regulations, contract drawings, classification rules, standards, and execution page.

Due to the nature of new yacht construction projects, roles and responsibilities of different stakeholders can overlap. Best practice is to include description of roles and responsibilities of every stakeholder in an attachment to contract, to avoid confusion.

Make sure you understand every clause in the contract personally. The language might be very specific, but knowing what you sign is absolutely crucial, even if you trust the professionals you hired.

In the end, you are the owner and end beneficiary. It is your yacht and your money, you should know what you are signing for.

Keeping all documentation saved and filed properly might be boring, but it is so important! With a project of such magnitude, paper chaos can come quite fast.

Shipyard will file documentation on their side, but your representative should also have own filing system to make sure you have all papers at hand.

Also, after the yacht construction is completed, as-built documentation shall be handed over to you.

Making changes while you build a yacht

Trust us, no matter how well you planned your new custom yacht in advance, you will want to change at least something later.

Change orders and how they will be handled in the building process are an important part to put down in the contract. Having clear rules on how change orders shall be handled and paid for will significantly ease the process. Make all your changes in writing as an attachment to the contract.

Generally, the fewer change orders you make, the better. The sooner they come during the yacht build, the better. They will also be considerably cheaper to implement.

Just think of how much will need to be redone, if you decide to make changes in hull structure once the yacht is almost finalized, interiors are finished etc.? It might be cheaper to build a second yacht…kidding, but you get our point.

Superyacht Construction: Comfort Onboard

Stabilizers.

Comfort on board of your yacht is central to enjoyment of trips and cruises! Seasickness is sadly something that many people get and it can ruin any vacation. No matter how luxurious a yacht, it is still moving in water, and at least some minimal motion will always be there.

Solution to seasickness are stabilizers. If you are sensitive to motion on water, make sure your yacht has a good stabilizer. It will make a great difference in your yachting experience.

There are many stabilizing systems of varous types on the market. Talk to your team at the design stage and later ask stabilizer manufacturer to provide a motion simulation study.

Noise & Vibration

Not so obvious aspect for new yacht owners are noise & vibration levels outside and inside your yacht. We love the speed that strong engines give – but they are loud. Engines cause noise – and so do propellers, generators, bow thrusters, hydraulics, gearbox…

Work with a good noise level specialist when constructing your yacht, to make sure that noise does not exceed your tolerance level. It is much easier and cheeper to minimize noise already during design and construction of your yacht.

Ideally, use another yacht as a reference point for setting acceptable vibration and noise levels. Test it at the dockside and during cruising. When the yacht is moving, you will hear not only the engine noise, but also sound of waves hitting the hull, wind, propellers.

Specify maximum sound levels in every cabin in the yacht building contract. Most people prefer to have at least some noise level in the cabins, not to feel too locked out of their environment. Also, getting below specific levels gets very expensive, and will probably be unnecessary.

Superyacht Build Success depends on Yacht Owner’s Involvement

Yes, as the future superyacht owner you also have an important role to play in superyacht construction. Only with your active involvement in the project, can the yacht designer and shipyard get all the important information and approvals in time and deliver great results.

Only by knowing what a perfect yacht means specifically for you, can they build this perfect yacht.

If the personal time you are willing to spend on the project is very limited, hire a knowledgeable representative.

Owner’s representative is a key stakeholder in a new yacht build, alongside shipyard’s project manager. Owner’s rep is the major contact point for all the other stakeholders. Make sure he or she has necessary experience, knowledge and power to represent you and make decisions on your behalf.

Yacht owner’s representative should be on pulse of construction schedule, cost, and current stage of the building process. Cooperation between the owner’s representative and the shipyard’s project manager is a key relationship in any superyacht new build.

In short: completing a successful superyacht build is only possible with active cooperation from the owner’s side. There are quite a number of new build projects that run into issues due to lack of owner’s participation.

New yacht construction is your biggest dream coming true, it’s fun to take active part it in!

Yacht Construction: Frequently asked questions

What does a custom yacht mean.

A custom superyacht means a yacht which is designed and build specifically to your requirements. A custom superyacht is unique. If you commission building a custom yacht, there will be no other yacht like yours in the world.

How long does it take to build a yacht?

Superyacht construction times vary depending on the size and complexity of the boat . It can take anything from 2 to 5 years to complete building of a custom superyacht.

How much does it cost to build a yacht?

