Contact Kato Marine: 7416 Edgewood Road Annapolis, MD 21403 Phone: 410-269-1218

Call us at the number above - or - Use our quick form - or - Email us

Kato Marine type 316 stainless steel arches:

All our arches are designed with the ability to lift dinghies in mind. They are all welded construction � no joining sleeves or similar. We have a huge number of options available, and because the arches are built to order we can accommodate most special requests. In order to make an arch for a boat that we have no information on, we must have the boat locally in Annapolis MD. Contact us directly to ascertain whether we have an arch for your boat.

Home » Blog » Gear » DIY sailboat arch

DIY sailboat arch

By Author Fiona McGlynn

Posted on Last updated: August 18, 2023

Build your own sailboat solar arch or radar arch for a fraction of the price.

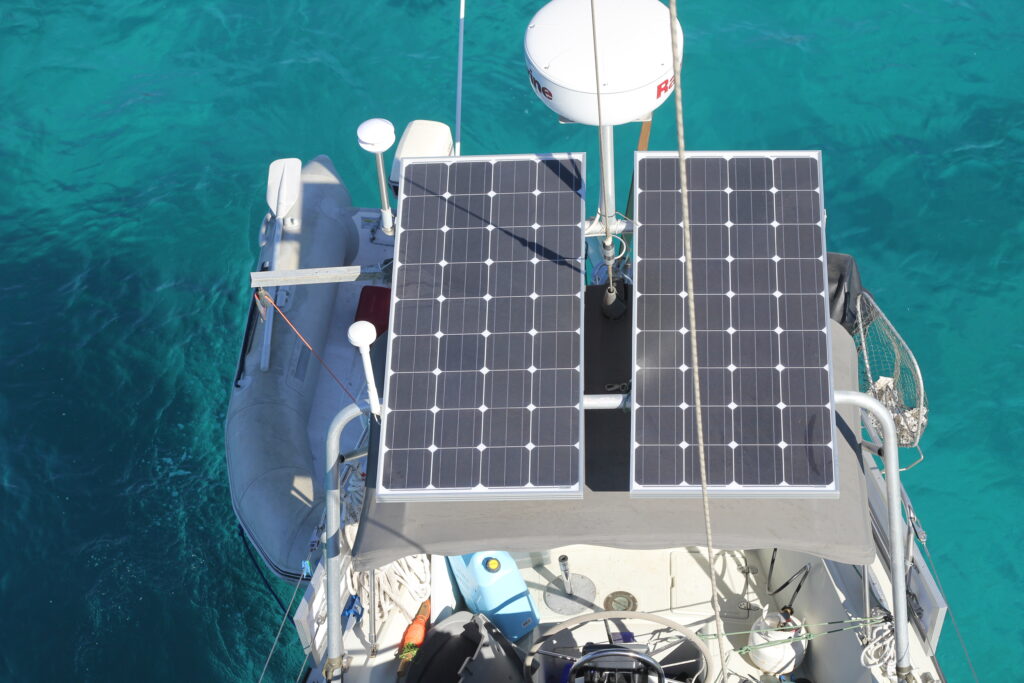

We were outfitting our 1979 Dufour 35 for a multi-year sailing trip and had decided to install a 400-watt solar array. But how to best mount them?

A structural arch made the most sense, and we didn’t have one. After a couple of quotes over $5000 USD for a ‘simple arch,’ we decided that we would have to build our own.

We sought opinions around the docks and almost universally received the advice, ‘Don’t do it…just don’t.’

But, being young and foolish we decided to try it anyway; what did we really have to lose? While it was more difficult than I had anticipated, we ended up with a product with we were quite happy with and it only cost us a little more than $200 USD.

Note: A version of this article was published in Good Old Boat Magazine

What is the purpose of a sailboat arch?

Structural arches, also commonly referred to as solar, stern, or radar arches, are a common feature of coastal cruising and bluewater sailboats .

They are used for a variety of purposes, but most commonly to mount and support:

- Solar panels

- A wind generator

- A radar radome

- A weather station

- Various communications antennae

- A dinghy davit, for raising and lowering the dinghy

What do sailboat solar arches cost?

While they provide many advantages, arches can often be prohibitively expensive (commonly from 5k – 12k); but with a little sweat equity, limited metal working skill, and some careful measurements there is no reason why you can’t build your own sturdy arch for a fraction of the normal cost.

Customizing your solar arch

There are as many shapes and sizes of structural arches as there are sailboats. Determining the style of an arch for your sailboat will depend on a variety of factors, primarily; aesthetics, cost, and function.

This article details my experience designing, fabricating, and installing a simple, aluminum arch that I use for solar panels, radar, AIS antenna, and a weather station, not to mention a hundred other small things.

The principles of design and fabrication are common to a wide variety of arches and can likely be used as the basis for other who want to modify the design to fit their own needs and boat shape.

I provide very little engineering guidance below and I recommend that readers creating their own arches first pass their design by a structural engineer or someone knowledgeable in structural design.

There are three main types of material from which to construct an arch; stainless steel, aluminum, and fiberglass.

There are a variety of factors that go into material selection, with the most common being; aesthetics, price, strength, and ease of construction. I made a subjective traffic light comparison of the different materials, to assist our decision-making process.

Stainless steel and aluminum compared closely for our needs, but as our chief concerns were price and ease of construction we opted to go with aluminum.

There are many different grades of aluminum and it is important to select one that will stand up to the marine environment.

We selected aluminum alloy 5052. It is a medium-strength aluminum alloy with good ductility and excellent corrosion resistance and for the latter reason is often preferred for marine environments.

High-grade aluminum cannot be easily found in conventional building supply stores like Home Depot.

Purchasing metal from a wholesaler, such as Metal Supermarket or Metals Depot , is much cheaper than buying from a local welder or manufacturer. A simple google search will supply you with the options for metal wholesalers in your area.

We purchased our raw materials for the arch for around $70 USD.

In addition to the aluminum tubing, we required the same type of aluminum in flat-stock and stainless steel bolts and lock-nuts to fasten the frame together and to secure it to the deck of the boat.

I made all the required cuts with a hack-saw and jigsaw, though a metal cutting blade on a radial arm saw or circular saw would have worked as well.

I cleaned up the cut edges and any sharp spots with a 5” angle grinder with a grinding disc made for aluminum. A titanium-coated drill bit was used to make the bolt holes.

Determining the shape

Once the material was selected we had to decide on a shape. We wanted as simple and robust a shape as possible.

