No products in the cart.

Sailing Ellidah is supported by our readers. Buying through our links may earn us an affiliate commission at no extra cost to you.

The Running Rigging On A Sailboat Explained

The running rigging on a sailboat consists of all the lines used to hoist, lower, and control the sails and sailing equipment. These lines usually have different colors and patterns to easily identify their function and location on the vessel.

Looking at the spaghetti of lines with different colors and patterns might get your head spinning. But don’t worry, it is actually pretty simple. Each line on a sailboat has a function, and you’ll often find labels describing them in the cockpit and on the mast.

In this guide, I’ll walk you through the functions of every component of the running rigging. We’ll also look at the hardware we use to operate it and get up to speed on some of the terminology.

The difference between standing rigging and running rigging

Sometimes things can get confusing as some of our nautical terms are used for multiple items depending on the context. Let me clarify just briefly:

The rig or rigging on a sailboat is a common term for two parts, the standing , and the running rigging.

- The standing rigging consists of wires supporting the mast on a sailboat and reinforcing the spars from the force of the sails when sailing. Check out my guide on standing rigging here!

- The running rigging consists of the halyards, sheets, and lines we use to hoist, lower, operate and control the sails on a sailboat which we will explore in this guide.

The components of the running rigging

Knowing the running rigging is an essential part of sailing, whether you are sailing a cruising boat or crewing on a large yacht. Different types of sailing vessels have different amounts of running rigging.

For example, a sloop rig has fewer lines than a ketch, which has multiple masts and requires a separate halyard, outhaul, and sheet for its mizzen sail. Similarly, a cutter rig needs another halyard and extra sheets for its additional headsail.

You can dive deeper and read more about Sloop rigs, Ketch Rigs, Cutter rigs, and many others here .

Take a look at this sailboat rigging diagram:

Lines are a type of rope with a smooth surface that works well on winches found on sailboats. They come in various styles and sizes and have different stretch capabilities.

Dyneema and other synthetic fibers have ultra-high tensile strength and low stretch. These high-performance lines last a long time, and I highly recommend them as a cruiser using them for my halyards.

A halyard is a line used to raise and lower the sail. It runs from the head of the sail to the masthead through a block and continues down to the deck. Running the halyard back to the cockpit is common, but many prefer to leave it on the mast.

Fun fact: Old traditional sailboats sometimes used a stainless steel wire attached to the head of the sail instead of a line!

Jib, Genoa, and Staysail Halyards

The halyard for the headsail is run through a block in front of the masthead. If your boat has a staysail, it needs a separate halyard. These lines are primarily untouched on vessels with a furling system except when you pack the sail away or back up. Commonly referred to as the jib halyard.

Spinnaker Halyard

A spinnaker halyard is basically the same as the main halyard but used to hoist and lower the spinnaker, gennaker, or parasailor.

The spinnaker halyard is also excellent for climbing up the front of the mast, hoisting the dinghy on deck, lifting the outboard, and many other things.

A sheet is a line you use to control and trim a sail to the angle of the wind . The mainsheet controls the angle of the mainsail and is attached between the boom and the mainsheet traveler . The two headsail sheets are connected to the sail’s clew (lower aft corner) and run back to each side of the cockpit.

These are control lines used to adjust the angle and tension of the sail. It is also the line used to unfurl a headsail on a furling system. Depending on what sail you are referring to, this can be the Genoa sheet , the Jib sheet , the Gennaker sheet , etc.

The outhaul is a line attached to the clew of the mainsail and used to adjust the foot tension. It works runs from the mainsail clew to the end of the boom and back to the mast. In many cases, back to the cockpit. On a boat with in-mast furling , this is the line you use to pull the sail out of the mast.

Topping lift

The topping lift is a line attached to the boom’s end and runs through the masthead and down to the deck or cockpit. It lifts and holds the boom and functions well as a spare main halyard. Some types of sailboat rigging don’t use a topping lift for their boom but a boom vang instead. Others have both!

Topping lifts can also be used to lift other spars.

A downhaul is a line used to lower with and typically used to haul the mainsail down when reefing and lowering the spinnaker and whisker poles. The downhaul can also control the tack of an asymmetrical spinnaker, gennaker, or parasailor.

Tweaker and Barber Haul

A tweaker is a line, often elastic, attached to the sheet of a headsail and used to fine-tune the tension on the sheet.

Barber haul

A barber haul is a line attached to a headsail’s sheet to adjust the sheeting angle to the wind. It is often used to pull the clew further toward the center or outboard than the cars allow.

Boom Preventer

A boom preventer is a line attached to the boom’s end when sailing off the wind. Its function is to hold the spar in place and prevent it from swinging wildly.

If the boat were to get an accidental gybe, it could cause serious damage to the rigging or even harm people on board. It is important for the rigger to be cautious when setting up the boom preventer.

Running Backstay

Running backstays is similar to a normal backstay but uses a line instead of a hydraulic tensioner. Some rigs have additional check stays or runners as well.

Bonus tip: Reefing

The term reefing is used when reducing the effective sailing area exposed to the wind of a given sail. Headsails are usually reefed by partially furling them in, and they often have marks for what we refer to as 1st, 2nd, and 3rd reefs.

The mainsail is reefed similarly with an in-mast furling or in-boom furling system.

On a traditional mast, we use a system called slab reefing. The system has reefing lines running through the boom to reinforced points on the luff and leech, allowing you to pull the sail down to the boom and effectively reduce the sail area.

Having at least two reefing points in the mainsail is normal, but most cruising sailboats have 3. The 3rd is used for the heaviest conditions, giving you only a tiny bit of sail area exposed to the wind.

You want to reef your sails before the wind increases to a point where your boat gets overpowered.

It is essential to practice your reefing technique . You will find yourself in situations with rapidly increasing winds where you need to reduce your sails quickly.

Rule of thumb: If you think setting a reef might be a good idea, do it.

Shaking a reef is the term used when we sail with a reefed sail and want to increase the sail area back to full.

Hardware used for sail handling and the running rigging

Furling system.

Most sailboats have their headsail on a furling system. A furling system is a tube that runs along the forestay from the bottom furler drum to the masthead swivel.

This system allows you to roll the headsail around the forestay, making furling the sail in and out accessible. It is also convenient when reefing the sail when the wind picks up, as you can easily do this from the safety of the cockpit. These furling systems come in manual versions and electric versions.

In-mast furling

In-mast furling is a system that rolls the mainsail in and out of the mast. To unfurl the mainsail, we use the outhaul .

In-boom furling

In-boom furling is a system that rolls the mainsail in and out of the boom. This system has been costly and has mostly been seen on big yachts earlier. They are becoming more affordable and common on smaller boats, though. To unfurl this setup, we use the main halyard.

A Stack pack is also called a Lazy Bag or Lazy Pack. It is a bag with a zip attached to the boom where the mainsail is stored when unused. It protects the mainsail from UV rays from the sun and weather elements. It is a very nice and tidy way to store the mainsail and reefing lines if you don’t have in-mast or in-boom furling.

Lazy Jacks is a system of lines running from the stack pack to the mast. The Lazy Jacks guide the mainsail up and down from the Stack Pack and prevent it from falling down on the deck. It is also possible to rig Lazy Jacks without a Stack Pack.

A block is a pulley with a sheave wheel. Blocks are used to change the direction of a pull on a line or rope and give a mechanical advantage. They have many uses, especially onboard sailboats.

A winch is a metal drum that gives you a mechanical advantage to control and tighten lines. These can be operated by turning a rope around it and pulling manually or by a winch handle to get more force. Most modern winches are self-tailing, which means they lock the line on so you can winch the line without holding on to it. Some boats even have electrical winches operated by a button.

Mainsheet Traveler

The mainsheet traveler is a horizontal track that the mainsheet is attached to through a series of blocks. The traveler enables you to adjust and lock the boom at an angle and also plays a critical part in trimming the mainsail.

Most cruising sailboats have their traveler attached to the top of the coachroof in front of the spray hood. A racing boat typically has the traveler in the cockpit near the helm to give the helmsman better control over the mainsheet.

The cars are basically a pulley or block attached to a track on the port and starboard deck that your headsail sheets run through. Cars are used to control the angle of the sheet between the clew and the deck. The cars are handy when you trim the sail to set the right balance of tension between the foot and leech, depending on your point of sail.

The jammer is used to lock a line in place. Most sailboats use these for locking the halyards, mainsheet, outhaul, reef lines, traveler lines, boom vang lines, etc. You can pull or winch a line through a closed jammer, but it won’t run away if you let go of it unless you open the lock.

As I explained earlier, it is normal to have most or all of the lines led back to the cockpit, and they are usually run through a series of jammers.

The jammers are often labeled with the name of the line it locks, which makes it easier to remember which line goes where.

