- Tenten 10-305

- Tenten 14-425

- Carabela 650

- Prao Vaka 600

- Prao Vaka 990

- Projects 2022

- Projects 2021

- Press review

Boats plans for self builder - in metric

Imperial plans on duckworks.

Rowing and sailing skiff

Boat Plans, Patterns and Supplies For the Amateur Boat Builder!

- Boat Plans Catalog – 300 Boats You Can Build!

- Boatbuilding Supplies & Epoxy

- Inboard Hardware

- Electrical Design Plans

- Books, DVD’s & Audio

- Boat Trailer Plans

- Raptor® Fastenings & Tools

- Glen-L RV Plans

- Gift Certificates

- Boatbuilder Blogs

- Boatbuilder Galleries

- Newsletter Archives

- Customer Photos Archives

- Where Do I Start…

- About Our Plans & Kits

- Boatbuilder Forum

- Boatbuilder Gatherings

- Boatbuilding Methods

- Featured Design on TV’s NCIS

- Our Boats in Action

Boatbuilding with Plywood

For most amateurs, plywood is the material of choice. Plywood is one of the cheapest and easiest building materials, one that the average do-it-yourselfer is both familiar and comfortable with. Plywood is also, pound for pound, stronger than steel. Because of its high strength to weight, plywood construction yields a boat that is much lighter and performs better than a “chopper gun” fiberglass boat. When used with the GLEN-L Epoxy Encapsulation System, plywood is as long lasting and as low in maintenance as any other material. No exotic tools are required, and with the possible exception of enough C-clamps, plywood boats can be built with the tools in the average home workshop. Plywood boats are frequently built in school wood shops or by youth groups as individual or group projects. To take full advantage of the material, our Plans and Patterns detail simplified construction methods geared to the abilities of the amateur. No difficult woodworking procedures, such as steam bending, are ever required, and the GLEN-L pattern system makes the difficult lofting procedure unnecessary.

Plywood is used as a “sheet” material in the majority of plywood boats, including Stitch-N-Glue. Plywood is also used in “cold-molded” construction and “multi-diagonal” planking. On each design page the method is listed under “Hull” in Characteristics.

SHEET PLYWOOD: This is the most common type of construction used by the home builder. Plywood is used in panels of one or two layers. This requires a minimum of cutting and fitting and requires much fewer frames than most “traditional” planking methods. For a look at the steps in plywood boatbuilding in more detail see our Sheet Plywood Pictorial Guide with captions .

COLD-MOLDED or MULTI-DIAGONAL: This method is utilized on round bilge hulls or hulls with compound shapes. The method involves cutting the plywood into strips (widths vary depending on curve), and laying up layers at angles to each other, glued and fastened. Epoxy is the recommended adhesive. Multi-diagonal Planking Pictorial Guide.

Uncommon Answers to Some Common Questions by Ken Hankinson, Naval Architect:

C ertain questions about plywood and its use in boatbuilding crop up time and again. Usually these are based on a desire to get the most value for the least bucks, to save time and effort, and to assure a level of quality that’s acceptable to the builder. Note that I didn’t say that builders ALL want ultimate top quality, and that’s intended. Just as in production boats, top quality is not always demanded, needed, nor expected. After all, not all boats need to last so long that they become exhibits in museums.

Q: Must all plywood used for boatbuilding be waterproof?

A: Basically there are three plywood grades; Interior, Exterior, and Marine. The typical assumption is that plywood used in boats must be made with waterproof glue. However, the accepted standard for such a glue is one whose bonds will survive a boil test. How many boats are ever subjected to boiling water conditions? None I know of.

Fact is, for generations, countless plywood boats have been glued together successfully with low-cost powder-water mix plastic resin glue (a urea-formaldehyde product). And while highly water-resistant, this glue won’t survive a boil test and is thus not considered totally waterproof. But it will survive hundreds of consecutive cycles of immersion in water at room temperatures.

The point is, Interior grade plywood is not rated for exterior or marine use where such panels may be exposed to moisture because grading standards permit non-waterproof glues in their manufacture. However, does this mean that such a panel might fail if exposed to exterior or marine conditions? Perhaps not if it is assembled with a highly water-resistant glue such as plastic resin. But one won’t know if such a glue has been used. Thus I ordinarily advise NEVER to use Interior plywood in a boat strictly because the standards permit use of a non-waterproof glue. Besides, the practice is penny-wise and pound-foolish. For structural members, stick to either Exterior or Marine panels.

Q: When should I use Marine plywood?

A: Some feel ONLY Marine plywood should be used for hull planking. But I think this is too rigid a rule. The important quality separating Marine grade from Exterior panels is the quality and soundness of the inner plies and their construction (both are made with waterproof glues as noted above). With the Marine panel, there should be no major voids or surface defects, and inner veneer joints (if they occur) should be tightly fitted.

That said, using Marine plywood is most critical in my opinion where panels must conform to rather extreme curvatures (the bow in most boats, especially the bottom), and for boats built with “stitch-and-glue” methods. Another case where Marine plywood would be highly advised is on boats intended for high speeds and/or severe service.

Here’s some reasoning. You might be able to save some bucks by using Exterior plywood for planking curved areas. And experience tells me that once such a panel has been bent into place, if it doesn’t fracture in the process, it will probably stay that way forever without incidence.

But the problem with lower-quality panels is that you may not always see the voids. And if your panel does break while you are installing it due to hidden voids, you will have to replace it with another, thus making the cost about comparable to what you would have spent on the better Marine panel in the first place. And there’s no guarantee that the next panel won’t fail as well.

As for “stitch-and-glue” construction, a void-free panel for planking is important so that the wire ties at joints don’t pull out under tension, which is likely to occur if stitching holes need to be located coincidentally with a void that suddenly crops up once the panel has been cut to shape. Such panels are also easier to work with for the same reasons when used for internal members and bulkheads on “stitch-and-glue” boats.

Q: When can I get by with Exterior plywood?

A: Other than as stated above, I’m not against using a good grade of Exterior plywood (for example, AB) for planking, and I’ve never heard of a boat falling apart because of it. You may have to make some repairs to the panel (e.g., fill voids) which can get tedious and is not always successful. But in flatter hull areas such panels will suffice for most boats. Exterior panels (with any major defects repaired when possible) can usually also be used for most internal members throughout a boat without problem for such items as transoms, gussets, bulkheads, etc.

In fact, I’m not totally against using lesser-quality AC plywood for planking on certain boats. In case you don’t know, an AC panel can have open and exposed defects on the C-side. But since the boat will probably by sheathed with fiberglass, some builders use the C-side outside and fill all the defects with resin putty prior to fiberglass application; they become invisible once painted. On smaller, simpler, low-powered boats without a lot of curvature, I see nothing wrong with this practice, and again, have not heard of such a boat disintegrating over time because of it.

Q: Why should I cover my plywood boat with fiberglass?

A: We generally recommend covering all plywood boats with fiberglass no matter how small. While some complain of an increase in weight, this is seldom more than an ounce or two per square foot of area in the typical application. Then too, even lightweight coverings (say 4 ounce cloth) are better than nothing.

When I speak of covering the outside of plywood boats with fiberglass, I use the term generically; you can use other fabrics such a Dynel or polypropylene, but fiberglass gives the best combination of price, ease of application, ready-availability, and protection in my opinion. Whichever fabric you select, the reasons for applying the covering are the same; added abrasion resistance, improved durability, extra reinforcing for finish coatings (especially at joints), reduced maintenance, better appearance, and to help insure against leaks.

Thus sheathings should be considered as basically cosmetic coverings; their intent is NOT to add strength. In fact, plywood is far stiffer than fiberglass. Hull strength comes from the plywood hull structure itself, and with proper design and construction, should prove more than adequate.

Glen-L carries epoxy , fiberglass cloth and application materials .

Q: What happens if I don’t sheathe my plywood boat with fiberglass?