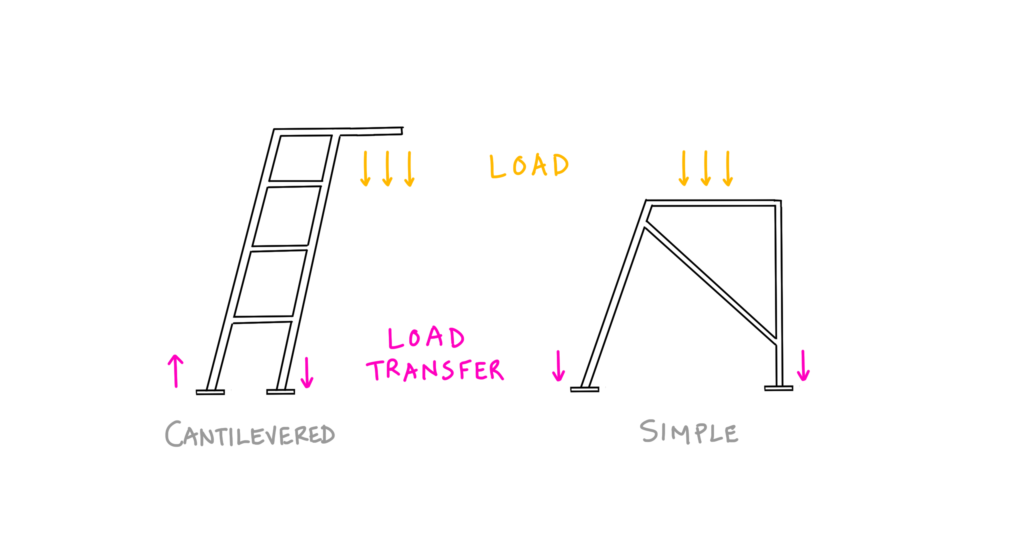

Many arches have a form that cantilevers over the transom of the boat. While the aesthetic is nice, the primary function of this shape is to support dinghy davits. Due to its cantilevered nature, it imparts a constant rotational force on the attachment locations.

We have a wind vane on the back of our boat, so hoisting the dinghy was out of the question. We opted for a simpler shape that transfers load straight down, thereby reducing stress on attachment locations.

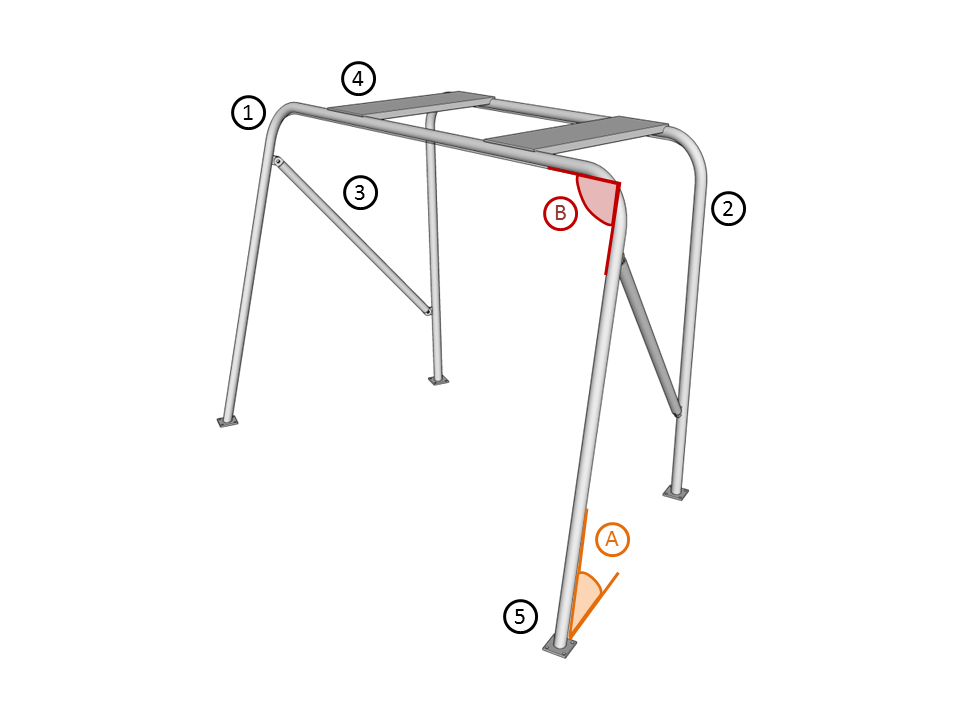

The arch design makes use of a forward tube (1) and an aft tube (2) with two bends in each tube. A tube connecting the aft and forward tubes at an angle creates a cross brace (3), resisting lateral force fore and aft and distributing dead load.

Two pieces of flat-stock aluminum (4) bolted on top of the forward and aft tubes also provide lateral resistance and further rigidity to the frame.

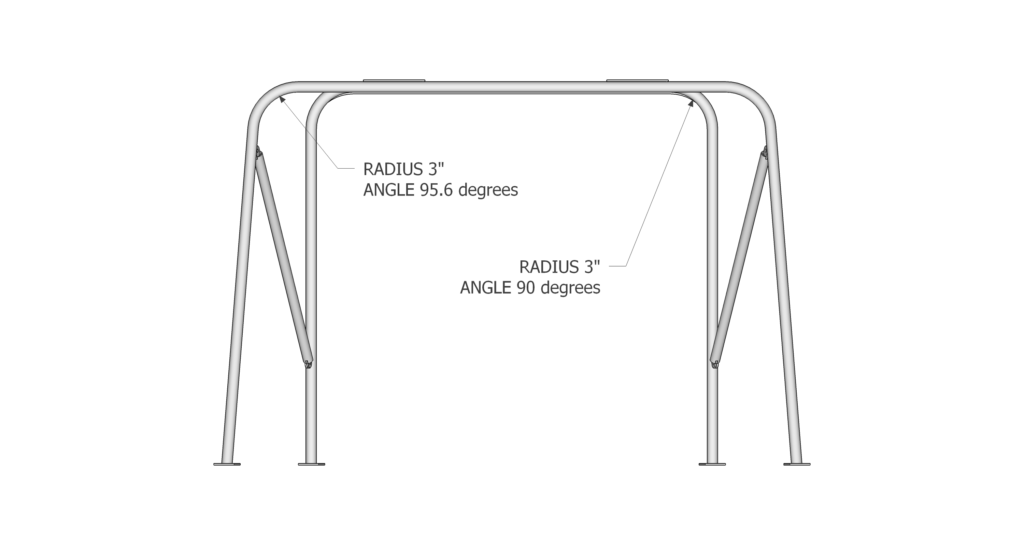

The 3” radius bends in the tubes resist lateral forces from the sides.

Four ¼” thick, 3” square plates (5) were cut from flat stock and welded to the ends of the tubes. These plates were bolted through the deck to matching plates on the other side.

Calculating the tube bends

After measuring everything out to ensure no obstruction, the next step was determining the slope angle (A) of the forward tube. The slope of the tube would give the arch a sleeker look and improve access on and off the boat.

