Your cart is empty

Use this bar to show information about your cookie policy.

Halyard Wrap, Diagnosis, Prevention and Repair.

DISCLAIMER: Although we will try to cover most aspects regarding halyard wraps, remember this is a BLOG and it is impossible to address every possible nuance and potential cause of these issues. It is always best to contact your local friendly yacht rigging service if you have any doubts as to how to deal with halyard wraps

In this post we will discuss some of the common causes of halyard wrap, how to spot them, and how to make sure they don't happen again!

By far the most common cause (in our experience) of halyard wraps is a combination of poor halyard lead angle (the angle that the halyard makes when it exits the sheave box and runs to the top furler swivel) and lack of halyard tension.

To try and make this very simply. WHEN THE FURLER SPINS, THE HALYARD SHOULD NOT ALSO SPIN WITH IT. What is supposed to occur when furling and unfurling is that the halyard swivel allows the foil to spin while at the same time allowing the halyard attachment point, or top half of the swivel, to remain static. Most roller furling manufacturers recommend that there is a lead angle of greater than 7˚. If the manufacturer does not require this angle they install some kind of wrap preventer that is fixed to the forestay wire directly above the foil that (in theory) prevents the halyard from passing around the forestay wire. With poor halyard tension or condition, wraps can still occur to these systems.

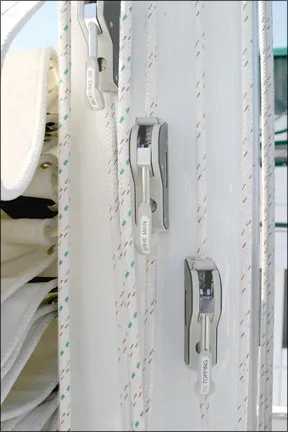

To create the 7˚ lead angle one usually has to install a halyard restrainer of some kind. Harken makes one and so does Selden . The Harken restrainer is good for all rope halyards, while the Selden restrainer can accommodate both wire and rope halyards. The restrainer is mounted directly to the mast a few inches (depending on the situation) below the halyard exit point and the halyard is routed through it before attaching the halyard to the top furling swivel. The restrainer deflects the halyard downwards and then outwards towards the foil at an angle that makes it almost impossible for a wrap to occur, provided enough halyard tension is applied to prevent slack in the jib halyard up top. Even with the halyard undertensioned a good lead angle is usually sufficient to prevent wraps occurring

Another potentially cheaper way to create this 7˚ angle is to install a strop between the head of the sail and the swivel, this works if your sail is very short and leaves a lot of halyard running parallel to the foil. By installing a strop that allows the swivel to reach close to the top of the foil (minus a couple inches) you can potentially create enough of an angle to prevent wraps from occurring.

Furlers that have a "wrap preventer" attached to the forestay wire require that the preventer be tightly clamped to the wire so that it does not simply spin around when the halyard (or arm of the swivel) comes up against it. There are written instructions with these parts, follow them closely or they will not clamp tightly enough to the wire to be effective. Once they are worn out, replace them.

On halyard tension: When hoisting your headsail make sure to put good tension on the headsail, as if you were sailing in a good stiff breeze. Feel the luff to make sure it's nice and snug. Sometimes a tight fitting boltrope can make a sail appear as if it is fully tensioned when in fact there is actually some slack up at the masthead. Feel that luff by hand before furling! If you are adjusting halyard tension whilst sailing, make sure to only slack the halyard once the sail is unfurled, and re-tension it before furling again.

An occasional cause of halyard wrap is a sail luff that is simply too long for the furler, thereby making it impossible to get adequate halyard tension and most likely pulling the top swivel over the top of the foil. This is bad. You should be able to see at least 1" of foil sticking up above the top swivel with the sail fully hoisted. If you can't, you need to shorten your sail.

How to diagnose the problem: This one is simple. If your furler is "jamming" or requires you to release a little and then furl some more in order to free it up, you most likely have a halyard wrap occurring. How to be sure? Break out the binocs or cast your eyes aloft whilst this jamming is occurring and watch the halyard. You will see it wrap around the top of the foil or forestay while someone is attempting to furl or unfurl it.

DO NOT PUT THE FURLING LINE ON THE WINCH. EVER! This is a wonderful way to break your forestay and potentially bring your rig down. If you are stuck out in a blow and can't seem to get the sail to furl, depower it, let it flap, and keep trying. If it will completely unfurl but not furl up, unfurl it and drop the sail on the halyard. Winching it while a wrap is occurring is not going to help. At all. Worst case, if a bad wrap has jammed everything and the sail is partly furled, obviously you can't drop the sail, so remove the sheets and manually pass the sail around and around the foil to get it as under control as possible. WORST WORST case. Send someone aloft to try and free the wrap. If they can't. Cut the sail off. Rather lose the sail than the mast.

A final word of warning: If you have been experiencing halyard wraps, and know that someone has attempted to winch the furling line to get it to furl, or that 250lb monster buddy of yours has heaved on it with all his might. Have a rigger go aloft (or you go aloft) and inspect the forestay at the masthead. There is a strong chance that the twisting tension on the forestay has damaged it. Look for wires that appear to be unraveled or even broken. This is VERY SERIOUS. You need a new forestay. Do not sail until one has been installed.

If you have any questions or comments we'd love to hear them. Please feel free to share this post with your friends through email or on Facebook , or Contact Us with any questions...

A short sentence describing what someone will receive by subscribing

100% free, Unsubscribe any time!

- Opens in a new window.

Home > Resources > Halyards, Sheets, and Lines: A Guide to Choosing and Maintaining Your Sailboat Rigging

Halyards, Sheets, and Lines: A Guide to Choosing and Maintaining Your Sailboat Rigging

11 May 2023

Ask Precision Sails , Hardware , Maintenance , Technical

How to Choose the Right Halyard/Sheet

When choosing a halyard for your sailboat, several factors come into play. These include the weight of the sail, the type of sail, the sailboat’s size, and the expected wind conditions. You should also consider the halyard’s stretch, which affects sail shape and performance. It is essential to choose a halyard that matches the load the sail will have on the line. Low-stretch halyards are ideal for racing and performance sailing, where every fraction of a knot counts.

Some Things to Consider when Choosing a Halyard or Sheet Include:

- Material: The material you choose for your line can affect its strength, durability, and stretch resistance.

- Diameter: The diameter of your halyard or sheet should be appropriate for the load the sail will apply to it and the size of your boat.

- Length: The length of your halyard or sheet should allow you to run your lines wherever they are needed, plus some extra for you to trim and tie off with.

- Attachment: The type of attachment you choose for your halyard or sheet can change depending on how you run your sheets and how the head of your sail is configured.

- Review Your Options: Making a decision about lines can be daunting, luckily Precision Sails has made it easy for you to pick your halyard or sheets by simplifying the process into two groups and pre-selecting the diameter, length, and attachment for your boat and line.

Here is a Quick Guide to Explain Material Choice:

The Precision Cruising series employs high-quality polyester lines, which are a good all-around option for starting and performing well. Polyester halyards and sheets are the most common and suitable for most sizes of sailboats, but they do stretch more than other lines like dyneema, spectra, or stirotex, which can affect sail shape and performance.

To address this, the Precision Performance series focuses on using stronger and stretch-resistant inner cores, making them ideal for racing sailboats that require high precision and tight tolerances. These lines are made of stirotex, which you may recognize by the name of spectra or dyneema. Stirotex is a chemically identical variation. The parent compound in these high-tension lines is HMPE. These lines are the strongest and least stretchy, making them the top choice for high-performance racing sailboats.