New build custom made superyachts are more expensive than serial production or semi-custom yachts. Their prices can go up to several tens of millions of dollars on average. Exact price range depends on the yacht size, complexity and finishings. The largest yachts in the world cost considerably more than a hundred million dollars, reaching over a billion dollars for the most expensive ones.

Who is involved in a superyacht build?

Yacht owner, owner’s representative, superyacht designer, naval architect, shipyard (full team typically led by a project manager), lawyers, insurance agent, superyacht financing specialist, classification society surveyor, possibly superyacht broker , superyacht captain & crew, to name the main stakeholders.

What are the best superyacht manufacturers in the world?

There is quite a number of prominent shipyards with expensive experience of building superyachts in the world. The exact choice will depend on the size of yacht, your preferences, budget and taste. With superyacht manufacturers, there is no one size fits all, but there are market leaders. Browse through our Comprehensive list of 193 Superyacht Brands to choose your favorite.

Summary: Build a Yacht

In this article, we discussed new superyacht building process from the yacht owner point of view. We highlighted main points you should keep in mind to avoid common mistakes during yacht commissioning and construction.

It is beyond the scope of this article to list all the important aspects of building a yacht. Hiring an experienced superyacht consultant will significantly ease the yacht build for you.

Get the best superyacht professionals onboard, stay curios and ask questions. With every completed yacht new build you will gain your own experience and know your yachting needs better. We know some serial yacht owners who complete a new yacht build project every couple of years. It’s fun!

And last but not least: building your own superyacht is such a unique adventure, which only few people get to experience. The absolutely main thing is to enjoy it to the fullest!

Do you have questions we have not covered?

Ask us in the comments below, or contact us directly at [email protected] ! We will define your needs and find the best solution together!

Article by Yachtowner.co

More Articles

Yacht Ownership Cost

Superyacht Management

Superyacht Websites List

Should I Buy a New or a Used Yacht?

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Yes, add me to your mailing list

Privacy Overview

Why build a yacht with Burgess?

Build a yacht

Discover the Burgess difference

Commissioning a bespoke superyacht is an exhilarating yet complex journey. With multiple decisions to make along the way, we guide you from your initial vision to maiden voyage and beyond.

We share your vision to achieve the remarkable

We reduce the risk and increase your enjoyment. Whether seeking a fully customised vessel or looking at the latest semi-custom platforms, our highly-skilled Technical Services team provides decades of experience and expertise, working together with you to realise your dream.

Dedicated in-house team working on your behalf

Every project offers a unique set of challenges, and for each we offer the complete range of technical, engineering and project management services in‐house, collectively serving as your personal project consultant. We have every angle covered, every step of the way.

Providing an unforgettable build experience

From vision to design brief to build, sea trials and delivery, we continue to be involved throughout the agreed construction period, offering peace of mind and a single point of contact. Your dream, our knowledge, one unique result.

- Delivered yachts

We successfully deliver more yachts in the 30-180m and over market than any other new construction team in the world.

- Length: 80.1m (262.8ft)

- Built: 2023

- Bilgin, Turkey

- Length: 87m (285.4ft)

- Built: 2020

- Lurssen, Germany

- Length: 60.6m (198.8ft)

- Built: 2022

- Heesen, The Netherlands

- Length: 107.6m (353ft)

- Benetti, Italy

- Length: 57m (187ft)

- Built: 2019

- Damen, The Netherlands

- Length: 56m (183.7ft)

- Length: 55m (180.4ft)

- Amels, The Netherlands

- Length: 93m (305.1ft)

- Feadship, The Netherlands

BRAVO EUGENIA

- Length: 109m (357.6ft)

- Built: 2018

- Oceanco, The Netherlands

- Length: 74.5m (244.4ft)

- Abeking & Rasmussen, Germany

You've viewed 10 of 47

Abeking & Rasmussen

Founded in 1907, Abeking & Rasmussen is globally renowned for producing high-quality custom motor yachts from 45-125m.

AKYACHT is an ISO 9001, Lloyd's-certified shipyard in Turkey. Its first breakthrough project was the spectacular 85m VICTORIOUS, the biggest superyacht ever built in Turkey.

Alia Yachts

Alia Yachts was founded in 2008 in Antalaya, Turkey. Its Lloyd's certified facilities are equipped for cutting edge yacht construction in carbon reinforced composite, steel and aluminium up to 80m.