Wherever possible it is nice to create parallel lines as too many intersecting lines can be displeasing to the eye, so I maintained the same slope as the pushpit.

The slope of the forward tube (A) also determines the angle (B) at which the tube will be bent in order to keep the sides of the arch in one plane and in line with the sides of the boat.

There are three ways to calculate the angle of bend (B) in the forward tube:

The first requires some complex trigonometry for which I created a calculator in Excel, which requires only the dimensions of the arch as inputs.

Another option is to use a free CAD (computer-assisted drawing) program such as Trimble SketchUp and draw the arch you want to build using the measurements you took from the boat. If using CAD, it is a simple process to measure the angle of the bend with the protractor tool.

Lastly, you can construct the arch out of a practice material such as PVC pipe or doweling and physically measure the angles and dimensions. This option also provides the chance to see how the arch interacts with other components of the boat.

Tube bending

Bending the tubing can be done for a low cost at home. It is possible to rent a tube bender from a building supply store for $50 USD per day or purchase a hydraulic tube bender for around $100-150 USD.

We ended up renting a tube bender and found the process quite easy.

We were advised by a tube bending company (Aggressive Tube Bending) to select tubing with a 1.5” outer diameter and a 0.145” wall as it didn’t require annealing (heating and slowly cooling) to bend to a 3” radius, whereas 2” tubing would have required annealing.

It is a good idea to contact a metal shop or tube bending company to ensure that your design can be fabricated without special equipment or techniques.

Usually, these questions can be answered quickly and over the phone and do not incur a consulting fee.

Installation

Dry-fit preinstallation.

My recommendation would be to dry-fit everything prior to any welding.

It takes a little extra time to assemble and dry-install the arch, only to disassemble it again, but the time saved in having to cut welds or modify a finished product is well worth it.

We designed and installed our arch while dry-docked in a boatyard. We tried to keep the solar panels parallel to the waterline, but when the boat went back in the water, due to weight redistribution, the panels ended up angled slightly forward.

It is a good idea to fit the arch on a calm day at the dock, rather than guess how the boat sits in the water.

Measure and cut the tubes

The most difficult process of the whole job was transferring the angle of the deck to the bottom of the tubes to ensure that the base plates would be flush when mounted. Because the deck slopes in two directions it would be impossible to assume an angle at which to cut.

The solution we devised was using a piece of ½” wood and tracing around the tube with an indelible marker (see image below).

We first made the tubes as secure as possible in the locations they would be when they are bolted to the deck. This required installing the flat stock between them and lashing them to as many points on the deck as we could find.

The bottom of the tubes rested on the deck. We used a 3/8” thick, block of wood, which was placed flat on the deck, as a guide and traced a line around each tube.

The line transferred the correct angle of the deck to the tubes. I made the cuts with a hack saw and cleaned them up with an angle grinder.

Weld base plates and attachment tabs

We hired an aluminum welder to weld 3”X3”X1/4” plates to the tubes that would be used to connect the arch to the deck of the boat.

When fitting the base plates to the tubing, trace the shape of the tube onto the baseplate to ensure the orientation of the plate is maintained.

We also welded tabs to the fore and aft tubes and corresponding tabs to the ends of the cross-brace tubes. The length of the cross-brace tube must be exact to connect to the attachment tabs on the fore and aft tubes, so careful measurements are required.

Install the fore and aft tubes

We bolted the fore and aft tubes to the deck prior to bolting together the rest of the frame.

We had planned to run the electrical cables for antennae and the radome through the tubes so we drilled 1” diameter holes in the base plates and through the deck where the base plates would be attached.

The 1” diameter hole will accommodate most electrical connectors. You may also want to install a ‘messenger line,’ which can be used to pull the cables through the frame after the arch is installed.

We applied Sikaflex 291 to the entire underside of the base plate immediately prior to installation to ensure a water-tight connection between the base plates and the deck.

The base plates were secured with 1.5” x 5/16” stainless steel bolts that connected to corresponding plates on the underside of the deck.

If there is not enough room for a plate on the underside, you can double up oversized stainless steel washers to meet the pull-out resistance requirements.

Stainless steel will react to aluminum and cause corrosion of the aluminum. A simple way to avoid this is to apply lanolin (we used Lanocote) to the stainless steel bolts to insulate them from the aluminum.

Bolt the frame together

Next we attached the cross-brace tubes. There will be a little flex in the frame, which provides some allowance for connecting the cross braces.

After securing the cross-brace tubes with stainless steel bolts, we installed the 1/4” flat stock to the tops of the tubes.

We had previously cut the flat stock into two 8” wide strips. If you are concerned about rigidity you can bend a 90-degree angle into the length of the flat-stock, though over a 3’ length, the deflection of unbent flat-stock will be minimal.

To improve corrosion resistance and the aesthetic appearance of the arch, the various pieces, now that they have been welded, can be anodized or painted.

Anodizing requires submersion in a shallow electrolytic bath, so the arch must be in its disassembled form in order to be anodized. We received a quote for $150 USD to anodize the arch in any color we wanted.

Another option is to have the arch powder coated. We received a quote of $100 to paint it white or black.

In the end, we opted to do nothing as we don’t mind the dull silver look of the aluminum and were still penny-pinching.

In retrospect, we wish we’d had the arch anodized bright orange, but we were in a rush and focused on keeping costs to a minimum.

The arch has not only been extremely useful for its intended purpose but also become invaluable for the various add-ons that we could never have foreseen.

In addition to being a mount for solar panels, radome, communications antennae, and the weather station, an arch is also a place that supports or provides attachment points for:

- the outboard fuel tank and outboard lifting tackle

- fishing rod holders and a fish cleaning station

- the stern anchor

- furling line and boom brake attachment points

- boogie board storage

It also adds to the sense of security in the cockpit and is a great handhold in rolling conditions. It was a lot of work, but in the end, only costs us $200 USD and we can no longer imagine our little boat without it.

*Note: We installed our radome directly over the solar panels, which was a bad idea as it shades a small portion of the panels most of the time, greatly reducing solar output. I would recommend installing the arch on an extension away from the solar panels so that the noon-day sun is unobstructed, or even better, installing the radome on the mast.

Fiona McGlynn is an award-winning boating writer who created Waterborne as a place to learn about living aboard and traveling the world by sailboat. She has written for boating magazines including BoatUS, SAIL, Cruising World, and Good Old Boat. She’s also a contributing editor at Good Old Boat and BoatUS Magazine. In 2017, Fiona and her husband completed a 3-year, 13,000-mile voyage from Vancouver to Mexico to Australia on their 35-foot sailboat.

Terms and Conditions - Privacy Policy

SprinterVan Roof Racks

Request Information

Thank you for contacting us about building a Radar Arch. We will get back to you as soon as possible with more details.

