This article is an excerpt from NauticEd’s online FREE Basic Sail Trim Course , an interactive online sailing course for beginner to intermediate sailors to learn the basics of sail trim. Or if you want to learn more, upgrade to the Skipper Course Bundle to become a competent sailor!

You can learn to sail and improve your sailing with NauticEd, the international leader in sailing education.

Fairlead Control

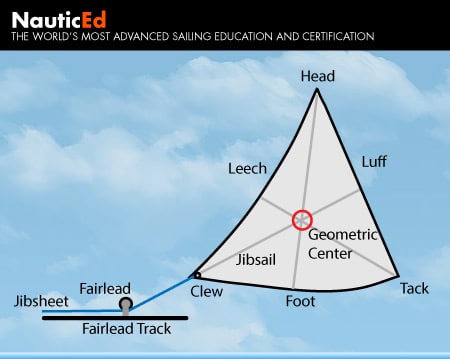

The fairlead is the first control device that the jib sheet passes through on its way back to the cockpit. You can move the fairlead forward or backward.

When you move the fairlead all the way forward, the angle that the jibsheet pulls down and back on the jib sail changes so that it is pulling down more down on the leech (back trailing edge) of the sail and less along the foot (bottom) of the sail. Therefore, in the wind, you’d expect that the foot might pooch out more whereas the extra tension on the leech would keep it taut.

Conversely, when you move the fairlead all the way back towards the cockpit, you’re pulling more tension on the foot and less on the leech. In this case, in the wind, the foot would stay taut and not move much but the leech would “twist” out and away downwind. This is especially prevalent at the top of the jib where there is little tension holding it in place.

Obviously, then, there is a balance of where the fairlead should be set depending on sail set, boat heading, wind conditions, and reefing. Here is a really good and rough rule of thumb to use to set the fairlead position. First, imagine the geometric center of the triangular-shaped sail. This is defined by drawing imaginary lines from each corner to the center of each adjacent line. Where they all intersect, this is the geometric center. Now adjust the fairlead forward or back so that an imaginary line extending along the jibsheet would pass through the geometric center of the sail.

That’s a good rule of thumb and will keep you out of trouble. You can also predict from this rule that the fairlead should move forward if the jib sail is reefed. If the jib sheet is eased and the sail goes out and forward then the fairlead should also go forward. But this is a completely fine-tuning adjustment and most people, even racers, tend not to bother with this adjustment.

In the situation of high winds, we want to dump out or spill (not use) the wind at the top of the sail because it creates too much heeling force. Thus it’s easy to imagine that if we moved the fairlead backwards, it would reduce the tension on the leech and allow the leech at the top of the sail to twist out downwind and thus spill the wind at the top.

An example: You’re sailing along at about 60 degrees off the wind on starboard (wind coming over the starboard side of the boat first). You look at the telltales and the bottom ones are flying fine but the top red is flying wildly. What should you do?

Let’s work through the process; Red is on the port side of the sail and in this case, the outer side of the sail. So it needs more wind on it to smooth out its erratic behavior. If we move the fairlead backwards it lessens the tension on the leech and allows the top to twist out a little. When the sail twists out, more wind flows on the outer side of the sail and will thus straighten out the crazy red telltale.

If you’re not getting it – don’t worry. We’ve included an animation of a boat on a port tack here below to help understand. The challenge is to get all the telltales flying back. You’ll need to adjust the headsail and the fairlead control to make this happen. We’ve included two sail set scenarios: Close Reach and Reach. Click and drag on the sheet control and fairlead control to find the perfect combination to make all the telltales fly evenly backward. Then make adjustments to observe and predict the telltales based on the theory above.

Figure 3.2-2 Fairlead Control Animation for a boat on port tack.

Learn Basic Sail Trim for FREE...

A FREE 1-2 hour course that teaches how to work with sails to get your boat moving. The free Basic Sail Trim Course is for any aspiring sailor as well as experienced sailors wanting to learn more. Or, consider upgrading to the Skipper Course Bundle to become a fully competent skipper!

Fairlead Sailing: A Comprehensive Guide to Mastering the Technique

by Emma Sullivan | Aug 10, 2023 | Sailboat Maintenance

Short answer fairlead sailing: A fairlead is a device used in sailing to guide lines and ropes, preventing them from chafing or causing excessive friction. It is typically designed as a small wheel or block through which the line can run smoothly. Fairleads play an essential role in controlling sails, rigging, and other equipment on a sailboat, ensuring efficient operation and reducing wear on the lines.

What is Fairlead Sailing and Why Should You Try It?

Fairlead sailing, also known as close-hauled sailing, is a technique used by sailors to navigate directly into the wind. It involves positioning the sails at an angle to catch the wind ‘s power and propel the boat forward efficiently. While it may sound counterintuitive to sail against the wind, fairlead sailing offers a unique challenge and exhilarating experience that all sailing enthusiasts should try.

So why should you give fairlead sailing a shot? Well, let’s dive deeper into this fascinating technique.

First and foremost, fairlead sailing pushes your sailing skills to new limits. Unlike other forms of sailing where you can simply go with the wind’s direction or speed downwind effortlessly, fairlead sailing requires mastering precise sail trim and boat handling skills. It forces you to think strategically about weight distribution, steering techniques, and adjusting sails accordingly. This level of control enhances your overall understanding of sailing dynamics and hones your abilities on the water.

Engaging in fairlead sailing also connects you with tradition and history. Dating back centuries, this technique has been utilized by sailors across different cultures. By trying fairlead sailing yourself, you become part of a long-standing seafaring legacy that has shaped our maritime history. There’s something profoundly poetic about embracing these age-old techniques while harnessing nature’s power against all odds.

Moreover, fairlead sailing instills patience and discipline in sailors. As much as we’d love smooth-sailing conditions all the time, we know it’s never that easy when facing headwinds or challenging weather patterns. Fairlead sailing teaches resilience by requiring you to adjust your strategy constantly while remaining focused on achieving your desired course. It develops problem-solving abilities under pressure and helps build mental toughness – valuable traits not only in the realm of sailing but also in everyday life.

Apart from personal growth opportunities, there are many practical benefits to trying fairlead sailing too! For instance, it allows for greater maneuverability when navigating narrow passages or crowded waterways . By sailing close-hauled, you have more control over your boat’s direction and can easily tack without veering off track. This flexibility proves invaluable, especially when exploring unfamiliar territories or participating in regattas where precision is key.

Last but not least, fairlead sailing offers a remarkable sense of freedom and adventure. There’s simply nothing quite like the feeling of defying the wind’s force and sailing against its resistance. The sound of the sails fluttering as they catch every gust, the spray of saltwater on your face, and the sheer exhilaration of charting your own course against nature’s whims make fairlead sailing an unforgettable experience.

In conclusion, fairlead sailing is not only a technical skill to be acquired but also an inherently rewarding endeavor for any sailor. It challenges you physically and mentally while connecting you with centuries-old traditions and pushing the boundaries of what you thought possible on the water. Whether you’re an experienced sailor seeking new thrills or a novice looking to expand your repertoire, don’t hesitate to give fairlead sailing a try – it might just become your next great passion on the high seas!

Exploring the Step-by-Step Process of Fairlead Sailing

Fairlead sailing is a technique that every sailor should have in their skill set. It involves using fairleads to control the direction of the sail , allowing for better maneuverability in varying wind conditions. In this blog post, we will dive deep into the step-by-step process of fairlead sailing, shedding light on its importance and providing clever tips along the way.

Step 1: Understanding Fairleads Before we embark on this voyage into fairlead sailing, let’s first understand what a fairlead is. Simply put, it is a small metal or plastic device used to guide lines (ropes) around corners or obstructions on a boat. Essentially, they act as pulleys for better line control.

Step 2: Finding the Right Placement The next crucial step in fairlead sailing is determining the appropriate placement of your fairleads. This will largely depend on the size and type of boat you are sailing . The general rule of thumb is to position them at an angle that allows for a smooth and direct route for your lines, avoiding any unnecessary friction or obstruction.

Tip: When placing your fairleads, try imagining them as strategic intermediaries between you and your sail’s control. This mental exercise will help you understand how different angles can affect steering response and overall performance.