Established in 1854, Cantiere Baglietto Spa specialises in the construction of new planing aluminium yachts between 35-50m in length, and steel and aluminium displacement superyachts over 40m.

With three facilities spread across Viareggio and Livorno in Italy, and rich brand heritage, Benetti is a leading light in the production of 35-70m superyachts.

Cantiere delle Marche

The Ancona-based Cantiere delle Marche (CdM), founded in 2010, builds 26-48m explorer yachts in steel and aluminum. CdM is the No.1 expedition yacht builder worldwide for the third year running.

With origins dating back to 1825, Codecasa is a family company specialising in the building of large yachts in steel and aluminium up to 72m in length and fast motoryachts up to 50m in length.

CRN Shipyards

Founded in Ancona in 1963, CRN yachts are often characterised by a distinctive pointed bow, which has become something of a signature for this Italian yard.

Custom Line

Founded in 1996, brand of Ferretti Group and based in Ancona, Italy, Custom Line designs and builds planing and displacement yachts in composite from 30-42m in length with over 250 yachts delivered.

Damen Yachting

Damen Yachting is the master yacht builder behind more than 100 Amels superyachts, SeaXplorer expedition yachts, yacht support vessels and major yacht refits.

Delta Marine

Located in Seattle, Washington, Delta Marine has a worldwide reputation for producing custom-built luxury yachts of up to 100m in length.

Based in the Netherlands and with roots dating back to 1849, Feadship is recognised as the world leader in the field of pure custom superyachts.

Fincantieri

Fincantieri Yachts, part of the leading Western shipbuilder Fincantieri, is a world leader in both superyacht and cruise ship design and construction.

Heesen Yachts

Renowned for its innovation, Heesen is the world leader in aluminium construction, and dominates the 50-60m semi-custom market.

Located in Ancona, ISA Yachts builds luxury superyachts from 44-80m in steel, aluminium and fibreglass.

Lürssen

Based in Germany, Lürssen is the leading shipyard for large luxury yacht building as well as refit of yachts from 50-200m.

Mariotti Yachts

Mariotti is a world leader in the fields of ultra-luxury cruise shipbuilding, superyachts and supply vessel construction.

Located in Northern Germany, Nobiskrug has built over 750 seagoing vessels, delivering a select portfolio of custom superyachts including the 143m Sailing Yacht A.

Oceanco builds award-winning large custom yachts, such as the 106.7m Black Pearl, the world's largest and most sustainable sailing yacht, and the 110m Jubilee, the largest Dutch-built yacht.

Pendennis is a world-class custom build and refit yard in Falmouth, UK, specialising in luxury sail and motor yachts between 30-100m.

Perini Navi

Renowned for pioneering automation and furling systems in large sailing yachts, Perini Navi today builds both sailing and motor yachts, most famous of which is MALTESE FALCON.

Established in 1980, Rossinavi builds custom superyachts between 40-70m in four locations between Viareggio and Pisa.

Royal Hakvoort

A family shipyard since 1919, Royal Hakvoort builds luxury yachts in steel and aluminium up to 65m in length.

Royal Huisman

A family-owned shipyard established in 1884, Royal Huisman specialises in the build and repair of custom luxury sailing yachts, as well as motor yachts.

Founded in 1958, Sanlorenzo builds a limited number of high quality, made to measure superyachts at its shipyard in La Spezia, Italy. Today, Sanlorenzo ranks highly among builders of Superyachts over 40m.

Tankoa Yachts

Tankoa specialises in semi-custom and custom yachts of 50-90m with Northern European quality and Italian DNA for design and flexibility.

The Italian Sea Group

TISG operates in the new-built industry with the brands Admiral (yachts over 50m) and Tecnomar (yachts up to 45m) while it works in the refitting industry with the brand NCA Refit (yachts over 60m).

Turquoise Yachts

Turquoise Yachts (formerly known as Proteksan Turquoise) is a builder of custom power and sailing superyachts, and Dr. Al Barwani, owner of Oceanco, recently became the majority shareholder.

Based in Zwartsluis, The Netherlands, Vitters has established a reputation for delivering sailing yachts of uncompromising quality and innovative design.

- Yacht designers

Bannenberg & Rowell Design

A luxury yacht and jet design company based in London’s Fulham. Headed up by Dickie Bannenberg, son of the great Jon Bannenberg, the studio is renowned for creative, contemporary and approachable design – both interior and exterior.