Available Options:

AJ30500 Adjust-O-Launcher Need more rod holders? Individual Adjust-O-Launcher aluminum rod holders can be mounted anywhere on the perimeter of the Sail Arch framework. A unique patented design available exclusively from Atlantic Towers, manufactured from all aluminum in natural aluminum or gold anodized finish Adjust-O-Launchers can be pivoted thru 12 positions for unmatched flexibility. Fits all marine standard 1-1/2” pipe (1.90” o.d.) AJ30500C Clear Anodizing: $129.00 AJ30500G Gold Anodizing: $159.00

Anchor/Running Light , a two way navigation lamp installed on an anodized aluminum mast with anodized finish to match the Standard Radar Arch. Functions as all round light with both sides illuminated, or forward steaming light with just forward half illuminated. Custom fitted shoe allows easy bolt-on installation on centerline of The Standard Radar Arch. 5” height or 18” height. $169

How is the Radar Arch shipped to me? Although the Standard Radar Arch is not heavy it is too large to go by UPS. We have discounted freight arrangements with several trucking companies, which cover all 48 states and Canada. We can also ship to Alaska, Hawaii and any overseas city, call us for details. The Standard Radar Arch is packed in a single large cardboard carton and normally ships to a commercial address.

What happens if my Radar Arch is damaged in shipping? Atlantic Towers wants you to enjoy your boat, not spend the season chasing a freight claim. If your Radar Arch arrives damaged, just refuse the shipment and we will send you a new one at no additional cost to you.

Can I return my Radar Arch if I decide I don’t want to keep it? Atlantic will accept the return of any Standard Structure within 30 days of it’s receipt by you. Simply return the Structure in the original packaging in new condition freight pre-paid and we will refund the purchase price less a 10% restocking fee

**NOTE: There is a 10% re-stocking charge for cancelled or returned merchandise**

Due to our dedication to continued product improvement, we reserve the right to make changes without notice.

- Hatch repairs

- Get A Quote

- Cranes and Hoists

- Arches and Hardtops

- Dinghy Davits

- Poles (Starlink, Radar, Wind)

- Dinghy Chocks and Cradles

- Parts Department

- Frameless Hatches

- Tubing - Aluminum and Stainless

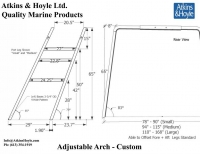

Solar / Radar Arch

Streamline your boat with our fully customizable Arch;

- Solar Panels,

- Dinghy Davits,

- Antenna Mount (Radar/ Starlink)

- Modular Design, boasts Atkins & Hoyle Fittings rather than welds.

- Constructed from Anodized Aluminum OR 316L Stainless Steel.

- 1.90" (1-½" Sch40; or 1.90" 11Ga)

- Adjustable in width.

- Total Weight: ~80 Lbs. (Aluminum) ~130 Lbs. (Stainless Steel).

- 6061 T6 (aircraft grade) Aluminum

- OR 1.90" 11 Gauge 316L Stainless Tube

- 3-¾" Outside Diameter

- 4-hole (¼")

- Sand Cast, AlMg-535 Alloy Polished Anodized

- Stronger and more reliable than welds

- Allows for quick shipping and assembly

- overall height

- overall width

- height of each gusset, align with (or miss) your pulpit and pushpit

- inward taper, change the standard 83°

- 100% Guarantee

- Terms and Conditions

- Hatch & Port Repair

- Hatches and Ports

©2024 Atkins & Hoyle. Since 1926. All rights reserved.

WEB Design Toronto by Vestra Inet .

Not yet a member click here to Register

Forgot password? Reset Password

Have an account? Click here to Login

Category: Arch Design

2022 Davit & Solar Arch Projects

2022 has been very busy at Klacko Marine. We’ve had some great arch projects on yachts by Beneteau, Dufour and Bavaria. Each arch was designed specific to the client’s needs both locally and remote from. The Beneteau 50 in Rhode Island, Dufour 530 Lake Champlain, Beneteau 423 Kingston, Benteau 45 Oceanis Grimsby, Beneteau 46.1 St.Clair […]

Dinghy Davit Bridle

Just a quick set of photos showing the process of setting up your dinghy bridle on a Highfield 310CL and Klacko Swingarm Davit Arch. Yacht is a Jeanneau 50 DS. Photos courtesy of GG. Bridle lines were roughed in using spare line, to get the right balance of swingarm angle and boat height off the […]

Viaggio: Beneteau 55 Oceanis Arch Project

Cruising with Style and Ease

Beneteau Oceanis Sunset Cruise

Some really awesome photos Thanks to CR for these great photos of their cruisings on the Great Lakes with a Klacko Davit Arch on their Beneteau Oceanis 41.

Captivating Catalina 425 Arch Project

This 425 Sailboat Arch has it all Photos Gallery of the Catalina 425 equipped with a Klacko Marine Davit Solar Arch.

Birds Eye view of a Beneteau 46 Oceanis

Some awesome aerial sailing footage from Take the Waters Added entertainment to check out with some breathtaking aerial drone footage by an awesome cruising couple. Definitely a favourite YT channel here at Klacko Marine. Subscribe and check out their blog & patreon site which they have posted some great articles and sailboat projects. UPDATE from […]

Take The Waters | Beneteau 46

Adventure awaits Recently had the pleasure to work for Brian and Mandi Russel to design and fabricate a custom davit and solar arch for their Beneteau 46 Oceanis sv Shonto. The results were well received and the arch has already found some interesting uses (see video below). They have been chronicling their up & down […]

Radar Arches in Action

A few quick photos of our recent fabrications… here, there and everywhere. Thanks to our client’s great photography, showcasing their exceptional yachts with Solar and Davit equipped Klacko Arches. More photos of our stainless steel works can be found here

Kestrel’s Low Profile Solar Installation

Great way to mount rigid solar over your bimini We are constantly asked if a Standard Canvas Bimini can support rigid glass solar panels safe and effectively. The answer is a resounding ‘NO’. Of course we all have dockmates who have loaded their bimini tops up with one or two solar panels and sailed the […]

Built to withstand the harshest environments

Klacko arches are fabricated to the highest standards and materials. Each solar davit arch is engineered to endure even the worst scenarios… we come out looking like a champ!From CAD engineered design to professional welding & fabrication, a Klacko Arch stands apart from many of its competitors.As you can see by these unfortunate scenes, both […]

Jeanneau 42DS Davit Arch & Pedestal Guards

Here are some quick photos of a recent project on a Jeanneau 42 DS sailboat. This Stainless Steel arch is fabricated to transport a 10ft rib and approx 600W of solar panels for bluewater cruising. New sternrails are integrated for better strength and storage capacity. Siderails integrated to existing gate stanchions for a fully integrated […]

Great Arches!

