Sailboat Mast Replacement Cost | Everything You Need to Know

The cost of sailboat mast replacement can vary significantly depending on various factors such as the size and type of the boat, the materials used for the mast, the complexity of the replacement process, and any additional repairs or upgrades needed. Mast replacement is a crucial maintenance task for sailboat owners, as the mast is the vertical structure that supports the sails and rigging, playing a vital role in the boat's performance and safety. Whether the old mast is damaged beyond repair or it’s time for an upgrade, the cost of a new mast can range from a few thousand dollars to tens of thousands of dollars, making it a significant investment for boat owners. It’s recommended to consult with professionals or marine experts to assess the specific requirements and costs associated with sailboat mast replacement, ensuring the best outcome within the estimated budget.

What Is the Average Price of a 35 Foot Sailboat?

However, it’s important to note that the price of a 35-foot sailboat can vary significantly depending on several factors. One such factor is the brand and model of the sailboat. Well-known and reputable brands often come with a higher price tag due to their quality and craftsmanship.

Additionally, the level of customization and the inclusion of luxury features can also drive up the cost of a sailboat. For example, a sailboat equipped with high-end amenities, such as a state-of-the-art navigation system, luxurious cabin interiors, and advanced safety equipment, may be priced higher than a basic, no-frills model.

Furthermore, the material used to construct the sailboat can influence it’s price. Fiberglass is a common material used in sailboat construction, and it offers a good balance of affordability and durability. However, sailboats made from more expensive materials, such as carbon fiber, may have a higher price point due to their lightweight and high-performance characteristics.

Used sailboats, particularly those in good condition and with well-maintained equipment, can be purchased at a lower cost compared to new models. However, older sailboats that require extensive repairs or renovations may be priced lower to account for the additional expenses.

Owners must also consider ongoing expenses such as maintenance, insurance, docking fees, and possible upgrades or repairs. These additional costs should be factored into the overall budget when considering the purchase of a sailboat.

It’s essential for potential buyers to carefully consider their budget and prioritize their needs and preferences when searching for a sailboat that suits their needs.

Factors That Influence the Price of a Sailboat

Factors that Influence the Price of a Sailboat

The price of a sailboat can be influenced by various factors. One such factor is the size of the sailboat. Generally, larger sailboats tend to have higher prices due to their increased materials, labor, and overall construction costs. The condition of the sailboat is another important factor that affects it’s price. A well-maintained sailboat with minimal wear and tear will command a higher price compared to one that requires extensive repairs or refurbishment. The age of the sailboat also plays a role – newer sailboats often come with modern features and designs, rendering them more expensive. Additionally, the brand and reputation of the sailboat manufacturer can impact the price. Well-known and respected brands tend to have higher price tags due to their established reputation for quality and craftsmanship. Lastly, the presence of any additional equipment or accessories, such as navigational or safety devices, can influence the price of a sailboat. Overall, the price of a sailboat is determined by a combination of these factors, and potential buyers should carefully consider them when assessing the value of a sailboat.

However, it’s important to note that attempting to repair a carbon fiber mast can be risky and may compromise it’s structural integrity. It’s always recommended to consult with a professional or the manufacturer to determine the best course of action in case of damage to ensure the safety of those on board.

Can a Carbon Fiber Mast Be Repaired?

Carbon fiber masts are known for their strength, lightness, and durability, which makes them a popular choice for sailing vessels. However, when it comes to repairing a damaged carbon fiber mast, the general consensus is that it isn’t safe or recommended. The main reason for this is the potential risk that a repaired mast may fail under the stress of sailing, which can lead to serious consequences.

Amateur repairs can easily lead to further damage or improper repairs that could compromise the entire masts structure, posing a severe risk to those on board.

To ensure the utmost safety and reliability, it’s best to consult with professionals and consider replacing a damaged mast rather than attempting a repair. Your safety and the safety of your crew should always be the top priority when it comes to sailing.

The Pros and Cons of Carbon Fiber Masts Compared to Other Materials (e.g., Aluminum, Wood)

- Carbon fiber masts have a higher strength-to-weight ratio compared to aluminum or wood, making them lighter and more rigid.

- They exhibit excellent fatigue resistance, allowing for long-term durability and reduced maintenance.

- Carbon fiber masts offer better resistance to corrosion and weathering, extending their lifespan.

- These masts provide improved performance in terms of stiffness, resulting in enhanced boat stability and increased speed.

- They offer a sleek and aesthetically pleasing appearance, which can enhance the overall look of the boat.

- Carbon fiber masts can be custom-built to specific measurements and designs, allowing for greater flexibility in boat construction.

- However, carbon fiber masts tend to be more expensive than aluminum or wooden alternatives.

- They may require specialized repair techniques and equipment in case of damage.

- Carbon fiber masts are more prone to catastrophic failure compared to other materials, such as wood, which can splinter instead of breaking completely.

- They can transmit more vibrations and shocks to the boat, potentially affecting comfort during rough sea conditions.

When it comes to the cost of a carbon mast, the price tag can vary based on factors such as size and specifications. Ranging from $975 for a mizzen to $2,250 for a larger mast, the price reflects the high-quality materials and craftsmanship used in it’s construction. If you’re interested in learning more or placing an order, feel free to inquire further using our convenient online order form.

How Much Does a Carbon Mast Cost?

Carbon fiber masts are highly sought after for their exceptional strength, lightweight design, and increased performance in sailing vessels. The cost of a carbon mast can vary depending on several factors, such as the size, type, and manufacturer. Generally, the price for a carbon fiber mast ranges from $975 for a mizzen mast, typically used on smaller sailing vessels, to as high as $2,250 for a large mast utilized on larger sailboats.

Many companies have order forms or websites where prospective buyers can learn more about the specific details and pricing associated with carbon fiber masts. These forms often provide detailed information on the different options available, allowing individuals to make an informed decision based on their needs and budget.

Additional factors can influence the overall price, such as the manufacturing process, technological advancements used, and any additional customizations requested by the buyer. Therefore, it’s crucial to have open communication with the supplier or manufacturer to fully understand the breakdown of costs and any potential additional expenses you may incur.

Furthermore, it’s worth considering the long-term benefits of investing in a carbon fiber mast. Additionally, the lightweight design guarantees improved speed and maneuverability, ultimately enhancing the sailing experience.

Prices can range from $975 for a mizzen mast to $2,250 for a large mast. However, it’s crucial to inquire directly with the manufacturer or supplier through order forms or websites to obtain an accurate quote based on specific requirements.

The Advantages and Disadvantages of Carbon Fiber Masts Compared to Other Materials, Such as Aluminum or Wood.

- Advantages of carbon fiber masts:

- High strength-to-weight ratio

- Stiffness and rigidity

- Corrosion resistance

- Excellent fatigue resistance

- Reduced weight for improved performance

- Enhanced durability and lifespan

- Disadvantages of carbon fiber masts:

- Higher cost compared to other materials

- More susceptible to impact damage

- Requires specialized repair techniques

- Limited availability of skilled technicians for repairs

- Less forgiving under extreme loads

- Potential issues with bonding and delamination

When it comes to the cost of a 45-foot sailboat, it’s important to consider the specific type and features you’re looking for. On average, a seaworthy monohull can be found in the range of $100,000 to $150,000, allowing you to embark on global sailing adventures. Alternatively, if you prefer a catamaran, be prepared to spend approximately $250,000 to $500,000 for a vessel of comparable size.

How Much Does a 45 Sailboat Cost?

When it comes to purchasing a 45-foot sailboat, there are a few factors to consider that can greatly impact the cost. One of the main determinants is whether you opt for a monohull or a catamaran. On average, a seaworthy mid-range 45-foot monohull suitable for sailing around the world can be acquired for approximately $100,000 to $150,000. This price range typically includes a vessel in decent condition and equipped with the necessary equipment for extended cruising.

On the other hand, if you prefer a catamaran, you should anticipate a higher price range. A 45-foot catamaran of similar quality and seaworthiness may cost anywhere from $250,000 to $500,000.

It’s important to note that these price estimates are simply averages and can vary greatly depending on various factors, such as the age, condition, and brand of the sailboat, as well as additional equipment and features included. Older models or those in need of repairs or significant maintenance may be available at lower prices, while newer or more luxurious vessels may command a higher price tag.

It’s advisable to conduct a thorough survey or inspection of the prospective vessel before purchase to ensure that any potential hidden issues are identified and accounted for in your budget.

It’s essential to assess your own budget and priorities, as well as consult with experts or experienced sailors, to determine the best option that suits your needs and financial capabilities.

Factors That Affect the Price of a Sailboat, Such as Age, Condition, and Brand.