Espen Oeino

Under the leadership of the eponymous Norwegian naval architect, Espen Oeino International has been designing iconic superyacht interiors and exteriors since the 1990s. Based in Monaco the studio has worked with Burgess on several projects, most notably the 72m Trinity Yachts-built ALBATROSS and the 156m Lurssen DILBAR, the largest yacht afloat by volume.

H2 Yacht Design

Jonny Horsfield established H2 Yacht design in London in 1994. Today it is a multi-disciplined exterior and interior styling team that has earned a reputation for challenging conventions in yacht design. The studio has so far collaborated on five projects with Burgess, most recently with Heesen.

Harrison Eidsgaard

International yacht designers and architects, Harrison Eidsgaard Design is headed up by its three partners, Peder and Ewa Eidsgaard and Ben Harrison. Undertaking both exterior and interior styling, the studio’s most notable yachts to date include the award-winning TANGO and ELANDESS, the latter being the studio’s first project with Burgess.

Jonathan Quinn Barnett leads a talented team of award-winning yacht designers. Established in 1995, the studio has created original exterior yacht designs and interior architecture for discerning clients in the luxury marketplace. With a critical eye on proportion and detail, designs of distinction associated with Burgess include the interior of OCTOPUS and popular charter yacht MUCHOS MAS.

Michael Leach Design

Established in 1997 by Mick Leach with Mark Smith joining in 1999, MLD is an multi award-winning design practice specialising in marine, aviation and residential projects. With over 60 years’ industry experience collectively, having worked in various top design offices, MLD is now established as one of the industry’s leading and most successful design offices.

Reymond Langton Design

Headed up by design duo Pascale Reymond and Andrew Langton, the London-based studio was founded in 2001. The studio has since delivered 28 motor and sailing yachts, including the 134m SERENE, the largest yacht built in Italy at that time. Originally based in London, the studio’s HQ has since moved to the historic city of Bath.

Situated in the stunning surrounds of Beaulieu in the New Forest, RWD is best known for the design of superyachts such as motor yacht HASNA and sailing yacht TWIZZLE. Founded in 1993, RWD has to date completed six collaborative projects with Burgess.

Sorgiovanni Designs

Established by yacht designer Sam Sorgiovanni in 1997, the eponymous design studio is based in Perth, Australia, and undertakes both exterior and interior designs. The studio’s unique location lends a point of difference to its body of work and it has become well-known for designing superyachts with an exotic feel, as well as great attention to detail.

Terence Disdale Design

Terence Disdale Design is an award-winning design studio located in London, and responsible for the interior and exterior design of the some of the world's most significant yachts. Renowned for a ‘beach house’ style, the studio’s most notable yachts include ECLIPSE and PELORUS, and it has no fewer than 10 collaborative projects with Burgess to date.

Tim Heywood Design

A multi-award-winning exterior yacht designer, Tim Heywood Design has produced some of the largest yachts on water, including the 133m AL MIRQAB. Located in Hampshire, the eponymous yacht designer cut his teeth under the guidance of Jon Bannenberg and in the 40 years since has completed six collaborative projects with Burgess.

Winch Design

A full-service award-winning British design and architecture studio specialising in the exterior and interior styling of motor and sailing yachts, aircraft, residential and commercial properties, Winch Design was established in 1986 and has to date completed seven collaborative projects with Burgess.

Superyacht interior design ideas

Burgess and Alia Yachts collaborate on their first new build yacht project together

Looking into future fuels

Thanks to you, Burgess nears its 49th year on a high

The smart way to build a semi-production yacht

Some of the best luxury yachts with pools

The rise of eco yachting

The essential yacht interior accessories

Sign up to our newsletter, stay in the loop.

Subscribe to our newsletter to keep updated with all things Burgess.

What would you like emails about?

- Chartering a yacht

- Buying or selling a yacht

- General superyacht news

In order to understand how we use and protect your personal information, please read our privacy policy .