At Klacko Marine, we’ve been busy in the workshop this 2018 sailing season. It was a full house as we fabricated custom integrated arches for Hanse, Catalina, Beneteau, Hunter, Jeanneau, Island Packet and Bavaria. All the davit and solar arch creations were custom made for each client to their exact specifications. Klacko aided with seasoned […]

Stainless Steel Arch Gallery Updates

Our Sailboat Arch Gallery has been updated See our latest work on some of the top yacht brands. Solar panel additions were very popular this year as well as the addition of heavy duty davits to make dinghy lifting a breeze. In some cases we integrated the existing sternrails and in others we created a […]

Catalina 445 Solar Arch Design

Solar davit arch installation on a brand new Catalina 445 Klacko Marine has partnered with Swans Yacht Sales. Four 160W Canadian Energy panels were custom mounted for seamless power while off the dock. We integrated the existing Catalina seating sternrail into the arch and 1 inch siderails to the first gate. All wiring for speakers […]

Dufour 500 Arch

A stylish cockpit arch that compliments the sleek lines of this modern yacht. Outfitted with integrated dinghy davits, lifting a dinghy has never been so easy and secure. Future accommodations have been made for up to 600W of solar power. The client has also requested extended sternrail to offer more mounting space, better handholds from […]

Yacht Arch Portfolio

Custom Arch Builders for Beneteau, Jeanneau, Catalina, Hanse, Dufour, Hylas, Bavaria and more. Find more photos and ideas here Klacko Marine is the leading builder of custom stainless davit solar arches in North America. Innovative designs and high quality craftsmanship provide a very robust ocean ready system. Our OEM integration allows a seamless appearance without […]

Very clean Catalina 445 Arch

Integrated Solar and Davits, make this arch a must have Catalina option Catalina 445 Stainless Arch. Constructed to the high expectations of the client. A robust arch was built to provide mounting for 400W of solar power, misc antennae for GPS, Wifi, VHF and future wind turbine. The dinghy lift was fabricated to fit the […]

Beneteau 41 Oceanis Arch Davit

Robust and simple Beneteau Radar Arch A recent build on a beautiful Beneteau 41 Oceanis. The client chose the minimalist swing arm davit design to keep thing compact, clean and pleasing to the eye. The swing arm davit system has been very successful in and enjoyed on over 60 arches built by Klacko Marine. Note […]

Saga 43 Radar Arch

Saga Yachts Klacko was proud to be the OEM metal hardware supplier for the Saga 35, 43, 48 and 409. We actively work with the Yahoo Saga Owners group to give advice and provide OEM solutions. We are able to reproduce or refurbish most metal hardware on your Saga Marine Yacht. The Radar arch on […]

Catalina 445 Arch

Bare bones arch out for sea trial on a Catalina 445 Notice there are no sternrails yet…..see next post to see how they turned out!

FRENCH KISS Jeanneau 409 Arch

Dinghy Arch addition to a Jeanneau 409 French Kiss’ new addition Thanks to the owners of sv French Kiss for the photos of the arch complete with new canvas and dinghy. Klacko marine fabricated a dinghy arch that would accomodate solar panels, wind generator, multiple GPS, VHF and wifi antenna, and lift their Highfield dinghy […]

Beneteau 48 OC Arch

Beneteau Oceanis 48 Cockpit Arch Custom arch fabricated for Beneteau Oceanis 48 Gypsea Winds (New Port, RI). Klacko utilized the ever popular and useful davit swing arm system. Side rails to the first gate add extra security in the cockpit as well as much needed mounting space. Sternrail was also extended for added functionality. A central […]

Beneteau Custom davit arch

Different Davits A different take on the traditional davit A very nice set of davits fabricated for a Beneteau owner who wanted traditional a traditional davit system melded with overhead mounting for solar panels.

Jeanneau 409 Sun Odyssey Arch

Arch Test Drive A quick motor out to test the new arch at Niagara On The Lake aboard sv French Kiss.

Jeanneau 45.2 Dinghy lift Arch

A Bayport Beauty Brand new davit arch addition to a Jeanneau 45.2

Hanse 415 Custom Davit Arch

North Channel Trekker Hanse 415 with custom davit arch system

Single Line system for Dinghy Lift Arm

A great way to lift your dinghy with a single line to the winch on the Klacko Swing Arm Davit system Note that a custom Harken or Ronstan fiddle block with cam cleat was used.

La Jeannoise, Jeanneau 44i Arch by Klacko Marine

La Jeannoise Solar Cockpit Radar arch by Klacko Marine http://www.lajeannoise.com/ Thanks to Carole et Denis for an amazing blog with out of this world photos of their voyages

Jeanneau 44i Arch at Sea

Cruising Video by Denis Dubois Aboard his Jeanneau 44i Here are some great videos shot by Denis. Klacko Marine is proud to have fabricated their custom arch system that allows easy lifting of their dinghy. It also provides a good structure for their solar panels and keeps all the electronics and cruising gear organized. Under […]

Klacko Marine featured in this month’s SAIL Magazine

Sail Gear: Cockpit Arch Convenience A nice feature article on the addition of Radar or Cockpit Arches to your yacht by Peter Nielsen, editor of Sail Magazine.

Relliance 44 Marine Arch for Ocean Cruising

Professional Marine Arch for Bluewater Cruising Custom arch built for a professional cruising couple

Beneteau 423 Davit Arch at Bronte Outer Harbour

Fully integrated arch and davit system Custom design and integrate arch and dinghy lifting davits. Solar panels to be mounted on davit arms. Fabricated by Klacko Marine Inc. More photos here

Hylas 47 Custom Solar Arch with Dinghy Davits

A Sleek and Minimalist Arch installation on a Hylas 47 Klacko was tasked with providing a design that met clients need to equip their new Hylas 47 with solar and easy dinghy davit lifting. Arch was all measured remotely and shipped to Florida without a hitch.

Need Help? | 954-575-8444 | Chat Now

- Shipping & Returns

- Product Support

- Account Details

Select your Region

Oceansouth products and prices may vary by region. In order to see the right products available to you, please select your location.

Boat Arch / Radar Arch

The free-standing Oceansouth Boat Arch is an excellent addition to your boat. It is easily assembled and features unique universal mounts. The universal base mount features a beveled base which enables a variety of possible mounting positions.

- Designed to fit any Boat

- Ø1¼” 316 Stainless steel tube

- Folding for Storage & Trailering

- Supplied with Support Plates to install Lights and Navigation Instruments

- Adjustable Width and Height

- SKU: MA 009

- Category: Fishing Arches / Radar Arches

RECOMMENDED ACCESSORIES

Cover Set (Vented and Full) for Mercury/Mariner

‘Clamp-On’ Fishing Arch

Fishing Bait & Fillet Table

Related products.