How to Maintain Your Halyards, Sheets, and Lines

Proper maintenance of your halyards is crucial for their longevity and reliability. Some tips for maintaining your halyards include:

Maintenance Checklist

- Regular inspection: Check your lines regularly for signs of wear, fraying, or damage.

- Cleaning: Clean your halyards and sheets periodically with soap and water to remove dirt and salt buildup.

- Lubrication: Lubricate your halyards and sheets with a silicone spray or dry lubricant to reduce friction and wear.

- Storage: When not in use, store your lines coiled neatly and out of direct sunlight if you can.

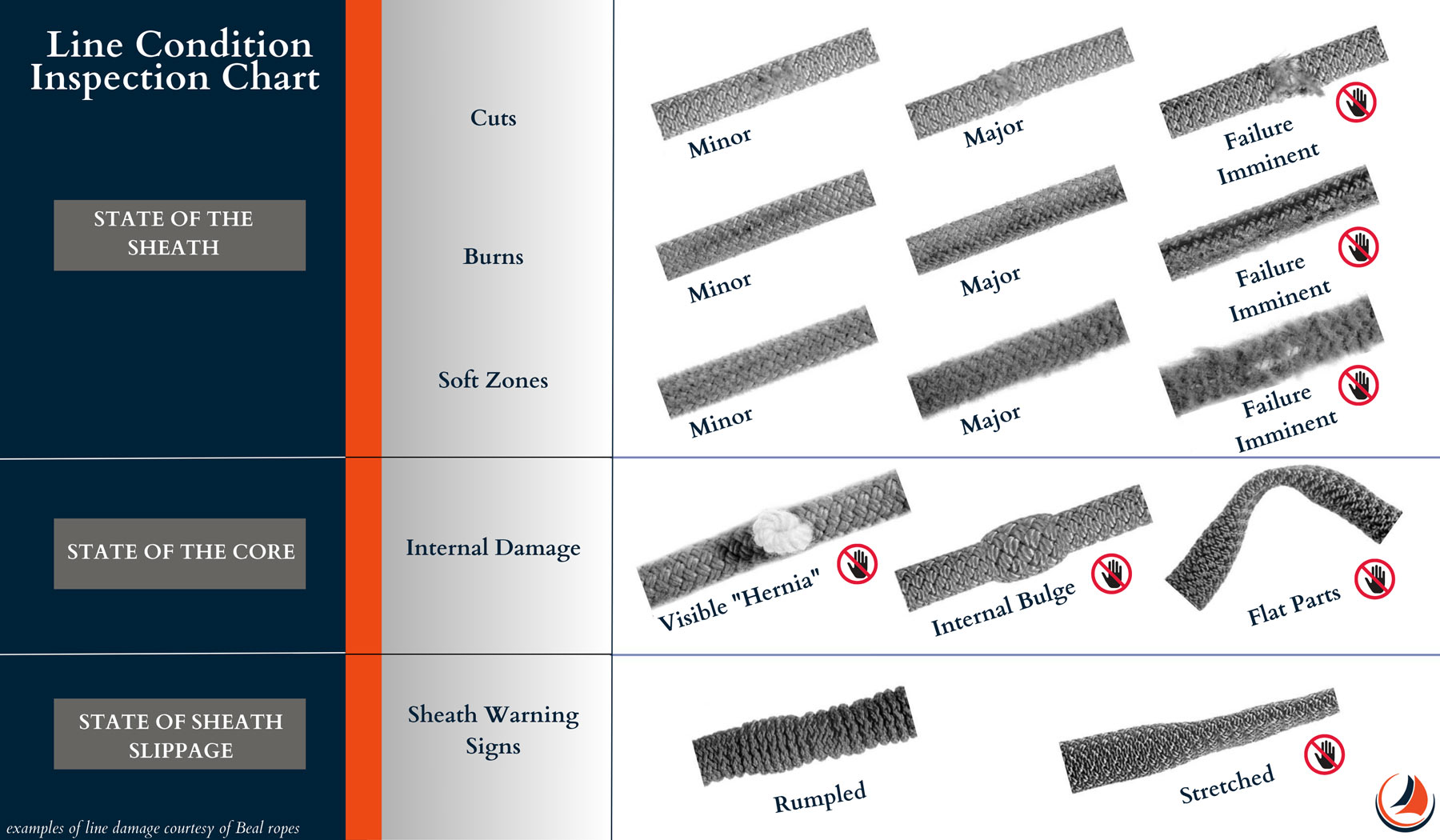

Signs of Wear – How to Inspect Your Lines

Lines that show obvious signs of deterioration must be discarded and replaced immediately. One of the most apparent and hazardous signs of wear on a line is a cut or damaged sheath that exposes the core. In such cases, it is important to retire the line immediately to prevent any further damage or potential failures.

Other signs may include hardness around the sheath or fuzziness. These signs may be particularly evident near the connection points or any areas of high friction. It’s also important to pay attention to any changes in the handling or feel of the line, as this may indicate internal damage or other issues that require attention.

A way to protect your investment is proper care and cleaning and avoiding the use of harsh chemicals or high-pressure washers, which can damage the fibers. This can be done by soaking them in a bucket of warm water with mild soap or detergent, then rinsing thoroughly and allowing them to air dry. This helps to remove any salt, dirt, or grime that may have accumulated, which can cause premature wear and tear if left unchecked.

A way to visualize this is to envision dirt particles getting trapped between the fibers of the line and causing small tears in the weave. When the line is put under tension, these dirt particles act like miniature saw blades, gradually weakening the line over time and potentially leading to catastrophic failures. Therefore, regular cleaning and maintenance of your lines, including halyards and sheets, is essential to ensure their longevity and reliability and to avoid any dangerous situations while out on the water.

Inspecting Your Lines for Damage

Pro tip: Usage level and proper care is a more important indicator than age

Let’s dispel some common misconceptions about when to retire a sailboat line. For example, some sailors may retire a line based solely on its age, rather than its condition. We want to stress the importance of inspecting lines regularly and retiring them when signs of wear or damage are detected, regardless of their age. Here’s a helpful checklist so you know what to look for on your lines.

Inspection Checklist

- Check for visual signs of wear and tear, such as fraying or abrasions, which can weaken the line and compromise its strength. Be sure to examine the line thoroughly, paying particular attention to any areas of high friction or wear.

- Run your hands along the length of the line, feeling for any hard or soft spots, which can indicate internal damage or wear. If you detect any abnormalities, consider retiring the line or seeking professional advice.

- Look for any signs of UV damage, which can cause the line to degrade over time. This is particularly important for lines that are exposed to sunlight for extended periods.

- Check the diameter of the line, ensuring that it matches the manufacturer’s specifications. Any significant deviations may indicate that the line has been stretched or otherwise damaged.

- Examine the connection points, including splices and knots, ensuring that they are secure and free from any signs of wear or damage.

To recap, lines, halyards, and sheets are an essential component of any sailing vessel, and choosing the right halyard for your boat is a necessary part of outfitting your vessel. Regular maintenance and proper care of your halyards can ensure their longevity and reliability. We hope this article has provided valuable insights into halyards, sheets, and lines, though we understand that it may seem like a lot of information.

If you feel overwhelmed by the amount of information, don’t worry, we have simplified the process of finding the right line for your boat. Simply fill out a form , and we will send you the best fit and our professional opinion based on the type of sailing you plan on doing. If you have any questions, comments, or wish to order lines from our sail consultants, please don’t hesitate to contact us.

FAQ’s

Q: What is a sailboat halyard?

A: Halyards are ropes or lines used to hoist sails, flags, and other equipment on a boat.