The price of a sailboat can be influenced by various factors, including it’s age, condition, and brand. Older sailboats, for instance, tend to have lower prices compared to newer ones. The condition of the sailboat also plays a significant role, as boats in good shape and well-maintained often command higher prices. Additionally, the brand of the sailboat can impact it’s price, with well-known and prestigious brands usually being more expensive. These factors contribute to the overall value and cost of a sailboat in the market.

Source: Yacht lifestyle and costs: What it’s like to live on a big boat

The materials used to construct ship masts have undergone significant changes over the years. While traditional sailboats relied on wood for their masts, modern vessels predominantly utilize aluminum for this essential component.

What Are Ship Masts Made Of?

Sailboat masts, with their iconic presence towering high above the boats, play a crucial role in sailing by providing support and structure for the sails. These masts, often exceeding the length of the boat itself, can be crafted from various materials. In modern times, aluminum has become the primary choice for constructing sailboat masts due to it’s advantageous properties.

With their robustness, they withstand the forces exerted by the wind on the sails, ensuring a stable and safe sailing experience.

However, it’s important to emphasize that traditional boats often utilized wood for constructing masts. Wood possesses a natural elegance that compliments the classic aesthetic of older sailboats. While wood offers a visually appealing option, it requires regular maintenance and care to prevent rotting and decay caused by exposure to the elements.

Regardless of the material chosen, sailboat masts need to be carefully crafted to endure the harsh conditions at sea.

Considering the vast array of sailboat sizes and designs, various factors influence the choice of mast material.

Different Materials Used in Ship Masts and Their Properties

Ship masts are essential components that provide support for sails and allow ships to navigate through water. They’re made from various materials, each with distinct properties.

1. Wood: Traditional ship masts were primarily constructed using wood due to it’s strength, flexibility, and resilience. Woods like oak, pine, and teak were commonly used. Wood is durable, yet it can rot or decay if not properly maintained.

2. Steel: Steel masts offer excellent strength and durability, making them ideal for large commercial vessels and warships. They can withstand extreme weather conditions and heavy loads without deformation. However, steel masts are prone to corrosion, so protective coatings are necessary.

3. Aluminum: Aluminum masts provide a lightweight alternative that reduces the weight on the ship’s structure. It offers good strength-to-weight ratio, corrosion resistance, and requires less maintenance than steel. Aluminum masts are commonly used in modern sailboats and small pleasure crafts.

4. Carbon Fiber: Carbon fiber composites have revolutionized mast construction, especially in high-performance yachts. They possess exceptional strength, stiffness, and lightness, allowing for faster boat speeds. Carbon fiber masts often require expert maintenance to ensure structural integrity.

Understanding the different materials used in ship mast construction helps in selecting the most suitable option based on factors like vessel type, budget, desired performance, and maintenance requirements.

It’s crucial for boat owners to thoroughly evaluate their specific needs and budget constraints before embarking on such a considerable expense. Seeking professional advice and obtaining multiple quotes from reputable marine services can help ensure a more accurate estimation. Additionally, regular maintenance and proper care of the mast can help prolong it’s lifespan, potentially reducing the need for costly replacements in the future.

Please watch this video on YouTube:

Related Posts

What is the lightest wingfoil board exploring the best options for optimal performance, what is stand up paddleboarding: sailing on water with a special board and sail, how to glue starboard to fiberglass, how to carry a windfoil board.

- Navigating the High Seas: A Comprehensive Guide to Sailboat Masts

Sailboat masts are the unsung heroes of the sailing world, silently supporting the sails and ensuring a smooth journey across the open waters. Whether you're a seasoned sailor or a novice, understanding the intricacies of sailboat masts is essential for a safe and enjoyable voyage. In this comprehensive guide, we will delve into the world of sailboat masts, discussing their types, maintenance, and everything in between.

Types of Sailboat Masts

Sailboat masts come in various configurations, each with its advantages and drawbacks. The two primary types are keel-stepped and deck-stepped masts.

Keel-Stepped Masts

Keel-stepped masts are the most common type, extending through the deck and resting on the boat's keel. They provide excellent stability and are suitable for larger sailboats. However, they require careful maintenance to prevent water intrusion into the boat's cabin.

Deck-Stepped Masts

Deck-stepped masts rest on the deck of the boat, making them easier to install and remove. They are commonly found on smaller sailboats and are more forgiving in terms of maintenance. However, they may offer slightly less stability than keel-stepped masts.

Components of a Sailboat Mast

To understand mast maintenance better, it's essential to know the various components of a sailboat mast. The key parts include the masthead, spreaders, shrouds, and halyard sheaves.

The masthead is the topmost section of the mast, where the halyards are attached to raise and lower the sails. It also often houses instruments such as wind indicators and lights.

Spreaders and Shrouds

Spreaders are horizontal supports attached to the mast to help maintain the proper angle of the shrouds (cables or rods that provide lateral support to the mast). Properly adjusted spreaders and shrouds are crucial for mast stability and sail performance.

Mast Materials: Choosing the Right One

Sailboat masts are typically constructed from three primary materials: aluminum, wood, and carbon fiber. Each material has its unique characteristics and is suited to different sailing preferences.

Aluminum Masts

Aluminum masts are lightweight, durable, and relatively easy to maintain. They are commonly used in modern sailboats due to their cost-effectiveness and longevity.

Wooden Masts

Wooden masts, while classic and beautiful, require more maintenance than other materials. They are best suited for traditional or vintage sailboats, where aesthetics outweigh convenience.

Carbon Fiber Masts

Carbon fiber masts are the pinnacle of mast technology. They are incredibly lightweight and strong, enhancing a sailboat's performance. However, they come at a premium price.

Mast Maintenance

Proper mast maintenance is essential for safety and longevity. Regular cleaning, inspection, and addressing minor issues promptly can prevent costly repairs down the line.

Cleaning and Inspection

Regularly clean your mast to remove salt, dirt, and grime. Inspect it for signs of corrosion, wear, or damage, paying close attention to the masthead, spreaders, and shrouds.

Common Repairs and Their Costs

Common mast repairs include fixing corroded areas, replacing damaged spreaders, or repairing shrouds. The cost of repairs can vary widely, depending on the extent of the damage and the materials used.

Extending the Lifespan of Your Mast

Taking steps to prevent damage is essential. Avoid over-tightening halyards, protect your mast from UV radiation, and keep an eye on corrosion-prone areas.

Read our top notch articles on topics such as sailing , sailing tips and destinations in our Magazine .

Stepping and Unstepping a Mast

Stepping and unstepping a mast is a crucial skill for any sailboat owner. This process involves removing or installing the mast on your boat. Here's a step-by-step guide for safe mast handling.

Step-by-Step Guide for Safe Mast Handling

- Gather the necessary tools and equipment.

- Disconnect all electrical and rigging connections.

- Use a crane or mast-stepping system to safely lower or raise the mast.

- Secure the mast in its proper place.

- Reconnect all electrical and rigging connections.

When and Why to Unstep a Mast

You may need to unstep your mast for various reasons, such as transporting your sailboat or performing extensive maintenance. It's crucial to follow the manufacturer's recommendations and ensure a safe unstepping process.

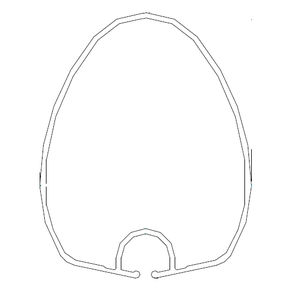

Sailboat Mast Boot: Protecting Your Mast

A mast boot is a simple yet effective way to protect your mast from water intrusion and damage caused by the elements. Here's what you need to know.

The Purpose of a Mast Boot

A mast boot is a flexible material that wraps around the mast at the deck level. It prevents water from entering the cabin through the mast opening, keeping your boat dry and comfortable.

Installing and Maintaining a Mast Boot

Installing a mast boot is a straightforward DIY task. Regularly inspect and replace it if you notice any signs of wear or damage.

Replacing a Sailboat Mast

Despite your best efforts in maintenance, there may come a time when you need to replace your sailboat mast. Here's what you should consider.

Signs That Your Mast Needs Replacement

Common signs include severe corrosion, structural damage, or fatigue cracks. If your mast is beyond repair, it's essential to invest in a replacement promptly.

The Cost of Mast Replacement

The cost of mast replacement can vary significantly depending on the type of mast, materials, and additional rigging needed. It's advisable to obtain multiple quotes from reputable marine professionals.

Yacht Masts: Sailing in Style

For those looking to take their sailing experience to the next level, upgrading to a yacht mast can be a game-changer.

Differences Between Sailboat and Yacht Masts

Yacht masts are typically taller and offer enhanced sail performance. They are often equipped with advanced rigging systems and technology for a more luxurious sailing experience.

Upgrading to a Yacht Mast

Consult with a marine professional to determine if upgrading to a yacht mast is feasible for your sailboat. It can be a significant investment but can transform your sailing adventures.