Fishing Arch (Rocket Launcher)

MacGregorSailors.com

Discussions relating to the MacGregor line of trailerable sailboats

Skip to content

- Main Site Board index MacGregorSailors Forums Repairs and Modifications

26M Stainless Transom Arch

Post by Duane Dunn, Allegro » Sun Jul 12, 2009 5:45 am

Re: 26M Stainless Transom Arch

Post by Rick Westlake » Sun Jul 12, 2009 1:08 pm

Post by K9Kampers » Sun Jul 12, 2009 3:06 pm

Post by pokerrick1 » Mon Jul 13, 2009 2:41 am

Post by Rick Westlake » Mon Jul 13, 2009 3:29 am

K9Kampers wrote: For mounting solar panels, here is an alternative that I found: Solar Stik

K9Kampers wrote: Btw, the principals of this product are Brian & Stephanie, if you recall their cruising posts aboard their Hunter 25.5 "Empty Pockets". Stephanie had a different bikini for every day of the month!

Post by Duane Dunn, Allegro » Mon Jul 13, 2009 5:08 am

Rick Westlake wrote: Has anyone built or installed an arch that goes clear across the transom?

Post by K9Kampers » Mon Jul 13, 2009 9:41 am

Post by Rick Westlake » Mon Jul 13, 2009 4:22 pm

K9Kampers wrote: Another direction to look at is a wakeboard tower. Different designs & configurations to fit entire width of boat. Look for ones that are made to tilt / remove. This company, as an example, was at the top of the search page: Bigairpylons

Post by Bobby T.-26X #4767 » Wed Jul 15, 2009 7:07 pm

Post by Love MACs » Wed Jul 15, 2009 7:16 pm

Re: "DāBob" Arch

Post by Rick Westlake » Thu Jul 16, 2009 1:05 pm

Post by Love MACs » Thu Jul 16, 2009 5:31 pm

Post by Bobby T.-26X #4767 » Fri Jul 17, 2009 11:28 pm

Return to “Repairs and Modifications”

- MacGregorSailors Forums

- ↳ Website News & Announcements

- ↳ MacGregor Powersailor Discussion

- ↳ MacGregor/Venture Discussion

- ↳ Performance & Tuning

- ↳ Trailers & Towing

- ↳ Repairs and Modifications

- ↳ Destinations, Clubs, Events and Venues

- ↳ Trip Logs

- TattooSailors Forums

- ↳ Tattoo Yachts Discussion

- Special Interest Forums

- ↳ Australia Group

- ↳ Canada Group

- ↳ European Group

- ↳ Rest of the World

- ↳ Admiral's Galley

- ↳ The Front Room

- Main Site Board index

- All times are UTC+01:00

Powered by phpBB ® Forum Software © phpBB Limited

Privacy | Terms

THE FUTURE OF SOLAR ARCHES FOR SAILBOATS

Strong and stylish, optimised for solar panels, custom fit for your boat, made from stainless steel, complete solar power solution for your boat.

We produce and deliver customised, affordable and stylish arches for mounting solar panels on sailboats.

Many sailors have a dream of a sustainable power production on their boat. It gives you the freedom for long passages and visiting remote destinations without having to worry about electrical power. Most sailors will choose a solution with solar panels which will raise the question; where to place them on the boat.? To get enough capacity, most often the panels will need to be placed on a solar arch on the stern of the boat.

Having a solar arch mounted, will also give you the option to carry and hoist a dinghy from the integrated davits.

As a sailor, you used to have two options, when looking to mount an arch on your sailboat to carry solar panels and a dinghy on the stern:

Buy a 100% standard product, which you then cut and drill so it fits onto your boat. This can be relatively cheap, but is definitely not pretty, since often the material is aluminium, so "normal people" are able to cut and drill without problems. It does not look great when the other tubes on your boat are most likely polished stainless steel.

Find a local blacksmith and ask them to make a one-off arch. That gives you maximum freedom to decide design (with the potential to mess it up, if you don't know what you are doing). This is always a VERY costly affair, as most one-off products are.

We have figured out a way to combine the best of both...

We have developed an advanced, yet simple process for our customers to perform the necessary measurements on their own sailboats, which we then use to finish a semi-standard product.

The result is a beautifully designed, structurally thought through stainless steel arch, optimized for carrying solar panels and a dinghy.

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Hunter Stainless Arch

- Thread starter ScottySailor

- Start date Jul 10, 2021

- Hunter Owner Forums

ScottySailor

Hey guys trying to get some info here I was thinking about running some extra wiring inside the stainless arch on my boat I already have wiring that goes to the stereo and light on the arch does anyone know if there are holes drilled through it or can you drill holes through it on the inside? Just wondering before I start taking it apart… Thanks Scotty Sailor

Same question came up recently on this thread: Hunter 33 Main Traveller Arch - Adding 12v Power to arch | Sailboat Owners Forums . I never looked at the

Georgedoyle

On my 49, there are two holes on each side where the arch articulates. To run wire through them, you need to detach your Bimini, remove the screws, and fold the arch forward. You'll be able to see the holes. A couple of things to note: the arch will bend forward on a pin that you can’t see from the outside. Removing the screws will allow the arch to bend. Also, you will need to drill a hole in the fiberglass under the starboard arch base to access the bottom of the arch. There is already a hole on the port side for the radio wiring. Just do the same thing on the other side. I recently ran the wiring for my solar panels through the arch. It worked really well. Now I have 400 watts worth of panels on the boat. On a mooring at Catalina, I run net 8-10 amps in the positive running both fridges and the freezer. No need to run the generator at all. I'm very pleased with the results.

Georgedoyle said: On my 49, there are two holes on each side where the arch articulates. To run wire through them, you need to detach your Bimini, remove the screws, and fold the arch forward. You'll be able to see the holes. A couple of things to note: the arch will bend forward on a pin that you can’t see from the outside. Removing the screws will allow the arch to bend. Also, you will need to drill a hole in the fiberglass under the starboard arch base to access the bottom of the arch. There is already a hole on the port side for the radio wiring. Just do the same thing on the other side. I recently ran the wiring for my solar panels through the arch. It worked really well. Now I have 400 watts worth of panels on the boat. On a mooring at Catalina, I run net 8-10 amps in the positive running both fridges and the freezer. No need to run the generator at all. I'm very pleased with the results. Click to expand

There is probably a hole in the arch on either side for running wiring. You will probably need to use a small hole saw to expose the hole on the side that isn't carrying your existing wiring. Once you drill out the fiberglass, it should be an easy run. You'll need to get into a cockpit locker to see how Hunter ran the wiring for the radio. Then, just duplicate on the other side.