A: If it is made with Douglas fir ( a reasonably tough material), surface checking and wavy surfaces will soon occur even if painted. These will be very difficult to alleviate even if the boat gets painted each season. Other plywood types with a more uniform grain pattern will fare better in this regard, but these will still require routine coating applications. And because many species of plywood are not as tough as fir, they will more easily suffer damage without sheathing.

If you absolutely insist on not sheathing your plywood boat, consider using medium-density overlay (MDO) panels. These still require routine coating, but the overlay prevents surface checking and presents a smooth paint-ready surface. These do cost more and may not be readily available, however.

Q: Epoxy resins sound great but they cost too much. Can I use polyesters for sheathings instead?

A: We quit offering polyester resins for sheathing application years ago simply because we no longer believed in them anymore for this purpose. Our feeling is that as long as you’re going to the trouble, you should use epoxy resins if at all possible; they’re worth the extra cost. The main reason is that they stick forever, and if you’re using as epoxy encapsulation system, (also highly advised), they are the only choice.

That said, if you are on a budget, polyesters are acceptable if you do it right, but they don’t have true adhesive properties. Finish results with either otherwise appear the same, but polyesters are less flexible and resilient so tend to crack more easily over time. When this occurs, water can creep behind the sheathing and cause problems.

As for the encapsulation process where all wood surfaces inside and out get coated, do NOT substitute polyesters this way in place of epoxies. Polyester resins simply don’t work the same; they don’t stick or apply well, and because of their lack of elasticity, crack easily which can promote rot due to entrapped moisture.

See the epoxies available from Glen-L.

Q: Epoxy glues may be superior but I’m allergic to them – what’s next best for plywood boatbuilding?

A: Because the stresses on a plywood boat are ultimately transferred to joints in the hull, a hard-setting glue (rather than a flexible mastic, for example) is required. As a result, glue choices are few. Prior to epoxies, the traditional stand-by’s were plastic resin and resorcinol. The latter is 100% waterproof while plastic resin is considered “highly water-resistant”. But as discussed above, plastic resin glues can work successfully in plywood boats for all practical purposes.

Currently resorcinol costs more than epoxies, and offers no benefits over plastic resin glue in my opinion. Unlike epoxies, both need well-fitted joints, specific limited temperatures, heavy clamping pressure, and leave colored glue lines. Since plastic resin glues don’t stain and clean up easily, mix with water, and are a fraction of the cost of resorcinol, they’re my choice in lieu of epoxies.

The only other alternative I’m aware of and have used with good results in the past is Aerolite, a water-resistant urea-formaldehyde based product by Ciba-Geigy sometimes imported from England but seldom found. This uses a powder-water mix along with a second liquid component, dries clear, and has some gap-filling properties. Once popular with kit airplane builders, it may still be available from suppliers in that field.

Glen-L’s Poxy Grip is an excellent adhesive for your Glen-L boat.

Q: Can I increase fiberglass thickness in order to get by with thinner plywood or compensate for lower quality plywood?

A: I don’t know how this line of thinking evolved, but the question keeps coming up. Primarily it involves the fallacy that plywood is weaker than, and inferior to, fiberglass. Keep in mind that while fiberglass is strong in tensile strength, it is not very stiff. Conversely, plywood is actually stronger on a weight basis in both tension and compression. More to the point, the modulus of elasticity (stiffness) is actually much higher for plywood than fiberglass for the same thickness.

Then too, for some reason many who ask this question think fiberglass is lighter and will thus save weight. This myth is quickly dispelled when a piece of each material gets thrown into a pond of water and the fiberglass sinks like a stone while the plywood floats.

So the simple answer is that if you reduce plywood thickness and make up the difference with fiberglass laminate, you get not only a more flexible panel, but one that weighs a lot more. It will also add considerably to your cost and effort. And if this question is asked because thicker panels are not available, the answer is to use a double thickness of plywood rather than attempt to make up the difference with fiberglass.

Q: Why is Marine plywood so expensive?

A: As for domestic panels, my first reaction to this question is that we’re fortunate to have any Marine plywood available regardless of the price. Of the total amount of plywood produced in this country, less than 1/10 of 1 percent is Marine grade. Environmental and economic factors, coupled with very modest demand should warrant even higher prices in the eyes of producers. And if you consider the price of plywood compared to other materials, it’s actually a bargain. On a cost per square foot basis, many common materials are considerably more expensive than plywood, such as carpet and resilient floor coverings. And you can’t even build a boat from that stuff.

While imported Marine plywood panels might cost twice as much as the domestic product or more (and we’re again fortunate to have this competition available regardless of the price), this is still a reasonable price compared to other alternatives.

Compared to all the other boatbuilding materials an amateur may use, only steel is cheaper than sheet plywood. And when you consider the speed and ease with which a plywood boat can be built, it’s still the material of choice for most do-it-yourself builders.

Q: Can I make frames out of plywood rather than solid lumber?

A: This is generally poor practice in the framed plywood boat for several reasons. First, a main reason for using solid lumber for frames is that grain gets oriented in the direction we want for strength. If plywood is used for frame members instead, because of the alternating grain direction of the plies, there is no strength in those veneers in the cross-grain direction. In other words, a plywood frame will need to be nearly double the thickness to have the same strength (see Fig. 1 below).

Second, longitudinal strength members (e.g., keels, chine logs, sheer clamps, stiffening battens, etc.) that intersect frames will require fastenings at contact points. If the frames are plywood, the edge grain of frames at such intersections will hold fastenings poorly, and if other than Marine panels are used, there is a possibility of voids at a point where they are least desirable.

Third, attempting to bevel or fair such frames when necessary is difficult because of the alternating grain pattern at edges. The tendency is to splinter the frame edges instead.

On the other hand, using plywood for joining sawn frame members via gussets, floor timbers, and the like is excellent because the alternating grain at such connections reduces splitting that would occur if solid wood members were used (see Fig. 2 below).

FIG 1 – Because of plywood’s cross grain, a plywood frame will be flimsy and not as strong as one from lumber of the same thickness. FIG 2 – However, because of plywood’s cross grain, using gussets, floor timbers, and similar members to join sawn wood frame members will largely prevent splitting at such connections.

Q: If frames shouldn’t be made from plywood, what about stems?

A: Actually stems from plywood, as long as they are thick enough (1-1/2″ is a nominal minimum) are preferable to solid lumber on the plywood boat. The reason is that a plywood stem is more dimensionally stable due to the cross grain. Such reduction in expansion and contraction reduces any tendency for movement or cracking along the centerline where planking halves join. While it could be argued that the plywood stem presents edge grain for the planking fastenings, in reality the bevels required here allow fastenings to set diagonally to the grain for a solid grip if long enough (see Fig. 3A) . An acceptable alternative is the stem made with a core of plywood and solid wood on both sides (see Fig. 3B) .

FIG 3 – A section through a plywood stem (A) shows that because of the bevels required, fastening into edge grain is largely avoided. An alternative is a stem with a plywood core and solid wood either side (B).

Q: Why shouldn’t sheet plywood planking be fastened to transverse frames?

A: The properly designed plywood planked hull incorporates as much as possible the principles of monocoque or “stress-skin” construction. Stitch-and-glue boats that depend upon glue bonded junctions reinforced with fiberglass tape often show pure adherence to such principles. However, not everyone is willing to trust their fate only to glue bonds; many still favor the extra security that fastenings and some internal framework can provide. After all, such construction has been proven strong and durable for generations whereas stitch-and-glue is still the new kid on the block.

But even when transverse frames are part of the design, it’s the plywood skin that takes the stresses which are ultimately transferred to glued and/or fastened joints at panel edges. And if such panels are fastened across the grain to frames, localized stresses that can lead to failure of the panel can be generated. How so?

Consider a plywood panel curved in place around a hull as being analogous to corrugated cardboard applied in similar fashion with the corrugations running lengthwise. We can pin or tack such a cardboard panel in place all around the edges to hold it in place. But what happens to the cardboard if we perforate it with a bunch of fastening holes crosswise? When bent in place, it would fold and break about the perforations.