Spinnaker Pole

A spinnaker pole is a spar used to wing out a headsail when sailing off the wind, particularly the spinnaker. The spinnaker pole should have the same length as the distance between the mast and the forestay measured along the deck. We use a fore and aft guy and the pole’s topping lift to rig a pole correctly.

The rigging varies depending on the layout of the boat, but it usually looks like this:

- One line runs from the bow to the end of the pole.

- An aft line runs from near the stern to the end of the pole.

- A topping lift is used to raise and lower the pole.

Whisker Pole

A whisker pole is similar to the spinnaker pole and is rigged similarly. It is typically built lighter and attached to a track on the mast. These can be found in fixed lengths or adjustable lengths. Ideally, the length should be the same as the foot of the headsail you intend to pole out.

Boom Vang/Rod Kicker

The Boom Vang has a few different names. Rod-kicker, kicking strap, or kicker. It is used to tension the boom downwards. When you are sailing downwind and have the boom far out, the mainsheet won’t pull the boom down as much as inboard, and you can then use the vang to adjust the twist and shape of the mainsail.

Mooring line

A mooring line is a traditional rope lead through a fairlead to the vessel’s cleat and a mooring buoy, key, or pontoon.

Final words

Congratulations! By now, you should have a much better understanding of how the running rig on a sailboat functions. We’ve covered the different lines, their purpose, and the hardware used to operate them. I hope you’ve enjoyed this guide and learned something new.

Now it’s time to take what you’ve learned and put it into practice by getting out on the water, setting sail, and getting hands-on experience with the lines.

Or you can continue to my following guide and learn more about the different types of sails .

Sharing is caring!

Skipper, Electrician and ROV Pilot

Robin is the founder and owner of Sailing Ellidah and has been living on his sailboat since 2019. He is currently on a journey to sail around the world and is passionate about writing his story and helpful content to inspire others who share his interest in sailing.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Beginner’s Guide: How To Rig A Sailboat – Step By Step Tutorial

Alex Morgan

Rigging a sailboat is a crucial process that ensures the proper setup and functioning of a sailboat’s various components. Understanding the process and components involved in rigging is essential for any sailor or boat enthusiast. In this article, we will provide a comprehensive guide on how to rig a sailboat.

Introduction to Rigging a Sailboat

Rigging a sailboat refers to the process of setting up the components that enable the sailboat to navigate through the water using wind power. This includes assembling and positioning various parts such as the mast, boom, standing rigging, running rigging, and sails.

Understanding the Components of a Sailboat Rigging

Before diving into the rigging process, it is important to have a good understanding of the key components involved. These components include:

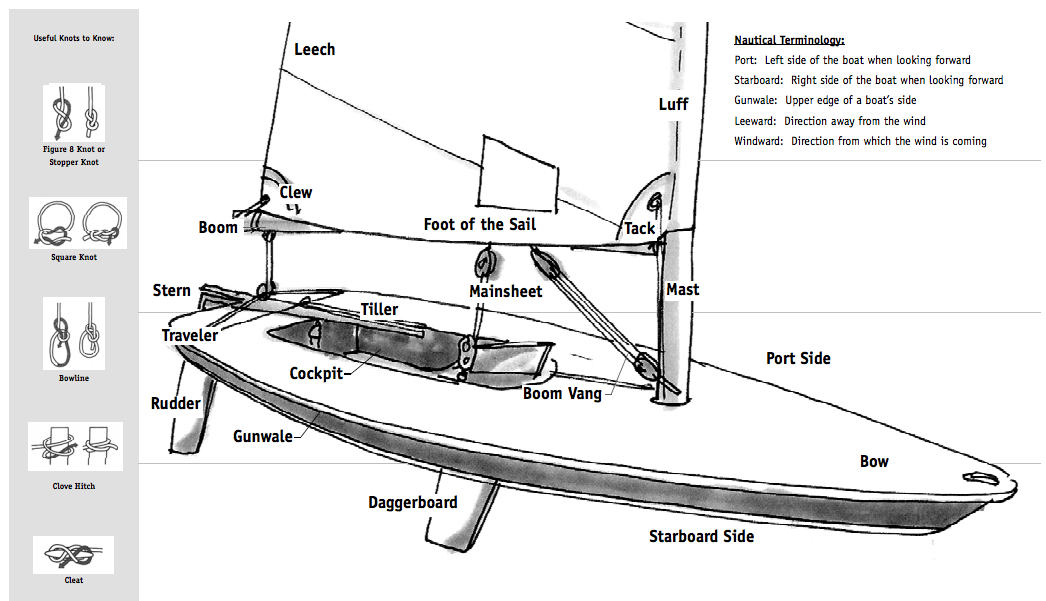

The mast is the tall vertical spar that provides vertical support to the sails and holds them in place.

The boom is the horizontal spar that runs along the bottom edge of the sail and helps control the shape and position of the sail.

- Standing Rigging:

Standing rigging consists of the wires and cables that support and stabilize the mast, keeping it upright.

- Running Rigging:

Running rigging refers to the lines and ropes used to control the sails, such as halyards, sheets, and control lines.

Preparing to Rig a Sailboat

Before rigging a sailboat, there are a few important steps to take. These include:

- Checking the Weather Conditions:

It is crucial to assess the weather conditions before rigging a sailboat. Unfavorable weather, such as high winds or storms, can make rigging unsafe.

- Gathering the Necessary Tools and Equipment:

Make sure to have all the necessary tools and equipment readily available before starting the rigging process. This may include wrenches, hammers, tape, and other common tools.

- Inspecting the Rigging Components:

In the upcoming sections of this article, we will provide a step-by-step guide on how to rig a sailboat, as well as important safety considerations and tips to keep in mind. By following these guidelines, you will be able to rig your sailboat correctly and safely, allowing for a smooth and enjoyable sailing experience.

Key takeaway:

- Rigging a sailboat maximizes efficiency: Proper rigging allows for optimized sailing performance, ensuring the boat moves smoothly through the water.

- Understanding sailboat rigging components: Familiarity with the various parts of a sailboat rigging, such as the mast, boom, and standing and running riggings, is essential for effective rigging setup.

- Importance of safety in sailboat rigging: Ensuring safety is crucial during the rigging process, including wearing a personal flotation device, securing loose ends and lines, and being mindful of overhead power lines.

Get ready to set sail and dive into the fascinating world of sailboat rigging! We’ll embark on a journey to understand the various components that make up a sailboat’s rigging. From the majestic mast to the nimble boom , and the intricate standing rigging to the dynamic running rigging , we’ll explore the crucial elements that ensure smooth sailing. Not forgetting the magnificent sail, which catches the wind and propels us forward. So grab your sea legs and let’s uncover the secrets of sailboat rigging together.

Understanding the mast is crucial when rigging a sailboat. Here are the key components and steps to consider:

1. The mast supports the sails and rigging of the sailboat. It is made of aluminum or carbon fiber .

2. Before stepping the mast , ensure that the area is clear and the boat is stable. Have all necessary tools and equipment ready.

3. Inspect the mast for damage or wear. Check for corrosion , loose fittings , and cracks . Address any issues before proceeding.

4. To step the mast , carefully lift it into an upright position and insert the base into the mast step on the deck of the sailboat.

5. Secure the mast using the appropriate rigging and fasteners . Attach the standing rigging , such as shrouds and stays , to the mast and the boat’s hull .

Fact: The mast of a sailboat is designed to withstand wind resistance and the tension of the rigging for stability and safe sailing.

The boom is an essential part of sailboat rigging. It is a horizontal spar that stretches from the mast to the aft of the boat. Constructed with durable yet lightweight materials like aluminum or carbon fiber, the boom provides crucial support and has control over the shape and position of the sail. It is connected to the mast through a boom gooseneck , allowing it to pivot. One end of the boom is attached to the mainsail, while the other end is equipped with a boom vang or kicker, which manages the tension and angle of the boom. When the sail is raised, the boom is also lifted and positioned horizontally by using the topping lift or lazy jacks.

An incident serves as a warning that emphasizes the significance of properly securing the boom. In strong winds, an improperly fastened boom swung across the deck, resulting in damage to the boat and creating a safety hazard. This incident highlights the importance of correctly installing and securely fastening all rigging components, including the boom, to prevent accidents and damage.

3. Standing Rigging

When rigging a sailboat, the standing rigging plays a vital role in providing stability and support to the mast . It consists of several key components, including the mast itself, along with the shrouds , forestay , backstay , and intermediate shrouds .

The mast, a vertical pole , acts as the primary support structure for the sails and the standing rigging. Connected to the top of the mast are the shrouds , which are cables or wires that extend to the sides of the boat, providing essential lateral support .

The forestay is another vital piece of the standing rigging. It is a cable or wire that runs from the top of the mast to the bow of the boat, ensuring forward support . Similarly, the backstay , also a cable or wire, runs from the mast’s top to the stern of the boat, providing important backward support .