Thanks George I can see up in there I drilled a hole you definitely helped me head on the right direction thanks very much

I’m glad it worked out for you. I’m starting to realize that Hunter really did thoughtful work when they built these boats. The level of engineering on my arch is impressive. I was also pleased to see that they included access on both sides of the arch to accommodate future additions and expansions.

Yes George definitely I can’t really understand all the hunter haters out there because I see so many different things on my boat that were well thought out ahead of time… And they’re all starting to appear on boats manufactured in the last two or three years

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

To revisit this article, visit My Profile, then View saved stories .

- Backchannel

- Newsletters

- WIRED Insider

- WIRED Consulting

Chris Baraniuk

Why the Baltimore Bridge Collapsed So Quickly

Just shy of half past 1 in the morning, the MV Dali , a giant container ship, was sailing gently out of the port of Baltimore when something went terribly wrong. Suddenly, lights all over the 300-meter-long vessel went out. They flicked on again a moment later, but the ship then began to veer to the right, toward one of the massive pylon-like supports on the Francis Scott Key truss bridge—a huge mass of steel and concrete that spans the Patapsco River.

The Dali ’s lights went out a second time. Then the impact came. The ship plowed into the support, with large sections of the bridge’s main truss section instantly snapping apart and falling into the river. It took just 20 seconds or so for the structure to come down.

Now, a major US port is in disarray, and several people who were working on the bridge at the time of its collapse are missing. A rescue operation is underway. President Biden has called the disaster a “terrible accident.” Ship traffic is currently stuck on either side of the crash site, and a major roadway through Baltimore has been cut off.

“It’s a dreadful tragedy and something you hope never to see,” says David Knight, a bridge expert and specialist adviser to the UK’s Institution of Civil Engineers. But commenting on footage of the bridge collapse , he says he is not surprised by the manner in which it crumpled.

Large steel structures may seem invulnerable, but steel, explains Knight, is relatively lightweight for its size. As soon as it is pushed or pulled the wrong way with enough force, it can fold like paper. In this case, the Francis Scott Key Bridge was a “continuous,” or unjointed, bridge that had a 366-meter-long central truss section. (Truss bridges use steel beams, arranged in triangular shapes, to support their load.) The central truss was made up of three horizontal stretches, known as spans, with two sets of supports holding these above the water. It was the third-largest structure of its kind in the world.

Will Knight

“When you take a support away, there is very little in the way of robustness,” says Knight. “It will drag down, as we saw, all three spans.” The separate approach spans remain standing. There is nothing in Knight’s view that immediately suggests any structural problem with the bridge. An engineering firm, Hardesty & Hanover, confirmed to WIRED that it performed an inspection of the bridge in 2019, and that other inspections have been carried out since, but did not provide any additional details on the state of the structure. WIRED has approached H&H for further comment. In June last year, the US Federal Highway Administration rated the condition of the bridge as satisfactory .

The immense force of the container ship impact should not be underestimated, adds Knight. Such vessels require a lot of power and time—perhaps many minutes—to come to a complete stop. The Francis Scott Key Bridge was completed in 1977. In more recent decades, bridge engineers have commonly incorporated defenses to reduce the potential damage by ship strikes when bridges are erected in similar locations, Knight says. These include hydraulic barriers and additional concrete around the base of bridge supports, for instance. However, even with such fortifications in place, heavy strikes can still cause devastating damage.

It is not clear why lights turned off and on again on the Dali , a Singapore-flagged ship built in 2015. “That is an indication of a massive problem,” says Salvatore Mercogliano, a maritime historian at Campbell University in North Carolina and a YouTuber who has analyzed the crash .

At the time of the accident, two pilots—mariners who board a ship to help it navigate particular stretches of water, including in and out of ports—from Baltimore were on board. The Dali was broadcasting its position publicly via the automatic identification system (AIS) and was traveling at a speed of over 8.5 knots. It then slowed to around 6 knots in the moments before the crash, according to AIS data .

Both pilots and all crew members on the Dali are accounted for. There are no reports of injuries, the ship’s management company, Synergy Group, said in a statement on March 26.

ABC News reports that the crew of the vessel made a desperate mayday call in an attempt to warn transport officials that the crash was about to occur. A report from the Cybersecurity and Infrastructure Security Agency, seen by ABC, says the Dali “lost propulsion” and that the crew were aware they had “lost control” of the ship. Maryland governor Wes Moore told reporters that , thanks to the mayday call, officials were able to stem the flow of traffic over the bridge, an intervention that he says “saved lives.”

Mercogliano says it is very difficult for ships of this size to make rapid adjustments to their trajectories. Video footage shows a sudden outpouring of smoke from the vessel’s stack, indicating a change in engine activity of some kind. What is particularly disturbing is that, in this case, the vessel ends up plowing straight into one of the key supports for the bridge, clearly off course. No information as to why this happened has become public.

Photographs of the aftermath show the bow of the ship pinned beneath fallen sections of the bridge . The anchor chain is visible, meaning that at some point the anchor was dropped, though it is not certain whether this happened before or after impact. The chain appears to be at an angle, however, which Mercogliano says could be a sign that it was dropped shortly before the crash and dragged for a brief time.

Lawyer James Turner of Quadrant Chambers in London specializes in, among other things, ship collisions. He says that there would have been no automated systems on board a merchant ship of this kind able to prevent the impact. Information from radar, AIS, and visual observations would have been available to the crew, however.

But data-collecting systems may now reveal exactly what happened. As on airplanes, commercial ships have data and audio recorders on the bridge, which are often a key source of information for investigators post-incident. “The master will hit a button and that ensures that the last two hours of audio recording are preserved, as well as all the data from the various parts of the ship, like the engine and steering and so on,” explains Turner. “That can be downloaded and queried.”

He adds that estimates of the ship’s speed at the time of the incident as recorded by AIS are likely “99.99 percent accurate.”

For now, the focus of responders will be on locating survivors from the fallen bridge. Two people have been rescued, one of whom is in the hospital. Six construction workers remain missing .

The disaster has come at a difficult time for shipping, with drought afflicting the Panama Canal and Houthi attacks striking multiple vessels in the Red Sea in recent months. Somali piracy is on the rise again , also. The grounding of the Ever Given in the Suez Canal is very much still within recent memory—it occurred a mere three years ago.

The Port of Baltimore insists in a statement that it has not been shut down—road vehicles are still operating within the port—however, all ship traffic in and out is suspended until further notice. AIS data reveals around a dozen commercial vessels at anchor outside the port, their entry now blocked by the stricken bridge and the Dali . It will take some time for the US Army Corps of Engineers to remove the steel pieces of the bridge, which present a significant threat to passing vessels, from the river.

“Whatever ships are in the port are now stuck,” says Mercogliano, who notes that Baltimore is an important port in terms of car deliveries and coal exports.

Overall, he argues, maritime operations are extremely safe today, though the volume and velocity of trade mean that when things go wrong it can be especially serious.