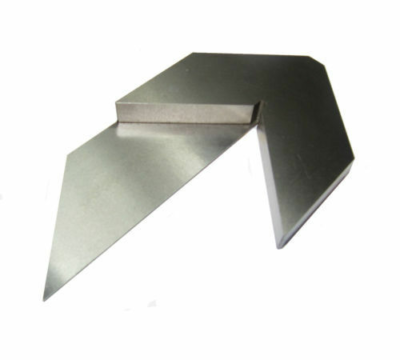

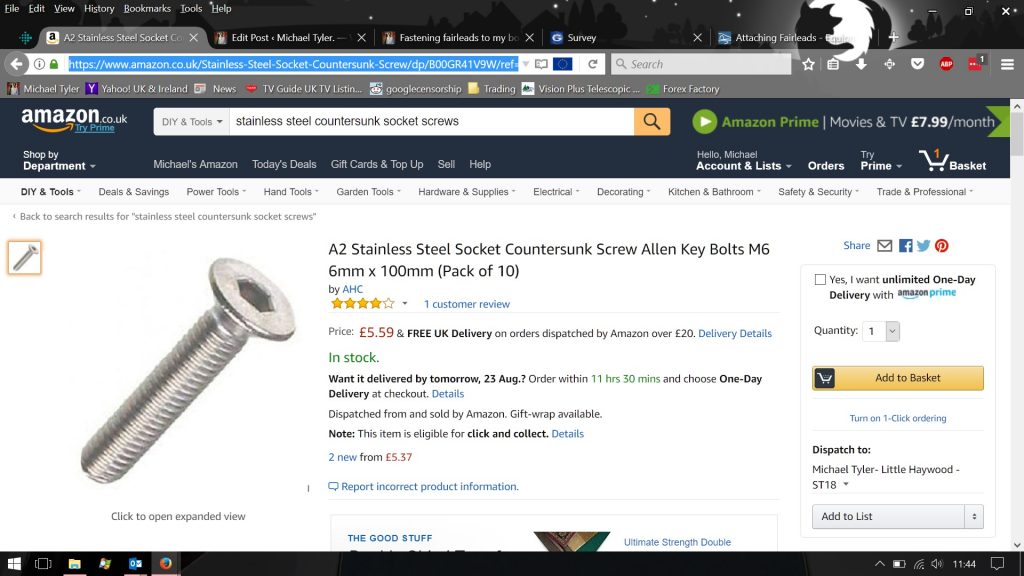

Step 3: Installing Fairleads Once you have determined the optimal positioning for your fairleads, it’s time to install them. Begin by selecting reliable hardware suitable for your specific boat setup – remember that quality matters here! Securely mount each fairlead with appropriate fasteners to ensure stability during maneuvers.

Pro Tip: Consider choosing low-friction materials like high-density plastics or stainless steel when installing your fairleads. These materials minimize unnecessary resistance and allow for smoother line management – a definite game-changer!

Step 4: Rigging Your Lines After successfully installing your fairleads, it’s time to rig your lines through them. Whether you are adjusting your headsail sheets or controlling the mainsail, ensure proper alignment through the fairleads. This will guarantee astute control and enhanced responsiveness when navigating challenging wind conditions.

Step 5: Put It into Action Now that everything is set up, it’s time to put your fairlead sailing skills to the test! Start by positioning yourself at the helm with a keen eye on your sail trim. As you make adjustments, pay close attention to how the fairleads affect line tension and overall handling. Fine-tune as necessary to optimize your sailing experience.

Clever Trick: One clever trick experienced sailors employ is marking their lines where they pass through the fairleads. By doing so, they can easily gauge any potential wear or stress points, allowing for timely maintenance – prevention is always better than cure!

In conclusion, fairlead sailing should be viewed as an art form – a dance between sailor, boat, and nature’s elements. With careful placement, quality installation and rigging techniques along with thoughtful experimentation on-the-water, you will develop a deeper understanding of how best to exploit this technique in different sailing scenarios. So next time you hit the open waters, embrace fairlead sailing and make waves like never before!

Frequently Asked Questions about Fairlead Sailing Answered

Welcome to our blog section, where we answer the Frequently Asked Questions about Fairlead Sailing. We understand that sailing terminologies and techniques can be a bit overwhelming for beginners and even experienced sailors. That’s why we have put together this detailed professional, witty, and clever explanation to provide you with all the information you need regarding fairlead sailing.

Q: What is fairlead sailing? A: Fairlead sailing refers to the practice of using fairleads on a sailboat to guide lines or ropes in order to redirect or control their path. Fairleads are typically mounted on the deck or mast of a boat and assist in reducing friction while allowing efficient adjustments during sailing maneuvers .

Q: Why are fairleads important in sailing? A: Fairleads play a crucial role in sailing as they prevent chafing and ensure smooth running of lines when adjusting sails or controlling other aspects of the boat. They help maintain optimal performance by reducing friction between lines and various parts of the vessel, allowing for quick and precise adjustments without compromising overall efficiency.

Q: How do fairleads affect sail trim? A: Proper placement of fairleads is essential for achieving optimal sail trim. By guiding control lines through fairleads placed strategically on the deck or mast, sailors can fine-tune sail adjustments such as halyard tension, jib sheeting angles, or cunningham controls. This ensures that sails are perfectly shaped, minimizing drag and maximizing speed.

Q: Do different types of fairleads exist? A: Yes! There are various types of fairleads available based on your specific needs. Some common types include standard eye fairleads, open roller fairleads (featuring rollers to further reduce friction), ball bearing ring fairleads (providing minimal resistance), and double-sided cheek block style fairleads (allowing line entry from two opposite sides). Choosing the right type depends on factors like expected load, line diameter, desired movement efficiency, and personal preference.

Q: How can fairleads be used for headsail control? A: Fairleads are commonly used in headsail control to optimize sail shape. By adjusting the position of the genoa sheet fairlead, you can change the angle and tension at which the jib or genoa is held against the wind. Proper alignment through fairleads ensures minimal friction and facilitates smooth trimming, allowing for faster acceleration and improved pointing ability.

Q: Are there any maintenance tips for fairleads? A: To keep your fairleads performing at their best, regular maintenance is crucial. We recommend periodically checking for wear or damage, such as cracks in plastic fairleads or corrosion on metal ones. Lubricating moving parts with a suitable marine grease will also help reduce friction and ensure smooth operation.

We hope these answers have provided you with a better understanding of fairlead sailing! Incorporating this knowledge into your sailing routine will help enhance your overall experience on the water. Happy sailing!

Top Tips for Mastering Fairlead Sailing Techniques

Fairlead sailing techniques are essential for any sailor looking to improve their skills and make the most of their time on the water. Mastering these techniques can greatly enhance your sailing abilities, allowing you to navigate more efficiently and effectively. Whether you’re a seasoned sailor or just starting out, these top tips will help you become a fairlead sailing pro in no time.

1. Understand the Concept of Fairlead:

Before diving into fairlead sailing techniques, it’s crucial to have a solid understanding of what fairlead actually means. In simple terms, fairleads are devices that guide control lines from sails and other sail -handling equipment in an efficient manner. They help ensure smooth movement and reduce friction during maneuvers on the boat.

2. Choosing the Right Fairleads:

One of the first steps towards mastering fairlead sailing techniques is selecting the appropriate fairleads for your boat. Factors such as boat size , rigging configuration, and intended use play a significant role in determining which type of fairleads will work best for you. It’s worth investing some time researching different options and seeking advice from experienced sailors or rigging experts to ensure you choose the right ones.

3. Proper Control Line Rigging:

Once you have your fairleads sorted out, it’s essential to rig your control lines correctly. This involves positioning and securing them through the appropriate fairleads to achieve optimal sail control. Take the time to adjust line lengths and tension properly, as this can significantly affect maneuverability and responsiveness in different wind conditions.

4. Sail Trim Techniques:

When it comes to sail trim, using your fairleads effectively is key. Experiment with adjusting both sides of the sail independently by moving your control lines through different sets of fairleads during various points-of-sail (upwind, reaching, or downwind). Observing how these adjustments impact performance will allow you to optimize power generation while maintaining balance and stability.

5. Maintaining Optimal Angles:

As you become more comfortable with fairlead sailing techniques, pay close attention to the angles at which your control lines enter and exit the fairleads. Both vertical and horizontal angles can significantly affect line friction and consequently impact performance. Aim for smooth entry and exit points, minimizing any sharp bends that could cause unnecessary wear or restrict movement.

6. Continuous Learning and Practice:

Mastering fairlead sailing techniques is an ongoing process that requires continuous learning and practice. Attend workshops, read books/articles, or seek insights from experienced sailors to expand your knowledge base. Additionally, spend ample time on the water experimenting with different combinations of fairleads, rigging setups, and sail trim adjustments to develop a deeper understanding of how these elements interact.

7. Embrace Feedback and Adaptation:

Finally, be open to feedback from fellow sailors or coaches who can provide valuable suggestions for improving your fairlead sailing techniques. Each boat has its own unique characteristics, so what works well for others may require some adaptation for optimal performance on your vessel . Continuously fine-tuning your approach based on feedback will ultimately help you reach new heights in mastering this essential aspect of sailing.

In conclusion, mastering fairlead sailing techniques requires a combination of knowledge, skills, practice, adaptability, and a touch of creativity. By incorporating these top tips into your training routine, you’ll soon find yourself confidently maneuvering through various wind conditions while optimizing speed and efficiency on the water. So go ahead – set sail towards becoming a fairlead sailing expert!

The Benefits of Incorporating Fairlead Sailing into Your Boating Routine

When it comes to boating, there are a multitude of techniques and practices that can enhance your experience on the water. One such technique that is gaining popularity among boating enthusiasts is fairlead sailing. This technique not only adds a touch of elegance to your boating routine but also offers a range of benefits that can greatly improve your overall sailing experience .