Sailboat Mast Steps: Climbing to the Top

Mast steps are handy additions to your mast, allowing easier access to perform maintenance or enjoy panoramic views. Here's how to use them safely.

Using Mast Steps Safely

Always use proper safety equipment when climbing mast steps. Make sure they are securely attached to the mast and regularly inspect them for wear or damage.

The Advantages of Mast Steps

Mast steps provide convenience and accessibility, making sailboat maintenance tasks more manageable. They also offer an elevated vantage point for breathtaking views while at anchor.

Mast Maintenance Tips for Beginners

If you're new to sailboat ownership, these mast maintenance tips will help you get started on the right foot.

Essential Care for First-Time Sailboat Owners

- Establish a regular maintenance schedule.

- Seek advice from experienced sailors.

- Invest in quality cleaning and maintenance products.

Preventing Common Mistakes

Avoid common pitfalls, such as neglecting inspections or using harsh cleaning agents that can damage your mast's finish.

Sailing with a Mast in Top Condition

A well-maintained mast contributes to a safer and more enjoyable sailing experience. It enhances your boat's performance and ensures you can rely on it in various weather conditions.

How a Well-Maintained Mast Improves Performance

A properly maintained mast helps maintain sail shape, reducing drag and improving speed. It also ensures that your rigging remains strong and secure.

Safety Considerations

Never compromise on safety. Regularly inspect your mast, rigging, and all associated components to prevent accidents while at sea.

Sailboat masts are the backbone of any sailing adventure, and understanding their intricacies is crucial for a successful voyage. From choosing the right mast material to proper maintenance and upgrading options, this guide has covered it all. By following these guidelines, you can sail the high seas with confidence, knowing that your mast is in top condition.

So what are you waiting for ? Take a look at our range of charter boats and head to some of our favourite sailing destinations .

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

Replacing Your Sailboat Rigging

- By Wendy Mitman Clarke

- Updated: March 23, 2020

Whether you’re buying a used sailboat that’s new to you or you’ve owned your boat for decades, the standing rigging is what keeps the mast in place, and thus requires particular attention. How do you know when it’s time to re-rig? There are some obvious answers to this one — for instance, if your wire rigging has broken strands or if it’s suffering from “candy-striping,” i.e., rust-colored streaks swirling down the wire. The latter may indicate two things: one, that it’s simply surface rust, which you should be able to polish off, or two, that as the wire was being manufactured, a strand might have picked up some contamination during the process and is compromised, which is cause for concern. A third visual indicator are cracks in swaged fittings, some of the most common end fittings for wire. Cracks are hard to see (use a magnifying glass), and sometimes marks that look like cracks can be left by the machine used to create the swage. Then there’s just age, and this factor as a reason to re-rig is more subject to a boat’s history than anything else.

“There’s a rule of thumb, but it varies rigger to rigger,” says Steve Madden, co-owner of M Yacht Services in Annapolis and the head of its M Rigging division. “My belief is that you should be replacing your sailboat’s standing rigging every 10 to 15 years.” But this time frame also is variable, depending on the boat’s purpose and use. For instance, for an offshore bluewater boat, Madden recommends 10 years, and for a serious coastal cruiser, more like 12.

“The biggest thing we like to have is the history of the boat: what kind of boat it is, how it’s been sailed and where has it been sailed,” says Jay Herman, owner of Annapolis Rigging. “That history will affect what kind of life you get out of your standing rigging.” Some insurance companies, he says, will require a re-rig if you’re purchasing a used boat that has standing rigging older than 15 years.

Either way, Jimmie Cockerill, co-owner of the Rigging Company in Annapolis, recommends that for a sailboat with wire rigging, the mast should be pulled and all fittings and wire visually inspected every five to six years. And although rod rigging may be able to last longer than wire, it too needs to be serviced every five to six years to get the most life out of it. Sticking to the 10-year rule, Madden says, means that for the most part, any corrosion or failure points will be eliminated with a re-rig.

How the rigging has been tuned is also part of a boat’s story. For instance, Madden says, he recently had a customer whose 46-foot cutter had a rigging failure at six years. The customer had had the boat re-rigged, and during a trip to the BVI, the new wire stretched. The owner didn’t adjust the rigging to compensate for the stretch for several seasons. “That was a case of not knowing that the worst thing you can do to standing rigging is have it loose on the leeward side,” he says. “Sailboat rigging very rarely fails from being overloaded. There’s such a safety margin in rigging. So you’re sailing offshore and you’re looking at the windward shroud that’s taut, and that’s not the one to worry about. It’s when the leeward side starts flopping around that you’re asking for trouble.”

Stainless steel has a finite number of cycles — essentially, movements, whether fore and aft or side to side. “The theory is that it can take 10 to 15 years of cycling, but this continual motion when it’s unloaded is what fatigues the wire,” Madden says. “There’s no real way of measuring that. Die testing won’t pick it up, and it’s rare that a wire will give you warning before breaking.”

So how often should standing rigging be replaced? For all of these reasons, most riggers agree that when your sailboat’s standing rigging approaches 15 years old, it’s a good time to consider replacing it.

Wire or Rod Sailboat Rigging?

Riggers say the question of whether to rig with wire or rod is usually fairly easily answered: Run what you brung. In other words, if your boat already has rod rigging, with all of the end fittings to terminate the rods both on deck and in or on the mast, then sticking with rod will ultimately be less expensive than making the switch to wire. Likewise, if you already have wire with fittings that accommodate your boat and mast, stick with wire. Aside from the relative cost differences between rod and wire (rod is more expensive), what also makes a switch pricey is having to significantly modify the mast to accept the different rigging.

Although rod rigging is more common on racing boats, many well-known cruising-boat builders, such as Valiant, Bristol, J/Boats and Hinckley, have rod-rigged models. The benefits of rod are less stretch, less weight, less windage, and arguably longer life than wire, because there’s less possibility for corrosion of the rod itself.

That said, some sailors prefer wire over rod for a number of reasons. First, it’s easier to fix in remote places and on your own. With a spare mechanical end fitting, wire and the proper tools, you can replace a stay pretty much anywhere. Similarly, it’s easier to find usable replacement parts far from busy ports. Wire rigging is generally less expensive and easier to handle. Finally, rod rigging requires a particular type of terminus — called a cold head — that can be fabricated only with a purpose-built machine, which only a rigging shop will have. You cannot use a mechanical fitting on rod rigging.

In the past, long-distance cruisers typically chose wire rigging with mechanical fittings for all of these reasons. They also would carry a piece of wire as long as the longest stay on the boat — coiled and stowed, which undeniably was sometimes easier said than done — as well as spare end fittings and the tools needed to replace a broken shroud or stay. Today, with the advent of super-strong synthetic line such as AmSteel and Dyneema, the need for that extra wire and gear is eliminated. For instance, the Rigging Company makes a spare-stay kit that can accommodate either wire or rod rigging repairs, Cockerill says. It has a synthetic stay with an eye splice, a toolless turnbuckle (the Handy Lock, made by C. Sherman Johnson), quick-release fast pins with an attached lanyard, several high-strength Dyneema loops, and even a heavy-duty zip tie to fish loops in and out of holes in a mast.

“The idea is you come on deck with this small canvas bag and make it happen,” Cockerill says. “Let’s say you ripped a tang out of the mast; you can use a Dyneema loop to create another attachment point. A smaller loop is a makeshift chainplate attachment — you can attach it to a neighboring chainplate and attach the stay to it. It’s good enough to get you to safety and someplace you can make a more permanent repair.” Riggers say very few sailors re-rig from wire to rod or the reverse, but if switching is on your mind, have a professional make a full assessment first.

There are so many variables in the system — types of end fittings, types of masts, types of attachment points — that each boat will have its own specific requirements that can affect cost. For that reason, it’s difficult to give an accurate estimate of the cost of making the switch, even for an average 40-footer.

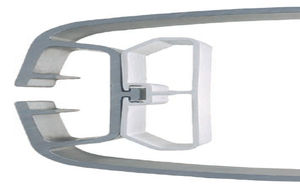

End Fittings for Sailboat Rigging

All standing rigging, whether rod or wire, has to end in a fitting that attaches to the deck and mast. The three most commonly used types of attachments are swaged and mechanical fittings for wire, and cold heads for rod. Generally, end fittings fall into a few classes: studs, eyes, forks and hooks, each of which comes in a dizzying array of sizes and configurations. There are multiple combinations and variations: For instance, if your mast has double tangs, most likely the end fitting will be an eye — although it can be a marine eye or an aircraft eye, which differ primarily in shape. All rod rigging terminates in a cold head, which accommodates the end fitting or is encapsulated by the end fitting. This could be a marine eye, a marine fork, a T-head or a J-hook, among others.