Q: What is a sailboat sheet?

A: A sailboat sheet is a line that is attached to the lower corner of a sail and used to control its position relative to the wind. The sheet is usually led through a block or a series of blocks, which allow the sailor to adjust the sail’s angle and trim it for maximum efficiency. In addition to controlling the sail’s position, the sheet also helps to control the sail’s shape and tension, which can affect the boat’s speed and handling.

Q: Can different types of materials be used to make halyards, sheets, and lines?

A: Yes, lines can be made of various materials such as polyester, nylon, stirotex, and dyneema. Each material has its own strengths and weaknesses, and the choice of material depends on the type of sailing and personal preference.

Q: How do I determine the length of halyard I need for my sailboat?

A: It’s important to consult with a sail consultant or experienced sailor to ensure you get the correct length. The length of halyard you need will depend on the height of your mast, the type and size of the sail you will be using, and where you plan on trimming your sails. Calculating the length is more complex than simply taking a guess, not to worry though, we have made it easy. Give us a call or fill out our form to let our system crunch the numbers for you.

Q: How do I know if my halyard or sheets are due for replacement?

A: Look for signs of wear and tear such as fraying, kinking, or stretching. If the line feels stiff or brittle, it may be time to replace it. Additionally, if you notice any damage to the sheave or winch, this may also indicate the need for a replacement. See the checklist above for detailed instructions.

Q: Are there any safety precautions I should take when using halyards and sheets?

A: Yes, it’s important to properly understand how to use a winch and don’t wrap the rope around your arm or fingers. Always be aware of your surroundings and avoid getting entangled in halyards or other lines. It’s also recommended to have a backup halyard in case of failure or emergency situations.

Q: How can halyards affect the performance of a sailboat?

A: The type of halyard used can have an impact on the performance of the sailboat. For instance, a stretchy halyard may cause the sail to lose its shape by releasing the tension on the sail over time, while a stretch-resistant halyard can help the sail maintain its shape in strong winds.

Q: Is it possible to splice or repair a damaged halyard or sheet?

A: It is possible to splice or repair a damaged halyard, depending on the extent of the damage and the material of the halyard. However, it’s essential to have the repair done by a professional or experienced sailor to ensure the halyard’s continued reliability and safety.

Q: How often should I replace my lines?

A: The lifespan of halyards and sheets can vary depending on factors such as usage, exposure to weather, and material. It’s recommended to regularly inspect your lines for wear and tear and replace them as needed. Condition is a much stronger indicator than age. Assuming light use and good condition, some materials like Stirotex have a longer lifespan, other materials may need to be replaced more often. In general, halyards and sheets should be replaced every 3-5 years for optimal safety and efficiency.

Related Posts

Full Battens vs Partial Battens vs 2 Full plus 2 Partial Battens

Full Battens VS Partial Battens At

Precision Sails we are asked every day during our customer quote consultation “Should I choose Full Battens or Partial Battens for my new mainsail?” Whether you are cruising or racing you will need to examine the pros and cons of adding full battens to your main sail.Positive Aspects of Full […]

My Need for Cruising Speed Demands a Great Suit of Sails

My Need for Cruising Speed Demands a Great Suit of SailsI like to sail fast mostly in the heavy winds that Lake Ontario throws.

How to Fold a Sail (Mainsail or Headsail) For safe Storage

Knowing how to fold a sail correctly will make your sails last longer and make them easier to set. Replacement sails are an investment and folding them properly is important to their longevity.

" * " indicates required fields

Cox Engineering

A technical information resource for yacht owners

Halyard wraps

A halyard wrap is the term used to describe the situation in which the headsail halyard winds itself around the forestay, ultimately causing the forestay to fracture. The fundamental cause is that the angle between the forestay and the halyard is less than about 10 – 15 degrees, which provides insufficient lateral force to the upper swivel to keep it stationary when the furling line is pulled. It is then easier for the halyard to wrap around the forestay. However, the same problem will occur if the headsail is furled or unfurled with the halyard loose, even if the angle between the two is sufficient. A furling line should never need to be hauled in with a winch. Always check the cause of the problem if extra force seems to be necessary.

In most cases the halyard sheave and the forestay terminal are fairly close together, meaning that the stay and halyard are almost parallel at the top swivel. There are two principal means by which the angle is increased, either a diverter or a deflector. A diverter is a bullseye fairlead riveted to the mast some way below the halyard sheave. A deflector is a small wheel with its own bearing, fitted above the top swivel. Both increase the angle between the stay and halyard, ensuring that the upper swivel remains stationary.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

In Search of the Snag-free Clew

What’s Involved in Setting Up a Lithium Battery System?

Reducing Engine Room Noise

Breaking Point: What Can Go Wrong With Your Yanmar?

Mildew-resistant Caulks for Boats

Can We Trust Plastic Boat Parts?

Repairing Molded Plastics

Mailport: Marine plywood, fuel additives, through bolt options, winch handle holders

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Safer Sailing: Add Leg Loops to Your Harness

Resurrecting Slippery Boat Shoes

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

The Ultimate Guide to Caring for Clear Plastic

- Sails, Rigging & Deck Gear

Practical Sailors Guide to Choosing Cost-Efficient Halyard Materials

Practical sailor testers evaluate the many cordage choices available for both furling sail halyards and conventional sail halyards, with a look at the different rope fibers out there and a specific focus on cost vs. line stretch..

Sail performance is directly affected by the type and condition of your halyards. Upgrading your halyards to a low-stretch fiber helps ensure youre getting the sails full power, and it can add life your sails. After testing a sampling of lines from New England Ropes, Novatech Braids, Samson Rope, and Yale Cordage, Practical Sailor found that line stretch decreases significantly as cost increases. And while the very-low- to no-stretch high-tech lines often come with through-the-roof prices, there are low-stretch halyard options available for the budget-minded sailor. This article offers a line cost vs. line stretch analysis and an overview of the fibers available. UV resistance and other factors like abrasion resistance and ease of splicing will be the subject of future tests on these halyard materials.

****

While considerable development continues in the realm of high-tech, high-budget halyards, cruising sailors and club racers face a variety of choices but few new products since our last comprehensive halyard comparison (“For All-Rope Halyards, Its Hard to Beat New England Ropes Sta-Set,” December 1997). One recent addition to the range is VPC, from New England Ropes, which brings the low-stretch, low-creep characteristics of Vectran into an affordable upgrade from polyester double braid. Creep is a fibers taffy-like gradual elongation over time while under a static tensile load, and given how most sailors today are relying on at least one permanently hoisted sail, this factor will likely come into play.

Over the last decade or so, the large production-boat builders have found that more than 80 percent of new-boat buyers are choosing in-mast furling mainsails on boats 30 feet and longer. These boats all have roller-furling headsails, too, so the selection of halyard material is simplified somewhat: The halyards for these sails are rarely handled, so “hand” becomes a less-important quality to consider.

Another attribute, though, becomes more important: durability under load. The working end of the halyard spends its life under tension, bent around a sheave at the masthead. Because the sail remains aloft indefinitely, the halyard is rarely inspected, and must be trusted to perform without supervision throughout a season, or longer, if the boat is sailed year-round. All of these lines, except the Amsteel, have polyester covers, so one can expect similar service lives.

For sailors who have conventional sails and use the halyards on a regular basis, hand remains important. So too does the lines willingness to run free without snagging. And these sailors have plenty of opportunities to inspect the line for wear at its critical points.