To further enhance the rig’s stability , intermediate shrouds are installed. These additional cables or wires are positioned between the main shrouds, as well as the forestay or backstay. They offer extra support , strengthening the standing rigging system.

Regular inspections of the standing rigging are essential to detect any signs of wear, such as fraying or corrosion . It is crucial to ensure that all connections within the rig are tight and secure, to uphold its integrity. Should any issues be identified, immediate attention must be given to prevent accidents or damage to the boat. Prioritizing safety is of utmost importance when rigging a sailboat, thereby necessitating proper maintenance of the standing rigging. This ensures a safe and enjoyable sailing experience.

Note: <p> tags have been kept intact.

4. Running Rigging

Running Rigging

When rigging a sailboat, the running rigging is essential for controlling the sails and adjusting their position. It is important to consider several aspects when dealing with the running rigging.

1. Choose the right rope: The running rigging typically consists of ropes with varying properties such as strength, stretch, and durability. Weather conditions and sailboat size should be considered when selecting the appropriate rope.

2. Inspect and maintain the running rigging: Regularly check for signs of wear, fraying, or damage. To ensure safety and efficiency, replace worn-out ropes.

3. Learn essential knot tying techniques: Having knowledge of knots like the bowline, cleat hitch, and reef knot is crucial for securing the running rigging and adjusting sails.

4. Understand different controls: The running rigging includes controls such as halyards, sheets, and control lines. Familiarize yourself with their functions and proper usage to effectively control sail position and tension.

5. Practice proper sail trimming: Adjusting the tension of the running rigging significantly affects sailboat performance. Mastering sail trimming techniques will help optimize sail shape and maximize speed.

By considering these factors and mastering running rigging techniques, you can enhance your sailing experience and ensure the safe operation of your sailboat.

The sail is the central component of sailboat rigging as it effectively harnesses the power of the wind to propel the boat.

When considering the sail, there are several key aspects to keep in mind:

– Material: Sails are typically constructed from durable and lightweight materials such as Dacron or polyester. These materials provide strength and resistance to various weather conditions.

– Shape: The shape of the sail plays a critical role in its overall performance. A well-shaped sail should have a smooth and aerodynamic profile, which allows for maximum efficiency in capturing wind power.

– Size: The size of the sail is determined by its sail area, which is measured in square feet or square meters. Larger sails have the ability to generate more power, but they require greater skill and experience to handle effectively.

– Reefing: Reefing is the process of reducing the sail’s size to adapt to strong winds. Sails equipped with reefing points allow sailors to decrease the sail area, providing better control in challenging weather conditions.

– Types: There are various types of sails, each specifically designed for different purposes. Common sail types include mainsails, jibs, genoas, spinnakers, and storm sails. Each type possesses its own unique characteristics and is utilized under specific wind conditions.

Understanding the sail and its characteristics is vital for sailors, as it directly influences the boat’s speed, maneuverability, and overall safety on the water.

Getting ready to rig a sailboat requires careful preparation and attention to detail. In this section, we’ll dive into the essential steps you need to take before setting sail. From checking the weather conditions to gathering the necessary tools and equipment, and inspecting the rigging components, we’ll ensure that you’re fully equipped to navigate the open waters with confidence. So, let’s get started on our journey to successfully rigging a sailboat!

1. Checking the Weather Conditions

Checking the weather conditions is crucial before rigging a sailboat for a safe and enjoyable sailing experience. Monitoring the wind speed is important in order to assess the ideal sailing conditions . By checking the wind speed forecast , you can determine if the wind is strong or light . Strong winds can make sailboat control difficult, while very light winds can result in slow progress.

Another important factor to consider is the wind direction . Assessing the wind direction is crucial for route planning and sail adjustment. Favorable wind direction helps propel the sailboat efficiently, making your sailing experience more enjoyable.

In addition to wind speed and direction, it is also important to consider weather patterns . Keep an eye out for impending storms or heavy rain. It is best to avoid sailing in severe weather conditions that may pose a safety risk. Safety should always be a top priority when venturing out on a sailboat.

Another aspect to consider is visibility . Ensure good visibility by checking for fog, haze, or any other conditions that may hinder navigation. Clear visibility is important for being aware of other boats and potential obstacles that may come your way.

Be aware of the local conditions . Take into account factors such as sea breezes, coastal influences, or tidal currents. These local factors greatly affect sailboat performance and safety. By considering all of these elements, you can have a successful and enjoyable sailing experience.

Here’s a true story to emphasize the importance of checking the weather conditions. One sunny afternoon, a group of friends decided to go sailing. Before heading out, they took the time to check the weather conditions. They noticed that the wind speed was expected to be around 10 knots, which was perfect for their sailboat. The wind direction was coming from the northwest, allowing for a pleasant upwind journey. With clear visibility and no approaching storms, they set out confidently, enjoying a smooth and exhilarating sail. This positive experience was made possible by their careful attention to checking the weather conditions beforehand.

2. Gathering the Necessary Tools and Equipment

To efficiently gather all of the necessary tools and equipment for rigging a sailboat, follow these simple steps:

- First and foremost, carefully inspect your toolbox to ensure that you have all of the basic tools such as wrenches, screwdrivers, and pliers.

- Make sure to check if you have a tape measure or ruler available as they are essential for precise measurements of ropes or cables.

- Don’t forget to include a sharp knife or rope cutter in your arsenal as they will come in handy for cutting ropes or cables to the desired lengths.

- Gather all the required rigging hardware including shackles, pulleys, cleats, and turnbuckles.

- It is always prudent to check for spare ropes or cables in case replacements are needed during the rigging process.

- If needed, consider having a sailing knife or marlinspike tool for splicing ropes or cables.

- For rigging a larger sailboat, it is crucial to have a mast crane or hoist to assist with stepping the mast.

- Ensure that you have a ladder or some other means of reaching higher parts of the sailboat, such as the top of the mast.

Once, during the preparation of rigging my sailboat, I had a moment of realization when I discovered that I had forgotten to bring a screwdriver . This unfortunate predicament occurred while I was in a remote location with no nearby stores. Being resourceful, I improvised by utilizing a multipurpose tool with a small knife blade, which served as a makeshift screwdriver. Although it was not the ideal solution, it allowed me to accomplish the task. Since that incident, I have learned the importance of double-checking my toolbox before commencing any rigging endeavor. This practice ensures that I have all of the necessary tools and equipment, preventing any unexpected surprises along the way.

3. Inspecting the Rigging Components

Inspecting the rigging components is essential for rigging a sailboat safely. Here is a step-by-step guide on inspecting the rigging components:

1. Visually inspect the mast, boom, and standing rigging for damage, such as corrosion, cracks, or loose fittings.

2. Check the tension of the standing rigging using a tension gauge. It should be within the recommended range from the manufacturer.

3. Examine the turnbuckles, clevis pins, and shackles for wear or deformation. Replace any damaged or worn-out hardware.

4. Inspect the running rigging, including halyards and sheets, for fraying, signs of wear, or weak spots. Replace any worn-out lines.

5. Check the sail for tears, wear, or missing hardware such as grommets or luff tape.

6. Pay attention to the connections between the standing rigging and the mast. Ensure secure connections without any loose or missing cotter pins or rigging screws.

7. Inspect all fittings, such as mast steps, spreader brackets, and tangs, to ensure they are securely fastened and in good condition.

8. Conduct a sea trial to assess the rigging’s performance and make necessary adjustments.

Regularly inspecting the rigging components is crucial for maintaining the sailboat’s rigging system’s integrity, ensuring safe sailing conditions, and preventing accidents or failures at sea.

Once, I went sailing on a friend’s boat without inspecting the rigging components beforehand. While at sea, a sudden gust of wind caused one of the shrouds to snap. Fortunately, no one was hurt, but we had to cut the sail loose and carefully return to the marina. This incident taught me the importance of inspecting the rigging components before sailing to avoid unforeseen dangers.

Step-by-Step Guide on How to Rig a Sailboat

Get ready to set sail with our step-by-step guide on rigging a sailboat ! We’ll take you through the process from start to finish, covering everything from stepping the mast to setting up the running rigging . Learn the essential techniques and tips for each sub-section, including attaching the standing rigging and installing the boom and sails . Whether you’re a seasoned sailor or a beginner, this guide will have you ready to navigate the open waters with confidence .

1. Stepping the Mast

To step the mast of a sailboat, follow these steps:

1. Prepare the mast: Position the mast near the base of the boat.

2. Attach the base plate: Securely fasten the base plate to the designated area on the boat.

3. Insert the mast step: Lower the mast step into the base plate and align it with the holes or slots.

4. Secure the mast step: Use fastening screws or bolts to fix the mast step in place.

5. Raise the mast: Lift the mast upright with the help of one or more crew members.

6. Align the mast: Adjust the mast so that it is straight and aligned with the boat’s centerline.

7. Attach the shrouds: Connect the shrouds to the upper section of the mast, ensuring proper tension.

8. Secure the forestay: Attach the forestay to the bow of the boat, ensuring it is securely fastened.

9. Final adjustments: Check the tension of the shrouds and forestay, making any necessary rigging adjustments.

Following these steps ensures that the mast is properly stepped and securely in place, allowing for a safe and efficient rigging process. Always prioritize safety precautions and follow manufacturer guidelines for your specific sailboat model.