A swaged fitting is a terminus that’s attached using a machine called a swager. It rolls the end fitting through two opposing dies and compresses the fitting on the wire so tightly that it can’t pull out. “The theory is that you’ve crushed it so tightly that all the wires inside have just merged into one solid piece of stainless,” Madden says. Swaging must be professionally done, and the result is extremely strong and generally has a long life. Top manufacturers of swaged fittings are Hayn Marine Rigging Products, Alexander Roberts and C. Sherman Johnson.

Mechanical fittings can be applied using a few common hand tools by the mechanically handy DIY sailor, which is one reason they’re popular. The two primary manufacturers of mechanical fittings presently are Sta-Lok and Petersen Stainless, which produces Hi-MOD. Both are located in the U.K., and the products are distributed in the U.S. through vendors like Hayn, West Marine, Defender, and local chandleries and riggers. Generally, they consist of either three or four parts (Sta-Lok has three; Hi-MOD has four), including a sleeve; a cone; in Hi-MOD’s case, a crown wheel; and the terminal (an eye, fork, stud, etc.). If you follow directions, they are fairly straightforward to install, although not especially easy. “The mechanical fasteners are great in that you can terminate and then look inside to be sure it’s formed correctly, so you do have a way of inspecting your work,” Madden says.

However, they generally cost more than a swaged fitting; Herman says while Hi-MOD’s newer mechanical fittings are “definitely more user-friendly to assemble, they’re twice the cost of a swaged fitting.” Some riggers will recommend swaged fittings for the mast end of the rigging and mechanical fittings at the deck level: Corrosion is less prevalent at the top of the mast, and you can more easily and regularly inspect mechanical fittings at deck level, where they’re frequently subjected to salt water

Should You Replace Your Sailboat’s Rigging Yourself?

So you’ve determined your sailboat’s standing rigging needs work. Do you hire a pro or go it alone? Good question. Yes, doing it yourself will theoretically save money. For an average 40-foot boat, Cockerill estimates about $100 per foot to re-rig with wire rigging ($4,000), as well as the round-trip cost to haul and launch the boat and unstep and step the rig (an additional $2,500 or so). By taking on the labor yourself, you’ll probably save as much as $2,000 on the re-rigging cost, he says. Madden says that cost isn’t linear, though; as you go up in size (a bigger boat needs heavier wire and larger fittings), you’ll spend more. He’d estimate more like $4,600 for a 40-foot boat, but all of these numbers depend on how much is involved: Are there furlers? What kind of end fittings? Are the chainplates sound? Depending on the answers to those questions and others, a professionally done re-rig for a 40-footer could be closer to $6,000 or more.

If you go DIY, you will be limited to mechanical end fittings unless you hire a rigger to swage your end fittings. The Rigging Company gears much of its sales to DIY sailors and is beginning an e-commerce site to cater specifically to handy individuals. But Cockerill says it quickly becomes evident whether an owner feels comfortable enough to do the work. “You should be mechanically inclined,” he says, “and the way to find that out is if I start talking all this technical jargon and you decide whether you’re suited to handle that at all.”

Additionally, a DIY sailor needs to do plenty of research, particularly when it comes to wire quality, which is something professional sailboat rigging companies watch like hawks. Although anyone can walk into a local chandlery and buy wire, that doesn’t mean the wire is of the highest quality. Marine-suitable stainless wire is called 316 grade, but even that doesn’t mean you’re necessarily getting high-quality wire. Much depends on where it is manufactured; Herman and other riggers say the best wire today is coming from South Korea through a manufacturer called KOS, making wire to military specifications. It’s imported and sold through distributors like Alps Wire Rope.

“We only sell guaranteed-content, guaranteed-process wire,” Herman says. “There are other wires out there that are cheaper, but they’re not guaranteed.”

As for sources of wire and fittings, there are many, including major chandleries and vendors, like West Marine and Defender, as well as some private riggers, like Annapolis Rigging and the Rigging Company, which will work with you to define what you need and help you source parts and materials.

One thing all the riggers I spoke with expressed emphatically was that stainless steel needs oxygen to create a fine film of oxidation that protects the metal. The fastest route to crevice corrosion is to cover the metal with plastic or leather turnbuckle covers or to coat the fittings in tape. Enough tape to cover a cotter pin suffices; otherwise, leave the metal open to the air. Likewise, if you are re-rigging your sailboatboat, use the opportunity to check your chainplates (easily the subject of another article entirely), since that’s one of the most common points of rigging failure.

Another factor in your DIY decision-making process is simple: peace of mind. “Most of my clients say to me without any prompting, ‘This is one area I feel should be done by a professional,’’’ Madden says. “You’re out there offshore and there’s a squall coming and you start worrying about the craziest of things, and you don’t want to have any unknowns.” That’s especially true of the system that keeps the mast and sails up.

Wendy Mitman Clarke is currently between passages. She’s the director of media relations at Washington College in Chestertown, Maryland, and she and her family continue to pine and plan for the day they can return to the cruising life.

- More: How To , mast , Refits , rig , rigging , sails and rigging , Upgrades

- More How To

3 Clutch Sails For Peak Performance

It’s Time to Rethink Your Ditch Kit

8 Ways to Prevent Seasickness

How To De-Winterize Your Diesel Engine

Kirsten Neuschäfer Receives CCA Blue Water Medal

2024 Regata del Sol al Sol Registration Closing Soon

US Sailing Honors Bob Johnstone

Bitter End Expands Watersports Program

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

DWYER MAST & RIGGING

The Aluminum Mast C ompany

Quality Sailboat Masts, Booms, Hardware and Rigging Since 1963

Dwyer Mast & Rigging manufactures high-quality sailboat masts, booms, hardware, and rigging. Originally founded in 1963 as Dwyer Aluminum Mast Company, the legacy continues as an OEM supplier by taking advantage of improved manufacturing methods to offer a wide range of products and services for the marine industry.

Our Services Include

Mast & Boom Extrusions // Dinghy & Keelboat Spars // Standing & Running Rigging // Hardware & Blocks // Round Tubing // OEM Supplier // Waterjet Technology // & more...

Manufacturing for the Marine Industry

Our formula for growth is simple - we never compromise with quality. By taking advantage of improved manufacturing methods and an ever-increasing volume, we have been able to maintain competitive prices and continue to provide much needed product to sailors, riggers, and boat builders.

Products & Servic es

Cont act Us

Rigging - Turnbuckles , Toggles , Wire & Rod Components, Norseman Cones & Fittings.

Furling Systems - Systems and replacement parts from a variety of Manufacturers.

Traveller Systems - Adjustable Track Systems for Mainsheet and other applications.

Sailboat Hardware - Rope Clutches, Blocks, Track & Fittings, Winches, etc.

Custom Parts - Custom items, or those out of production or otherwise unavailable.

Consultation - Special projects, research, or information not detailed on-site.

Copyright 1996 - 2024, Rig-Rite, Inc. Disclaimer Web Site maintained by The WATER Group

What Is A Sailboat Mast?

A sailboat mast is one of the most defining features of a sailboat (along with the sails of course!) You can immediately tell that a boat is a sailing boat when you spot the tall mast sticking out of the hull.

But why do sailboats need a mast? Having lived on a sailboat for years now I’ve never really questioned the need for a mast. It’s such an integral part of the boat that I just sort of forget it’s there!

When our friends recently lost their mast due to a rigging failure it got me thinking – why do sailboats need a mast and what function (aside from holding up the sails) do they actually play. It turns out, quite a lot!

We’re going to dive into the fascinating world of sailboat masts, exploring different rigs, mast materials, and the different functions that masts play. It’s important stuff if you want to go sailing, and a lot of it I should have known sooner!

As an Amazon Associate, we earn from qualifying purchases. We also earn from other affiliate programs. This means we may receive a small commission on products purchased through our links at no extra cost to you.

Table of Contents

Why do sailboats need a mast, parts of the mast, what materials are masts made from, single mast rigs, sailboats with two masts, sailboats with three masts, how to look after your mast.

A sailboat mast is a vertical, upright structure that supports the sails of a sailboat. It is a crucial component of the boat’s rigging system and plays a key role in harnessing the power of the wind to propel the vessel. Typically located in the center of the boat, the mast extends upward from the deck or hull.

The height of the mast varies depending on the size and type of the sailboat, directly impacting the sail area and overall performance of the boat.

Together with the boom (a horizontal spar attached to the bottom of the mast), the mast allows sailors to control the shape and orientation of the sails, optimizing their efficiency in different wind conditions.

The design and configuration of the mast can vary depending on the type of sailboat, such as a sloop, cutter, ketch, or schooner.

Sailboats require a mast primarily to support the sails.

It holds the sails in an elevated position, allowing them to catch the wind effectively. Without a mast, the sails would lack the means to be raised and positioned to harness the power of the wind.