So, what exactly is fairlead sailing? In simple terms, it refers to the practice of using fairleads – small metal or plastic guides – to redirect lines on a boat . By incorporating these guides into your sailboat’s rigging system, you can achieve more efficient sail control and maneuverability. Let’s delve deeper into the advantages of incorporating fairlead sailing into your regular boating routine.

Improved Sail Control: Fairleads allow for better control over the sails by reducing friction on the lines. When lines are rerouted through fairleads, they glide smoothly without any unnecessary resistance or chafing against other parts of the boat . This improvement in sail control enables you to make precise adjustments and fine-tune your sails for optimal performance in different wind conditions.

Efficient Line Handling: With fairlead sailing, line handling becomes much easier and more efficient. The use of fairleads ensures that lines are properly guided around obstacles such as bulkheads, coamings, or stanchions without getting tangled or obstructed. This eliminates frustrating situations where linework gets jammed or hampers quick responses during maneuvers.

Enhanced Maneuverability: Fairlead sailing provides sailors with increased maneuverability due to the reduced friction on lines. Redirecting lines through fairleads allows for swift adjustments and greater ease in changing directions or carrying out complex maneuvers like tacking or jibing. As a result, you’ll find yourself navigating through tight spots or crowded harbors with great finesse and confidence.

Reduced Wear and Tear: Friction causes wear and tear on both lines and the boat itself. By incorporating fairleads into your rigging system, you can significantly reduce this friction and extend the lifespan of your ropes and sails . Moreover, the reduction in wear and tear on lines means less frequent replacement, translating into cost savings over time.

Safety First: Fairlead sailing also enhances safety while out on the water. With smoother line control comes reduced risk of sudden jerks or snags that could potentially lead to accidents or injuries onboard. The secure routing of lines through fairleads ensures a neat and organized sailboat deck, minimizing tripping hazards and creating a clutter-free environment for you and your fellow passengers.

Visual Appeal: Beyond the functional benefits, fairlead sailing adds an aesthetic touch to your boat’s overall appearance. The clean lines created by properly guided rigging enhance the visual appeal of your sailboat , showcasing a level of sophistication and attention to detail that sets you apart from other boaters.

Incorporating fairlead sailing into your boating routine is a simple yet impactful way to elevate your overall sailing experience. It not only improves sail control, line handling, maneuverability but also prolongs the life of your equipment while ensuring a safer environment aboard. So why not give it a try? Discover the myriad benefits of fairlead sailing for yourself and set sail with style!

Unlock the Secrets: Insider Insights on Perfecting Your Fairlead Sailing Skills

When it comes to sailing, there are few skills as crucial as perfecting your fairlead technique. While it may seem like a simple concept, understanding the nuances of fairlead sailing can make all the difference in enhancing your performance on the water. In this blog post, we will dive deep into the hidden secrets and insider insights that will help you master this essential skill.

First and foremost, let’s clarify what a fairlead is. Essentially, a fairlead is a device or passage that allows a line (such as a sail control line) to move smoothly along its predetermined path. By ensuring smooth movement of these lines, fairleads minimize friction and maximize efficiency – ultimately translating into improved boat handling and speed.

Now, let’s unlock some insider insights on how to perfect your fairlead sailing skills:

1. The Importance of Positioning: One key factor in effective fairlead sailing is proper positioning of these devices on your boat. Whether you’re dealing with jib sheets or other control lines, strategic placement of fairleads will significantly impact their overall efficiency. Experiment with different setups to find what works best for your specific sail plan and boat design.

2. Consider the Angle: Another critical factor to consider is the angle at which lines approach the fairleads. Ideally, you want them to be at an angle that allows for smooth movement without introducing unnecessary friction or wear. Be mindful of any sharp angles or areas where lines might rub against other objects – such points can easily cause unwanted drag.

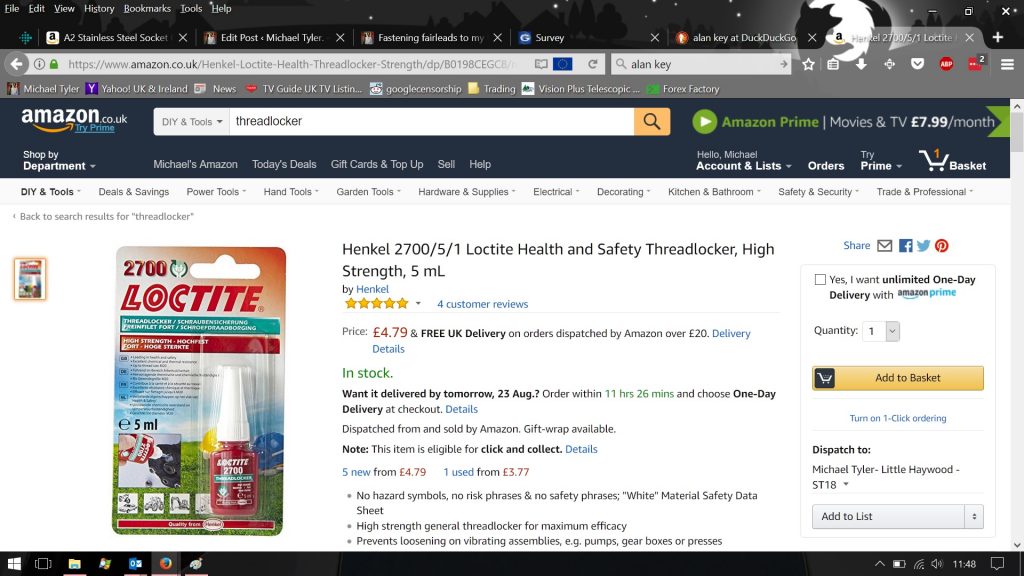

3. Constant Inspections and Maintenance: To ensure optimal performance, regularly inspect your fairleads for any signs of wear or damage. Over time, even small imperfections can accumulate and hinder smooth running lines – so prompt attention and maintenance are essential .

4. Don’t Forget Lubrication: Friction is the enemy when it comes to efficient fairlead sailing. To combat this, lubricate your fairleads regularly using a suitable marine-grade lubricant. This simple yet often overlooked step can make a world of difference in reducing resistance and allowing for seamless movement.

5. Communication is Key: When sailing with a crew, effective communication becomes crucial for successful fairlead sailing. Ensure that everyone understands their responsibilities when it comes to adjusting controls and trimming sails – cohesive teamwork will optimize fairlead usage and overall performance on the water.

Now that you’re armed with these insider insights, it’s time to spice things up with some professional wit and clever tips:

– “Just like a perfectly tailored suit, proper fairlead positioning is all about finding the right fit for your boat – so go ahead and play dress-up with those lines!” – “Think of your fairleads as the dance partners of your sail control lines – they need to move smoothly together without any clumsy missteps.” – “Pretend you’re a detective investigating ‘The Case of the Hidden Friction.’ Your mission? Uncover any hidden sources of drag and swiftly eliminate them from your fairlead setup!” – “Remember, sailors: maintenance is not just reserved for relationships. Keep those fairleads happy with regular inspections and TLC.”

In conclusion, uncovering the secrets behind perfecting your fairlead sailing skills requires attention to detail, strategic positioning, proper maintenance, clear communication, and a touch of humor along the way. With these insider insights in hand, you’ll be ready to unlock new levels of efficiency and performance on every adventure at sea. Happy sailing!

Recent Posts

- Sailboat Gear and Equipment

- Sailboat Lifestyle

- Sailboat Maintenance

- Sailboat Racing

- Sailboat Tips and Tricks

- Sailboat Types

- Sailing Adventures

- Sailing Destinations

- Sailing Safety

- Sailing Techniques

Cleats and fairleads

Cleats can be bought in a variety of shapes and sizes. In general the larger a cleat, the less the wear on lines and the easier it will be to make up a line on it. There should be no sharp edges anywhere on the cleat. Every boat should be equipped with at least four deck cleats for mooring and larger boats should have more. A Samson post or central bollard, which provides a stronger point at which to secure lines and the anchor chain, is often fitted on the foredeck and sometimes at the stern as well. Fairleads located at the bow and stern of a boat are used to guide lines onto the boat and prevent them from becoming entangled in the lifelines and rigging. Fairleads can be open at the top or closed. The latter are generally preferable as the line cannot slip out. Sometimes they are set into the raised edge around the foredeck. like cleats, fairleads should have no sharp edges which could cause excessive chafe on your lines. A method of protecting against chafe is described, above right.

The layout of a foredeck with a central bollard, showing the cleats and fairleads.