- Mediterranean

- French Riviera

- Corsica & Sardinia

- The Balearics

- Croatia & Montenegro

- The Bahamas

- Caribbean - Leeward Islands

- Caribbean - Windward Islands

- British Virgin Islands

- US Virgin Islands

- New England

- Indian Ocean

- South East Asia

- French Polynesia

- The Red Sea

- Motor yachts for charter

- Sailing yachts for charter

- Latest offers

- Destinations

- New to charter

- Meet the Charter team

- Superyacht videos

- 360° yacht tours

- Corporate & event charters

- Inspiring charter ideas

- Charter FAQs

- Every day different

Charter KADIMO'S

Available between 10 June - 10 July

Elevator serving lower to sun decks means the boat can accommodate all generations

Charter BARBARA

Available 1-12 July and August onwards

Spa facilities including massage and beauty rooms, private master deck and indoor and outdoor cinemas

- Motor yachts for sale

- Sailing yachts for sale

- Yachts for sale over 200 feet

- Yachts for sale from 150 to 200 feet

- Yachts for sale under 150 feet

- Tenders and chase boats for sale

- Yachts under construction

- Meet the Brokerage team

- Berths for sale

- Sold yachts

- Yacht marketing

- New Build Sales

- Refit a yacht

- Meet the Technical Services team

- Meet the Yacht Management team

- Crew vacancies

- Meet the Crew Services team

- Procurement Services

- Charter Management

- Sales Management

- Yacht Marketing

- Meet the Insurance team

- 360 degree yacht tours

- Boat shows and events

- Office vacancies

- Talent pool

- Office locations

- Burgess in Asia

- Burgess Blue Oceans

- Strategic partners

- Press centre

- Company Operations

- Crew Services

- New Business

- Technical Services

- Yacht Management

- Burgess Impact Report 2023

Filter your results

- Yachts for charter

- Yachts for sale

- Frank Magazine

- Denison History

- Virtual Tours

- Alaskan Yachts

- Azimut Yachts

- Back Cove Yachts

- Beneteau Yachts

- Benetti Superyachts

- Bertram Yachts

- Boston Whaler

- Broward Yachts

- Buddy Davis Sportfish

- Burger Yachts

- Cabo Yachts

- Carver Motoryachts

- Center Console

- Chris-Craft Yachts

- Cruisers Yachts

- DeFever Trawlers

- Dufour Sailboats

- Fairline Yachts

- Feadship Yachts

- Ferretti Yachts

- Formula Yachts

- Fountaine Pajot Cats

- Grady-White

- Grand Banks Trawlers

- Hargrave Yachts

- Hatteras Yachts

- Hinckley Picnic Boats

- Horizon Yachts

- Hydra-Sports

- Intrepid Boats

- Jarrett Bay Sportfish

- Jeanneau Yachts

- Kadey-Krogen Trawlers

- Lazzara Yachts

- Luhrs Sportfish

- Marlow Yachts

- Maritimo Yachts

- Marquis Yachts

- McKinna Motoryachts

- Meridian Yachts

- Midnight Express

- Mochi Craft

- Neptunus Motoryachts

- Nordhavn Trawlers

- Nordic Tugs

- Ocean Alexander Yachts

- Offshore Yachts

- Oyster Sailing Yachts

- Pacific Mariner Yachts

- Palmer Johnson Yachts

- Pershing Yachts

- Prestige Yachts

- Princess Yachts

- Pursuit Yachts

- Riva Yachts

- Riviera Yachts

- Sabre Downeast

- San Lorenzo Yachts

- Sea Ray Boats

- SeaVee Central Consoles

- Selene Trawlers

- Scout Yachts

- Sunseeker Yachts

- Tiara Yachts

- Trinity Superyachts

- Viking Yachts

- Westport Yachts

Building A Custom Superyacht [Complete Newbuild Guide]

![yacht building cost Building A Custom Superyacht [Complete Newbuild Guide]](https://cdn.denisonyachtsales.com/wp-content/uploads/2019/07/Building-A-Custom-Superyacht.jpg)

July 25, 2019 11:40 am

The process of building a large yacht explained.

Placing an order for the build of a large yacht is no small undertaking. It is likely the result of a lifetime—perhaps even generations—of wealth building for such a purchase to become an option. When the time comes, how does the client start the process and where does he or she look for suitable partners? The maritime world is famously full of jargon, and the luxury yacht business is no different. Brokers , naval architects, interior designers, class societies, custom yachts, production yachts, flag states, owner’s supply, surveyors, shipyards, subcontractors, builder’s risk insurance , project managers, tank testing . . . you catch my drift.

Thought-through decisions and complicated contracts should certainly be anticipated, but as a wise man once told me about yachting, “At the end of the day, it’s all about cocktails on the beach.” While the dream of being on the water waits at the end of a newbuild process, building a yacht should be an enjoyable and rewarding process in itself.