There are a few other important jobs that the mast plays:

Control and Manipulation of Sails: The mast, along with the boom (a horizontal spar attached to the mast’s lower end), enables sailors to control and manipulate the sails.

By adjusting the angle and tension of the sails through the mast, sailors can optimize their performance according to wind conditions and desired boat speed.

This control allows for maneuverability and efficient use of wind power.

Structural Integrity: The mast contributes to the overall structural integrity of the sailboat. It helps distribute the loads and forces exerted by the sails, rigging, and masthead components throughout the boat’s hull and keel.

The mast’s design and construction ensure stability and strength, allowing the boat to withstand the forces generated by the wind.

Attachment Points for Rigging: The mast provides attachment points for various rigging components, including halyards (lines used to raise and lower the sails), stays (wires or rods that support the mast in different directions), and shrouds (wires that provide lateral support to the mast).

These rigging elements are essential for properly tensioning the sails and maintaining the mast’s stability.

Height and Visibility: The mast’s height contributes to the sailboat’s visibility, allowing other vessels to spot it more easily, particularly when sailing in congested waters. The mast’s presence also serves as a visual reference for determining the boat’s position, orientation, and distance from potential hazards.

While the mast’s primary purpose is to support the sails and enable control over their position, it also plays a significant role in maintaining the structural integrity of the sailboat and enhancing its visibility on the water.

Basically, the mast is pretty darn important!

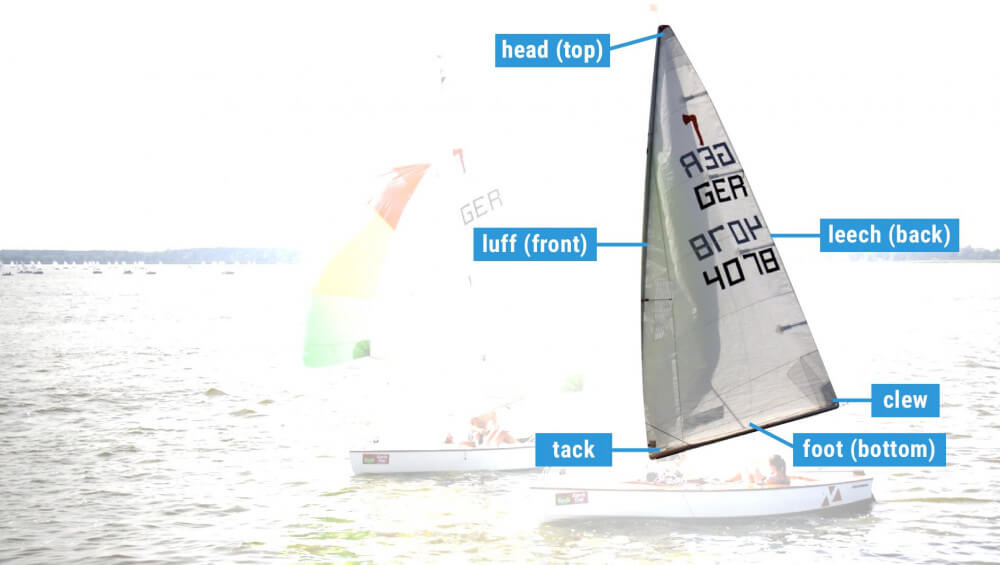

Along with a million other confusing sailboat terms , the mast has lots of different parts too. A sailboat mast consists of several distinct parts, each serving a specific function. Here are the different parts commonly found on a sailboat mast:

- Masthead: The masthead is the topmost section of the mast. It often includes attachment points for various components such as halyards (lines used to raise and lower the sails), the forestay (the wire or rod that supports the front of the mast), and other rigging elements. The masthead may also house instruments like wind vanes or antennas.

- Spreaders: Spreaders are horizontal bars attached to the mast, typically positioned at specific intervals along its length. They help support the rigging wires and prevent excessive sideways bending of the mast. The position and angle of the spreaders contribute to the proper alignment and tension of the rigging.

- Shrouds: Shrouds are the wires or cables that provide lateral support to the mast. They connect the mast to the sides of the boat, helping to stabilize the mast and distribute the loads generated by the sails. Shrouds are typically tensioned using turnbuckles or other adjustable fittings.

- Backstay: The backstay is a cable or wire that provides support to the rear of the mast. It helps counterbalance the forces exerted by the forestay and the mainsail, preventing the mast from excessively bending forward. Adjustable backstays allow for tuning the mast’s rigidity based on wind conditions and sail trim.

- Halyard Sheaves: Halyard sheaves are small wheels or pulleys located at the masthead or lower down the mast. They guide halyards, which are lines used to raise and lower the sails. Halyard sheaves minimize friction, allowing smooth and efficient hoisting or lowering of the sails.

- Gooseneck: The gooseneck is a fitting that connects the boom to the mast. It allows the boom to pivot or rotate horizontally, enabling control over the angle and position of the mainsail. The gooseneck may include a pin or other locking mechanism to secure the boom to the mast.

- Mast Step: The mast step is the base or fitting where the mast rests and is secured to the deck or hull of the sailboat. It provides stability and distributes the loads from the mast to the boat’s structure.

These are some of the primary parts found on a sailboat mast. The specific configuration and additional components may vary depending on the sailboat’s design, rigging system, and intended use.

I was surprised to learn that sailboat masts are commonly made from several different materials, each offering its own advantages in terms of strength, weight, and flexibility.

The choice of material depends on various factors, including the type and size of the sailboat, desired performance characteristics, and budget.

Here are some of the materials used for sailboat mast construction:

Aluminum is a popular choice for sailboat masts due to its favorable combination of strength, lightweight, and corrosion resistance. Aluminum masts are relatively easy to manufacture, making them cost-effective. They offer good stiffness, enabling efficient power transfer from the sails to the boat.

Carbon Fiber

Carbon fiber has gained significant popularity in sailboat mast construction, especially in high-performance and racing sailboats. You’ll see black carbon fibre masts on fancy sailboats!

Carbon fiber masts are exceptionally lightweight, providing excellent stiffness-to-weight ratios. This allows for enhanced responsiveness, improved performance, and reduced heeling (tilting) of the boat.

Carbon fiber masts can be precisely engineered to optimize flex patterns and provide targeted strength where needed.

Traditional sailboats, particularly those with a classic or vintage design, may have masts made from wood. Wood offers an aesthetically pleasing and traditional look.

Wooden masts can be constructed using solid wood or laminated techniques, which involve layering thin strips of wood for added strength and stability. Wood masts require regular maintenance, including varnishing and sealing to protect against moisture.

In some cases, steel may be used for sailboat masts, especially in larger vessels or those designed for specific purposes, such as offshore cruising or heavy-duty applications.

Steel masts offer robustness and durability, but they are heavier compared to other materials. They require adequate corrosion protection to prevent rusting.

Composite Materials

Sailboat masts can also be constructed using composite materials, such as fiberglass or fiberglass-reinforced plastics. These materials provide a balance between cost, weight, and strength. Fiberglass masts can be an option for recreational sailboats or those on a tighter budget.

It’s worth noting that advancements in materials and manufacturing techniques continually evolve, introducing new possibilities for sailboat mast construction.

The choice of mast material should consider factors such as boat type, intended use, performance requirements, and personal preferences, balanced with considerations of cost and maintenance.

Different Types Of Masts

There are several different types of masts used in sailboat designs, each with its own characteristics and purposes.

We’ve included how the masts are fixed on the boat. This one is an important one when buying a sailboat as you might have a preference over how your mast is attached to the hull or deck.

We’ve also included different rigs, as some boats have just a single mast and other sailboats will have two or more masts. Again, you might have a preference as to which rig set up you prefer so it’s worth knowing the pros and cons of each.

Keel-stepped Mast

A keel-stepped mast is one that extends down through the deck and is secured to the boat’s keel or structural framework. Keel-stepped masts offer stability and strength, as they transfer the loads directly to the boat’s foundation.

They are commonly found in larger sailboats and offshore cruising vessels. We loved knowing our deck was secured to one of the strongest parts of the boat.

It does come with some problems though, like the fact it can leak and start raining in the boat! A decent mast boot will stop this.

Deck-stepped Mast

A deck-stepped mast rests on a step or fitting on the deck, rather than extending down through it. Deck-stepped masts are typically used in smaller sailboats and are more straightforward to install, maintain, and unstep.

They are often lighter and less expensive than keel-stepped masts but may sacrifice some stability and rigidity.

Fractional Rig

A fractional rig features a mast where the forestay is attached below the masthead, typically at a point less than halfway up the mast’s height. This design allows for a larger headsail and a smaller mainsail.

Fractional rigs are popular on modern cruising and racing sailboats as they offer versatility, easy sail control, and improved performance in various wind conditions.