The same thing can happen in a sheet of plywood. Placing a row of fastenings across the plywood panels grain can weaken a panel and create a similar condition, especially so when the panel is also under tension due to bending. Conditions are exacerbated on the higher-speed powerboat where panel loads are greatly magnified due to slamming loads while planing.

In short, while frames on the plywood boat may contact planking and be glued at such points, ordinarily such contact is not actually necessary and in fact, frames can usually be relieved from such contact without detriment. In reality, it’s the longitudinal members doing most of the work and this is why planking panels are preferably fastened only to these and at the ends of panels and NOT to frames between.

Q: What about using plywood for sailboat rudders, centerboards, and daggerboards?

A: If a Marine grade panel is used, and these are thick enough (say 1″ or more), plywood is sometimes acceptable. However, I’ve seen many plywood rudders and daggerboards break in use, and again, the problem is that areas of cross grain within a panel tend to be weak and lead to fracture. Sailors often don’t realize just how much stress can be applied to a rudder turned hard over on the small sailboat or just how much force a capsized sailor exerts while standing on a daggerboard attempting to right the small dinghy.

Another difficulty is that rudders and daggerboards should be faired to an airfoil sectional shape which is not as easy to do with plywood. Thus solid wood is preferable, or you might use a rudder or daggerboard with a plywood core (1/2″ or thicker with solid lumber laminated to both sides (see Fig. 4A and 4B) . Plywood boards and rudders should be encapsulated with epoxy and fiberglass cloth in any case.

FIG 4 – A section through a sailboat rudder faired to an airfoil below water (A) is difficult to do with plywood; solid wood is preferable. However, one with a plywood core and solid wood each side is acceptable and perhaps preferable for larger rudders where solid wood will tend to split and/or must be glued up from narrower widths (B).

Q: Can I use nails in place of screws for fastening plywood planking and decking?

A: As a general rule on the framed plywood boat, because planking panels carry loads to the panel edges, screws give superior holding ability compared to nails, especially when panels are under the stress of bending. Nails in this situation lack the leverage inherent in screws to maintain this tension if a glue joint lets go for some reason (albeit a rare occurrence).

Conversely, in flatter areas of a hull (especially on small boats or those not intended for high speed or rough water use), and at mid areas within a panel, nails are acceptable if long enough and of ample wire size. In most cases, deck panels can be nailed although I still prefer screws at panel edges in the case of powerboats since the deck is usually an important strength membrane.

While nails may be relatively inexpensive, you should still pre-drill pilot holes for all but the smallest sizes. As for driving screws, do NOT countersink the heads below the outer veneers of the sheet of plywood; the screw should compress all veneers in the panel (see Fig. 5A and 5B) .

FIG 5 – The “right” way (A) and “wrong” way (B) to drive a screw used to fasten plywood planking. All veneers in the panel should be under compression.

Glen-L carries silicon bronze nails and screws as well as stainless steel fastenings for above the waterline.

Comments are closed.

Connect with us:

Customer builds.

Useful Information

- Cost & Time To Build

- Links & Suppliers

- Online Glossary

- Support Knowledge Base

- Teleseminars

- Wood & Plywood

Building Links

- How Fast Does It Go?

- Install A Jet Ski Motor

- Modifying The Motorwell

- Sailboat Hardware Notes

Glen L Marine Design

- About Glen L

- How To Place an Order

- Privacy Policy

Copyright Info.

Copyright 2006-2022 by Glen L Marine Designs. All rights reserved.

Mailing Address: 826 East Park Ave. Port Townsend, WA 98368

Web design by Big Guns Marketing , LLC.

- About Modern Wooden Boats

- Tips & tricks

- What’s inside a boat plan ?

Petrel 33: widen your horizons

Petrel 33 is the logical evolution of her smaller sister petrel 28 , with the task to expand the horizons of cruising activity for a 4-6 person crew, raising the bar of onboard comfort, keeping the boat size under the critical (for a homebuilder) size of 34 foot – 10 meters of overall length., a “new classic” looking cruiser, sturdy, with no frills and weird solutions, ready to let you sail with a decent speed and a very good comfort level both at anchor and sailing., the starting point is the very good sailing capabilities shown by the petrel 28, so i decided to develope this hull into a enlarged design, keeping a quite narrow hull for actual standard, prolonging the bow lines for a plumb stempost; i expect to have a similar behaviour of the proven 28footer, with a tender weather helm in every situation, a very soft and gentle wave riding attitude in a seaway, and a good acceleration coming out of the tacks, i expect a little bit more speed given the longer water length ; section are moderately full at the bow, maximum beam is around 60% of hull lenght , transom sections keep a moderate vee.

Stability calculations give us good parameters (see stability curve attached) , with a real large positive area stability, a 123° AVS (Angle of Vanishing Stability) with loaded boat, and a minimal negative area in the stability curves.

Rig and sailplan:

Sailplan is based on a 50% area split among mainsail and a furling jib ; we kept the upwind sailing area to a moderate value, avoiding “wannabe racers” temptations; a decent sized gennaker can be hoisted on the fixed bowsprit, an obvious choice given the fact that the new generation furlers are making this sails very easy to manage for cruising crews too, adding the pleasure of sailing downwind in light airs at a decent pace, a weather situation which is quite a pain in normal mainsail + jib configurations ; in roughest situation you can hoist a storm jib on a removable internal stay fitted on a high load chainplate leaning on the forward structural bulkhead ; rig is a classical 2 spreaders mast , spreaders are 15° swept, there is a structural backstay and no structural runners, lower shrouds are doubled., deck gear configuration features classical sturdy and manageable solutions, without too many frills : 4 self tailing winches to pull sheets, halyards and control lines, 2 stoppers array on cabin top panel, 2 tracks for jib cars, so that the jib can keep a decent shape even furled, a small track for the mainsail purchase, all the control lines are led to cockpit to avoid bow walks in “spicy” situations (plans will detail how to make bombproof fitting points for lifelines too);, boat will be powered by a diesel (20-30 hp) or electric (7 kw) inboard engine fitted with a saildrive or shaft-line transmission ; this will allow to keep a decent pace while motoring in zero wind situation, or to add a good booster to sail thrust if needed; i expect to reach a 6.5 knots boat speed at 2000 rpm with a 30 hp diesel engine., rudder and steering system:, rudder is a single blade semi-compensated one with tiller steering system ; there will be two options detailed on plans: spade rudder with ss steel shaft (this solution is depicted in rendered images), and an easier to build transom hung rudder., finkeel is naca profile keel made of welded steel plates, ; ballast is made by lead poured in the keel hollows ; keel is fitted on the hull with a web of bolts on solid hardwood floors, with nuts and high thickness ss steel counterplates under the cabin floorings; keel load is carefully distributed to avoid any local high stress area., interiors and on board living:, this area marks the main differences among this 34 footer and her smaller sister; higher hull topsides and two more meters of boat make a world of difference in terms of interiors and on board comfort; we have 6 regular berths, a comfortable galley and dinette area, a decent volume for on board systems and storage, all that you need to medium-long range sailing given the size of the boat ; both forward and after cabin are closed with a small door to gain a little bit more privacy ; cabin height is around 191 cm , cockpit is quite wide, and it’s designed to be comfortable for a crew of 6 while sailing with the heeled boat too ; transom area is protected by a sturdy wooden hinged structure that can be lowered when moored to be used as a transom platform. low sleek coamings protect the forward area of the cockpit , making the primary winch basement too; toerails and good sized areas among cabin flanks and hull sheerline make going to the bow a very safe operation even when boat is heeled and in rough conditions;, building system:, given the good amount of miles sailed by petrel 28 in every sea state with very good reliability, i keep a similar structure for this project, upgrading the scantlings to cope with higher stresses; so the boat structure is a grid of plywood bulkheads and frames linked by solid wood stringers and a mixed plywood-solid wood structure forming keel backbone and stempost ; hull planking is made by 12 mm plywood, with the radiused area made by two layers of 6 mm plywood panels , all glued to the underlying structural grid , in a reliable , sturdy and easy to build system called “radius chine” ; cabin , cockpit and deck surfaces are made by 10-12 mm plywood panels stiffened by a grid of secondary stringers, solid beams and other structural elements; the hull bottom is further stiffened by a number of solid wood floors , tightly spaced in the centerboat area, where they bear the finkeel loads. all critical areas and structural bondings are strengthened and stiffened by epoxy resin laminated glass fabric and epoxy resin liquid joinery and structural bondings. this building system is definitely suited to be realized by home builders or small boatyards, with a basic level of wood craftmanship , in a decent amount of time given the size of the boat., in my view this will allow a small boatyard to build and offer a highly customized top level sailboat keeping the final prize to a reasonable level, which is basically the main concern when it comes to manage a small boatyard..