2. Attaching the Standing Rigging

To attach the standing rigging on a sailboat, commence by preparing the essential tools and equipment, including wire cutters, crimping tools, and turnbuckles.

Next, carefully inspect the standing rigging components for any indications of wear or damage.

After inspection, fasten the bottom ends of the shrouds and stays to the chainplates on the deck.

Then, securely affix the top ends of the shrouds and stays to the mast using adjustable turnbuckles .

To ensure proper tension, adjust the turnbuckles accordingly until the mast is upright and centered.

Utilize a tension gauge to measure the tension in the standing rigging, aiming for around 15-20% of the breaking strength of the rigging wire.

Double-check all connections and fittings to verify their security and proper tightness.

It is crucial to regularly inspect the standing rigging for any signs of wear or fatigue and make any necessary adjustments or replacements.

By diligently following these steps, you can effectively attach the standing rigging on your sailboat, ensuring its stability and safety while on the water.

3. Installing the Boom and Sails

To successfully complete the installation of the boom and sails on a sailboat, follow these steps:

1. Begin by securely attaching the boom to the mast. Slide it into the gooseneck fitting and ensure it is firmly fastened using a boom vang or another appropriate mechanism.

2. Next, attach the main sail to the boom. Slide the luff of the sail into the mast track and securely fix it in place using sail slides or cars.

3. Connect the mainsheet to the boom. One end should be attached to the boom while the other end is connected to a block or cleat on the boat.

4. Proceed to attach the jib or genoa. Make sure to securely attach the hanks or furler line to the forestay to ensure stability.

5. Connect the jib sheets. One end of each jib sheet should be attached to the clew of the jib or genoa, while the other end is connected to a block or winch on the boat.

6. Before setting sail, it is essential to thoroughly inspect all lines and connections. Ensure that they are properly tensioned and that all connections are securely fastened.

During my own experience of installing the boom and sails on my sailboat, I unexpectedly encountered a strong gust of wind. As a result, the boom began swinging uncontrollably, requiring me to quickly secure it to prevent any damage. This particular incident served as a vital reminder of the significance of properly attaching and securing the boom, as well as the importance of being prepared for unforeseen weather conditions while rigging a sailboat.

4. Setting Up the Running Rigging

Setting up the running rigging on a sailboat involves several important steps. First, attach the halyard securely to the head of the sail. Then, connect the sheets to the clew of the sail. If necessary, make sure to secure the reefing lines . Attach the outhaul line to the clew of the sail and connect the downhaul line to the tack of the sail. It is crucial to ensure that all lines are properly cleated and organized. Take a moment to double-check the tension and alignment of each line. If you are using a roller furling system, carefully wrap the line around the furling drum and securely fasten it. Perform a thorough visual inspection of the running rigging to check for any signs of wear or damage. Properly setting up the running rigging is essential for safe and efficient sailing. It allows for precise control of the sail’s position and shape, ultimately optimizing the boat’s performance on the water.

Safety Considerations and Tips

When it comes to rigging a sailboat, safety should always be our top priority. In this section, we’ll explore essential safety considerations and share some valuable tips to ensure smooth sailing. From the importance of wearing a personal flotation device to securing loose ends and lines, and being cautious around overhead power lines, we’ll equip you with the knowledge and awareness needed for a safe and enjoyable sailing experience. So, let’s set sail and dive into the world of safety on the water!

1. Always Wear a Personal Flotation Device

When rigging a sailboat, it is crucial to prioritize safety and always wear a personal flotation device ( PFD ). Follow these steps to properly use a PFD:

- Select the appropriate Coast Guard-approved PFD that fits your size and weight.

- Put on the PFD correctly by placing your arms through the armholes and securing all the straps for a snug fit .

- Adjust the PFD for comfort , ensuring it is neither too tight nor too loose, allowing freedom of movement and adequate buoyancy .

- Regularly inspect the PFD for any signs of wear or damage, such as tears or broken straps, and replace any damaged PFDs immediately .

- Always wear your PFD when on or near the water, even if you are a strong swimmer .

By always wearing a personal flotation device and following these steps, you will ensure your safety and reduce the risk of accidents while rigging a sailboat. Remember, prioritize safety when enjoying water activities.

2. Secure Loose Ends and Lines

Inspect lines and ropes for frayed or damaged areas. Secure loose ends and lines with knots or appropriate cleats or clamps. Ensure all lines are properly tensioned to prevent loosening during sailing. Double-check all connections and attachments for security. Use additional safety measures like extra knots or stopper knots to prevent line slippage.

To ensure a safe sailing experience , it is crucial to secure loose ends and lines properly . Neglecting this important step can lead to accidents or damage to the sailboat. By inspecting, securing, and tensioning lines , you can have peace of mind knowing that everything is in place. Replace or repair any compromised lines or ropes promptly. Securing loose ends and lines allows for worry-free sailing trips .

3. Be Mindful of Overhead Power Lines

When rigging a sailboat, it is crucial to be mindful of overhead power lines for safety. It is important to survey the area for power lines before rigging the sailboat. Maintain a safe distance of at least 10 feet from power lines. It is crucial to avoid hoisting tall masts or long antenna systems near power lines to prevent contact. Lower the mast and tall structures when passing under a power line to minimize the risk of contact. It is also essential to be cautious in areas where power lines run over the water and steer clear to prevent accidents.

A true story emphasizes the importance of being mindful of overhead power lines. In this case, a group of sailors disregarded safety precautions and their sailboat’s mast made contact with a low-hanging power line, resulting in a dangerous electrical shock. Fortunately, no serious injuries occurred, but it serves as a stark reminder of the need to be aware of power lines while rigging a sailboat.

Some Facts About How To Rig A Sailboat:

- ✅ Small sailboat rigging projects can improve sailing performance and save money. (Source: stingysailor.com)

- ✅ Rigging guides are available for small sailboats, providing instructions and tips for rigging. (Source: westcoastsailing.net)

- ✅ Running rigging includes lines used to control and trim the sails, such as halyards and sheets. (Source: sailingellidah.com)

- ✅ Hardware used in sailboat rigging includes winches, blocks, and furling systems. (Source: sailingellidah.com)

- ✅ A step-by-step guide can help beginners rig a small sailboat for sailing. (Source: tripsavvy.com)

Frequently Asked Questions

1. how do i rig a small sailboat.

To rig a small sailboat, follow these steps: – Install or check the rudder, ensuring it is firmly attached. – Attach or check the tiller, the long steering arm mounted to the rudder. – Attach the jib halyard by connecting the halyard shackle to the head of the sail and the grommet in the tack to the bottom of the forestay. – Hank on the jib by attaching the hanks of the sail to the forestay one at a time. – Run the jib sheets by tying or shackling them to the clew of the sail and running them back to the cockpit. – Attach the mainsail by spreading it out and attaching the halyard shackle to the head of the sail. – Secure the tack, clew, and foot of the mainsail to the boom using various lines and mechanisms. – Insert the mainsail slugs into the mast groove, gradually raising the mainsail as the slugs are inserted. – Cleat the main halyard and lower the centerboard into the water. – Raise the jib by pulling down on the jib halyard and cleating it on the other side of the mast. – Tighten the mainsheet and one jibsheet to adjust the sails and start moving forward.

2. What are the different types of sailboat rigs?

Sailboat rigs can be classified into three main types: – Sloop rig: This rig has a single mast with a mainsail and a headsail, typically a jib or genoa. – Cutter rig: This rig has two headsails, a smaller jib or staysail closer to the mast, and a larger headsail, usually a genoa, forward of it, alongside a mainsail. – Ketch rig: This rig has two masts, with the main mast taller than the mizzen mast. It usually has a mainsail, headsail, and a mizzen sail. Each rig has distinct characteristics and is suitable for different sailing conditions and preferences.

3. What are the essential parts of a sailboat?

The essential parts of a sailboat include: – Mast: The tall vertical spar that supports the sails. – Boom: The horizontal spar connected to the mast, which extends outward and supports the foot of the mainsail. – Rudder: The underwater appendage that steers the boat. – Centerboard or keel: A retractable or fixed fin-like structure that provides stability and prevents sideways drift. – Sails: The fabric structures that capture the wind’s energy to propel the boat. – Running rigging: The lines or ropes used to control the sails and sailing equipment. – Standing rigging: The wires and cables that support the mast and reinforce the spars. These are the basic components necessary for the functioning of a sailboat.