Masthead Rig

In a masthead rig, the forestay attaches at the top of the masthead. This design is commonly found in traditional sailboats. Masthead rigs typically feature larger headsails and smaller mainsails. They are known for their simplicity, easy balance, and suitability for cruising and downwind sailing.

There are various different rig set ups that just have one single mast. We’ll look at a few of the most popular types, but be aware that there are quite a few variations out there these days! It can get a little complicated!

The sloop rig is one of the most popular and widely used single mast rigs. It consists of a single mast with a mainsail and a headsail. The headsail, typically a jib or genoa, is attached to the forestay at the bow of the boat, while the mainsail is attached to the mast and boom.

Sloops offer simplicity, versatility, and ease of handling, making them suitable for a wide range of sailboats, from small day-sailers to larger cruising vessels.

A cutter rig utilizes two jibs : a smaller headsail attached to the forestay and a larger headsail called a staysail attached to an inner stay or a removable stay.

The mainsail is usually smaller in a cutter rig. This rig provides versatility and options for different sail combinations, making it suitable for offshore cruising and handling various wind conditions.

We absolutely loved our cutter rig as it gave so much flexibility, especially in heavy weather. A downside is that tacking is a little harder, as you have to pull the genoa past the stay sail.

Sailboats with two masts tend to be seen on older boats, but they are still popular and quite common, especially with long-distance sailors looking for versatility.

The yawl rig features two masts, with a shorter mizzen mast positioned aft of the main mast and rudder stock. The mizzen mast is usually shorter than the main mast.

Yawls offer versatility, improved balance, and increased maneuverability, making them suitable for offshore cruising and long-distance sailing.

A ketch rig has two masts: a taller main mast located near the boat’s center and a shorter mizzen mast positioned aft of the main mast but forward of the rudder stock. The mizzen mast is typically shorter than the main mast.

Ketch rigs provide additional sail area and options for sail combinations, offering good balance and flexibility for cruising and long-distance sailing. A lot of long-term cruisers love ketch rigs, though they tend to be found on older boats.

The downside is that you’ll have two masts with accompanying rigging to maintain, which isn’t necessarily a small job.

Sailboats with three masts or more are rare. They tend to be seen only on very large, expensive sailing yachts due to the additional expense of maintaining three masts, rigging and additional sails.

They aren’t great for single-handed crews but they do look very impressive and can power bigger vessels.

Schooner Rig

A schooner rig features two or more masts, with the aft mast (known as the mizzen mast) being taller than the forward mast(s).

Schooners are known for their multiple headsails and often have a gaff-rigged or square-rigged configuration on one or both masts. Schooner rigs offer impressive sail area, versatility, and classic aesthetics.

Schooner rigs are much rarer than the rigs mentioned above so it’s unlikely you’ll find one on a cruising vessel.

These are just a few examples of the different types of masts used in sailboat designs. Each rig type has its own advantages and considerations in terms of sail control, performance, balance, and intended use.

The choice of mast and rig depends on factors such as boat size, purpose, sailing conditions, and personal preferences.

We didn’t know the first thing about looking after our mast when we first moved aboard and we made it our mission to find out. When you’re sailing frequently then the last thing you want is to experience a mast coming down mid-passage!

Taking proper care of your sailboat mast is important to ensure its longevity and optimal performance. Here are some tips on how to look after your mast:

- Regular Inspections: Conduct regular visual inspections of your mast to check for any signs of damage, wear, or corrosion. Look for cracks, dents, loose fittings, or any other issues that may compromise the mast’s integrity.

- Cleaning: Keep your mast clean by regularly washing it with fresh water. Remove dirt, salt, and other contaminants that can accelerate corrosion. Use a mild detergent or boat-specific cleaner, and rinse thoroughly.

- Corrosion Prevention: Protect your mast from corrosion by applying a suitable corrosion inhibitor or protective coating. Pay particular attention to areas where fittings, rigging, or other components come into contact with the mast.

- Lubrication: Lubricate moving parts such as sheaves, shackles, and slides with a marine-grade lubricant. This helps prevent friction and ensures smooth operation. Be cautious not to over-lubricate, as excess lubricant can attract dirt and debris.

- Rigging Maintenance: Inspect your rigging regularly for signs of wear, such as broken strands, fraying, or excessive stretching. Replace any worn or damaged rigging promptly to avoid potential mast damage.

- UV Protection: The sun’s UV rays can degrade and weaken the mast over time. Protect your mast from UV damage by applying a UV-resistant coating or using mast covers when the boat is not in use.

- Storage Considerations: If you need to store your boat for an extended period, consider removing the mast and storing it horizontally or in a mast-up position, depending on the boat design. Store the mast in a clean, dry, and well-ventilated area to prevent moisture buildup and potential damage.

- Professional Inspections: Periodically have your mast inspected by a professional rigger or boatyard to assess its condition and identify any potential issues that may require attention. They can provide expert advice on maintenance and repair.

Remember, if you are unsure about any maintenance or repair tasks, it’s always recommended to consult with a professional rigger or boatyard to ensure proper care and safety of your mast.

We learned so much from having our rigging inspected, so we highly recommend you do this if you’re at all unsure.

Conclusion: What Is A Sailboat Mast?

In conclusion, a sailboat mast is a crucial component that plays a vital role in the performance, control, and integrity of a sailboat. It’s a good idea to learn about sailboats before you head out on a sail – unlike us!

The mast serves as a vertical structure that supports the sails, allowing them to capture the power of the wind effectively. The mast enables sailors to control and manipulate the position of the sails, optimizing performance based on wind conditions.

Additionally, the mast contributes to the overall structural integrity of the boat, distributing loads and forces throughout the hull and keel. Various rigging components, such as halyards, shrouds, and spreaders, are attached to the mast, providing support and enabling precise sail control.

By understanding the importance of the mast and properly caring for it through regular inspections, cleaning, corrosion prevention, lubrication, and rigging maintenance, sailors can ensure their mast’s longevity and optimal performance.

A well-maintained sailboat mast contributes to a safe, enjoyable, and successful sailing experience.

- How much do new sails cost?

- How long do new sails last?

- Storm sails

Similar Posts

13 Best Small Catamarans For Cruising 2024

How Long Do New Sails Last?

Sailing Stories

The Best Shallow Draft Liveaboard Sailboat 2024

Can You Sail In The Rain?

12 Tips For Restoring an Old Boat: Costs, Time, And Expert Advice

- Search forums

- Practical Boat Owner's Reader to Reader

New mast cost

- Thread starter Hacker

- Start date 18 Mar 2017

- 18 Mar 2017

Well-known member

I'm considering a Moody 40 which has in-mast furling. I'd prefer to have a slab reefed version. Can anyone suggest a ball-park cost to replace the rig. I'm assuming it should include mast, boom, rigging and mainsail. I'm assuming that I will be able to reuse antennas, etc (if they are serviceable). I just want to have an idea of what the additional cost would be if I'm unable to find a slab-reefed version.

I'd suggest far far more than justifiable. Unless you were to sell the in-mast furling or swap it with a Moody 40 owner who has slab and wants in-mast. Perhaps you could fit a slab furling sail to a track riveted over the in-mast furling aperture. Use a loose footed main like the racing boys and you hardly need to modify the boom either. Whatever you do, I'd ensure it was reversible because as time creeps on I'm sure you'd find in-mast furling more and more appealing, plus it would increase the likely resale value.

Daydream believer

Instead of guess work & irrelevant replies , would it not be more accurate just to ring up a mast supplier & ask for a budget quote? A sail maker will quickly give you a price for a range of sails Guess £ 3-4 K for rigging, or ask a local rigger for a budget Then you add yard costs for haulout etc & you have a fair idea

Active member

Don't forget to allow for the fair few mast base blocks, deck organisers, and clutches you'll need to handle the additional lines that slab reefing involves as well as the cost of fitting them, which may involve headlining removal to fit backing plates etc. I very much doubt such a conversion makes any economic sense whatsoever versus putting the conversion cost into your purchasing budget and increasing to range of boats you can consider with that substantially increased budget.

Hacker said: I'm considering a Moody 40 which has in-mast furling. I'd prefer to have a slab reefed version. Can anyone suggest a ball-park cost to replace the rig. I'm assuming it should include mast, boom, rigging and mainsail. I'm assuming that I will be able to reuse antennas, etc (if they are serviceable). I just want to have an idea of what the additional cost would be if I'm unable to find a slab-reefed version. Click to expand...

pvb said: it's a big job! I'd suggest you prepare yourself for a quote in the region of £15k..... Click to expand...

dom said: ...+++++++++ IMHO Click to expand...

Agree the 315-20k estimate. For roughly a quarter of that you could have the existing system checked over and possibly minor replacements and a new high tech sail! Presumably the rig has been on the boat for the last 20 years plus, so why would it not be satisfactory? Suspect you will find the majority built will have in mast so finding one without an for sale may be a bit of a struggle.