Clutch slippage is also a factor. In last years rope clutch test (“ Clutch Play ,” April 2006), we used three of the halyards featured in this comparison. Subjected to 400-pound loads in two of our preferred clutches, the Lewmar D2 (the easiest to bleed) and the Spinlock XAS (the best gripping), Yales Vizzion proved to hold the best (average slippage 3/8-inch), followed by Samson Warpspeed (13/32-inch) and New England Ropes Sta-Set (7/16-inch). We will be looking at all these halyards clutch performance in a future test.

Regardless of sail type or deck gear, one factor always affects the choice of line for any halyard, and that is stretch. When the goal is to get the best performance out of a sail, its halyard should stretch as little as possible when it comes under additional load from a freshening breeze or sailing closer to the wind. When a halyard stretches, it allows the sail fabric to move aft. The draft of the sail moves with it. This results in the driving force rotating aft, creating more heeling moment and more weather helm. The boat is sailing less efficiently than it could, and you may be forced to reef earlier than you otherwise would.

As its fabric pulls aft, a sail on a mast track will scallop between the slides, and horizontal wrinkles will form at the slides. Apart from looking unseamanlike and making life less pleasant aboard, this also puts uneven stress on the sail fabric, which could&emdash;depending on how much sailing you do under these conditions&emdash;shorten its useful life.

So, heres another reason to renew your halyards, and perhaps even upgrade them: to save wear and tear on your sails.

Ironically, a cruising-boat owners budget is often expended on comforts and electronics, while the sails, which one would suppose are the boats reason for existing in the first place, get short shrift. When it finally comes time to specify the halyards and running rigging, the pot is empty. Ultimately, for the sake of a hundred dollars saved on a halyard, the owner never sees the full performance he paid for in his new sail.

For an average boat in the mid-30-foot range, a new mainsail can cost from $2,000 upward, and the premium for a “performance” mainsail over a basic Dacron model starts at about $500. Anyone investing that much would be well advised to hoist it on a halyard that does it justice. For about $100 over the cost of a basic polyester double braid, halyard stretch can be reduced by 75 percent, and the sail will be better able to deliver its promised performance.

By the same token, if you have an aging sail thats rather stretchy along the luff, you could eke another season or two out of it while you save up for a new one by spending a couple of hundred dollars on a less stretchy halyard. The halyard you bought will still be good for the new sail a few years down the road.

Another benefit of a low-stretch halyard is that it reduces effort in the cockpit. Trim-conscious sailors will find they have to make fewer adjustments to the halyard to keep the draft where they want it.

How We Tested

For this article, we looked exclusively at the cost/stretch aspect of new halyards. The Stretch to Cost Table on page 14 shows quite dramatically how great the benefit is for an additional investment that is really quite small, relative to the cost of a new sail. While we specifically looked at a main halyard, the results apply equally to a jib halyard for the same reasons.

For our comparison, to keep the math simple, our hypothetical test boat was somewhere around 35 feet, with a mainsail luff length of 40 feet. Running the halyard back to the cockpit, we assumed 50 feet of line between the winch and the head of the fully hoisted sail. Again for simplicity, we assumed a halyard load of 1,000 pounds, which is a reasonable maximum to expect the mainsail to exert on it&emdash;after that, its time to reef. (Once reefed, stretch resistance becomes even more important on a conventional sail, because the exposed halyard is now longer by the depth of the reef. When a luff-furling sail is reefed, adjusting halyard tension is pointless.)

For each sample of cordage we examined, we took the manufacturer-supplied stretch characteristics and calculated the stretch in inches that would result from our 1,000-pound load acting on the 50-foot standing part of the halyard. To simplify the pricing, we assumed buying 100 feet of line to provide an ample tail in the cockpit and enough extra length to allow “freshening the nip” a few times over the halyards life.

Our baseline rope was double-braid polyester, 7/16-inch in diameter. This kept our assumed 1,000-pound load at no more than 15 percent of the lines average breaking strength. A smaller diameter would probably suffice in the real world, but it would stretch more, precisely the opposite of what were trying to achieve.

The resulting graph of inches of stretch plotted against cost produced a dramatic curve, from which its quite obvious that the first $100 you spend over the basic polyester double-braid halyard buys a significant reduction in stretch. We should note that the values used for stretch are interpolated from data provided by the manufacturers in their literature or on their websites. While they may not be precise, we are confident that they reliably illustrate the argument. We intend to do our own testing on all of these lines, including stretch, to be reported on in a future issue.

The prices used in the graph are the lowest prices we found for each product. While researching these, we were reminded of how important it is to shop around. The price sources we used, and they are by no means exhaustive, appear in the “PS Value Guide Halyards” at left.

Learning the Ropes

The fibers commonly used in the products we studied are polyester, ultra-high-molecular weight polyethyline (UHMPE, sometimes written UHMWPE), para-aramids, and liquid-crystal polyester polyarylate (LCP). Polyolefin (polypropylene) is also used to add bulk to some fiber combinations.

This side of the Atlantic, polyester is usually known by its Dupont trade name, Dacron. It is inexpensive (relatively), has good tensile strength, and resists degradation by UV light, but it has a low Youngs Modulus (meaning, its stretchy). Compared to 7×19 stainless-steel wire, which was commonly used in the past for halyards, its very stretchy.

UHMPE comes under two common brand names, Spectra and Dyneema. Each of these has variants, but thats beyond the scope of this article. UHMPE has high strength and low stretch, which in combination with its generally good resistance to UV makes it well suited to halyards.

Para-aramids include Kevlar, Technora, and Twaron, variations on a molecular theme from different manufacturers. They exhibit similar strength to UHMPE at a lower price, but the trade-off is theyre not totally happy bending, they don’t perform well under abrasion, and they don’t stand up to sunlight as well. In sailing applications, they are usually found protected by a covering of some sort, except when they are the protection&emdash;against the heat generated when highly loaded lines are blown off a winch.

Vectran is the only LCP found in marine rope. It has high strength, low stretch, and better abrasion resistance than the para-aramids. It is far less susceptible to creep that UHMPE, and for that reason, it is useful when under standing loads. It, too, needs protection from UV.

Polyolefin, sometimes listed as MFP, is an inexpensive fiber used to bulk up small volumes of high-tech fibers to increase diameter and improve “hand.” It is basically polypropylene, and used by itself, appears in ski-tow ropes and on life-saving equipment. Its light, and it floats, but it doesn’t stand up to UV light.

Plotting Price vs. Stretch

Plotting cost against stretch using the same 1,000-pound load on a range of ropes produces a very clear picture of what youre buying. (For loads other than our 1,000 pounds, scaling up or down should produce the same relationship between stretch and cost.) You can almost halve the stretch by simply upgrading from 7/16-inch Sta-Set to the same size in Sta-Set X. Going up another level (see rope list) halves the stretch again, even with a reduction to 3/8-inch diameter to reduce cost. As stretch approaches zero, cost goes through the roof, but thats of little consequence even to the serious club racer, because several choices lie within a reasonable price point.

One way to use the graph would be to pick a maximum cost youd be comfortable with and look at the individual plots to the left of that number. Youll find that some of them are higher-tenacity material at smaller diameters. We figured 5/16-inch (8 millimeters) is as small as is comfortable to handle. Depending on your boats current winches, rope clutches, and sheaves, these may not work for you.

We included one single-braid line, Amsteel, simply for comparison. If youre tempted to go that route, you should consult a rigger about covering it so that it can lock properly in stoppers.

UV resistance and other factors like abrasion resistance and ease of splicing will be the subject of future tests on these halyard materials.

Conclusions

When it comes to making your decision, you will have to take into account factors beyond dollars and stretch&emdash;nothings simple. And until we do further testing, any definitive recommendations would be premature. Nonetheless, using the accompanying tables you should be able to find a good halyard that best meets your requirements and budget.