Building plans and study plans: project Petrel 33 is is completed : now I’m starting the long and meticulous process of drawing the building plans; complete plans will be available approximately at the end of spring at this link , anyway if someone is so committed to long for an immediate start of construction he can purchase plans starting from now, a first batch of drawings (hull parts , assembly scaffold and hull structures) will be delivered within a week so that he can start building, the rest will follow as scheduled within half of June 2018; study plans and bill of materials will be available approximately within the end of April 2018 and will be downloadable form this page for free, as usual. Stay tuned !!!

Plans price: 900 € for paper sheets, 840€ for pdf format drawings, 350 € for cad engraving files (required if you want to cut all the plywood parts with cnc machinery, includes keel steel plating shapes) ; plans will be made approximately of 27 drawings and a 25 pages booklet with assembly sequence, tips and tricks, plans can be purchased here, a discount will be available for the first buyer ., petrel 33 specifications, hull length: 9,90 m (bowsprit included), overall length: 9,90 m, maximum beam: 3,03 m, prismatic coefficient: 0,53, sink rate: 170kg/cm, canoe body wet surface: 18 m2, draft at design displacement: 1,80 m, vacant ship diplacement: 3400 kg (all gear up, no water and food, no fuel), design displacement: 4050kg (crew of 4 + luggage, 50kg fuel, acqua 150 liters water, 100 kg extra), maximum displacement: 4500 kg (crew of 6 + luggage, full fuel, full water), ballast: 1300 kg: fixed keel, upwind sail area : 47,3 m2 , mainsail 23.2 m2, jib 24 m2, staysail on removable babystay: 6.5 m2, gennaker: 65 m2, mast height on dwl: m 13,3, performance parameters : sa/displ^0.66 = 19.5 , sa/wet surface = 2.6 (canoe body only), engine: diesel inboard with saildrive or shaftline transmission, 20-30 hp, 50 liters fuel tank , electric engine specifications on plans, accommodations: 6 fulls sized (1,90 m or more) berths, 1 v berth at bow, 1 double berth on transom , 2 galley berths, interiors: charting table with main electric panel, vhf radio and chart plotter area, galley with stove, sink and 30 liters fridge, enclosed toilet with wc sink and shower, central table in dinette with foldable wings. 190 cm height in the whole galley area., systems: 12 v and 220 v wiring scheme, fresh water and black water plumbing scheme, 200 or more liter freshwater tanks.; two service batteries and a engine dedicated battery, ce label : possible b6/c10 , data to be required as extra item..

- plans: 900€ for paper version, 840 for PDF version , 350 for CNC cutting files , can be purchased here

By continuing to use the site, you agree to the use of cookies. more information Accept

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.

MIKE WALLER

Yacht design.

WE SPECIALIZE IN BOAT PLANS FOR AMATEUR BUILDERS

We provide stock boat plans for both monohull and multihull sailing vessels, including sailing skiffs and sharpies. Our designs mainly feature timber construction, in plywood or cedar strip plank composite construction, using the W.E.S.T. system (wood epoxy saturation technique). Our designs are intended mainly as cruising boats, although several have done well in racing. All designs are suitable for amateur boat builders.

MONOHULLS

multihulls , photos from our builders.

Photo galleries are provided on each design page where available

- No products in the cart.

Build your own sail boat with Hartley Boat Plans. Hartley sail boats are the benchmark in reliable and sea worthy trailer sailers, in fact the name trailer sailer was coined by these amazing craft. Many of these build plans also have a printed study pack available to help you through your project.

Cape Bay 45

Cape Otway 37

Chuckles 18

Dateline 51

Eastcoaster 16

Easthaven 34

Hartley 16ft (5m) Trailer Sailer

Hartley 30 (Plywood Version)

Hartley 30 (Steel Version)

Royal Suva 52

Samson ‘C-Baron’ 55

Samson ‘C-Breeze’ 45

Samson ‘C-Deuce’ 45

Samson ‘C-Fever’ 62

Samson ‘C-Lord’ 53

Samson ‘C-Quence’ 36

Samson ‘C-Witch’ 63

Tahitian 27

Tahitian 33

Tahitian 38

Tahitian 45-50

Westhaven 32

- Plans & Kits

- Qty in Cart

West Mersea Duck Punt PDF Free Plans

Making Hand Screw Clamps Free Instructions

Tape & Glue Process Free Instructions

Lisa b good - free plans.

Folding Mast & Boom Free Plans PDF

Slipper PDF

Drifter 12L Free Plans

Wanigan (free plans).

1 Sheet Wedge Plans PDF

Drifter 12 Free Plans

Mouse Free Plans

Little bretton free plans.

- Total: items /

- Add all to cart

Adding your products to cart

- BOATBUILDING SUPPLIES

- Aluminum & Steel Powerboats

- Aluminum & Steel Work Boats

- Classic Dinghy - Cedar Strip

- Classic Mahogany Runabouts

- Classic Runabouts

- Hydroplanes - Inboard

- Hydroplanes - Outboard

- Kayaks - Fabric Covered

- Kayaks - Plywood

- Powerboats 10'-16'

- Powerboats 18'-26'

- Sailboats - Monohull

- Sailboats - Multihull

- Sport Runabouts

- Tunnelhulls

- Skerry from plans

- How to decide what to build

- Tender plans Some Free

Free Plans for Stitch and Glue Boatbuilding

Some free boatbuilding plans are very good, others are worth exactly what you pay for them. If you choose to use free boat plans, do your homework, and try to find others who have built from the plans. There are many Yahoo and Facebook groups out there. It's worth it to do a search. It's a good idea to check the measurements and to build a model from the free plans just to make sure you understand the process.

Here is my page on stitch and glue boatbuilding

Stitch and glue plans are good wooden boat plans for beginners.

Making a model will pay back later and save you time when you build because you will have figured out how the boat goes together.

Your model will also help you decide if you like the look of the boat BEFORE you spend a lot of time and money building a wooden boat from scratch.

In a more complex boat, free is not always less expensive because the designer of bought plans will usually have taken the time to give you better instructions, material layouts, and is often available to answer questions.

I built the green pram using the stitch and glue method of boatbuilding. The plans were free. Follow my day to day diary building Gavin Atkin's Apple Pie dinghy.

Free Stitch and Glue Boat Plans in no Particular Order.

Email me if a link is broken. I try to update everything often but the internet is a fast paced place. (and I'm not so quick)

I've included some plans that are free but not strictly pure stitch and glue. Some are combination methods and some are build with little support pieces, chine logs, that are used to screw onto or glue on. They are easy techniques.

I have not built most of these boats and cannot endorse them. It's up to you to figure out if they are suitable for you.

- Apple Pie Pram I built this and found it to be a lovely usable tender.

- Clown 450 Free sailboat plans and instructions IN FRENCH but nicely illustrated. Have a look.

- Micro Folding Dinghy Free Plans. Since the seams are glued but not rigid, it is not really Stitch and glue but interesting to look at.

- Thai Inspired Longtail Boat

- Free Stitch and glue plan for a Simple to Build Cruising Kayak from Spira International

- Free plans for Doris the Dory from In the Boatshed. Combination building methods.

- Herring Skiff Free Stitch and Glue Boat Plans 12 Ft Motor Skiff

- 4. Metre Dayboat by Radoslaw Werszko. Can be use with outboard. Nice contruction photos.