CRUISING/Preparation for docking

Preparation for docking

When coming in and out of congested harbors and marinas, if you have an engine, you should always use it. This does not mean, however, that you should not bother to learn how to handle your boat under sail in such situations. Inevitably, there will come a time when, owing to engine failure, you will have to maneuver under sail and you must be prepared for such an eventuality. This means that you should practice regularly, preferably at times when you have room to make a mistake. Because of the risk of engine failure when motoring, you should always have at least one sail ready for hoisting and an anchor ready to be dropped in case of need. It is bad practice to leave from or return to a berth under power with the mainsail cover on, the headsails bagged in the fore cabin and the anchor stowed. Should the engine fail, it would take some time for the sails to be hoisted or the anchor dropped —by which time you could have drifted into another boat, causing considerable damage.

Continue reading here: Effects of wind and tide

Was this article helpful?

Related Posts

- Getting in and out - Sailing Procedures

- Boat Parts For Beginners Sailing Cleats Shackles

- Ketch Schooner Yawl Cutter

- Reefing - Sailing Procedures

- Catamarans - Sailing Procedures

- Changing course - Sailing Procedures

Readers' Questions

How to run lines through a fairleads to a mooring cleat?

To run lines through a fairlead to a mooring cleat, follow these steps: Determine the direction of the desired line from the fairlead to the mooring cleat. Start by passing the line through the fairlead, which is a device that guides the line and prevents chafing. Pull the line firmly through the fairlead until there is enough slack to reach the mooring cleat. Thread the line over the top of the mooring cleat, making sure it is positioned correctly to ensure a secure hold. Wrap the line around the base of the mooring cleat, moving in a figure-8 pattern. After a few wraps, create a half-hitch by passing the line under itself and then over the cleat's top horn or through a locking mechanism if present. Continue forming half-hitches until the line is secure. Ensure the line is tight and the knots are secure by pulling on it gently. To untie the line, simply remove the half-hitches and unwrap the line from the base of the mooring cleat. Pay attention to any specific instructions or guidelines provided by the manufacturer or harbor/marina regulations regarding proper line handling and cleat usage.

Practical Boat Owner

- Digital edition

- Ben Meakins

- September 22, 2009

A device made to lead a rope smoothly or fairly. May be made of plastic or wood or metal, and in a variety of forms. Some fairleads are open, for example those mounted on side-decks to prevent chafe of mooring lines, and others are closed as is the case with the Bullseye sheet lead. A fair lead is fixed to the boat, whereas a Dead-eye is usually free to move: for example a dead-eye may be attached to a sail.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Tartan 30: An Affordable Classic

Ericson 34-2 Finds Sweet Spot

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Solar Panels: Go Rigid If You have the Space…

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

Waste Not is the Rule. But How Do We Get There?

The Scraper-only Approach to Bottom Paint Removal

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sails, Rigging & Deck Gear

Refining Furling Line Fairleads

Low-friction harken blocks stand out in pss fairlead test field..

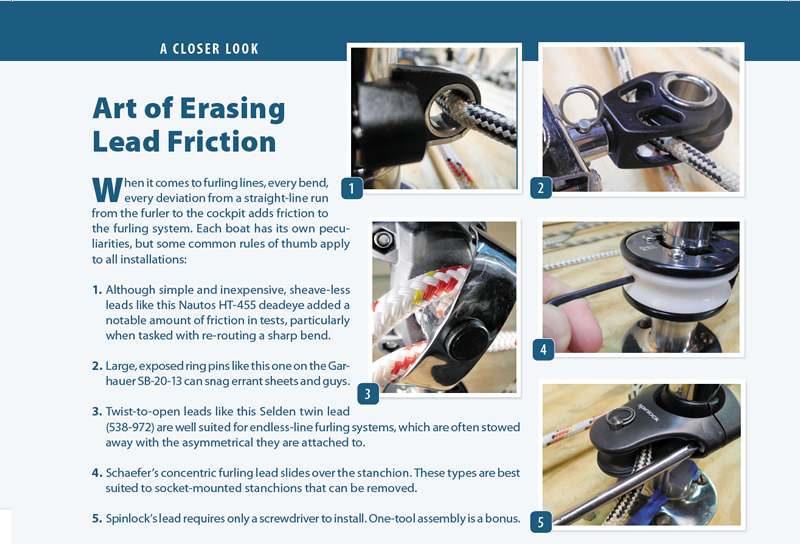

There was a time when headsail handling meant snapping on bronze piston-hanks and hauling on a smooth-running halyard. Times have changed, and now its all about how the furling drum rotates and the headsail wraps around a foil-covered headstay or freewheeling torque rope. (See PS August 2009 for our in-depth jib furler comparison.) Some systems behave more willingly than others, but all benefit from low-friction leads guiding the furling line back to the cockpit. The following report takes a close look at how these fairleads stack up and how much efficiency they add to the furling process.

Every bend and change of direction in a line requires a fairlead or block, and some amount of friction is added at each deflection, increasing the total tension it takes to furl the sail. Interestingly, the ideal number of routing blocks is none; a straight run with no line deflection generates zero friction. But few deck designs and hardware layouts allow for a straight and direct line lead.

On most boats, the furling line is shunted outboard along the stanchions in order to keep the decks uncluttered. Because routing along the stanchions defies the rule of straight-line efficiency, it makes sense to minimize the friction through the use of low-drag blocks for furling-line fairleads. Fortunately, the industry has responded to our headsail furling needs by designing and manufacturing a wide array of stanchion-mounted blocks that pivot, twist, and align with changing angles of pull.

The range of products dedicated for this purpose is surprising. Ultimately, we winnowed the field to 20 different furling line fairleads from six manufacturers. Our assumption going into this test was fairly straightforward: Friction caused by line deflection is an enemy to furling efficiency. Our search focused on finding the blocks that generated the least amount of friction, as measured on our now-familiar test jig , but we also looked at other elements that are critical to this function.

During the course of testing, it became clear that there are different segments of a line lead, each with specific challenges. No single fairlead fit all the demands of running a furling line from the stem to stern. For example, the initial lead from the furling drum to the first fairlead involves multiple constraints. This block not only guides the line; but it keeps it spooling evenly and prevents it from chafing on the drum cover.

Following the all-important lead block is a set of routing fairleads. These keep the furling line following the curve of the lifeline stanchions. Finally, there is the last block, one that must smoothly redirect the furling line to a belay point (jammer, cleat, cam cleat, rope clutch) in the cockpit.

What We Tested

Although you could make your own furling fairleads by pairing a set of specialized blocks or deadeyes with homemade Dyneema loops and shackles (see PS April 2015 online ), this test is limited to pre-fabricated hardware that easily clamps to lifeline stanchions, requiring little time or effort to install.

After some preliminary testing, it became clear that these fairleads fell into five specific categories, based on their purpose or design characteristics. Three sheaveless deadeye fairleads were put in one group; blocks that featured wide-angle, multi-axis articulation were put in another. Fixed, non-articulating blocks had their own category, as did single-axis blocks that articulated in only one plane. Three of the six manufacturers in the test sent a block that led the furling line outboard of the stanchions-these, too, had their own category.

Garhauer, a California-based company known for providing rugged, affordable sailing hardware, submitted four different products to test. Each one clearly reflected the companys highly customizable, machine-shop approach to manufacturing. These mostly metal, clamp-on blocks feature highly polished stainless-steel and anodized aluminum shells and high molecular weight plastic bearings. Three of the Garhauer blocks were clamp-on designs, while one was a dual-sheave fairlead that slipped onto the stanchion, requiring that either the stanchion or the lifelines be removed.

Harken, a long-time leader in sailing hardware and a prominent player in the racing scene, provided several products, each offering an effective way to overcome furling-line friction. Its selection included a set of classic bullet blocks with stainless-steel shells reinforced with stainless-steel straps, a couple of 40-millimeter, lightweight Carbo blocks, and a larger 57-millimeter ratcheting lead block. Four of the five Harken fairleads were injection molded, a process in which nylon resin reinforced with glass fiber is thermo-molded to form the shell and clamp body. More and more products in the Harken lineup are constructed using this process.

Nautos, an international sailing hardware company with manufacturing facilities based in Brazil, also favors an injection-molded body. A clamshell-like clamping arrangement secures its blocks to the stanchions. The four products the company provided included three clamp-on block leads and one deadeye fairlead. As with Harken, Nautos largest swiveling lead block also had a ratchet function. The ratchet, which adds friction to the block when tension is applied in the direction of the drum, helps to reduce the load between pulls and adds some tension to the line as the sail unfurls.

Schaefer, an American company with a long history in the sailing hardware business, remains committed to stainless-steel blocks and clamps. Its blocks incorporate Delrin ball bearings and efficiently designed races to reduce friction. Ring pins and Nylock nuts ensure that fasteners don’t slip. Schaefers outside-the-stanchion clear-step fairlead block is designed to keep decks clear on smaller boats, or on cruising boats with narrow sidedecks that could quickly become cluttered if the lines were routed inboard. Its spring-supported lead block twists to align with challenging furling drum lead angles at the all-important first fairlead on the pulpit.