“We move goods a lot faster than ever before, and there’s very little margin for error,” he says. “When there is a mistake, the mistakes tend to be very large.”

You Might Also Like …

In your inbox: Introducing Politics Lab , your guide to election season

Google used her to tout diversity. Now she’s suing for discrimination

Our in-house physics whiz explains how heat pumps work

The big questions the Pentagon’s new UFO report fails to answer

AirPods Pro or AirPods Max? These are the best Apple buds for your ears

Alex Christian

Matt Reynolds

Rob Reddick

Beth Mole, Ars Technica

Stephen Armstrong

IMAGES

VIDEO

COMMENTS

Kato Marine has been builidng sailboat arches for 20 years. Since we started our criteria was that the arches should be; (a) aesthetically pleasing, (b) strong, functional and made from stainless steel, and (c) finished to Kato's usual high standards. Soon we found ourselves making the arches for the same boat models repeatedly and we started ...

For Sailors, the "Tower in a Box" Arch from Atlantic Towers is designed to mount to the deck, transom, hull sides or a combination. The approximate 30 degree angle, clears most existing biminis, back stays, and pushpits. Mounting hardware (feet) is shipped loose and epoxied and screwed into the legs at the time of installation.

In 2017, Fiona and her husband completed a 3-year, 13,000-mile voyage from Vancouver to Mexico to Australia on their 35-foot sailboat. Solar arches and radar arches are common on cruising sailboats but they can be pricey. We built our own sailboat arch for only $200.

We build and ship custom stainless steel davit arches across North America. For international clients, we offer extended services to work with your local fabricator. For a personalized Klacko Arch Consultation please contact Doug Gierula by email or phone. An extensive portfolio of our sailboat arch fabrication can be found here

When deciding to invest into a Sailing Vessel Radar Arch, we can provide the highest quality design on the market. Our design incorporates many of your boats systems into one place with an integrated davit system, solar panel mounts, and many more accessories. Conditions can get rough on the open ocean, we guarantee the integrity of all Radar ...

Atkins & Hoyle is the leading North American manufacturer of the highest quality marine products. Our portlights for sailboats, marine boat hatches, boat hardtops, yacht davits, sailboat davits, dinghy hoists and other dinghy lift systems and marine cranes are unmatched in the industry. Our stainless steel radar arch is modular and fully ...

Boat Arch / Radar Arch. $ 180.99. Add. Enhance your boat with our robust boat arches. Ideal for radar and fishing, these arches combine functionality with style. Shop our selection now.

A unique patented design available exclusively from Atlantic Towers, manufactured from all aluminum in natural aluminum or gold anodized finish Adjust-O-Launchers can be pivoted thru 12 positions for unmatched flexibility. Fits all marine standard 1-1/2" pipe (1.90" o.d.) AJ30500C Clear Anodizing: $119.00.

Wells Marine has been selling stainless steel arches for cruising sailboats for nearly 25 years. You can sometimes see Wells at boat shows where you can go through their library of binders with pictures of boats they've adorned with roughly 100 lb arches made of 1.5" 316L stainless tubing. I even found my boat in their binders, a Celestial ...

Special thanks to Anders, who made it possible for us to purchase this arch (and therefore make this video) by giving us his old radar. Without it, we would ...

Adjusts to fit 104" to 123" - $2099. Radar Arch for Express Style Boats. Adjusts to fit 88" to 100" - $1799. Adjusts to fit 92" to 112" - $1899. Adjusts to fit 104" to 123" - $1999. (add 4 rod rocket launcher $390) View all Radar Arch Options. Proprietary telescoping design allows adjustment to fit larger express style and flybridge boats to 40'+.

We are proud to serve the marine industry by manufacturing exceptional stainless steel products. (705) 725-1779 (800) 268-0395 Home; About; ... Radar arches; Anchor carriers; After market bolt-on anchor carriers ... At Stainless Outfitters Inc., we proudly serve the marine industry and create exceptional stainless steel products for boats ...

The width of the arch (1,5 m - 4,5 m) Suitable for most sailboats between 25 and 55 feet. The height of the arch (1,2 m - 2,5 m) Forward legs offset, meaning how much you want the forward legs spread out to the sides, relative to the aft legs. Height of horizontal cross-tubes. Length of and distance between davits.

Custom - Modular Stainless Steel Radar Arch for Boats. Al Mg Cast Connections, Zero Welds. Strong, light, and very durable. Made in Canada, Shipped Globally. ... Upgrade your arch from Alum. to Stainless Steel Double the strength! CAD $1500.00. USD aprx $1122.75-+ Add to cart: Solar Panel Mounts

Here are some quick photos of a recent project on a Jeanneau 42 DS sailboat. This Stainless Steel arch is fabricated to transport a 10ft rib and approx 600W of solar panels for bluewater cruising. New sternrails are integrated for better strength and storage capacity. Siderails integrated to existing gate stanchions for a fully integrated

The free-standing Oceansouth Boat Arch is an excellent addition to your boat. It is easily assembled and features unique universal mounts. The universal base mount features a beveled base which enables a variety of possible mounting positions. Designed to fit any Boat; Ø1¼" 316 Stainless steel tube; Folding for Storage & Trailering

At Stainless Outfitters Inc., not only do we suggest that you add a radar arch to your boat, but we also recommend choosing our high-quality stainless steel radar arches for the best possible fit and usage. Radar arches serve multiple purposes, primarily for safety as you navigate crowded waters or plan to do any boating at night. Radar arches ...

More than 15 years manufacturing custom stainless steel arches for sailboats. We have developed these 2 standard arches, adaptable to any sailboat up to 50 feet. Eolios Arch. MonoArch ITC. With a system of ball joints that allows the arch to be adjusted to any transom and to pass the cables through the inside of the tubes.

26M Stainless Transom Arch. At the BWY rendezvous two weeks ago one of the boats had a new Stainless Steel transom arch installed that BWY is now selling. I shot a couple pictures for everyone to look at as some here have talked about building ones for their boats. It has a double bow construction with connectors.

THE FUTURE OF SOLAR ARCHES FOR SAILBOATS. STRONG AND STYLISH. OPTIMISED FOR SOLAR PANELS. CUSTOM FIT FOR YOUR BOAT. MADE FROM STAINLESS STEEL. Complete solar power solution for your boat ... Affordable and stylish stainless steel arches for mounting solar panels on your sailboat!

Sep 11, 2019. 126. Hunter 49 2 San Diego,Ca. Jul 11, 2021. #4. Georgedoyle said: On my 49, there are two holes on each side where the arch articulates. To run wire through them, you need to detach your Bimini, remove the screws, and fold the arch forward. You'll be able to see the holes.

Steel structures aren't as strong as you might think—and the immense power of a container ship shouldn't be underestimated.