- Several free plans also by Radoslaw Werszko.

- Very simple Sailing Dinghy Designed to be built very quickly. Simplicity boats. Not strictly stitch and glue but simple. There is even a song!

- Free Guillemot Kayak Plans from Guillemot Kayaks.

- Guillemot Kayaks offsets for Ganymede Kayak PDF. Also instructions on Instructable

- Mini Sharpie is a one sheet boat from Simplicity Boats.

- Ella Rowboat Free online plans. Stitch and Glue Assembly.

- Cinderella Rowboat Also from in the boatshed

- Blondie Sail trainer and yacht tender designed by John Bell, pdf file

- How to build Cheap Boats Sailing Canoe. Includes sailing rig. Not very detailed but interesting as a historical document.

- Elf designed by Steven Lewis and available from Duckworks Magazine. Offsets and diagrams. 12 ft long sailing and rowing boat.

- Mouse Boats on Yahoo groups. Plans from Duckworks also. Lots of fun in a tiny boat. Good project and very popular, for children or adult to use in quiet water. Stitch and Glue.

- Free plans for a Bernarda 10 Well not quite free, you have to send the designer a photocopy of your money!! This is a great funny web page.

- Free Pirogue boat plans from Morten Olesen, Naval Architect. You need to email for the plans but it's free. Also other plans for sale.

- Gavin Atkin's "In the boatshed" has several free boat plans . A mother lode of nice designs. Lots of easy to build stitch and glue plans

- Free 3 sheet dory Instructions and photographs. Hannu's Boatyard, he has several models. Can easily be built stitch and glue along with the frames.

- Bateaux Bois Free and paid Plans for some respectable boats. Look under 1- Plans Bois. In many languages. Get Mr. Google to translate but it's well worth having a look.

- Free Stitch and Glue plans for single and double kayaks from Kayakyak. These have been built and tested. Nice looking boats. The Plans are actual plans not offsets.

- Portable Boat Plans has several designs for free. Many other of his plans are very inexpensive. Ken Simpson designs inexpensive easily built boats.

- Duck Punters Free Plan Fairly tender sailing canoe type. Wander around the website some. Designed for chine logs but can be converted.

- Plans for U , Almost free ($3) Expired copyright plans. Norwegian pram looks promising. Not much detail but documentation of how the boat was built in the past. 10 plans for 3 dollars.

- Puddle Duck Racer , the little boat that could. Very simple 8ft boat. Free plans. Usually built with chine logs but could be adapted to stitch and glue as long as you glass tape the seams.

- Mike Waller Design has Pippie8 Tender Exceptionally well laid out and documented free plans

- Bateau.com has 3 free designs A 7.5 ft sailing dinghy, a folding kayak and a canoe.

- Free rowing flat bottom boat from Mark Wallace. Table of offsets. Can be sailed.

- Mike Gill mini Tugboat free plans. Cute boat.

- Free rowing skiff from In the Boatshed

- Flo-Mo Amazing collections of plans. Some great experiments from a meticulous craftsman. 1-2-and 3 sheet designs. Great fun.

- Free Optimist Sailing dinghy plans are in Italian! Get Mr Google to help you translate. Proven design. If you plan to race make sure dimensions are exact so you're class legal.

- Free Optimist Sailing dinghy Original optimist plans

- Wooden Boat Magazine free plans for a Motor Holly Point Skiff.

- Many free plans from the Toledo Community Boat House Some Stitch and glue and some other methods. Great resource.

- Plywood stitch and glue Kayak Instuctables are a greatre source. Go to the website and do some searching. Changes all the time.

- Useful Boatbuilding Books My page on boatbuilding books, most of which I have in my library. Some good information.

- Rodent, Sailing Dinghy for a youngster Could be built as stitch and glue. Shown as chine log construction. Email for plans.

Many people offer free plans from old publications such as Popular Mechanics. Since epoxy was not available then, they are not stitch and glue. They could be adapted however. It is usually possible to replace chine logs (strips of wood that connect bottom and side with screw and glue) with an epoxy fillet and fiberglass cloth. It is important to strengthen the seams, inside and out, with fiberglass strips if you remove the chine log.

More Free Plans hiding in Books.

A very good way of getting free plans is by purchasing designer's books. For 20 or so dollars you can get plans for several boats AND detailed instructions on how to build them.

Many designers offer plans at very small cost. It's often a better bet to purchase these than some of the free plans. Check out Duckworks plan pages There are many good designers here and a few free plans as well.

If you are looking for wooden boat plans for beginners it's hard to beat stitch and glue.

- Carbon Fiber Characteristics

- Boat,Oar & Paddle Plans

I try to be accurate and check my information, but mistakes happen. A good set of plans can save you lots of time and if you've paid for them you can actually often contact the designer and get help.

The ads on my pages connect to Amazon. If you buy something from a link on my page, I get a referral fee that pays the web page expenses (not my time, that's for sure.)

Free boat, paddle & oar plans

Boat, Paddle and Oar Plans

Boatbuilding and sailing articles.

Small Print

This information is for general knowledge. Before you start, do your homework. Make sure you understand the plans before you start and work safely. I don't endorse any of these designers or plans. After you've decided to build, enjoy yourself.

Home » Ocean Explorer – a micro cruising sailboat for inland waters from Perttu Korhonen

Ocean Explorer – a micro cruising sailboat for inland waters from Perttu Korhonen

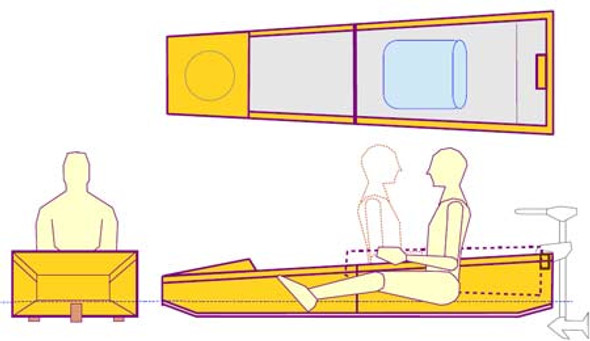

Plywood microcruiser for rivers and lakes – cabin and cockpit fitted into a tiny 8 foot sailboat which sails pretty well – see the video below!

Owning “yacht” – you don´t have to be rich – only little playfully attitude. Perrtu Korhonen

This is the story of an actual three day trip of Perttu and his nephew in Finland.

Plans $40 from Duckworks and is complete with all details from making the hull to making the sail from a polytarp. I wonder if it qualifies as a tiny house. Maybe a tiny house … boat.

Perttu in Finland built one of my OZ PDRacers (now OZRacer) last year as well as building a Quick Canoe that he built in the snow during the last winter and used for camping and daytrips.

He is an adventurin’ sort of guy.

During this last winter he had a secret project. Most of the Duck community fell over with surprise when he introduced his really nicely resolved Ocean Explorer – an 8ft long cabin boat.

It uses the sail, foils and spars from his OzRacer/OZPDRacer.

It makes a lot of sense for colder climates where it can be hard to find a warm and windless place to sleep.

He’s had it away on a couple of trips – he made this neat video of one of the trips.

I couldn’t decide if it was the most crazy thing or most wonderful thing I had ever seen – but was sure it was great!

Ocean Explorer.

He used the spars, sail and foils from my OzRacer.

So we got together via the net and worked it all out to produce a really good set of plans.

About 80 pages. It includes all the methods to build the hull, centreboard and rudder, make the polytarp sail (though you can use regular sailcloth if you like) and make the spars.

A low cost professionally made dacron/polyester sail designed by Michael Storer is available from Duckworks . It is labelled as the Oz Sail.

Perttu spent hours doing really cool perspective drawings of the construction, I fiddled through my Oz stuff to grab what was needed for his plan. He made some suggestions for the Oz stuff and I made some suggestions for his hull – it is really very simply constructed for a boat with so much surface area.

A nice collaboration despite being about 10,000miles apart. The new shape of the world – or size – or something.