Selden, the Swedish spar maker that has expanded into the hardware business, sent us four injection-molded, bushing-type, mini-sheave blocks that toggle in one plane. During installation, the owner carefully aligns the blocks according to the optimal furling line run. A set-screw then locks the angle in place. Selden also sent its quick-opening Double Fairlead designed for endless-line furlers. The lead is supposed to be paired with Seldens double cam-cleat, and presumably Seldens endless-line furler, one of the higher-rated products in our endless furler line test. (See PS April 2011 and March 2008 online.) Selden also manufactures a deadeye lead and ratchet block that are worth looking at; we plan to test these for a followup report.

Spinlock, a British company best known for its line of high-performance cam cleats and rope clutches (see PS November 2014 online ), manufactures two compact, lightweight stanchion-mount leads. The larger block incorporates a removable sheave to expedite use with endless-line furlers. It also can be tilted to adapt to minor offsets in lead angles. The smaller unit is an injection-molded, deadeye fairlead with a stainless-steel insert and a split clamp that attaches to the stanchion.

Photos by Ralph Naranjo

How We Tested

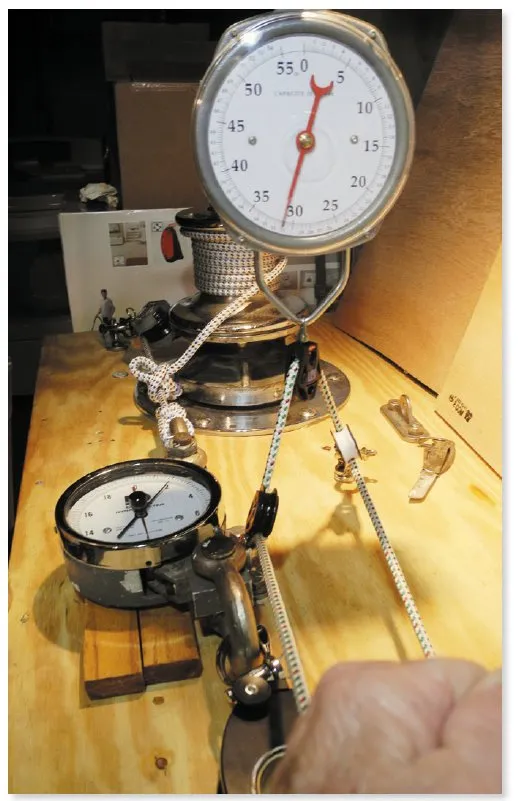

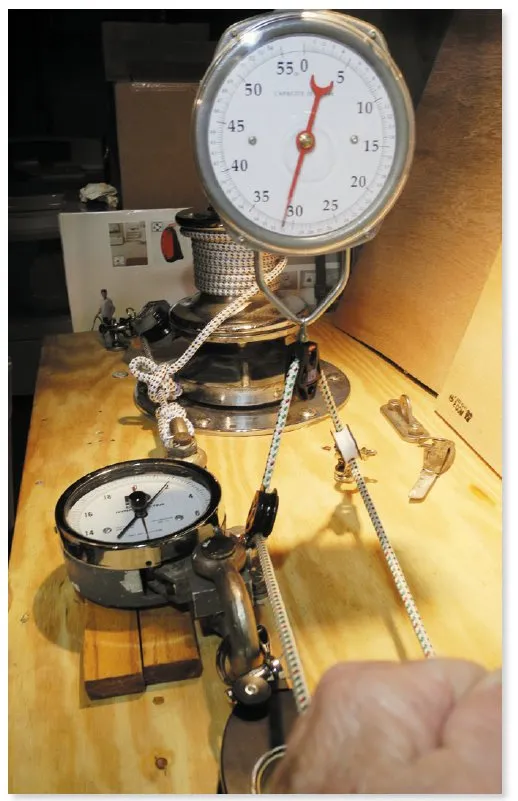

Our initial look focused on characteristics such as design, size, weight, and construction. The focus of our testing, however, was to accurately measure the friction each fairlead added to an evenly tensioned line.

The jig we used for testing was a variation of the jig we set up to measure friction in snatch blocks. (See PS August 2008 and August 2007 online .) Two large, smooth-running Garhauer snatch blocks were positioned opposite each other, and a continuous loop line was run between them. One block was fixed to a secure base, and the other was led to a Dillon dynamometer connected to an Ideal electric windlass. The windlass was used to tension the continuous loop running between the two blocks. After preliminary testing with line loads ranging from 50 to 500 pounds, testers settled on 200 pounds as the ideal tension for this test.

Testers then mounted a deck socket and lifeline stanchion to the test jig. The stanchion was set off to the side of the continuous loop, so that when the line was run through the fairlead being tested, the angle formed was 152 degrees (a close approximation of the angles formed in actual installations).

Before each test, testers tensioned the two, large ball-bearing snatch blocks to 200 pounds and used a spring scale to measure the force required to move the endless loop. This number, which varied between seven and eight pounds, became the baseline. For the test itself, the fairlead or block being evaluated was fixed on the stanchion and the loop was routed through it. Testers used the spring scale to measure the effort required to move the loop. We tested each block and deadeye fairlead five times. The highest and lowest scores were eliminated, and the middle three were used to determine an average.

In cases when a particular block design required slightly different mounting location on the stanchion (outside versus inside the stanchion, for example), testers could alter the position of the tension-inducing snatch block to ensure that the 152-degree offset angle remained consistent throughout the test.

We also took a close look at chafe points, the ruggedness of the clamp, and ease of inspection-particularly the ability to see how well the fasteners were attached.

The bench testing was supplemented with onboard real-world comparisons. This phase of the testing brought to light several key issues that were not readily apparent during our bench test.

Although our inspection of materials and construction offered insight into the durability of these fairleads, we did not fully explore longevity. A followup report will compare the long-term effects of weathering and exposure to ultra-violet rays, paying particular attention to corrosion resistance.

Observations

During onboard testing, we noted several different fairlead challenges. The first was at the bow, where the furling line leads from the roller drum to the first lead block. This location presented myriad alignment problems, and establishing the optimum lead angle and block twist at the pulpit was often frustrating.

The challenge of fitting the critical first fairlead, of course, will vary from boat to boat. In general, you want to position the lead block as close to the deck as possible; this reduces side loads on the furler and headstay. However, the height of the first block is usually determined by the position of the furling drum. The furling line should lead at a nearly perpendicular angle to the headstay (and thus the drum). In most cases, the first block is positioned on the pulpit rather than on the deck. In some instances, the first lead may have to be placed further aft on the deck.

Key attributes we look for in this first lead block are low friction, an ability to pivot in all planes, and an ability to swivel. A ratchet block can also be helpful here to grip the line between tugs and provide some resistance as the wind catches the sail and unfurls it. (See PS May 2009 online for our last test of ratchet blocks.)

The block used for the primary lead is often the right choice for the last turning point, where the furling line is redirected inboard toward a rope clutch, jammer, or cleat where it can be belayed in the cockpit. Swiveling, pivoting, and minimal friction are essential here, and if you are going to fit just one ratchet block, this is the most logical spot for that block.

Between the first and last blocks are several blocks that serve to maintain a fair lead and keep the decks clear. These tend to be fairly well aligned on a horizontal plane, but the vertical plane bows outward to follow the outline of the deck. Modern boats with narrow decks benefit from fixed leads that hold the furling line close to the stanchion, and many owners even consider investing in a set of outside-the-lifeline leads to keep narrow decks as clear as possible.

One of the key questions we had going into the test was how well the deadeyes, with their low-cost, easy-to-maintain design and no moving parts, compared to conventional blocks. The answer quickly became obvious: In terms of friction, blocks trump deadeyes every time-something sailors have recognized for centuries. In a no-load context, smooth surface, non-sheaved fairleads work just fine, but as soon as load increases, friction takes over and a deadeye delivers more grip than slip. When we finally tallied our test data, fairlead friction was three times greater when a line passed through a deadeye than when it passed over a sheave.

Lead/End Blocks

When it comes to lead blocks best suited to handling the rope-to-drum challenge, we liked Garhauers robust stainless-steel, spring-supported, freely articulating SB-25 and Schaefers 300-35, an elegant, smaller, and lighter rendition of a stainless-steel furling fairlead.

While stainless steel is a sensible material for a furling block, we are not averse to composite construction. Harkens composite 7401 proved to be a light and compact favorite. Its limited range of articulation may not be enough to suit all pulpit-to-drum geometry, but when it fits, its a star performer. Harkens dual-sheave model, the 7405 was a double-barrel rendition of this Harken lead.

Nautos (92088) and Harken (7402) both sent us blocks that featured a useful ratchet option. Both are effective as either the lead or end-point block, and the ratcheting feature helps prevent the furling line from slipping between tugs.

Both designs are slightly hampered by the use of some square-wheel geometry. The circular sheave of a regular block is replaced by an octagonal-shaped sheave that improves the ratchets holding power, but getting the line over the miniature high spots takes just a little extra tugging-as our tension readings revealed.