4. What is a spinnaker halyard?

A spinnaker halyard is a line used to hoist and control a spinnaker sail. The spinnaker is a large, lightweight sail that is used for downwind sailing or reaching in moderate to strong winds. The halyard attaches to the head of the spinnaker and is used to raise it to the top of the mast. Once hoisted, the spinnaker halyard can be adjusted to control the tension and shape of the sail.

5. Why is it important to maintain and replace worn running rigging?

It is important to maintain and replace worn running rigging for several reasons: – Safety: Worn or damaged rigging can compromise the integrity and stability of the boat, posing a safety risk to both crew and vessel. – Performance: Worn rigging can affect the efficiency and performance of the sails, diminishing the boat’s speed and maneuverability. – Reliability: Aging or worn rigging is more prone to failure, which can lead to unexpected problems and breakdowns. Regular inspection and replacement of worn running rigging is essential to ensure the safe and efficient operation of a sailboat.

6. Where can I find sailboat rigging books or guides?

There are several sources where you can find sailboat rigging books or guides: – Online: Websites such as West Coast Sailing and Stingy Sailor offer downloadable rigging guides for different sailboat models. – Bookstores: Many bookstores carry a wide selection of boating and sailing books, including those specifically focused on sailboat rigging. – Sailing schools and clubs: Local sailing schools or yacht clubs often have resources available for learning about sailboat rigging. – Manufacturers: Some sailboat manufacturers, like Hobie Cat and RS Sailing, provide rigging guides for their specific sailboat models. Consulting these resources can provide valuable information and instructions for rigging your sailboat properly.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

- Outhaul Systems Guide

- Outhaul Systems - Normal

- Outhaul Systems - Quick Release

- Clew Blocks

- Outhaul Elastics

- Block Assemblies at Boom

- Block Assemblies at Gooseneck

- Primary/Secondary Assemblies

- Calibration Strips

- Primary and Secondary Lines

Downhaul Systems Guide

- 6:1 Downhaul Systems

- 8:1 Downhaul Systems

- 10:1 Downhaul Systems

- Primary Line Assemblies

- Lower Strop Assemblies

- Caribiner Attachment

- Kicker Systems Guide

- Kicker Systems

- Kicker Components

- Kicker Primary Line Assemblies

- Ratchet Blocks

- Boom/Traveller Blocks

- Kicker Blocks

- Control Line

- D12 Dyneema

- Wear Protect

- Block Plate and Assemblies

- Cleats and Cleat Assemblies

- Wind Indicators

- Mast Retainer

- Centreboard Strop

- Centreboard Friction Pad

- Centreboard Elastic and Clips

- Self Bailer and Springs

- Transom Bung

- Titanium Mega Bolt

- Silicone Sealant

- Hiking Straps

- Toggles and Dogbones

- Loops and Soft Shackles

- Splicing Kits and Tools

- Universal Joint

- Tillers, Extensions etc

- Gift Vouchers

This section doesn’t currently include any content. Add content to this section using the sidebar.

Add description and links to your promotion

Your headline

Image caption appears here

Your product's name

Add your deal, information or promotional text

The following is designed to help you choose the optimum downhaul (cunningham) system by looking at what is important, the types of system available, and then the blocks, rope, and lower block attachment options.

What’s important

In comparison with the outhaul system, the downhaul is conceptually a lot simpler. However, the downhaul system has to really work well – it’s hard pulling the luff down – and the last thing we need is a poor system that makes it harder than it needs to be. After the kicker this is where money is best spent getting the best system that you can afford, so that you can effectively control your sail shape. Unlike the outhaul where every turning point can have a block, the downhaul system primary must pass through the sail cringle and that means friction. We need to minimise the friction in the system by using the largest sheave blocks we are allowed to use under the Laser class rules (30mm) and by minimising the friction through the sail cringle by using slippery rope for the primary line.

Types of System

There are two types of downhaul system and it is important to select what is right for you. The decision should be based on the rig you are using, and your weight and strength.

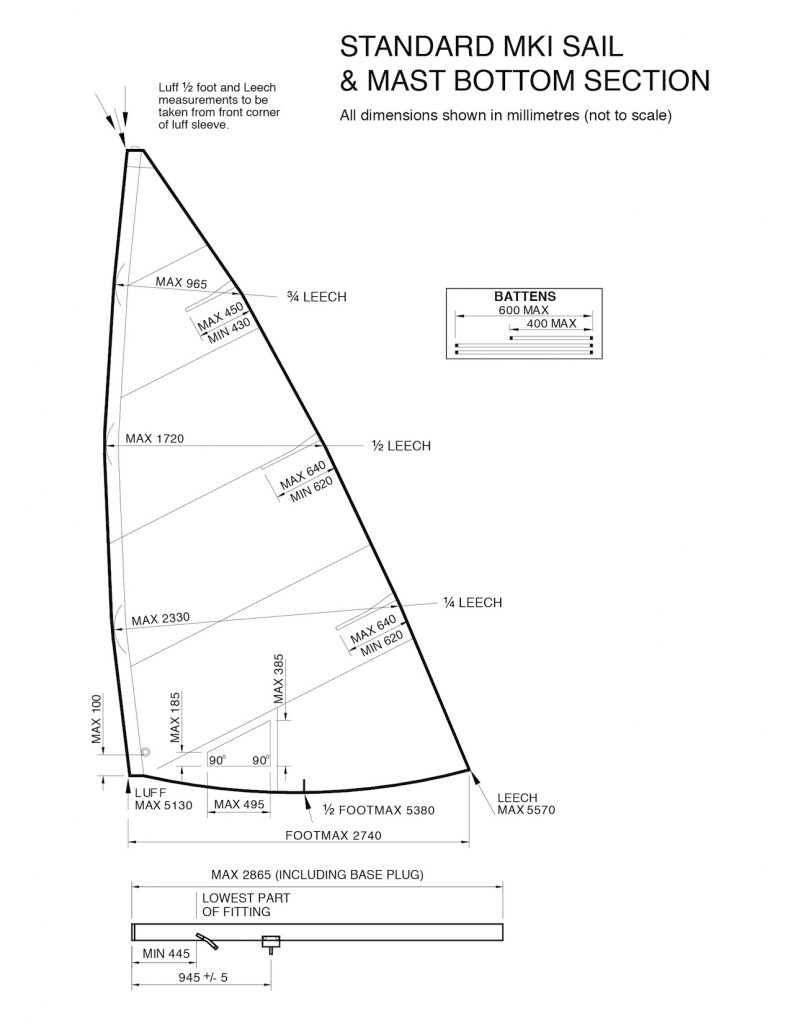

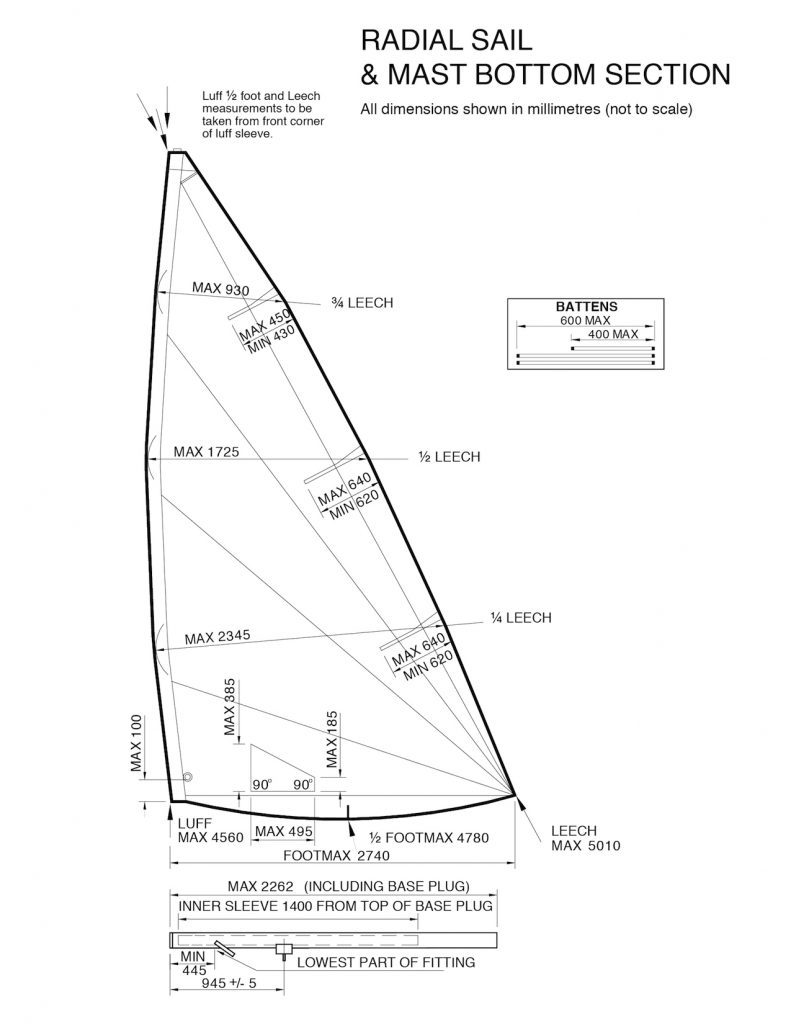

- 6:1 Downhaul System – This is what the majority of Laser sailors use for the 4.7, Radial and the old Standard MKI sails. It gives sufficient purchase for those rigs, and minimises excess rope in the cockpit when pulled on hard.