Perttu headed off on the boat for several days with a compact crewmember.

Looking aft in the cabin – adult legs go under the cockpit seats.

There are two very important things with this boat.

One is that the boat is designed to be sailed with the hatch SHUT in all but the best weathers.

Also to make progress upwind in choppy water it is important to the weight of loose gear next to the centrecase in the middle of the boat to help keep the boat on its lines.

Perttu on the building

Last winter was quite busy for me. I lost my sense of realism when my girlfriend was going to Africa for four weeks. I had bought plans for two kayaks and I was focused of building them for both of us. Then Mik´s Quick canoe came on marked and I could not resist buying plans and building one. And then I get the idea of Ocean Explorer and I started to draw sketch of it. I liked it immediately and when Hanna left to Africa I started to build it in our living room – ( I forgot to tell her – now we are repairing our living room… ). oh1 | Flickr – Photo Sharing!

Idea was to make small, cheap and light “yacht looking boat” with good performance. It´s cheap to build, light and sails good – the look of boat is little odd on front view, but I still like it. loma3 | Flickr – Photo Sharing!

In end of last summer I made three days exploring trip with it. Maybe I have lively imagination, but I felt like real sailor- sleeping inside cabin – on boat which I have build by myself – feeling how waves moves the boat… loma2 | Flickr – Photo Sharing!

Scotty on my forum

Scotty went ahead and did some great google sketchup drawings of the boat and some of the parts on my forum .

Perttu’s Cruise in Finland

Yes a real multiday cruise in a tiny and cheap boat. I Launched my boat in Porosalmi Harbour.

I had three days to explore Linnansaari National Park in lake Saimaa Finland. The harbour was in sheltered bay and the wind was behind me. When I sailed on a reach, open lake area winds picked me up and I reefed the sail one step down. It was fun sailing. I was moving windward and the waves started to grow bigger and bigger. My boat name is iSo (big), but she started to feel small. It was a little scary and exiting at the same time. I started to look for shelter behind the islands and soon I reached a sheltered bay on one small island. I was so focused on sailing and taking photos, that I wasn´t sure in which island it was. I don’t have GPS– with maps there is always possibility to get lost! In the evening the winds are usually gentler. I had time to make coffee and refit the wind indicator, which had dropped into the cockpit. The bay was only 50m wide and it was a little battle to sail out to open lake. In the evening the winds were nicer and the sun was shining – not a trouble in the whole world.On one island there were 15 canoes and a group of young germans singing Kumbaya my Lord – I thought I must sailed too far south. The first night inside the cabin. The boat moves little with waves. I was reading a book and listening to the radio. Nice feeling – dawn comes and I fall into sleep. 12.8. 07:00 – Holiday – Why wake up at 7 o’clock? 09:30 – Stuck in calm. I miss yesterday´s winds and surfs. History knows greater sailors and explorers than me, maybe we still share something common – moments like this? That spirits up my mind and I start reading and let the sail up. 11:00 – Water supply showing alarming low. Sun is burning hot. In these latitudes the sun can be an enemy – am I gonna survive?My boat carries Michael Storer’s lugsail and it picks up even the littlest whisper of wind. I am actually moving slowly. My destination is Linnansaari Island´s north edge. The map says it has a dock for small boats. My boat has berth´s for two – is that dock going to be too small? 11:50 – A bird. Sign of land, binoculars! coconuts – whiskey for all! 12:00 – Back to reality (at least half of reality) – no whiskey for sailors! – Maybe a little in the evening? It´s time for lunch break. Tuna and pasta. (I caught the tuna earlier this morning.) When I moored, the winds started to blow. Luckily they died as soon as they appeared – I had time to eat in peace and take a small nap. 14:15 – In Linnansaari Island small boat’s dock. My fear was unnecessary. The boat just fit the dock. I hiked to a cliff which gave a great view of the lake. 17:00 – Moored to rocky island. Coffee break and swimming – feeling free. You don’t have to be rich, (with money) to complete your dreams! 16:00 – Nice steady winds – not big, but keeps us moving. 20:45 – Found nice place between two small islands. I took a couple of photos, set up the boom tent and slid into my sleeping bag. Later I watched the sunset through the cabin window.

13:08 – Friday the 13th. Beautiful morning, no clouds and the sun warms nicely. After breakfast I headed back to the harbour where I started. This trip is going to end soon. It´s time to start planning the next one. Any questions or comments: Plans are $40 and include Perttu’s hull and Michael Storer´s Lug rig, spars, sail design for home sailmaking, and foil shapes.Plans for this baby are available from Duckworks or BoatCraft Pacific and soon all storerboats agents.

26 thoughts on “Ocean Explorer – a micro cruising sailboat for inland waters from Perttu Korhonen”

Hi….Michael…the new SkechUp for the 12ft design .is i think the very practical One….love that it has mor space..and payload.. hope to see that…i was playing micro sail boat for quit some times…..!!!have tons of adventure ..on that type

http://www.flickr.com/photos/22625264@N04/sets/72157622492439800/

the 8″ is too short for me (space), the 12″ is too long (car). i guess i’ll have to “stitch” the 8″ read to the 12″ front. otherwise i can’t roofrack that one on my compact car… (volkswagen rabbit, roughly 10″ long) also i need less height than the 12″ one…

what do you think – could be done in glass fibre with no wood for 30 kilograms ? (building a outer form, laminating in carbon or metal struts and using baloon pressure lamination techniques)

what about a 5hp suzuki engine (we have very few wind) ?

It is a common misconception, but modern wood construction is much lighter than fibreglass. Even with carbon you would find it difficult to get close to the weights of the same structure in premium plywood such as the gaboon species. Sometimes called Okoume. Still much cheaper than Carbon particularly when considering the cost of moulds and materials that won’t go into the boat

Fibreglass will be about 60 to 100% HEAVIER than wood. Glass specific density – 2.5gm/cm^3 Resin specific density – 1gm/cm^3 Okoume wood specific density – 0.35gm/cm^3

About 3hp would be more than enough for little boats like this. More will just make the boat stand up with its nose high in the air. Sensible speed is about 5knots (nautical miles per hour)

Best wishes Michael

What is the approximate dry weight of the OE with and without sails/rigging? I’m wondering if the boat is (at least in theory) car-toppable.

Cheers! ~Rob

I will forward this to Perttu and ask him for an approximate figure. It will vary a lot depending on the plywood and timber selected.

One thing to be aware of is that BULK can be as big a problem as weight when roofracking.

I calculated the approximately weight for hull and it shoud be around 45 -55 kg ( birch plywood ) Approx 130 lbs. and 5.5 kg for spars ( pine ) Thanks Perttu

(Comment from Michael … the hull weight looks about what I would expect but would depend on the timber. The whole rig for the OzRacer (the first two Oz PDRacers we built) was about 18 to 20 lbs (7kg) for the sail, rig and the few fittings and ropes).

Perttu and Michael, thanks for the response! That’s certainly an impressive weight and well within the 75kg limit of my roof rack (all bulk concerns aside …). I think it may be doable with speed restrictions and short trips.

Hello everybody, this boat is wonderful :-).

I have some question: is the ocean explorer a good boat for two persons?

What do you think to use that in the mediterranean sea? Do you think that the ocean explorer can works well in the normal waves of that sea?

Thank you very much

Paolo, Italy

Sorry, I forgot one thing.

The “Stitch and glue” is the construction tecnique?

No, it is not stitch and glue. It uses timber with square cross section in all the corners.

This requires fewer building steps than stitch and glue because the hull shape is so simple.

I would not recommend the Ocean Explorer for the Meditteranean. If you know it already, you know there are many beautiful sailing days when you could sail any boat, but then the screaming strong winds come from the mountains or the deserts. I don’t think it would be safe. It really is a boat for rivers and lakes with good sailing conditions because it is such a tiny boat.

As far as two people … It depends on the two people. I have slept in a very small tent with another person and it had been fine. I have slept in a much bigger tent with one person and they found it difficult. It is a small space with a small vertical dimension.