Bottom line: When the tug of war was over, the Garhauer SB-25 earned our Best Choice for lead furling block. For the cockpit-end lead, we gave the Best Choice to Harkens ratcheting 7402, which featured a secure four-fastener stanchion clamp and ball-joint articulation. It is more expensive, but in our view, its worth the extra cost. Our Budget Buy was the Nautos 92088, which added only minor friction but was significantly less expensive.

Articulating Blocks

All of the blocks in this group adapt to some tilt or angle change, but their flexibility is limited. Spinlocks SPWL-2 utilizes an innovative axial ball-joint that centers on the stanchion, allowing the sheave to can’t into alignment. There is no swivel function, so care must be taken to be sure that the range of tilt allows for a fair lead. This lightweight, small-sheave, bushing-type block (no roller or ball bearings) scored surprisingly well in friction testing-nearly as well as many of the ball-bearing-equipped blocks.

Two Nautos products that we tested, the HT-450A and the 92388, use the same two-bolt clamp. Each offers a single-plane tilting feature combined with a swivel function. These are well suited for stanchion-to-stanchion line guides. Both are bargain-priced, and the small-sheave bushing version (HT-450A) comes with a pull-pin to release the sheave. This feature, which lets you release the line from the block without threading back through it, could come in handy when trying to free a line that is hockled, knotted, or snagged. It will also benefit those who berth at a dock and like to stow the lines forward when alongside to reduce the trip hazard when boarding. The Nautos 92388 features a smooth-spinning, ball bearing race and is reinforced with stainless-steel straps.

The Selden 538-972 is an injection-molded composite lead that easily disassembles into its component parts. Its fiber-reinforced resin composite cage holds a plastic sheave that spins on a bronze shaft. It has a wide toggle range and an effective swivel action.

Bottom line: The Nautos HT-450A generated slightly more friction than the bearing-type blocks, but its attractive pricing and additional features, like swiveling ability and removable sheave, made it our Best Choice in this category.

Limited Articulation

This category features four blocks that spin smoothly but offer even less articulation than the above group. They are best suited to the middle section of a furling line that lacks any sharp angles of deflection. Two standouts were the Harken 168NP and the Garhauer SB 20-13. Each of these blocks features efficient ball bearings, a stainless-steel stanchion clamp, a full swiveling body, and a fixed mount. The chief difference between them is in the mounting. The Harken uses a rubber bushing and ball socket to allow a bit of flex, and this gives it a slight advantage over the smooth-running Garhauer.

Our favorite in this group was the Schaefer 300-34, a no frills, fixed-mount fairlead (no tilt and no swivel) that is carefully engineered to reduce the intrusion of the furling lines on your side-deck. The compact, ball-bearing block mounts on the inboard side of the stanchion, but it achieves almost the same results as an outboard-mounted lead by keeping the furling line close to the stanchion.

Garhauer also sent us a double-sheave furling block, model D, which is designed to accommodate twin leads from an endless furling line. The fairlead offers two bushing surfaces and a central ball-bearing sheave. This design allows you to open the fairlead and quickly insert the endless furling line rather than feed it through each block, one at a time.

Ideally, this block should be located on the stanchion so that the sheave that handles the inhauling line, which imposes the most load on the block and stanchion, is below the outhauling line. Poor alignment of this block can cause the line to rub on the stainless-steel side plates or bushing surfaces, causing a significant increase in friction.

Bottom line: The Schaefer 300-34 was our Best Choice in this category; its especially well-suited for those looking to maximize sidedeck space.

Deadeye Fairleads

The term deadeye is ancient mariner speak for a fairlead that has no rolling sheave or other mechanical means of reducing fiction. Shape, smoothness, lubrication, and material choice are the key variables. The fact that there are no moving parts to break hardly makes up for the increase in friction such engineering delivers.

Spinlocks SPWL1 and the Nautos HT-455 both feature injection-molded parts with a stainless-steel sleeve. Split clamps are used for mounting. Both are nicely crafted, but the lighter, slightly more compact Spinlock keeps the furling line a little closer to the stanchion. More importantly, the curved inside surface of the Spinlocks line-lead ferrule imparted far less friction that the flatter inside surface of the Nautos. The more rugged clamp body and visible hex nut on the Nautos will appeal to cruisers, but the slipperier Spinlock was still the testers favorite in this group.

Seldens easy-opening, twin-line guide is designed to accommodate lines led inboard of the stanchion. The Double Fairlead is not intended to be a lead or end block, only for the intermediate points. Interestingly, in our testing, it produced less friction and imparted less stress on the pivot spindle when mounted outboard.

Bottom line: Were not big fans of deadeyes, even for this application. If you do prefer the simplicity of going bearing-less, the Spinlock SPWL1 earned our Best Choice for conventional furling line while Seldens Double Fairlead earned a Recommended rating.

Outside the Stanchion Fairleads

Routing furling lines outboard of the stanchions can add more space to narrow, line-cluttered decks. Several hardware makers have blocks designed to surround a stanchion and lead lines outside just above well-secured bases.

Schaefers clear-step (506-44) is slipped over (or under) the stanchion and secured in place with a single se-screw. The blocks large-radius hub and ball-bearing system delivers a superior, friction-free spin. Harkens 7403 tandem sheave rendition clamps onto a stanchion without having to pull the stanchion from its socket or remove lifelines to install. Garhauers tandem, stainless-steel outside-the-stanchion lead can also be slotted right onto a stanchion and locked in place with just one cap screw.

Bottom line: It was tough to pick a winner in this group. All are in the $40 range and all scored well in our pull test. If you can pull your stanchions from their bases, or easily remove your lifelines, we like the Schaefer blocks. However, if the Schaefers are too much hassle for you to fit, either the Harken or Garhauer are a good choice for anyone looking to route their furling lines outboard. In the end, we picked the Harken 7403 as our Best Choice because of its slightly better friction rating.

We kicked off this round of testing with some preconceived notions-some held and some didnt. The most obvious assumption that stuck was that blocks trump deadeye fairleads, especially as loads escalate. What fell apart was the idea that one specific fairlead should be used at all deflection points along the furling line run. In order to get the most efficiency and reliability out of your furling fairleads, youll want to select the specific type block for the specific job. Thus, we have our various categories, arranged by design and function.

Among the most important lessons we learned was to make sure stanchions are well secured-especially when fairleads and tension loads are well above deck level. Keep fairleads as low as possible in order to lessen the leverage associated with side loading. And finally, give extra thought to the line lead angles at the rope drum and where the reefing line is finally tensioned by hand or by using a winch.

The bottom line is that friction adds up, and stringing together a series of inefficient line-deflection hardware makes little sense. Keep in mind that a clear, straight run always delivers less drag than a deflected line running through the best of blocks. So when engineering a route for your furling lines, try to minimize the turning points. This is easier said than done, so the next best thing is to choose blocks that score well in tension testing, not simply sound like a roulette wheel when you spin them with your finger.

Our final task was to pick a block from each category to suit the needs of a crew aboard a 35- to 40-foot cruising sailboat. In some cases, there were several options in a near dead heat, but after considerable debate, heres how the chips fell: The Garhauer SB-25 was our top articulating lead block; the ratcheting Harken 7402 was a favorite for the cockpit-end; the Nautos HT-450A was our favored limited articulating block (middle section); the Schaefer 300-34 was our favorite low-profile, inside-the-stanchion block; the Spinlock SPWL1 was our top deadeye-style block; and the Harken 7403 was our best product for use outside of the stanchion.

- Untangling Furling-line Fairlead Logistics

RELATED ARTICLES MORE FROM AUTHOR

Nice article, but you only show solutions for 1″ post. That is useful for most; however, I have larger diameter and difficulty finding anything for 1.25″ posts other than the larger Schaefer blocks which unfortunately tend to deform when tightened sufficiently (there is only one set screw) creating resistance.

Well, I was hoping Myles would get a response. There are more vessels (including mine)now have 1.25”. As has been stated, there are not many options. Any response or assistance would be helpful

Regards, Cristian

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Safety At Sea For You & Your Family – The Joe...

What’s The Best Vinyl Window Cleaner for Your Boat?

40-Footer Boat Tours – With Some Big Surprises! | Boat Tour

Electrical Do’s and Don’ts

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

What is The Difference Between Mooring Chocks and Roller Fairleads?

Boating is not only a leisurely pastime but also a crucial mode of transportation for many, and the safety and reliability of boats are paramount. When it comes to boat anchoring and docking, having the right equipment and mechanisms in place can make all the difference in ensuring a seamless and secure experience. Among the various components that play a crucial role in this process, mooring chocks and roller fairleads stand out as two key elements, each with its unique functions and advantages.

Boats of all sizes, from small recreational vessels to large commercial ships, rely on these mechanisms to guide and secure lines during mooring and docking operations. The effectiveness of these components can impact not only the safety of the boat and its occupants but also the longevity of the vessel itself. For boat owners and enthusiasts, understanding the distinctions between mooring chocks and roller fairleads is essential to make informed decisions when outfitting their vessels.