- 8:1 Downhaul System – The 8:1 system is essential if you are using the newer MKII standard sail where the additional purchase is really needed due to the stiffer sail material used. The 8:1 system is also ideal for lighter sailors in 4.7 and Radial rigs who are struggling to pull their downhaul on really tight. For more detail as to why you should use an 8:1 for the MkII sail read this short write up by Southeast Sailboats sponsored GBR Team sailor Michael Beckett from November 2016. “ The new 8:1 downhaul is complete game changer (not a phrase we often hear when talking about Laser kit). Not just for smaller sailors but for any sailor trying to get to grips with the new MkII sail. The new and stiffer Dacron cloth requires greater tension to be applied to achieve the same depowering of the sail in hiking conditions (10+ knots). It is an inevitable conclusion that the old 6:1 systems used on the MkI aren’t going to be sufficient, no matter how hard you think you can pull. The issue one would expect from a greater number of purchases is all the additional rope in the cockpit. However, the MkII the sail stretches over a far smaller range so there is still less rope in the cockpit, making this the ideal system (even after the sail has seen many months of use).

Optimised for Rig Type

Because the tack cringle on the MkII standard sail is positioned higher than all the other rigs, our systems are optimised (4.7/Radial/Standard MkI or Standard MkII) to ensure that the rope lengths/block positions are ideal. If you want to be able to sail either the 4.7/Radial/Standard MkI and the MkII standard rig with the same downhaul system there are ways of rigging the system to compensate that are described later.

Block Types

With the much higher loads involved, and the desire to reduce friction, you should use the largest blocks allowed. We recommend Harken’s T2 Soft-Attach 29mm block for the downhaul (which is what you get with a new Laser), or the more economic Allen 30mm Tii blocks. If you are not racing then you could consider the smaller sheave blocks from Harken or Ronstan. One of the other benefits of the larger 29/30mm sheave blocks is that when the secondary line wear out it is easier to fit a new one through the larger central 'axle' of the block. Two blocks are required to put together a 6:1 purchase system – one at the base of the mast by the kicker attachment and one that is floating just below the sail cringle. For an 8:1 system three blocks are used.

More expensive, high load blocks run better under load, reducing friction in the systems and hence improving system efficiency and effectiveness. We have made (and will if requested) systems using the amazing Harken 29mm FLY block for customers who want the ultimate downhaul irrespective of price, but we don't list these solutions due to the very high price. However, we how listed solutions using the Allen 30mm High Load block which provides 'high load' benefits at a more affordable price - this is now our premium solution available in both 6:1 and 8:1 configurations.

For the primary line a thicker D12 Dyneema line than is normal is best to reduce the chance of it getting trapped between the gooseneck and boom, Standard on our systems is 5mm SK78 D12 Dyneema for Harken 29mm systems, and 4mm SK78 D12 Dyneema for the other block types. For the secondary line (the one that you pull on) we use Robline Dinghy Control as the standard line and Marlow Excel Racing GP78 as the premium line. The Marlow Excel Racing GP78 has Technora in the cover which makes it more durable. Gottifredi Maffioli EVO Race 78, which is similar in performance to Dinghy Control is available as a no-cost option - If you want that line just add a note at checkout. All our secondary line ends are epoxied/heatshrink sleeved to help keep them nice and tidy. We offer a wide range of primary/secondary colour combinations. If you want more information on our secondary lines and how to select which is best for you read our article on selecting secondary lines .

Rope Length (Handle Type)

The secondary control line length can be selected for either a simple loop handle or a braided handle.

Lower Block Attachment

Finally, you need an appropriate method of attaching the free end of the primary line. A good way of doing this is to use the lower block strop around the mast as the anchor point for the end of the primary line. It has a number of advantages – it doesn’t put additional load on the kicker assembly; there are no pins or shackles or knots to mess about with; and the primary line and block are symmetrically positioned.

Lower block strop and primary line termination

The simplicity of rigging depends on the type of system that you are using (6:1 or 8:1), and the handle type (simple or braided chain). For the least simple to rig (8:1 system with a braided chain handle) to avoid having to thread the secondary line and re-do the chain handle, some customers have opted to terminate the primary line at the top of the kicker/vang assembly (either using a pin or caribiner). If you want to rig your primary that way, select ‘Top Of Kicker’ under the Systems Option section, and we will shorten the primary line by 10cm/4 inches.

Using a Caribiner

Using the Same System with Multiple Rigs

As mentioned, as the tack cringle on the MkII standard sail is positioned higher than the other rigs, our systems are optimised to the rig that you are using. If you want to be able to sail either the 4.7/Radial/MkI and the MkII standard rig with the same downhaul system it needs to be adapted in some way as the primary line length for the MkII is 10cm/4 inches longer. We feel that the best way of compensating for the above is to order a Standard MkII optimised system, and add the ‘Top Of Kicker’ under the Systems Option section. When using the system with a Standard MkII sail, terminate the primary at the top of the kicker assembly using a caribiner. When using a 4.7/Radial/Standard MkI sail, terminate the primary via the lower block strop which will effectively shorten the primary line length by approximately 10cm.

Rigging Instructions

All our systems are supplied with detailed rigging instructions which can be seen here: 6:1 downhaul installation instructions

6:1 downhaul 'top of kicker' installation instructions

8:1 downhaul installation instructions

8:1 downhaul 'top of kicker' installation instructions

Building an 8:1 downhaul video

Downhaul FAQ’s

- You sell both 6:1 and 8:1 downhaul systems – which is best for me? The 6:1 system is best for the 4.7, radial and standard Mk1 rigs. The 8:1 is best for the standard Mk2 sail which uses a heavier cloth. If you are a lightweight sailor you may want to use the 8:1 for the radial or 4.7 rigs, accepting the tradeoff of ease of use versus more rope in the cockpit.

- I sail both radial and the new standard Mk2 rigs – is it possible to have a downhaul system that works for both? Yes. The tack cringle/grommet on the new Mk2 sail is about 5-6 cm higher than on all the other sails, and whilst this doesn’t sound much, when it is combined with a 6:1 or 8:1 system this distance is multiplied. Our usual downhaul system fixed the primary line at the level of the kicker tang on the lower mast. One option is to use that fixing position for the radial/Mk1, and to move the fixing position up to the top of the kicker assembly for the Mk2. This reduces the impact of the difference. It can be reduced further by using a snap type caribiner on the kicker assembly such that the primary attachment point for the Mk2 is even higher .

- Why is the downhaul primary line so thick? From a strength perspective Dyneema is so strong that we could probably use a very thin 1.5mm line, but it would probably saw into the tack cringle and would certainly get snagged in the gooseneck. Over the years the line has got thicker, as the type of blocks – such as the Harken 29mm block – can accept larger lines, and reducing the chance of it getting caught in the gooseneck.

- Can I see the instructions as to how the systems are rigged? Yes, follow the following links:

General Questions:

- I am unsure of what is best for me – do you offer free advice? Yes, we offer free advice on what we feel is best for you, based on years of sailing the ILCA/Laser at championship level. Just contact us at [email protected]

- I like to rig my ILCA/Laser differently. Do you offer custom systems? Yes. A quick walk around the boat park at even a world championship will show that there is no ‘right way’ to a rig a Laser – a lot is down to personal preference, and we are happy to build up exactly what you want.

- Do I have to have everything spliced together? The answer is no, but there are a number of reasons why we splice our systems together. For the primary lines, the fixing to the new ‘soft attach’ blocks is important that it is done correctly, as an incorrectly fixed primary line can pull apart the head of the block. For the secondary lines, particularly the smaller Harken 18mm and Allen 20mm blocks, the size of the sheave makes it difficult to thread a 4mm control line through when a 3mm primary line has already been threaded through .

- Having a spliced system is great, but what happens when the ropes inevitably wear out? If you liked the original spliced system that we supplied we can rebuild the system using your original blocks. Just send the blocks back to us and we can replace and re-splice the lines for you.

- I have just bought a new ILCA dinghy and I have the bag of blocks and ropes that comes with it. Can you put it all together for me? Yes, we have done this for a number of customers. The bag of ropes that comes with a new Laser can be daunting. We can turn all those ropes and blocks into a ready to fit system - just email us at [email protected] for more information.