First: What size and type of line do you currently have? If this is original equipment, the entire halyard system may have been designed around it, from the masthead sheaves to the turning blocks at the base of the mast, to the clutch on the cabin top. Before electing to go down a size, or even two, in line diameter, you need to be sure this wont trigger a cascade of modifications necessary to accommodate it.

If you had wire, you will have to change the masthead sheaves to suit any synthetic line (and those sheaves are probably due for replacement anyway). Sheaves grooved for wire will make short work of a synthetic replacement. The higher high-tech lines, such as the 12-strand, single-braid Dyneema or Spectra (Amsteel, for example), work best under high loads in a sheave with a flatter-profile groove. The line flattens, reducing the difference in tension between the inner and outer fibers. Double-braid lines, which are the most suited to cruisers and casual racers anyway, are less fussy.

Going down a size in diameter will help your halyard systems efficiency by reducing internal friction as it turns around the now relatively larger sheaves. Most rope manufacturers specify a sheave-to-line-diameter ratio of 8:1 for optimal performance, but you rarely see this in many production-boat setups.

Going down two sizes, from 7/16-inch to 5/16-inch, will certainly get you into the high-tech material within your budget, but you may not get the stretch savings you hoped for. Also, you may find your stoppers wont accommodate the line.

Check the range of sizes your clutch or stopper will handle. If it will accommodate a size smaller than your present halyard, you can move up to a higher tenacity fiber core for better performance and down in diameter, and still gain the low-stretch advantage.

If you have permanently hoisted sails, you might want to look at a low-creep fiber for the halyards. This usually means a Vectran blend, and therefore more expense, but you wont suffer from gradual loss in luff tension as the season goes by. Because your sail is either all the way up or off the boat, the fall of the halyard, the part that would be hung on the mast or wherever when the sail is up, doesn’t have to be high-tech. A good rigger will be able to combine a single-braid standing part with a cover-only tail, saving both weight aloft and money.

Make sure you make both the tail and standing part long enough to permit freshening the nip a few times. Where the halyard sits on the masthead sheave, it will wear, and it will be exposed to ultraviolet (UV) light. Regular inspection, and cutting off and replacing the splice once in a while should prevent an untimely failure.

All of the lines discussed here can be spliced, but their differing constructions will dictate just what type of splice to use. Splice required is listed in the Value Guide, with additional information available on the manufacturers websites. Most of the suppliers also offer splicing services, and depending on line size and splice complexity, $15 to $30 seems like a bargain when measured against frustration most of us part-time riggers will suffer should we attempt the job ourselves.

- Practical Sailor Halyard Lines Value Guide

- Stretching Dollars

- Splice-Ability

RELATED ARTICLES MORE FROM AUTHOR

So why is the plot of price vs. strech included?

Where are the “accompanying tables” ?

To Karen- The tables are in the Also With this Article links at the bottom. To Darrell- Your pricing guide is really out of date. APS does not exist anymore. Hall Spars does not appear to sell line. DR Marine does not sell Portland Braid. The prices seem way out of date. Novabraid Polyspec was extremely hard to find online which raises concerns about it. I found it from The Chandlery Online for $1.69/ft.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Island Packet 370: What You Should Know | Boat Review

How To Make Starlink Better On Your Boat | Interview

Catalina 380: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

- Skip to main content

- Skip to primary sidebar

- Skip to footer

The Boat Galley

making boat life better

How to Quiet Clanking Halyards

Published on October 25, 2017 ; last updated on June 12, 2020 by Carolyn Shearlock

Clank . . . clank . . . clank. The halyards were quiet earlier, but as the wind changed they’re driving you nuts, particularly if you are trying to sleep.

But if you’re new, it can be equally frustrating to figure out how to stop the clanking.

First off, what seems like the obvious choice — tightening the halyards so there is no slack to clank — does not work. It just changes the pitch of the clank.

On our personal boats and several charter boats that we’ve been on, we’ve learned numerous ways that work. All involve getting the halyard far enough away from the mast that it can’t bang against it. And note that if you have external halyards, both ends may need to be led away from the mast.

Bungee to Sidestays

Using bungee cords to pull halyards away from the mast is the fastest and easiest solution . . . if you have a bunch of bungee cords.

Simply slack the halyard a bit, hook the bungee on it and then hook the bungee on the sidestay. If it’s too long to really pull the halyard off the mast, we tie a knot in the bungee or wrap the bungee around the sidestay and hook it back on the halyard or on another halyard if there are two that we need to quiet.

Out in the sun, bungees will last anywhere from six months to a year. We use them for many things and tend to just buy a “jar” of varied sizes, either from a home improvement store or Amazon:

- Jar of 24 Assorted Bungee Cords with Hooks on Amazon or see related products for more options

Note: the mini bungee cords are great for many things on a boat, but aren’t strong enough to keep halyards from clanking.

Alternative: In a pinch, you can do the same thing with a piece of line, but it takes longer to set up and longer to un-rig when you want to sail. Smaller line works better than heavier line.

Shroud Cleat

If you looked closely at the picture above, you may have noticed another way to keep halyards off the mast: a shroud cleat. These are usually used for cleating off flag halyards, but often have an eye at the top that you can clip a halyard to. Tighten the halyard so that there is no slack to slap against the mast.

You can get lightweight nylon and plastic shroud cleats with eyes on Amazon ( see here ) but we greatly prefer the stainless ones available from C. Sherman Johnson via West Marine (and interestingly, they’re about the same price as many of the lesser quality ones on Amazon):

- Stainless Shroud Cleat from West Marine

They are slightly cheaper from Defender , but if you’re near a West Marine Store their free ship-to-store more than makes up for it.

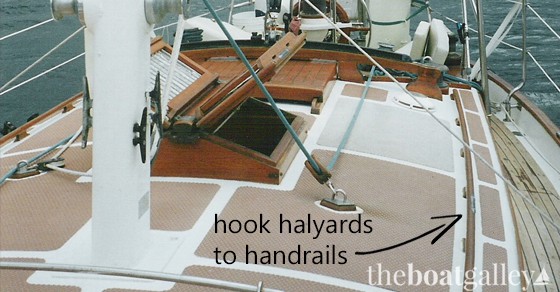

Hook Halyards to Handrails

If your halyards are long enough and you have handrails in the right spot, you can wrap the halyard around the handrail and clip it back to itself, then tighten the halyard to keep it off the mast.

Belaying Pin Rack

Sometimes, “classic” looking boats, such as our former Tayana 37, will have a rack of belaying pins on the shrouds. These are perfect for attaching the halyards to!

Depending on the halyard length, you can wrap them around the pins, just wrap around the bar and clip back on the halyard or make a loop from another line around the bar and clip the halyard to that. Again, tighten the halyard so there is no slack.

Be Kind to Your Neighbors

Even if you don’t spend nights on your boat, be kind to your neighbors and silence your halyards. If you’re not on your boat fulltime — or are leaving for a few days — you probably have one or two people that you’ve asked to “keep an eye” on your boat. Be sure that they know that it’s okay to come aboard to quiet a clanking halyard should the need arise!

And check out our other courses and products

Find this helpful? Share and save:

- Facebook 1.2K

- Pinterest 216

Reader Interactions

Cory N Mendy says

October 25, 2017 at 11:09 am

Oh lord this brings back memories of being naked on deck at two am just pulling as hard as I could on those halyards wondering why it wasn’t helping. Sigh.

Ken Karibe says

October 25, 2017 at 11:41 am

I’ve found very long lasting bungees at Home Depot. They are orange and come in a plastic jar. I believe they are store branded HPX.