Not everyone will like it, but some who have the spirit of adventure will think it is cute and fun.

Excellent pictures, and funny story of the holiday trip. I especially like the shots on flicker of your living room co nstruction. If my wife was away, I would likely do the same if I had to, knowing she would HIGHLY disapprove. I love the final product, and am considering making one when I get home from West Africa rotational work.

I surfed the web and love the videos of your boat under sail. Post more to Youtube if you have any. I just restored an 18ft 1972 Folbot sailing kayak and had a blast learning to sail it last month while at home on days off. My wife said not to come home with another project that kept me up all hours of the night in the garage …… I think I will be in hot water when I pull in the drive way with the plywood in my truck :)

Bill, Surette’s Island, Nova Scotia

This is exactly what I am looking for! When do you think these plans will be available?

Plans are for sale now!

Ooze Gooze plans on Duckworks

I didn´t draw boom tent for this boat, same type boom tent like Ocean Explorer can´t be use, because cockpit is longer than boom. Boom tent is so nice equipment, that I would miss it, so that may come in future as add on – and curtains for sure – ha!

Now there is optional plans for outboard mount and some another small things, but that boom tent needs some thinking — Thanks

This is fantastic!

My wife (Finnish, coincidentally!) and I currently enjoy infrequent weekends doing minimalist canoe camping in the hidden lakes of the Canadian Shield (we’re not much for crowds). Our children are very near the age where they can be left on their own, so for over a year I have been conspiring to build a PD Goose for “luxury” camp cruising. My new home with double garage was completed over the winter and I came back to this page to visit the Goose plans when I saw this!

I intend to check back frequently and be one of the first in line when the 12ft plans are ready.

All the best from Canada,

Guess what Darren,

We finished the plans yesterday. Plans are for sale now!

More pics of the Ooze Goose sailing micro cruiser will go up here as we get them together.

Perttu’s computer drawings are a wonder.

Wow!…..How exciting!

Not only am I enticed about about this microcruiser’s sailing performance, but I am already being flooded with dreams of my sweetie and I on ultra-romantic wekkend and long-weekend getaways….I can picture us anchored up in some of our favourite private gunkholes – her stretched out sunbathing in the cockpit; me sitting on the bow catching supper; swimming; an ice chest full of cold ones; and the best part – no hauling camping gear ashore and back again!

Is this plan set also going to come with all the extra goodies – boom tent, curtains, blocks, etc?

The plans come with some of those accessories drawn up just like the smaller version. I will dig up Perttu for comments about what is there exactly – he will reply here and the reply should be forwarded to you automatically.

We are really interested in the performance too and how it handles different conditions. It is not really an “open water” boat, I would probably think of it like an open boat in terms of seaworthiness. If you keep that in mind and gradually extend what you do I think it will be very good fun.

Plans are for sale now Darren.

I’m loving this design. I really think there is genius in it. Great collaboration. I don’t think I can resist building one…I’ll send pictures

Most of the Genius is Perttu’s. I just supplied the running gear to make it go nicely.

I’m quite taken with your Ocean Explorer. My only problem is my wife always comes sailing with me, so the boat would have to sleep 2 adults. I’m 5’10” and my weight is 210 pounds; my wife is 5’3″ and her weight is 110 pounds. Could you design a larger Ocean Explorer that would sleep my wife and I? I sure hope so. We tent camp in a two person pack tent that weights 6 pounds. Good protection with a bit of comfort would be fine for us. Thanks so much for your help. We hope you have a great year.

Perttu and I are working on a 12ft version. It is a lot of work so it might take some time to get it ready.

One of the best ways to monitor what is happening is to join my forum as well as this website.

auch ich denke übereine 10 ft version nach- gegebenenfalls 12 ft-,auf keinen fall größer oder schwerer. habe großes interesse an neuesten informationen.

Thankyou Roland,

I work slowly when creating new plans. But I will write something here when it is ready.

12ft is a good choice. 10ft makes it difficult to get good performance when there are two people on the boat.

Leave a Comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Click here for details of the Terms & Conditions, Use of our Plans, Back-up, SFDesign Philosophy etc

- Row boat plans

- Sailboat plans

- Power boat plans

Sailboat plans 18-24 ft

Questions? Suggestions? Contact us at: [email protected]

I’m Arch Davis – I learned boatbuilding and design in New Zealand in the 1970s. I have been helping people to build beautiful wooden boats since 1988. You can see a few of them by clicking on Picture Gallery . My approach to design is to put into your hands the means to use modern materials – marine plywood and epoxy resin – to build a truly lovely boat with classic lines.

I believe that a boat should be beautiful, not just by virtue of her lines, but also in her construction. No material makes this possible like wood. My aim is to take advantage of wood’s unique strengths, in a structure that captivates the eye. I want you to feel that you are always doing good work in building one of these boats.

You’ll see that I have a small collection of designs. That is because I understand your need for clear, comprehensible, detailed plans and instructions. I put a lot of time into my drawings, building manuals and DVDs. I also spend a lot of time helping people through their projects, on the phone or by e-mail. I really am here to help!

If you see something that you like in my collection, please feel free to contact me with any questions. I am available on the phone at 207-930-9873, or email me at [email protected] .

Wooden Boat Plans and Boat Kits by Arch Davis

Grace's Tender - More than just a tender, this little dinghy is a fine vessel in her own right. She is a pleasure to row, and sprightly under her simple sailing rig - a great boat for youngsters to mess about in. Bay Pilot 18 - an 18 ft pilothouse cruiser for outboard power. Laughing Gull - 16 ft self-bailing sailing/rowing skiff. Ace 14 - 14 ft performance daysailer Penobscot 13 - 13 ft little sister to Penobscot 14. Penobscot 14 - 14 ft glued lapstrake sailing/rowing skiff. Penobscot 17 - big sister to the Penobscot 14 Sand Dollar - 11 ft sailing/rowing skiff. Jack Tar - 26 ft plywood lobster boat design Jiffy 9-7 - suitable for rowing or a small outboard motor Jiffy 22 - outboard powered cabin skiff Jiffv V-22 - vee-bottom sister of the Jiffy 22

About My Boat Kits

I also have epoxy kits and plywood packages for all my designs, plus sails, rigging, and numerous other items. Here's my daughter, Grace, setting up the frames for a Grace's Tender kit.

Please call or write to me at: Arch Davis Design 37 Doak Road Belfast, Maine 04915 Tel:207-930-9873

If you would like to receive a newsletter from Arch Davis Design, send me an e-mail at [email protected]

Driftboat Wood Kit

Boatbuilders FORUM

Boat plans, patterns and supplies for the amateur boat builder.

Every year, thousands of amateurs much like yourself build their own boats the proven Glen-L way. Many builders save 50% or more over the price of a factory-built boat. It’s easier than you might think, and it can be a rewarding experience.

Industry experts

Established in 1953

300+ Models

International shipping

Plans & Patterns

All plans come with a 30-Day money back guarantee.

Providing boat Plans & memories Since 1953

For more than 60 years Glen-L has been the world’s premier supplier of boat plans and patterns designed for the amatuer builder. We make it even simpler by offering associated supplies and hardware kits for each design.

More Products

Boatbuilding hardware

Books, DVDs, & Audio

Tools & Raptor® Fastenings

Epoxy and Supplies

Featured designs.

View Plan Details

Cabin Skiff

Plywood Boat Plans

Easy Plywood Boat

Plywood construction, some epoxy, and a little bit of time are a small investment when compared to the sheer joy you’ll have on a lazy summer afternoon rowing around in your new fishing boat.

Having always been around boats, it’s been a dream of mine to build a center-console fishing boat. Something in the 27-foot range that can handle off-shore fishing in my retirement years. Now, that’s a long ways off. So, in the meantime, the boat shown here is a good way to test the waters (pun intended) of boat building. In the world of wood boats, there are a few ways to build them. The method we chose for ours is a plywood construction, coated in epoxy resin (to water-proof it). It’s actually pretty straightforward, but there are some angles to tackle. By not applying fiberglass, you remove one of the tedious steps of boat building. What you’re left with is a 14-foot flat bottom boat that’s perfect for exploring small lakes, rivers, and ponds.