(+44) 07880 500233

southeastsailboats

southeast_sailboats

Southeast Sailboats

We use cookies on our website to give you the best shopping experience. By using this site, you agree to its use of cookies.

By Product Categories

Small Boat Blocks

Big Boat Blocks

Complementary Hardware

Travelers & Genoa Leads

Mainsail Handling

Headsail Handling

Mooring Solutions

Spare Parts

Accessories

Harken Canvas

Fly Soft-Attach Blocks

Carbo Air Blocks

Small Boat Classic

Flip-Flop Small Boat

GP Catamaran Ceramic Mainsheet Systems

Protexit™ Exit Blocks

Through-Deck

Wire High-Strength

Dinghy Vang

Small Boat Deck Organizers

Midrange Classic

Midrange Deck Organizers

Zircon Blocks

Element Blocks

Black Magic Air Blocks

Cruising ESP Blocks

Megayacht Blocks

Stainless Steel Blocks

Black Magic Air Runners

FlatWinder Powered Blocks

Mastbase Blocks

Over-the-Top

Crossover Blocks

Big Boat Deck Organizers

Cam Cleats & Kits

Cam Cleat Accessories

Cam Cleat Bases

Stand-Up Bases

Deck Organizers

Spinnaker Pole Cars

Soft Attachments

Fixed Padeyes

Removable Padeyes

Bolt-Down Fairleads

Grand Prix Jib Leads

Halyard Tensioners

Tiller Extensions

Peter's Desk Drawer

Dinghy Jib Leads

Crossbow Pivoting Self-Tacking Jib Traveler

13 mm Micro

22 mm Small Boat

27 mm Midrange

32 mm Big Boat

Windward Sheeting

42 mm Mini-Maxi

T-Track Genoa Lead

Access Rail System

13 mm AA Battcar System

22 mm A Battcar System

27 mm B Battcar System

32 mm C Battcar System

18 mm Switch Battcar System

26 mm Switch Battcar System

26 mm Trysail Switch

32 mm Switch Battcar System

32 mm Trysail Switch

40 mm Switch Battcar System

40 mm Trysail Switch System

Furling Mainsail Outhaul Systems

Single Line Reefing

Harken Vang-Master

Carbo Racing Foil

Small Boat Furling

Small Boat Underdeck

Reflex Furling

MKIV Jib Reefing & Furling

MKIV Underdeck Jib Reefing & Furling

Furling Accessories

Powered Furling

MKIV Ocean Furling

SnubbAir (Not a Winch)

Grand Prix Winches

Air Winches

Circuit Breakers

Analog Switches

Digital System Switch

Aluminum, Chrome & Bronze Winch Handles

Carbo OneTouch Locking Winch Handle

Service Kits

CLR Mooring Winches

Electric Captive Reel Winches

Hydraulic Captive Reel Winches

UniPower Radial

Single-Acting Integral Backstay Adjuster

Single-Acting Cylinders

Locking Cylinders

Double-Pull Cylinders

Grand Prix Cylinders

Hydraulic Cylinder Rod End Blocks

Hydraulic Cylinder End Fittings

Control Valves

Control Manifolds

Control Panels

Compact Control Panel

Rotary Pumps

Hydraulic Pump Handles

Power Systems

Repair Kits

Ball Bearings

Block Spare Parts

Traveler Cars

Furling Spare Parts

Winch Spare Parts

Winch Service Kits

Blockheads Gear

Promo & Gifts

Marine Grip

Jeep/Truck tops

Garage storage

One-design Covers

Boat accessories

Canvas bags

By Type of Sailing

Dinghy / One-Design

Offshore Racing

Coastal / Day Cruising

Bluewater Cruising

Megayachts / Custom

Service Guide

Tech/Service

deck layouts

Data Sheets (SDS)

How to choose

System diagrams

Calculators

Reeving diagrams

Traveler Purchase Selection Guide

How to Choose

Testimonials

Hoister Videos

Request a Quote

Request Samples

Fabric details

Cover Styles

Canvas Videos

Contract Services

Materials and Components

Our Equipment

Contract Cut-and-Sew Project Spotlight

- Harken at the front

- Safety & Rescue

Support / Selection tools / System diagrams

Cunningham Systems

The cunningham controls the fore and aft position of draft in the mainsail or genoa and works together with the traveler, mainsheet, outhaul and vang to optimize sail shape and increase boatspeed. Cunningham controls lead to the crew to encourage adjustment as wind speed changes.

Typical Boat Length: Small Boat: 22' - 28' (6.7 - 8.5 m) Midrange: 29' - 34' (8.8 - 10.4 m) Big Boat: 35' - 42' (10.7 - 12.8 m)

4:1 Cascaded

This simple 4:1 system leads aft to the cockpit. A favorite on small keelboats and daysailers.

8:1 Cascaded

The most basic cunningham is a self-cleating 4:1 tackle positioned at the mastbase.

4:1 Double-ended Cascaded

This system is easy to adjust from the trapeze. It’s easy to rig and unrig. Popular on smaller beach cats.

12:1 Cascaded

This simple 2:1 purchase is attached to a 6:1 cascade for a 12:1 system. Used on larger racing and cruising boats.

6:1 Double-ended Jib Downhaul

Small boats like J/24s use a double-ended genoa cunningham system to adjust draft from the weather rail.

Product Categories

- United States

- New Zealand

- United Kingdom

The $tingy Sailor

Diy trailerable sailboat restoration and improvement without throwing your budget overboard.

Control Mainsail Draft with a Boom Downhaul

A boom downhaul is one of the three possible control lines for the three sides of the mainsail. The other two are the boom vang (controls leech tension) and the mainsail outhaul (controls foot tension). Catalina 22 and similar sailboats have a short length of line attached to the bottom of the gooseneck car on the boom that ties off to a cleat at the base of the mast as shown below. It simply keeps the boom from sliding up past a certain point on the mast after you hoist the mainsail. It gets the job done but it isn’t easy to adjust, especially while under sail.

Some people call this simple arrangement a boom downhaul, which I suppose is technically correct, but I call it a tie-down since it isn’t as easy to trim as what I’m going to describe and it would be confusing to call them both the same thing.

Most cruising sailboat owners don’t adjust their tie-down often (or ever) because it’s too much trouble to go forward and adjust for the relatively small improvement it makes. Most racers adjust it whenever wind conditions change.

This project is a true boom downhaul that makes it so easy to trim from the cockpit, even while under sail, that it can become a regular part of trimming the mainsail.

A boom downhaul works like a Cunningham by tightening the luff of the mainsail to flatten it and to move the belly of the mainsail forward, which improves its aerodynamics and reduces heeling. It helps most in moderate to heavy winds and can make a significant difference in the mainsail shape.

A Cunningham works by connecting a hook on one end of a block and tackle to a grommet above the tack of the mainsail. Then when you harden the Cunningham, it pulls the luff flat while at the same time creating a wrinkle in the foot the mainsail. The boom stays stationary on top of a stop in the mast slot. A boom downhaul is simpler than a Cunningham

It may help to think of a boom downhaul as simply a boom tie-down line led aft to the cockpit. The advantages of a downhaul over a tie-down is that you can always trim it regardless of how high the mainsail is hoisted and it doesn’t make a wrinkle in the foot of the mainsail that disturbs air flow.

A boom downhaul is easy to set up if you have an empty turning block at your mast step, an open sheave in a deck organizer, and an unused cleat at the bulkhead. Just replace your existing boom tie-down line with enough line to lead it through the turning block and deck organizer to the cockpit like shown below.

I prefer to use 1/4″ New England Ropes Sta Set with a spliced eye in the dead end to receive a halyard shackle. Instead of tying the line to the gooseneck car with a bowline knot, the shackle is faster and easier to detach. This way, you can leave the downhaul line in place and just disconnect it from the gooseneck car if you need to remove the boom, such as to unstep the mast for trailering.

Rigged this way, the boom downhaul doesn’t offer any mechanical advantage over a boom tie-down. In fact, it has the disadvantage of the friction added by the turning block and the deck organizer. But it usually doesn’t take a lot of force to tighten it fully anyway.

To make it even easier to adjust, you can rig it with a block attached to the gooseneck car instead. Start the line at a becket on the turning block at the mast step or attach it to the mast step plate as in the picture at left. Reave the line up through the gooseneck car block, down through the turning block, and then lead it aft to a bulkhead cleat. That gives the downhaul a 2:1 mechanical advantage. If necessary for heavy wind sailing, you could increase the mechanical advantage even more by using double blocks in both positions.

Would you like to be notified when I publish more posts like this? Enter your email address below to subscribe to this blog and receive notifications of new posts by email. You will also receive occasional newsletters with exclusive info and deals only for subscribers and the password to the Downloads page. It’s free and you can unsubscribe at any time but almost nobody does!

Share this:

8 thoughts on “ control mainsail draft with a boom downhaul ”.