Scott Beachbum says

October 25, 2017 at 12:12 pm

But I like the sound… Sailboat windchimes!

Pamela Dakin Harwood says

October 25, 2017 at 12:39 pm

I don’t mind when they are slatting against a wood mast, but otherwise it keeps me awake.

Tom Haupt says

October 25, 2017 at 12:28 pm

Why? I love that sound.

Dan N Jaye says

October 26, 2017 at 7:32 pm

Besides annoying the neighbours it puts lots of unnecessary wear on your halyards and you will have to replace them sooner.

September 5, 2021 at 10:02 am

Exactly! Ever heard the term gill guys used to describe the devices to prevent banging? I can not find it written but old sailors told me about that term

July 24, 2019 at 8:09 am

Slatting halyards: not only chafing the halyard itself, but is eating the anodizing, paint, or whatever finish on the mast. Not good.

Fiona Winter says

October 25, 2017 at 1:01 pm

One of my favorite memories of sailing is those old halyards clanking! ⛵️

Ted Broom says

October 25, 2017 at 9:34 am

We used bunch cords for years. Get longer life out of them by wiping high spf sunscreen into them once in a while. Works great to get longer life out of them.

Patti Smith says

October 25, 2017 at 4:26 pm

I love the sound of them clanking, it’s soothing

Ray-Dianna Kowerchuk says

October 25, 2017 at 8:15 pm

Yes it’s my wind chime

Ron Madewell says

October 26, 2017 at 11:27 am

Gee Carolyn, it appears your rapidly being outvoted. Sorry, have to join crew for a mutiny…lol

Carolyn Shearlock says

October 26, 2017 at 11:37 am

I’m really surprised at how many say they like it. Somehow, I don’t think they live full time on their boats . . .

Keith & Nicki, s/v Sionna says

October 27, 2017 at 8:25 am

In fairness to both, from a distance I find the sound pleasant, but on our boat or a closer neighboring boat, it’s maddening! I too have done the “naked madness at 3am” routine trying to silence the noise! And we have a ketch, so twice as many lines to deal with! On Sionna we have short lengths of small line (3/16″) permanently served to the forward lower shrouds of both masts for the purpose. Free, simple to adjust, and last a couple of years, even with daily liveaboard use. Stow with a rolling hitch to the shroud when we’re sailing, always there when we need them.

October 26, 2017 at 1:52 pm

Got to agree with you Carolyn. It’s may be ok for a short period of cocktails in the evening, but all night trying to sleep with hatches open will drive us nuts. We have found that mostly it comes from unattended boats.

Florian Wolf says

October 26, 2017 at 9:05 pm

That’s why you need to have a wooden boat with wooden rig and proper ropes – not the modern stuff :-)…

Karen Stresau says

October 27, 2017 at 7:27 pm

Barking dogs are another major annoyance.

October 29, 2017 at 3:35 am

Can you bind them to the shrouds as well? Or maybe the owners?

October 29, 2017 at 10:18 am

That would make it a little tough when you want to go sailing — much longer to undo.

Tim Seppala says

October 27, 2017 at 8:02 pm

Halyards… after 39 years aboard. I agree -All your comments are true. Now I wish my neighbors would only agree…

Bill Witherup says

October 31, 2017 at 9:27 am

Interesting solutions, but why not use what you’re likely to already have? For traditional rigs, simply lead the aft lead of the halyard forward of the spreaders with a flip of the slack, ditto the forward lead aft of the spreader. Belay at the normal points of cleat and spinnaker pole ring or whatever on the mast. Don’t tension too tight. With the halyards “fouled”in diamond loops on the spreader and upper shrouds,you’ll have a quiet night. In the morning simply flip them free and tension off again. If you have a noisy “halyard” that you cannot trace at 3:00 am, it might be time to investigate internal wiring to the masthead. Unfortunately, that’s not quite so easy to fix.

Cap'n Dave says

June 15, 2019 at 5:26 pm

This is the easiest method I’ve found, but it does lead to chafe. The new (or should I say “new” – it’s been a couple of years now) jib halyard I put up is already showing some fuzz where it hits the upper shrouds.

As for the wiring inside the mast? Yep, I hear it, but only if I go into the head at 3am (keel-stepped mast). I rarely hear it when I’m in the V-berth.

Now if I can just arrest the harmonic vibration of the shrouds themselves! Sometimes that really creates a staccato that you can’t really hear outside, but oh can you hear it down below!

Liah Hunter says

January 29, 2018 at 10:27 pm

I live on our race boat, again full of interesting challenges, especially with 4 headsail halyards, a foil, main halyard and topper. Makes quite a racket when the wind gets up. We’ve discovered clipping them to the lifelines works best as it’s furthest from the mast and means you can easily see if they’re tangled before you go sailing. Then we use one to wrap a couple of turns around the foil and that stops that rattling.

As far as damage goes, our neighbour’s Ladyjacks were run forward and have carved massive gouges into his carbon mast!

Anonymous says

May 15, 2018 at 10:11 am

Your marina neighbors will thank you

November 4, 2018 at 4:00 pm

Any advice to silence the noise of wires inside the mast?

November 4, 2018 at 5:09 pm

I have heard of people cutting up pool noodles and sliding section in the mast, and others who have used styrofoam peanuts. With either, you have to be very careful not to bind up the halyards — and it’s a bear of a job if you ever want to get them out. I’ve never personally done either.

Mara - S/V Dust in the Wind says

November 10, 2019 at 12:10 pm

When mast is down and you are possibly re-wiring, tie wires together with a cable tie and leave the tail on on. Stagger their direction. In-mast halyards, etc. will still work through and slide on by, but the wiring will stay silent and you will be able to sleep! Did that on our Tartan 27-2…..what a difference!!! Just moved up to a Pearson 34-2 and can’t wait to take the mast down to do the same. May have to wait another year though. Everything works, and it’s not in the budget for just a noise issue! 🙁

November 10, 2019 at 12:11 pm

PS – Pool noodles/pipe covers, styrofoam peanuts, etc. will all eventually degrade…..making a huge mess!

November 10, 2019 at 3:54 pm

The one problem with using wire ties (zip ties/cable ties) is that if you ever need to replace just ONE of the wires — and want to remove the bad wire — it’s impossible to do so.

November 4, 2018 at 6:14 pm

Wonder, since many boaters also might have a bicycle on board, they might have some old innertubes as well. Would cutting them into sleeve lengths of fully extended bungee cord, and then slipping them over the said bungee cord for sun protection?

Angela Sargent says

September 21, 2021 at 1:53 pm

Gentle musical wind chiming halyards are not the problem! Hammer and tongs that play a variable volume percussion, fading away just long enough to lull the nearby sailor to sleep, then reaching a sudden crescendo in the wee small hours with a gusty blow going through are maddening!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Each week you’ll get:

• Tips from Carolyn • New articles & podcasts • Popular articles you may have missed • Totally FREE – one email a week

SUBSCRIBE NOW

How to Tie a Halyard Hitch Knot

A simple hitch knot that creates a self-tightening loop at the end of the rope. It’s most commonly used in sailing for attaching a halyard to a shackle.

The Halyard Hitch has other names as well, like the Halyard Shackle Knot or Sunfish Halyard Knot.