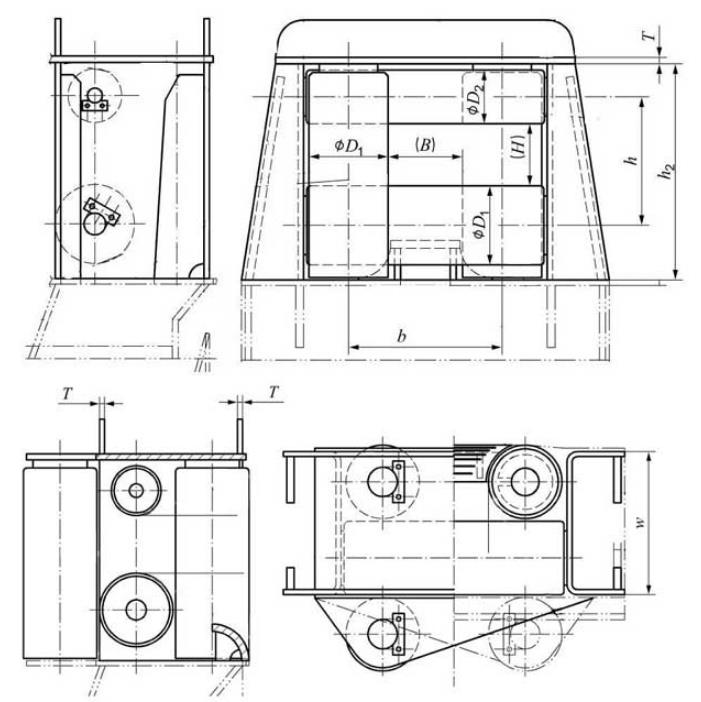

1. Mooring Chocks

What Are Mooring Chocks?

Mooring chocks are specialized boat hardware components designed to facilitate the secure and controlled management of lines used during mooring and docking. They are typically constructed from durable materials such as stainless steel or aluminum and come in various shapes and sizes to accommodate different boat types and line diameters.

How Do They Work?

Mooring chocks work by providing a designated channel or passageway for mooring lines. These lines are led through the chocks, which serve as guideposts to keep the lines in position. This controlled arrangement ensures that the boat remains stable and stationary while minimizing line movement, chafing, and potential damage to the boat’s structure. Mooring chocks distribute the forces applied to the lines, making them an integral part of safe and efficient mooring.

Types of Mooring Chocks

- Fixed Mooring Chocks

Fixed mooring chocks are permanently attached to the boat, offering a stable and unchanging point for securing mooring lines. They are generally ideal for vessels with specific mooring configurations and when consistent line positioning is required. Fixed chocks are robust and reliable, ensuring consistent performance during docking.

- Hinged Mooring Chocks

Hinged mooring chocks are designed to pivot or swing, allowing flexibility in line placement and adjustment. This flexibility makes them particularly useful for accommodating changing mooring conditions or different line angles. Hinged chocks can be locked into place when needed and are favored for their adaptability in various mooring scenarios.

Installation and Usage

- Proper Placement on the Boat

The correct placement of mooring chocks is critical to their effectiveness. They should be strategically positioned on the boat’s hull or deck to ensure that lines are directed away from the boat’s structure and into the water. The placement should account for factors such as boat size, line diameter, and mooring configuration.

- How to Secure Lines Using Mooring Chocks ?

To secure lines using mooring chocks, lines are threaded through the chocks’ passageways, ensuring they are properly tensioned. The chocks prevent lines from slipping or moving excessively, maintaining the boat’s position during mooring. Lines should be carefully and evenly distributed through the chocks to balance the load on the boat.

Advantages and Disadvantages

Pros of Using Mooring Chocks

- Enhanced safety: Mooring chocks help prevent lines from chafing, which can weaken them and compromise safety.

- Improved stability: They contribute to the boat’s stability during mooring and docking operations.

- Line management: Chocks keep lines organized and reduce tangling.

- Long-lasting: Quality mooring chocks are durable and resistant to corrosion.

Cons of Using Mooring Chocks

- Limited line adjustment: Fixed chocks may offer limited flexibility in line placement.

- Initial cost: Quality mooring chocks can be relatively expensive compared to some other line management options.

Mooring chocks are integral components for safe and effective boat docking and mooring operations . The choice between fixed and hinged chocks depends on specific needs and preferences, but both types play a crucial role in maintaining the security and stability of a boat during these critical maneuvers.

2. Roller Fairleads

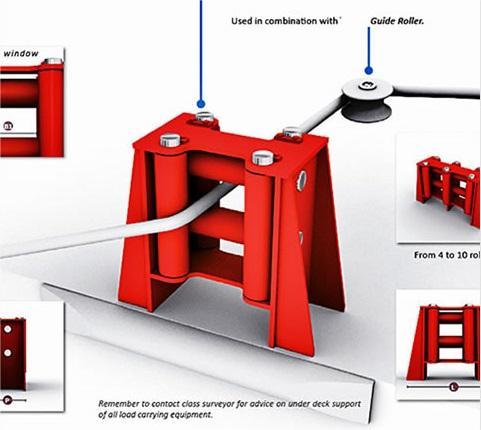

What Are Roller Fairleads?

Roller fairleads are essential components of a boat’s anchoring and docking system designed to guide and manage lines, ropes, or cables during various maritime operations. These components consist of a set of cylindrical rollers strategically placed to facilitate the smooth passage of lines while reducing friction and wear.

Roller fairleads work by minimizing the resistance between lines and the boat’s structure, allowing lines to move freely and effortlessly. The rollers reduce friction, which can cause chafing and wear on the lines, potentially compromising their integrity. Roller fairleads are commonly used in anchoring, mooring, and docking operations to maintain the integrity of lines and ensure safe, controlled movement.

Types of Roller Fairleads

- Vertical Roller Fairleads

Vertical roller fairleads are designed to guide lines in a vertical orientation, typically in situations where lines need to be led vertically or near vertically, such as anchor lines. They are commonly used to maintain proper tension in the anchor line and prevent it from coming into contact with the boat’s structure.

- Horizontal Roller Fairleads

Horizontal roller fairleads are configured to guide lines in a horizontal orientation. They are often used for lines that need to be led along the boat’s surface or deck, such as mooring lines. Horizontal fairleads ensure that lines are evenly distributed and prevent them from rubbing against the boat’s structure.

The placement of roller fairleads depends on the specific requirements of the boat and the type of lines they are meant to guide. Typically, they should be strategically positioned to ensure that lines pass through them without rubbing against the boat’s structure. Proper placement minimizes line wear and enhances safety during docking and anchoring.

- How to Route Lines Through Roller Fairleads

To route lines through roller fairleads, boat operators should thread the lines through the rollers, ensuring that they are guided smoothly and evenly. The objective is to prevent lines from tangling, chafing, or creating excessive friction, which could compromise the lines and the boat’s safety.

Pros of Using Roller Fairleads

- Reduced line wear: Roller fairleads minimize friction, preventing chafing and premature wear of lines.

- Line guidance: They guide lines efficiently, ensuring smooth and controlled movement during anchoring and docking.

- Enhanced safety: By preventing lines from rubbing against the boat’s structure, roller fairleads contribute to a safer and more secure boating experience.

Cons of Using Roller Fairleads

- Initial cost: Quality roller fairleads may involve an initial investment, but their long-term benefits often outweigh this cost.

- Installation complexity: Installing roller fairleads may require some expertise, especially for boats without existing fairlead systems.

Roller fairleads are indispensable components for maintaining the integrity of lines and ensuring safety during anchoring, mooring, and docking. They play a crucial role in preventing line damage and ensuring the smooth operation of these critical maritime maneuvers.

3. Key Differences Between Mooring Chocks and Roller Fairleads

Understanding the distinctions between mooring chocks and roller fairleads is essential for boat owners and operators to make informed decisions, as each component has its own set of advantages and is best suited to particular maritime scenarios. Proper selection and usage of these components contribute to safe, efficient, and reliable anchoring and docking operations.

4. Choosing the Right Option for Your Boat

(1) factors to consider.

Boat Size and Type

- The size and type of your boat play a significant role in determining whether mooring chocks or roller fairleads are more suitable.

- Larger vessels may require heavy-duty, permanently fixed mooring chocks, while smaller boats may benefit from the flexibility of roller fairleads.

- Consider the weight and dimensions of your boat to ensure that the chosen mechanism can handle the load effectively.

Docking Conditions and Environments

- The specific conditions in which you plan to dock your boat are crucial. Different environments may favor one mechanism over the other.

- If you frequently dock in changing or challenging conditions, roller fairleads may be more adaptable to handle varying line angles and friction.

- For consistent, stable mooring, mooring chocks might be preferable, especially in more controlled docking environments like marinas.

P ersonal Preferences and Usage Patterns

- Your personal preferences and usage patterns should influence your choice. Consider how you prefer to manage lines and what aligns with your boating habits.