- 19 Mar 2017

Thanks for all the replies. Helpful at many levels! I'll either need to decide that inmast is ok (been on a boat that had a major jam in heavy weather) or hold out for one that has slab reefing.

Give these chaps a ring, always very helpful http://www.allspars.co.uk/

- 20 Mar 2017

A big disadvantage of in mast is the weight up the mast. I have seen a Sadler 29 where the owner was able to remove it & he claimed a big improvement on several aspects. Is this possible with some larger masts?

Daydream believer said: A big disadvantage of in mast is the weight up the mast. I have seen a Sadler 29 where the owner was able to remove it & he claimed a big improvement on several aspects. Is this possible with some larger masts? Click to expand...

What about getting supersize slugs that work with the existing slot to convert the mast to slab? Bit of fabrication here and there could sort you. Might even be able to attach a new overlay to the existing slot to take standard slugs.

jac said: I wopuld have thought that proportionately though, it would be worse on a smaller, light displacement boat. The furling spar itself will be pretty much the same dimensions so no real differencxe and most of the weight is lower down where the sail is larger so the taller mast will only have a minimal effect. The overall weight will be more of course but set against a much bigger displacement weight and amount of ballast I would expect the larger boat to swallow it with less noticeable side effects. Click to expand...

Daydream believer said: The furling section would be much larger as it takes a much larger sail. Furthermore the furling section has to be parallel so the extra size at the bottom is carried all the way up the mast. The furling rod is much longer & has to be thicker to accept the torque over a greater length. I would also point out that at all times the sail is fully up the mast so in reefed state the sail stays in the mast. With slab reef part of the sail comes much lower down the sail. I know from experience how many crew it used to take to carry our mainsail ashore on a large boat so the weight is not insignificant I was looking at some masts in Oysters yard & I would ( from memory) suggest that the in mast reefing adds 40% extra to the weight of the mast. Those with in mast might like to confirm/deny if this is accurate or not & I would bow to their greater knowledge. However, There is a weight penalty whatever one says Click to expand...

NormanS said: Yes, I'm sure there is a weight penalty - just as there is with a furling Genoa. There seems to be general acceptance of the latter. Click to expand...

Daydream believer said: ........I was looking at some masts in Oysters yard & I would ( from memory) suggest that the in mast reefing adds 40% extra to the weight of the mast. Those with in mast might like to confirm/deny if this is accurate or not & I would bow to their greater knowledge. However, There is a weight penalty whatever one says Click to expand...

Members online

- Cymrogwyllt

- Fr J Hackett

- PabloPicasso

- houldsworth

- snowbird30ds

- WherEmEweeD

- Suffolk Explorer

- Black Diamond

- Scarboroughsloop

- jointventureII

- Disassemble

- Peterlewis321

Share this page

How Much Do New Sails Cost?

Sooner or later it needs to happen: you need to replace those precious sails. Everybody knows it's expensive, but how expensive exactly? Let's look at the data.

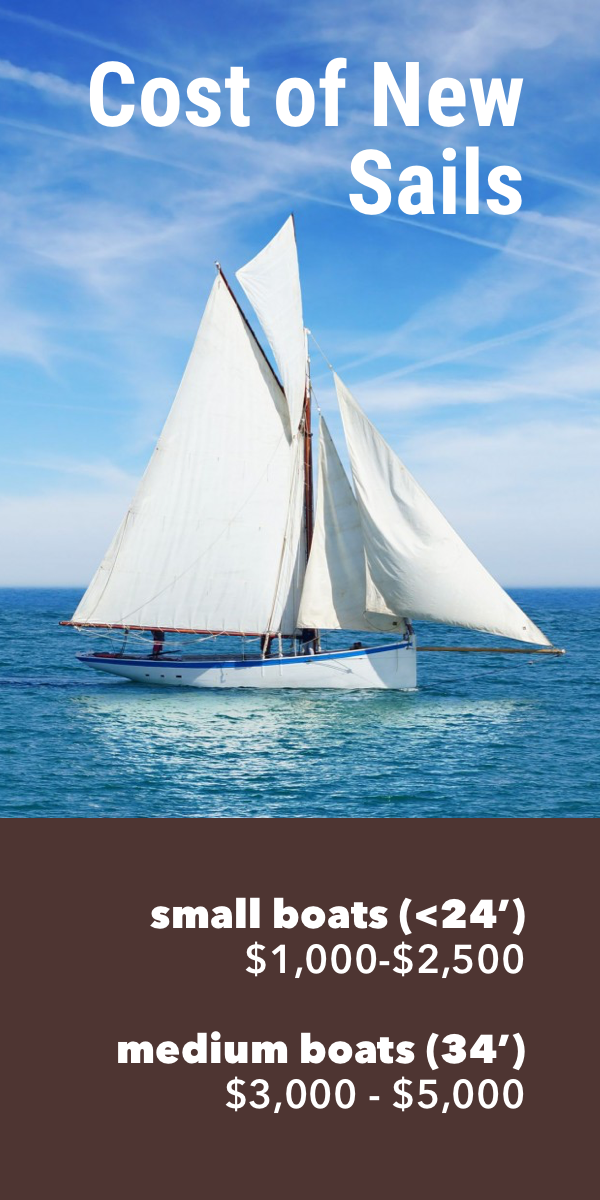

How much do sails cost? Replacing the jib and main sail on a 24' Bermuda sloop will typically cost between $1,000-$2,500. Sails on mid-sized boats (34') will generally cost between $3,000-$5,000. Prices can greatly vary depending on boat length, sail material, quality of fabric, and so on. Cost increases relative to sail area and hull length.

Of course it's a matter of 'how long is this piece of string?' - but it's not impossible to give something of an answer. It frustrated me that nobody just stated a price. So to fix the problem, I've come up with a new formula. Also, better quality doesn't always give you the best bang for your buck. Read on to find out why.

On this page:

Estimated cost for different boat lengths, how to estimate sail cost, cleaning and repairing your sails instead, factors that determine the cost of sails, when to replace sails, what material is most cost-effective, how to calculate sail cost, some sailmakers to start looking, related questions.

So I gave you a wide price range, partially because it depends on so many factors (see next heading). Let's dive more into detail here.

I've compared price quotes for 22 different sailboats and came up with the following list:

The cost of jib and main replacement

The jib and the main on a Bermuda sloop rig.

- on boats from 18' to 24' , it costs roughly $1,000 - $2,500 for the sails

- on boats from 24' to 32' , it costs roughly $2,500 - $4,000 for the sails

- on boats from 32' to 36' , it costs roughly $3,000 - $5,000 for the sails

- on boats from 36' to 42' , it costs roughly $4,000 - $7,000 for the sails

- on boats from 42' to 50' , it costs roughly $5,500 - $9,000 for the sails

The cost of main sail replacement

Only the main on a Bermuda sloop rig.

- on boats from 18' to 24' , replacing the main costs between $650 - $1,200

- on boats from 24' to 32' , replacing the main costs between $1,000 - $1,500

- on boats from 32' to 36' , replacing the main costs between $1,500 - $2,500

- on boats from 36' to 42' , replacing the main costs between $2,000 - $3,000

- on boats from 42' to 50' , replacing the main costs between $2,500 - $4,000

Please note: These are ballpark figures for basic sails. If you want to calculate the cost more precisely, read on. Or get a quote from a professional! Most sailmakers are eager to help you out (and of course to get you as a customer). The quotes by premium companies tend to be on the higher side.

Interested in the total average cost of owning & buying a sailboat? You got it! I've compared thousands of sailboat prices and the recurring costs in my in-depth article the Average Cost of Buying & Owning a Sailboat (With 4 Examples ) (new tab)

First we have to estimate the sail area.

To quickly estimate the sail area for different boat lengths, multiply the hull length (in ft) with the following ratio (I've made up):

For example, a boat of 24' will have total sail area of approximately 360 ft2.

Of course this is a very rough estimation, and you should definitely measure your sails, but for a quick cost estimation it will do.

The surface factor will only work with a standard Bermuda sloop rig, using a 100% jib and regular main.

The price of sail cloth per square foot:

You want to get the current sail cloth price per square foot. To do this, simply get a price quote for two or three different sail areas, and divide the total cost by the surface area.

I've done it with 22 quotes on January 4th, 2019:

- On average, basic Dacron sail cloth costs about $6-$7 per square foot

- This is the price per square foot for the finished sail

- It's a basic inland sail, with 2 reefs, of regular weight

- It doesn't take into account any special orders (numbering, logos, and so on)

Let's say you have a 35' sloop and want to have a quick indication of the cost of replacing the jib and main sail.

Simply multiply the boat length by the surface factor by the price of sail cloth.