I’m looking to rig mine from the halyard plate, to the block attached to the gooseneck car, to the cockpit. Any idea the length of line needed? Also, did you use a simple shackle to attach it to the halyard plate?

I used 12′ of 5/16″ New England Ropes Sta Set. You can find the lengths necessary to lead all of the running rigging lines to the cockpit listed in Lead All Lines to the Cockpit for Safer Sailing .

It’s hard to see in the picture but yes, I use a regular shackle to attach the dead end to one of the holes in the halyard plate. If you have a bail attached to the base of your mast for a boom vang like you can see in this post, another option for attaching the downhaul turning block is to shackle it to the bail also. That frees up a hole in the halyard plate for something else. You can see that in the third picture in Lead All Lines to the Cockpit for Safer Sailing .

This cat has all sorts of really useful sail rigging ideas! I am well pleased and actually impressed.

Thanks for the compliment.

On the last option, could you tie off the line to the freed up cleat, then up to the block and on to the cockpit? I seem to be missing the last image showing the 2:1 setup…

Thanks for the explanation of how the three control lines impact the sail shape…now I just need to try them out (along with all the other great rigging suggestions on your site)!

Yes, you could start it there but it might interfere with a boom stop if you have one in between the cleat and the boom. That’s why I led it over the opposite side of my mast step plate. The 2:1 picture is the main picture of the post on the left. The top and bottom are cut off a bit, sorry.

Hi Stingy, Your boom downhaul is a nice simple way to adjust luff tension. I’m curious if the boom downhaul offers any sail shaping advantages over a fixed boom and using the main halyard tension to adjust luff tension? Perhaps the friction of the sail slides or bolt rope gives an advantage to tensioning the luff separately from the head and tack.

Thanks in advance for your reply. Really enjoy your site!

They both basically achieve the same thing but a downhaul is a lot easier to adjust, especially if you’re single-handed or short-handed. On my boat, to get it any harder than when I originally set it through a cam cleat, I would have to leave the helm and “sweat” the line from the cabin roof or lead the halyard to an unused primary winch and crank it tight. But if I had fully hoisted the mainsail to begin with, there wouldn’t be any more height to be gained anyway and I could easily jam the end of the halyard in the masthead. For that reason, if you stick with a boom tie-down, set it so that it stops your mainsail head board a couple inches below maximum hoist. Then you will at least have the space to harden it if you need to.

With a 2:1 downhaul, I just reach over to the bulkhead and haul the line a couple inches and voila. Likewise, if I then turn downwind and want to ease the luff, I can do it just as easily.

Leave a comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

About the Centerboard

Climbing on the Lift

Downwind Sail Trim

The spritsail, spars and rigging that accompany Crawford Boat Building's MELONSEED SKIFF are an example of simplicity and efficiency. It is unlikely that any rig is the equal of the sprit rig in providing performance with a minimum of hardware and fuss.

The following is a illustration followed by a description of the component parts, their assembly and function:

click on the boom or mast for more...

Masthead Rigging

Feed the 1/8” braided Dacron line through the grommet as shown.

Put the two ends through the hole in the top of the mast.

Put your thumb between the two lines, and take the line on the left side of your thumb and pass it through the left side of the grommet. Do the same with the right side line and put it through the right side of the grommet.

Keeping the lines neat “right to left” make more passes through the hole with the lines as seen next.

IMPORTANT: You will tie off the excess with a square knot, but before you do, be sure that the sail is NOT pinched up tight against the mast, and that the luff runs STRAIGHT up the mast. The luff should be stretched fairly tight but not overly tight. Each lace line should allow the luff to be spaced evenly away from the mast.

Cut off the excess line with a heat gun, or if you don’t have one, trim it with a scissors and then VERY carefully burn the ends of the line to seize them and keep them from fraying. I also melt the line (tricky!) in one side of the knot just a tiny bit so that it won’t become undone.

Technically a SPRIT BOOM ... This has a slot in the end that goes forward and a hole with a snap attached to it in the aft end. To get optimum performance on all points of sail the boom will be set on the opposite side of the sail from the sprit - (It doesn't matter which side you put either spar on.) This causes the least average overall interference to the shape of the sail. You may set both spars on one side of the sail if you wish although you will get a better shape sail on one tack than the other. (This can only be useful if you are going to be on mostly one tack over a sustained distance.) Attach the boom to the sail by clipping the snap on the end of the boom to the grommet on the CLEW of the sail. The clew is the corner of the sail that is on the bottom of the sail closest to the transom.

The forward end of the boom is attached to the mast with another small line called a Boom SNOTTER. This short line should be permanently on the mast for sake of convenience. It has either a knot or a loop in one end, and goes down through the eye strap to the jamb cleat. Put the knot or loop into the SLOTTED of the boom, and tension the boom snotter according to the wind strength.

The item from which the rig gets it's name. This is a 10' stick with a spike in the upper end and a line (called a snotter) attached through a hole in its bottom end. Setting this into the rig is extremely simple, but adjusting the upward tension against the sail top (PEAK) is the single most important adjustment you will make. It goes like this: Grab the sail peak and insert the spike into the rope loop that is sewn into the sail. Push the sprit upward. Tie off the snotter to the cleat located on the mast nearby. Now this is where you can get the most out of the rig's performance potential. The more the wind, the stronger the sprit tension! If you ever see sag lines in the sail because the sprit is not tensioned enough, then you are not getting maximum performance. Remember, soft wind, soft sail .... stiff wind, stiff sail. There are some very technical reasons for this, but that's a two beer conversation. A simple rule of thumb is to always OVERTENSION the sprit a bit anyway because the snotter seems to slip a bit naturally. When sailing to windward, you should never see sag lines in the sail in any direction.

A quadrilateral (square) sail of dacron weighing approx. 4-5 oz. per yard. It has numerous holes called grommets set into it, to which line (rigging) is attached. The edge that is set against the mast is called the LUFF. Using the light 15" light lines provided, tie the luff to the mast so that sail stands evenly about "' away from the back edge of the mast. Tie each of these LACE LINES tight with a good firm square knot. Tie the top most grommet to the hole in the top of the mast using a longer (24") lace line, and go through the hole at least twice and tie off very well. At no point should the sail luff appear crimped!

The corner of the sail that is at the bottom of the luff is called the TACK. Hanging down from the tack is a line attached to the sail called the DOWNHAUL. Now refer back to the mast hardware descriptions and this will start to come together. Tie the downhaul line to lowest cleat on the mast, the one just above deck level, the downhaul cleat. Be sure to tension the luff fairly tight. Good luff tension is very important. The sail is on the mast now so let's continue to rig it up.

A 10' length of solid wood which sets into the boat and is held in place by the mast step at its bottom (heel), and the mast partner at deck level. It has four pieces of hardware fastened to it. Starting from bottom to top they are:

1. A small 3" cleat that the sail downhaul is tied to. On the opposite side of the mast are the other three pieces.

2. A second cleat to tie off the boom snotter.

3. An eye strap to turn this snotter.

4. Further up the mast, a cleat for the sprit snotter.

Don't be confused by the unfamiliar nautical terminology at this point. Just notice the four pieces of hardware. The rigging will be described later.

A 25' length of dacron line with a snap on one end. Snap the sheet onto either the grommet in the clew (along with the boom end snap) or to the snap itself. Newer boats have a RING attached to the bottom of the boom. Snap the sheet to this ring. Run the other end of the sheet through the block on the rudder head and IMMEDIATELY tie a figure eight-knot in the end.

One of the wonderous features of the Melonseed Skiff is that with just a little practice, this rigging drill can be accomplished in

ONLY A MINUTE OR TWO!!!

Now that you have accomplished all this, take fifteen knots of wind and two hours of spare time. Mix well. Apply as often as necessary! Caution; continuous use of this rig and boat can lead to addictive sailing behavior.

Operating and understanding the Melonseed Centerboard:

The centerboard is a plate of 1/2" PVC plastic that is held in place in the centerboard trunk by a bolt, rubber washers, metal washers and a lock nut on its forward lower end. Actually, the board does not ride on the bolt as you might imagine from a visual inspection, but there is a piece of PVC plastic tube that acts as a ‘bushing” around the bolt. There is Sika-flex 291 adhesive sealant between the rubber washer and the fiberglass centerboard trunk. It is a very strong and watertight system that should endure well as time goes on because the friction is really minimized by the water lubricated PVC on PVC system.

The board will rise by itself if you run aground or strike an underwater object.

The string that raises and lowers the board is called a centerboard “pennant”. The pennant is attached to the top aft end of the board by a very simple system of holes and a knot. Once a year or so, check the condition of the pennant where it connects with the board to be sure there is no wear on the pennant.

There are two (permanent ??) magic marker marks on the pennant to indicate the depth settings of the centerboard. With the board pulled up all the way there should be one mark on the pennant at 12” back from the cleat, and another one at 22” back.