Quick Guide: How to Tie the Halyard Hitch Knot

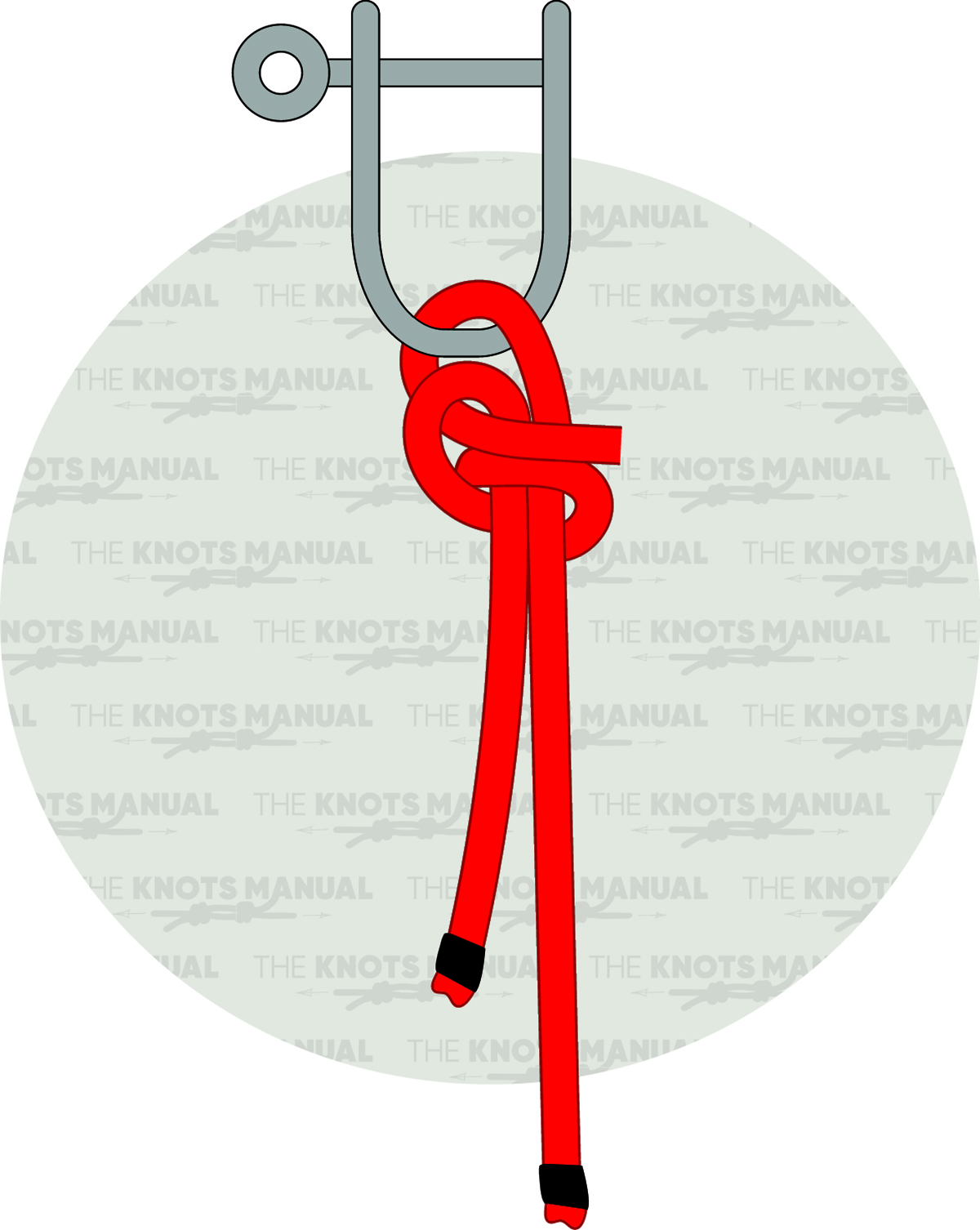