35' x 18 x $6.5 = $4,095

If these numbers surprise you, there's always an alternative. It can be a great idea to clean and repair your sails instead of immediately replacing them. Especially if you're an inland cruiser.

It's an idea worth considering. You can hire professionals to do it for you at 1/10 of the cost of new sails. Not bad if they can last you another 5 years or so.

I've included the sail repair company at the end of the post in my list of sailmakers.

Repairing your own sails

For large areas: If you have sewing experience (or are willing to gain it), you could very well repair your own sails. You need special heavy-duty needles and a leather sewing palm.

- If you want to give it a go, I recommend you to get this starter kit (click to check current price on Amazon ).

- You will also need some repair patches . Regular sails are mostly made of Dacron. I was very surprised at the great price of these Dacron repair strips (click to check current price on Amazon ).

This is the way to go for larger areas.

For smaller areas , you have another option. If you're not that great at sewing or don't have the patience, simply get some sail repair tape instead. It works, but it is a temporary solution at best, in my opinion.

- Check out this easy to use, heavy duty sail repair tape (link to Amazon ).

I've also noticed that you can order sails now on Amazon (crazy world). They seem to have jibs and genoas for the most popular sailboat models (Hunters, Catalinas, and so on) at a competitive price. So I definitely recommend shopping around for the best price.

There are many factors that determine the actual cost. The most important two are sail area and sail quality.

Sail area is largely determined by boat length.

Let's say there are three sail qualities available: budget sails (motor skipper), mid-priced cruising sails (about right), and performance racing sails (money is no objection).

Other factors that determine cost:

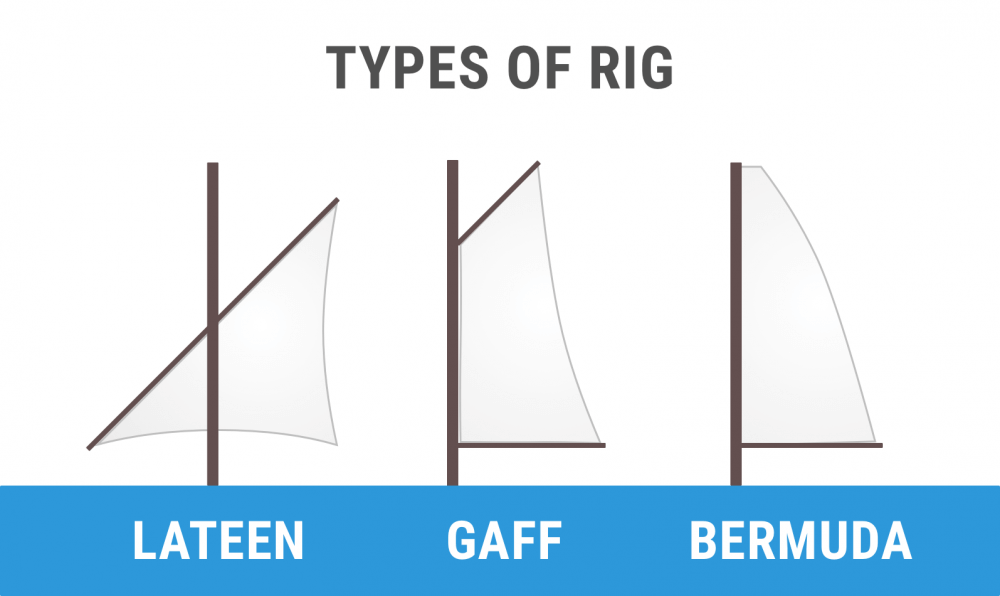

- sail quality - weight of the fabric ranging from 5.10 - 10.88oz

- rig type - ie. gaff or bermuda; roller furling or hank on

- amount of sails

- sail type - inshore or offshore; cruising or racing

Sail area is literally the amount of fabric needed for your particular boat. In general, longer boats need bigger sails. But if you use a genoa instead of a regular jib, you also require more sail cloth.

Sail quality consist of the materials used, tightness of the weave, and overall quality of the finish.

By saving on the sail quality you make sure you need to replace it sooner. This can really add up over time, if you plan on keeping your boat for half a lifetime (not everybody does, and that's fine too).

Rig type determines what kind of designs you can use. For example, a gaff rig needs a quadrilateral sail, which generally increases sail area.

If you want to see the different rig types in one overview, check out my Guide on Rig Types (new tab ) - with a great infographic !

The cost increases quite a bit if you get a roller furling main and jib.

It's easy to imagine why the amount of sails affects the total cost of replacing the sails. For most standard keelboats, the rigging consists of a main and jib, so that's what I'll use as an example here.

The sail type overlaps with sail quality. The major distinction here is inshore vs. offshore. Offshore sails are of higher quality than inshore sails. For example, inshore sails don't have reinforced clew patches, less stitching, or no double tapes. The reason is that inshore sails will probably have to deal with lighter winds.

Race sails can be more expensive than cruising sails - but the biggest cause is that they aren't made to last. Cruising sails can last you up to 10-15 years, so I'd prefer them over a budget or racing sail any day of the week.

If you want to learn the names of all the different sails, I highly encourage you to check out my Guide on Sails and Rig Types (new tab ) with lots of photos here!

When do you need to replace sails? On average, sails need replacing every 5-10 years, depending on quality of the fabric and the amount of sailing. Most people replace their sails every 7 years. You can recognize worn-out sails be excessive flapping, disintegrating stitching, and wrinkles behind the luff when on a beam reach.

The most important reasons for sail wear are:

- exposure to UV (by far the most damaging)

- flogging of sails in the wind

To make sure your sails wear as little as possible, get a good sail cover , and use it. It extends the lifespan of your sails with years, and is way cheaper than replacing them.

You can get well-priced, simple mainsail covers for most standard sizes. I recommend checking out these generic covers at Amazon .

You should definitely replace your sails if you're leaving for an ocean passage or any kind of long voyage, a race - or when they're flapping almost all the time, at all angles and with all wind speeds.

Why does it matter to replace your sails? Decent sails help you to love your boat. Bad sails will help you to hate your boat and sailing in general. Your boat will be lighter and easier to handle. Some say you gain about 1 knot speed-wise - I'm not sure but you'll definitely be faster. It becomes easier to maneuver. You'll be able to sail in much lighter air.

The list goes on. New sails really pay off.

The difference in performance is just unimaginable. If you've sailed with old sails until now, and are planning to get a new boat, maybe just consider replacing the sails.

In recent years, sail materials have developed a lot. From the 1980s onwards, nearly all sails were made from Dacron (woven polyester). In recent years, more and more sails are being made of laminated fabrics and woven nylon.

In professional racing, carbon sails are becoming increasingly popular. Carbon is the highest performing yarn currently available. Its biggest advantage is that it doesn't react to UV exposure, the number one sail killer.

In comparison, Dacron sail can withstand about 6 months of UV.

Also in comparison, Carbon is about 10-15 times more expensive than Dacron.

Some say investing in carbon sails is the way to go, but they are so expensive that they are not cost-efficient at the moment - not yet.

So let's say you replace your current Dacron sails every 7 years, and you decide to buy Carbon sails today.

It would take you 70-100 years to earn back your initial investment.

Carbon is, in a way, the Lithium-Ion of sails.

In my opinion, the best sail material for cruising is Dacron

The most cost-effective sail material is still Dacron. Although carbon sails have many advantages, they are very expensive. Dacron has a decent life span, holds its shape well, and is lightweight and reasonably priced. But it's mostly because it's so inexpensive compared to carbon yarn.

If you want to know everything there is to know about the cost-effectiveness of different sail cloths, check out this study here .

Fabric weight and cost

Heavier fabric tends to be a bit more expensive, but this is offset by the fact that smaller sails get more expensive because of the overhead cost.

So larger sails use heavier fabric, which is more expensive. Smaller sails are more expensive to stitch, attach all the hardware to, and so on.

If you're unsure about the fabric weight, here is the average fabric weight used per boat length:

- boats under 20' tend to use 5.10oz

- boats from 20' to 22' tend to use 6.18oz

- boats from 23' to 27' tend to use 7.18oz

- boats from 28' to 38' tend to use 8.18oz

- boats from 38' to 44' tend to use 9.18oz

- boats from 45' to 50' tend to use 10.18oz

- boats over 50' tend to use 10.88oz

The price of a sail is calculated by first calculating the sail area. The official way to do this is by getting out your calculator and typing in the following formulas:

Calculating Mainsail Area:

Mainsail area = P x E / 1.8 where: P = Luff length E = Foot length

Calculating Headsail Area:

Headsail area = I x J / 1.8 where: I = Mast length J = Luff to headstay

Let's calculate the sail area of something real quick. Here are the rig dimensions of a 22' Abbott:

For the mainsail , I use P (luff length) and E (foot length).