- Newbuild Process Overview

- Latest Trends In Yachting

- Newbuild Partnerships

- Flexibility

- Project Management

- Newbuild Projects For Sale

- What Sets One Builder Apart from Another?

- What Sets A Brand Apart?

NEWBUILD PROCESS

“Production” Yachts tend to be in the smaller range and the process will likely be simpler than for a custom build. With a finished product already in inventory and available, only minor interior design elements need to be added per the client’s choice. A number of yacht builders will begin building larger yachts in anticipation of finding a buyer later, offering “semi-custom” as an option for elements of the interior layout and design.

For the custom build, the process will look something like this:

Vision > Design > Contract > Build > Sea Trial > Delivery > Cocktails on the Beach

The above is an intense simplification. Each stage involves multiple levels of experts and support staff. The client will want to surround him or herself with qualified attorneys, technical advisors, and translators of the jargon. One other important element to mention is that the design and build contract cost will not be the only outlay required to reach the endpoint. Custom yacht contracts mostly do not include items known as “Owner’s Supply,” i.e. tenders and water toys, audio-visual/entertainment systems, loose furniture, tableware, and more. Each of these will need to be procured, stored, insured, and integrated into the yacht itself as part of the process.

LATEST TRENDS

Step one, “Vision,” allows almost anything to be conceived and delivered in a yacht. There are plenty of “concept designs” available on the internet to offer the client inspiration for their vision, but we have seen a few trends in recent years. The “plumb bow,” the explorer yacht, hybrid propulsion, podded propulsion, as well as attention to environmental impact elements of the design and subsequent operations are all topics which have received attention in the industry press.

PARTNERSHIPS

As with any high-value undertaking, a large yacht construction project will require numerous partnerships and you may be asking yourself, “Who is involved with a custom yacht build process?” With the client at the top, some or all of the following will be necessary for a successful and enjoyable project experience:

A yacht broker , to advise the client on availability and the suitable market for construction and opening budget concepts. A naval architect for concept design. An engineer for detailed design. An interior designer. Attorneys for contract review, tax advice, etc. An insurance broker . A yacht builder , who may also provide some or all of the naval architecture, engineering, and even interior design services. Flag State , to provide surveyors with approval of safety code compliance. Classification Society, a third-party service assuring the quality of construction. Owner’s Project Manager , to record and represent the client’s interests across the entire project. (Depending on the size of the yacht, this may be one person or a team.) Yacht crew. (Depending on the size and complexity of the yacht, it may be wise to start bringing a crew into the project 6-12 months from completion.) Owner’s supply vendors , for audio-visual/entertainment systems, tenders, spares, and consumable supplies all needed to be managed and integrated into the final delivery.

FLEXIBILITY

The best plans are flexible and organized carefully so that changes or delays do not derail a project entirely. With this in mind, each partnership must be equally flexible throughout the project since an owner’s design needs, the yacht’s delivery schedules, and compliance requirements often change.

PROJECT MANAGEMENT

The process of building a large yacht is a long-term commitment and a major investment. A prospective client may consider hiring a project manager to assist with fielding the complexities at hand, protecting the client’s interests in the process and enabling the finished dream to be delivered on time and on budget. For a “simple” project, the project manager may be one person attending the yard on an occasional basis, but for larger builds, expect to see numerous staff on the project management team—some full time and others with short-term specialties needed during particular phases of the build.

NEWBUILD PROJECTS FOR SALE

Denison Yachting represents a number of builders in various regions of the United States with dealerships for Hatteras and Horizon, both of which typically build production or semi-custom yachts. Additionally, Denison is currently offering a number of new construction projects from yards Rosetti, Numarine , and Van der Valk , who all offer fully custom and semi-custom projects. Each year, we commit to visiting various yards in Italy , Germany , and The Netherlands to stay up to date on project availability and maintain relationships with the world’s top yacht builders.

Yacht brokerage houses often show newbuilds for sale. This may be a case where a builder has a design that they are promoting to the market, or maybe have even started construction without a specific client under contract. In some cases, clients or builders will start new construction as a speculative investment intending to sell the contract to a third party.

WHATS SETS ONE BUILDER APART FROM ANOTHER?