SELECT YOUR PLAN PACKAGE

- Premium (unavailable) Learn more about our premium plans

Premium Files

You can download the additional shop drawings that you purchased using the link in this box.

What You Get:

- 15 pages of step-by-step instructions

- Over 60 full-color photos and illustrations and exploded views

- Hardware sources and materials list

Note: After your purchase, you will receive an email containing a PDF attachment of your purchased plan, as well as instructions for logging in to download the plan and access any other associated files and videos, which will all be located on this page.

Product Recommendations

We don't have any links to project supplies and hardware for this particular project yet, but here are some other products that might be of interest to you. (We may receive commission when you use our affiliate links. However, this does not impact our recommendations.)

Titebond Molding Glue

Table Saw Blade

Double-Sided Tape

Universal Fence Clamps

Affiliate link.

Since you are an affiliate, you can use this url to link people to this page and get credited for it:

COMMENTS

Idea 21 small sailboat plan is the latest development of my family of small plywood & epoxy sailboats plans for homebuilders: it was quite a time since I was thinking of an evolution of her smaller 19 footer sister, so I finally take the decision to publish this new plan. The goals of this plan is simple: add interior volume, simplify the work for homebuilders switching to a complete plywood ...

Cuts through river and lake chop with zero bouncing and pitching. Pack includes 23 and 27ft Dayboat versions in one plan pack includes Venezia below. Simple plywood construction. 10 or 15hp 4-stroke for 8 to 10 knots. Venezia and Dayboat Launch Boat Plan Package. More about the 23ft Plywood Dayboat/Launch Boat Plan.

Two sailboats plans in one ! A pocket cruiser with a double chines hull. - LOA 4.50 m x beam 1.80 m - SA 12 m² - Weight 295 kg - Weight full load 580 kg - Cruiser for three ( CE D/3 protected waters ) One double berth, a single bunk, galley and toilet locker. Full plans in PDF with 3D building guide and photos.

For most amateurs, plywood is the material of choice. Plywood is one of the cheapest and easiest building materials, one that the average do-it-yourselfer is both familiar and comfortable with. Plywood is also, pound for pound, stronger than steel. Because of its high strength to weight, plywood construction yields a boat that is much lighter […]

Plywood Boats to Build Yourself - by Dudley Dix Yacht Design. Plans for building a plywood boat in your garage, build methods for beginners to experienced builders. ... DUDLEY DIX YACHT DESIGN. Build Your Own Plywood Boat ~ Album of plywood boats ~ Plywood boat plans ~ Kits - USA ~ Kits - International ~ Main website ~ Mobile website ~ Full ...

Marjorie 26' Barge. Two sleeping cabins, a head, galley, and a pilothouse. Catalogue of all small boat plans and custom small boat designs by Tad Roberts. Plans for plywood, lapstrake, plank-on-frame, cold-molded, sheath-stripped, and aluminum construction. Free plans for Tern, 24' gaff ketch.

The Storer Rowboat is a pretty and fairly fast plywood rowboat plan that is easy to build. The shape is derived from the famous Goat Island Skiff sailboat plan which rows fast without much effort. This rowboat will be fast and responsive under oars. Buy Rowboat Plans Here $75.

plans price: 900 € for paper sheets, 840€ for pdf format drawings, 350 € for CAD engraving files (required if you want to cut all the plywood parts with CNC machinery, includes keel steel plating shapes) ; plans will be made approximately of 27 drawings and a 25 pages booklet with assembly sequence, tips and tricks, plans can be purchased ...

Buy Goat Island Skiff Plan - $100. Buy a Goat Island Skiff Sail and/or Ropes and Fittings. How to Rig the Lug Rig of the Goat Island Skiff for. Length - 15'6″ (4.73m) Beam - 5ft (1.52m) Hull Weight - 128lbs (57kg) - Gaboon (Okoume) Ply. Sail Area - Lug 105 sq ft (9.75 sq metres)

YACHT DESIGN. We provide stock boat plans for both monohull and multihull sailing vessels, including sailing skiffs and sharpies. Our designs mainly feature timber construction, in plywood or cedar strip plank composite construction, using the W.E.S.T. system (wood epoxy saturation technique). Our designs are intended mainly as cruising boats ...

Westhaven 32. $ 285.00 - $ 300.00 (USD) Build your own sail boat yatch from 9 feet to 63 feet in length. Fully featured wooden boat plans for home construction in Plywood, Steel and Fibre Glass.

2 longitudinals of 3/8" plywood, 14" high, provide the fore and aft structure over the length of the boat. Six bulkheads tied into these give great rigidity. The space below the sole is filled with polyurethane foam. The bottom is made of 3/8" plywood; the topsides, the sole, and the deck are of 1/4" plywood.

To download plans click HERE The idea for the 1 Wedge1 Sheet Wedge came from my desire for a simple, low cost, yet useful small portable hull design. It includes an ample beam and freeboard, decent volume, seating for one, and optional safety buoyancy...

Our plans include large format full-size paper patterns, ready to use, no need to print them and no lofting required. DIGITAL PLANS - We also offer digital plans, sent by email, as an option. Digital plans, sometimes referred to as PDF plans, will need to be printed using a large format (36" wide) printer. Clark Craft offers hundreds of boat ...

Very simple 8ft boat. Free plans. Usually built with chine logs but could be adapted to stitch and glue as long as you glass tape the seams. Mike Waller Design has Pippie8 Tender Exceptionally well laid out and documented free plans. Bateau.com has 3 free designs A 7.5 ft sailing dinghy, a folding kayak and a canoe.

Plywood microcruiser for rivers and lakes - cabin and cockpit fitted into a tiny 8 foot sailboat which sails pretty well - see the video below! Owning "yacht" - you don´t have to be rich - only little playfully attitude.

List of Latest Site Updates. 22/01/24 - Details for an electric pod drive and spade rudder added to the Felix 16 launch plans.; 14/01/24 - Standing Lug rig added to the Stornoway 14 dinghy.. 05/01/24 - My artwork is now also for sale from my Etsy page - www.paulfisherart.etsy.com. 02/01/24 - Recent watercolour and acrylic paintings for sale by Paul Fisher have been put up in a new section on ...

Sailboat plans; 18-24 ft Sailboat plans 18-24 ft. Design Length Beam Sail area Engine power Compare; Swaggie by John Welsford A mighty, miniature long range cruiser ... Plywood Lapstrake Traditional Trailer-sailer 22' 4" 6.8 m: 7' 3" 2.2 m: 253 sq. ft. 23.52 m 2: 6 Waller TS ...

Please call or write to me at:Arch Davis Design37 Doak RoadBelfast, Maine 04915Tel:207-930-9873. If you would like to receive a newsletter from Arch Davis Design, send me an e-mail at [email protected]. Arch Davis Design - Offering Boat Plans, Kits, Videos and DVDs For The Amateur Boat Builder including sail boats, row boats and power boats.

Providing boat Plans & memories Since 1953. For more than 60 years Glen-L has been the world's premier supplier of boat plans and patterns designed for the amatuer builder. We make it even simpler by offering associated supplies and hardware kits for each design. About Us.

Plans; Design Studio; Info. Licensing; What do CNC cutting files / plans included? What do 1:1 PDF Plans included? What do Plotting Points PDF Plans included? What do STUDY PLANS include? Plywood Boats Gallery; Plywood Boat Plans; Contact us

Building an 11ft Plywood Boat from start to finish using the Stitch and Glue method. Pointing out mistakes and how to avoid them.BOAT PLANS: https://plywood...

Easy Plywood Boat. Plywood construction, some epoxy, and a little bit of time are a small investment when compared to the sheer joy you'll have on a lazy summer afternoon rowing around in your new fishing boat. Having always been around boats, it's been a dream of mine to build a center-console fishing boat. Something in the 27-foot range ...