- Some boat owners value the ease of use and versatility of roller fairleads, while others may prioritize the stability and durability of mooring chocks.

- Reflect on your own needs and how the chosen mechanism fits into your boating routine.

(2) Consultation with Experts

Seeking Advice from Professionals

- If you are uncertain about which mechanism is best for your boat, do not hesitate to seek advice from boating professionals or marine experts.

- Professional insight can provide valuable guidance based on your specific boat, docking conditions, and usage requirements.

- Consultation with experts can help ensure that you make an informed decision that aligns with the unique characteristics of your vessel.

(3) Budget Considerations

- Budget considerations are essential when choosing between mooring chocks and roller fairleads.

- Mooring chocks, especially high-quality fixed versions, may come with a higher upfront cost, but they can offer long-term durability and reliability.

- Roller fairleads vary in price depending on their design and materials. Consider your budget and weigh it against the long-term benefits of your chosen mechanism.

Selecting the right option for your boat is a decision that impacts safety, stability, and overall performance during docking and anchoring operations. By carefully evaluating boat size, docking conditions, personal preferences, and seeking expert advice, you can make an informed choice that enhances your boating experience. Additionally, factoring in budget considerations ensures that the chosen mechanism aligns with your financial resources and long-term investment goals.

In the realm of boating, where safety and efficiency are paramount, the choice between mooring chocks and roller fairleads is more than a mere hardware decision; it’s a crucial step toward ensuring a secure and enjoyable boating experience. As we conclude this exploration into these two essential components, it is clear that understanding their differences and evaluating their suitability for your unique needs is fundamental to informed decision-making.

Mooring chocks, whether fixed or hinged, play a vital role in securing lines, distributing forces, and maintaining stability. They excel in situations where consistent line placement is needed, making them a reliable choice for vessels that maintain the same mooring configuration. With the assurance of stability and line control, mooring chocks are valued by those who prioritize consistency in their docking routines.

Roller fairleads, on the other hand, offer versatility and adaptability. These line-guiding components are designed to reduce friction, minimize line wear, and ensure controlled line movement. They are particularly beneficial in dynamic docking scenarios and for boats that frequently navigate varying conditions. Roller fairleads provide boat operators with the flexibility they need to adapt to changing environments and line angles.

In conclusion, your boat is more than just a vessel; it’s a gateway to adventure, leisure, and exploration. The choices you make regarding its equipment, including mooring chocks and roller fairleads, have a direct impact on your experiences afloat. As you weigh the advantages and disadvantages of these components and consider their suitability for your vessel, remember that informed decisions lead to safer, more enjoyable, and more reliable boating adventures. Whether you opt for the steadfastness of mooring chocks or the versatility of roller fairleads, the goal is the same: a safe and secure journey on the water, where every docking and anchoring operation is executed with precision and peace of mind.

Related News

A Guide to Know Roller Fairleads

A Guide to Choosing the Right Marine Mooring Bollard Types for Your Needs

What is the difference between bollards and cleats on a boat?

Maintenance and Safety Considerations of Roller Fairleads

Roller fairleads: effortless cable management and increased efficiency, how to install and maintain mooring chocks.

Unveiling the Importance of Mooring Chocks: Safeguarding Ships and Ensuring Secure Berthing

Mooring Bollards: The Importance, Design, and Safety Considerations in the Maritime Industry

If you have any suggestions or questions for us. Please contact us!

Get Free Quote

- Privacy Overview

- Strictly Necessary Cookies

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

What Is The Roller Fairlead And How To Select The Best Manufacturer

Fairlead refers to the general name of the various devices which guide, limit, or change the direction and position of the cable without damaging the cable. Roller fairlead is one of the most widely used fairleads and is an important part of the marine mooring device.

Important Marine Mooring Device – Roller Fairlead

The constitute of roller fairlead.

The roller fairlead is consisting of vertical rollers and horizontal rollers, which are replaced with a roller cable and have added a horizontal roller. It can direct cables from all directions can be guided. In addition to commonly used four-rolled fairlead, there are types of three rollers, five rollers, six rollers, seven rollers and nine rollers. The warping roller fairlead is made of several independent rollers, closed and open, according to the number of separate rollers, the types of double rollers, three rollers, and four rollers are widely used. It can simultaneously derive the root cable, mostly used in large and medium-sized ships.

Important Role For Marine Mooring Device

The roller fairlead is suitable for the mooring of the engineering ship and the strait waterway with multi-directional conductors. There are also a relatively large roller fairlead that allows the ambulance person to transport the wounded person from here when there is an accident. The function of the roller fairlead is related to the normal navigation of the ship and the efficiency of the treatment personnel, even related to the life safety of the ship.

Working Principle Of Roller Fairlead

One basic working cycle of the roller fairlead is divided into five processes including intake, compression, combustion, expansion, exhaust. When the roller works, the piston is moved back and forth in the cylinder, and this motion is converted to the crankshaft rotation motion by the crank link mechanism. The top of the piston movement in the cylinder is called a dead center, and the lowest position of the cylinder achieved by the movement is referred to as a stopping point. The piston from the dead point to the stop point becomes a stroke. Every turn in the crankshaft, the piston has two strokes. The working system of the fairlead mainly includes roller cooling, roller lubrication, and fuel system.

1.Cooling System

The system is divided into freshwater cooling systems, seawater cooling systems, and central cooling systems. In order to spread this heat, the cooling liquid is used to continuously flow through the thermal member.

2. Lubrication System

The system includes lubrication, cooling, cleaning, sealing, corrosion, reducing noise.

3. Fuel system

The system mainly includes fuel installation, storage, dismissal, purification, heat, etc. The heating equipment to maintain heavy oil in the oil tank for maintaining the fluidity of heavy oil. Heavy oil should be purified and atomized by purification and atomization before transporting the roller fairlead high-pressure oil pump.

Installation Precautions For Roller Fairlead

For the installation of the roller fairlead, what should be paid attention to?

It is necessary to pay attention to safety, although the device is not flammable, the safety environmental requirements should meet.

2. Environment

It is necessary to pay attention to avoiding environmental moisture and ensure that the environment has been in a dry state, avoiding rust in the process of installation.

3. Packaging

In the packaging requirements, it is to ensure excellent functions, extending the service life.

Maintenance Of Roller Fairlead

The roller fairlead is always exposed. If it is not well maintained in use, it will increase the chance of damage in use. The maintenance work is needed. So, how does the maintenance work do? Here are some instructions.

Anti-rust Work

For roller fairlead, made with stainless steel materials, people should apply a certain anti-rust oil on its surface before use, and reduce the rust chance in use through anti-rust oil, to ensure a good appearance.

Checking Work

Each component of roller fairlead is needed to be checked for daily use. For any small problem in the check, it is necessary to be paid attention and solve it, which will reduce the chances of damaging for ensuring the long-term service life.

Preventing Deformation

The deformation will affect the use. If the deformation is serious, it will directly lead to the occurrence of fracture. So in the applications,can prevent it from deforming through the control of the pressure. Daily maintenance can ensure the normal use of roller fairlead, guaranteeing the good effect.

How To Select The Best Roller Fairlead Manufacturer

Roller fairlead has a very important role in the marine industry. To ensure good performance, how to choose the high-quality products from the best roller fairlead manufacturer and what factors should be considered are important?

1. Appearance

The material quality, structure, processing level of a roller fairlead, can be reflected from the appearance. In terms of the reliability of the roller fairlead, it is very important that there are no defects in the appearance, which will affect the intensity. Because of the roller fairlead in use, it is necessary to withstand the huge external force of the ship and it is necessary to ensure that the structure of the roller fairlead is stable, not damaged by the external force, with high requirements in strength. A good roller fairlead manufacturer should use high-intensity materials and does a good job in processing and surface treatment, ensuring that there is no strength defect in the surface. Otherwise, even if there is no problem with the material intensity, it will also cause problems in the strength due to the surface defect, which will affect the normal functionality use.

The best manufacturer should adopt excellent quality material with the advanced process, then the color of the appearance will be uniform and bright.

2.Specifications

To select a quality roller fairlead, it is necessary to pay attention to the requirements on the specifications, the requirements on the specifications, which is required to transmit the cable on the specifications, because the cable has differences in size, length. The device that can be stored and used is also different from the specifications. The best roller fairlead supplier should have different specifications to meet the requirements of the installation.

3. Environmental Restriction

Because of the different environments, there is a certain limit on the material of roller fairlead, especially for the marine equipment and the wear of metal device is very large. The requirements of corrosion resistance for the roller fairlead should be considered. The supplier should adopt excellent corrosion resistance materials for superb roller fairlead.

The price always is an important factor for choosing the best-value manufacturer. The most competitive prices with quality products can be a great advantage.

5.Craftsmanship

An excellent manufacturer & supplier should have advanced craftsmanship and strict quality requirements, which should meet the needs of effect and performance.