Boat International’s Builder Directory includes 1,805 separate entries, so the choices are broad. Builders can be found in Italy, Germany, the Netherlands, the UK, the USA, Turkey, China, Taiwan, Australia, and beyond. Some builders may specialize in a particular material, i.e. GRP, aluminum, or steel, and others may limit the size, the numbers, or the design choices (custom/production.) A client may use any of these to narrow down the selection, but the real distinction between builders will be the manner in which they treat the client. If the client is made welcome in the builder’s facility throughout the process, that builder will more than likely succeed. If the builder is transparent in their process, then they will succeed. If a builder says “yes” to every client request but fails to deliver, then they will likely fail.

Once a client has a particular style of yacht in mind, the selection of suitable builders will narrow down even further and the client’s broker should assist that process with their knowledge of the market. Then the client may consider asking candidate yards to suggest design concepts, then begin the evaluation and decision process. If using an independent naval architect to produce a concept, they may suggest suitable builders for the vision.

WHAT SETS A BRAND APART?

There are innumerable brokerages willing to sell a client a newbuild, and just as many builders who would likely be willing to deal direct. Do all of those companies have the depth of experience, integrity, expertise, and background that is needed to assist a client seeking to embark on such a high-value and complex project? Has that broker taken the time to learn the market options available? Do they have the skills necessary to listen and advise for the client’s benefit rather than their own? Denison has the build and brokerage experience matched with the knowledge and integrity required to take a client to the next level of their yachting dream.

Latest News

NEWS | April 24, 2024

77 alen yachts 2023 sold by alex g. clarke [sunya].

77 Alen Yachts 2023 Sold by Alex G. Clarke [SUNYA] SUNYA, a 77′ Alen Yachts built in 2023 was sold by Alex G. Clarke, who represented both the Seller and the Buyer. Designed to provide an unmatched level of luxury and performance, SUNYA comfortably accommodates six guests across three elegantly

High-Definition Screen Time

High-Definition Screen Time Massive, high-definition screens are transforming yacht interiors like never before. This article was written by Rachel Ingram. Photography courtesy of the manufacturers. As technology continues to play an increasingly important role in the lives of yacht owners, digitization is seeping

NEWS | April 22, 2024

82 catana 2007 sold by jason walton [paradoxe].

82 Catana 2007 Sold by Jason Walton [PARADOXE] PARADOXE, an 82′ Catana built in 2007 was sold by Jason Walton, who introduced the Buyer. Alexis de Boucaud with The Multihull Company represented the Seller. CATANA and designer Gilles VATON , with this 82’, raised the turn over for

How Much Does it Cost to Design a Yacht, Engineering Rates, & Pricing for Companies?

- 3D Modeling , CAD Design , Product Design

- last updated Feb 10, 2023

This post tells you more about how much it costs to design a yacht, engineering rates, and company pricing. Designing a yacht is complicated; even an experienced naval architect may need six months to more than a year to produce a complete ready-to-build yacht design. A yacht should be an attractive, comfortable, efficient, safe, and effective means of water transportation. While the aesthetic aspect is critical, the exterior design process is simple compared to the marine engineering and mechanical design services required for the internal systems. The outer shell appearance will also affect the propulsion, electronics, stability, structural rigidity, plumbing, and hydrodynamics.

RELATED: What are boat design costs & naval engineering rates for marine services companies?

How Much Does it Cost to Design a Yacht?

The cost for a yacht “design only” work ranges from $3,000 to $30,000, depending on the plan’s details. Generally, the design cost of a yacht should not exceed 15% – 20% of the overall build. However, some small boats with sophisticated onboard equipment and luxury features require the assistance of a more experienced engineering design expert than their larger counterparts. The money you spend on the design may account for a significant percentage of the overall cost.

Fee structures

A naval architect may use one of the standard pricing structures below.

* Fixed commission

The fixed commission is a set percentage of the cost of the completed yacht. One issue with a fixed pricing structure is the owner’s lack of project specifications. A naval architect needs a comprehensive, well-defined description of a yacht concept and an elaborate design contract to consider fixed commission an option. The precise contract specifications restrict the client’s ability to demand design revisions. As far as marine and yacht design services are concerned, a slight interior layout or mechanism change can alter the entire design approach.

RELATED: Accessible design: better products for everyone

Every modification to the original concept must come with a formal “change order” and a separate fee for renegotiation. As a result, the fixed percentage fee structure can be complex. The total cost of a completed yacht remains unknown until the project concludes. Factors such as the contractor’s experience, builders’ qualifications, and labor can significantly affect the price. A fixed commission is often an overly expensive pricing structure for the owner.