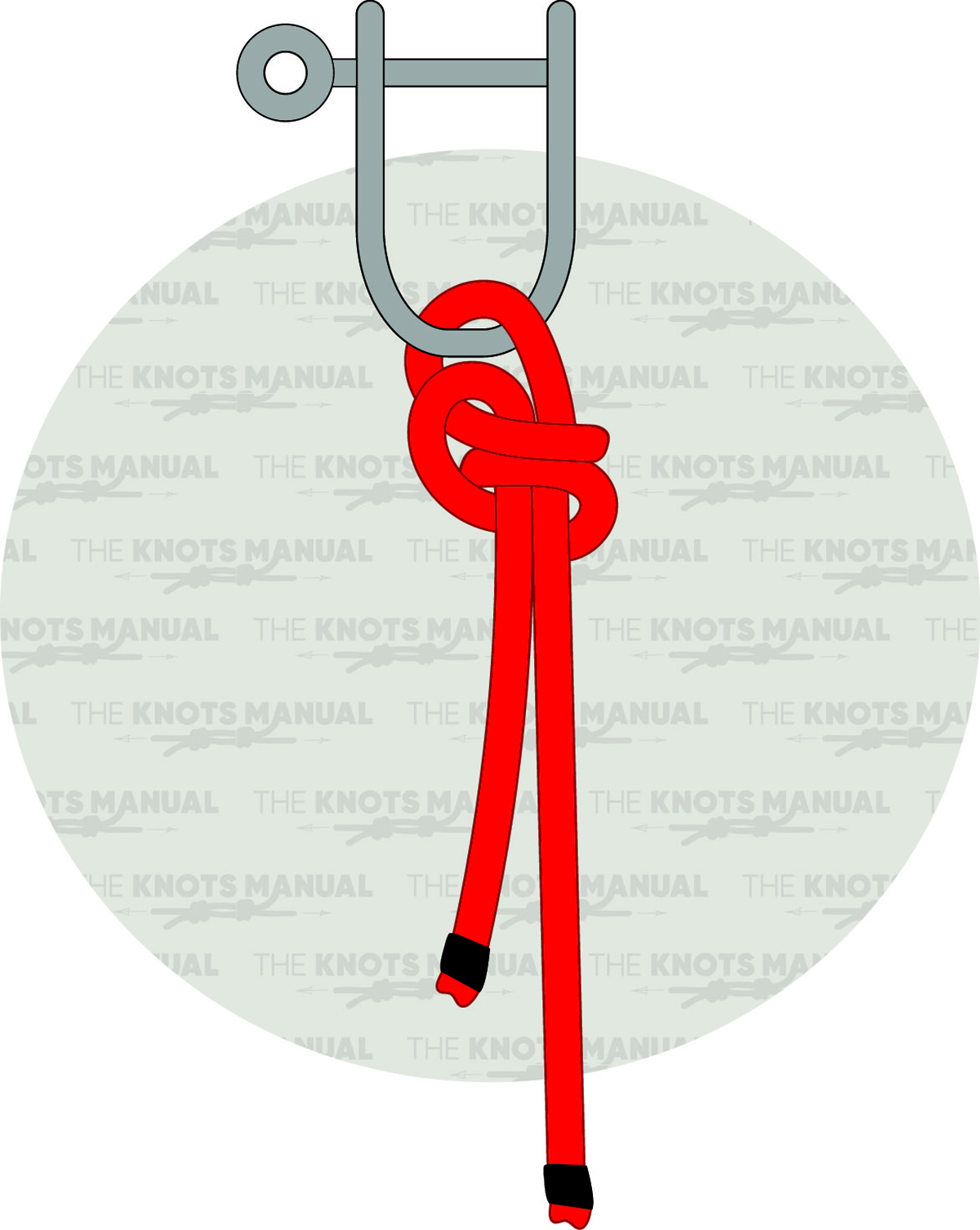

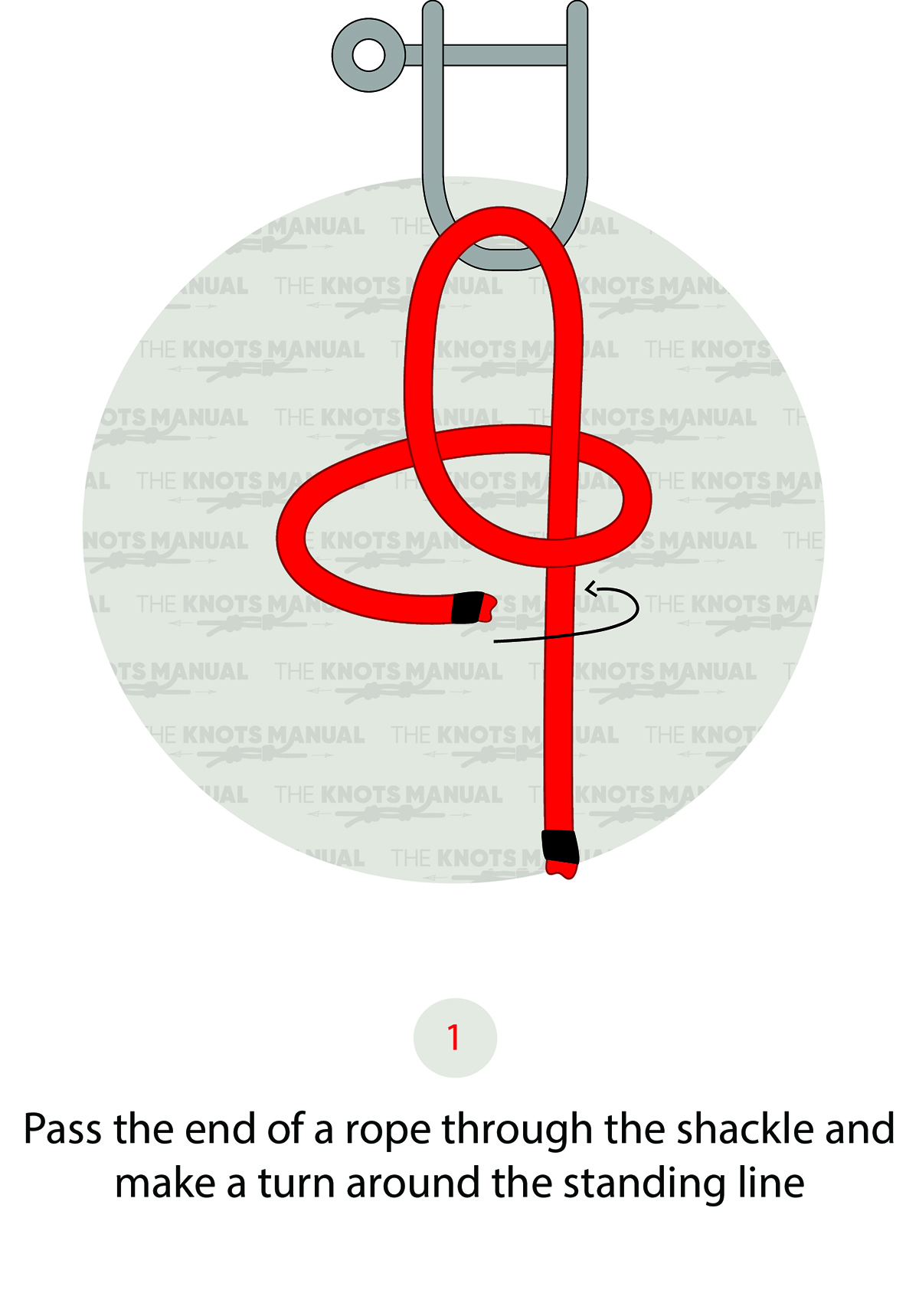

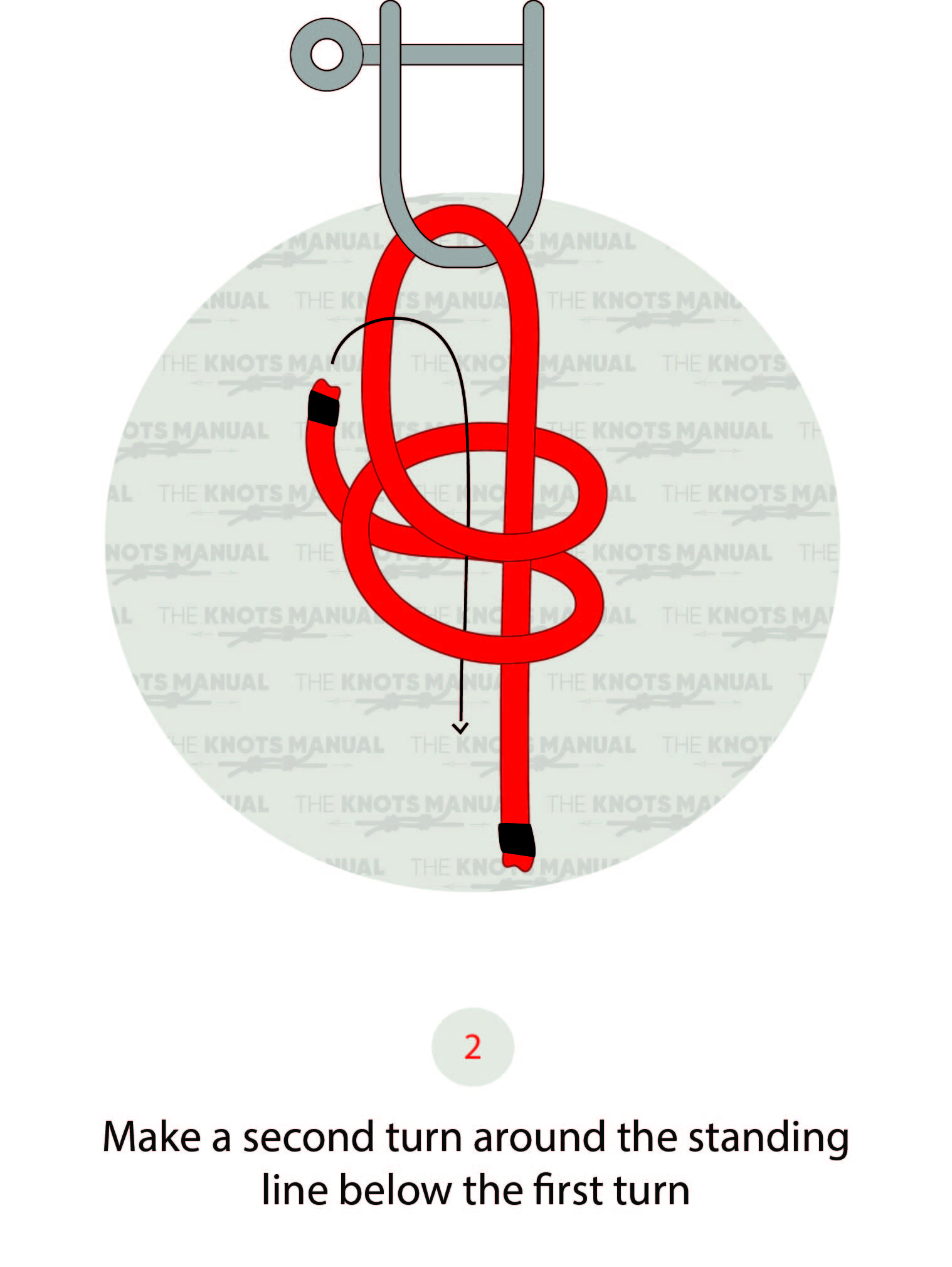

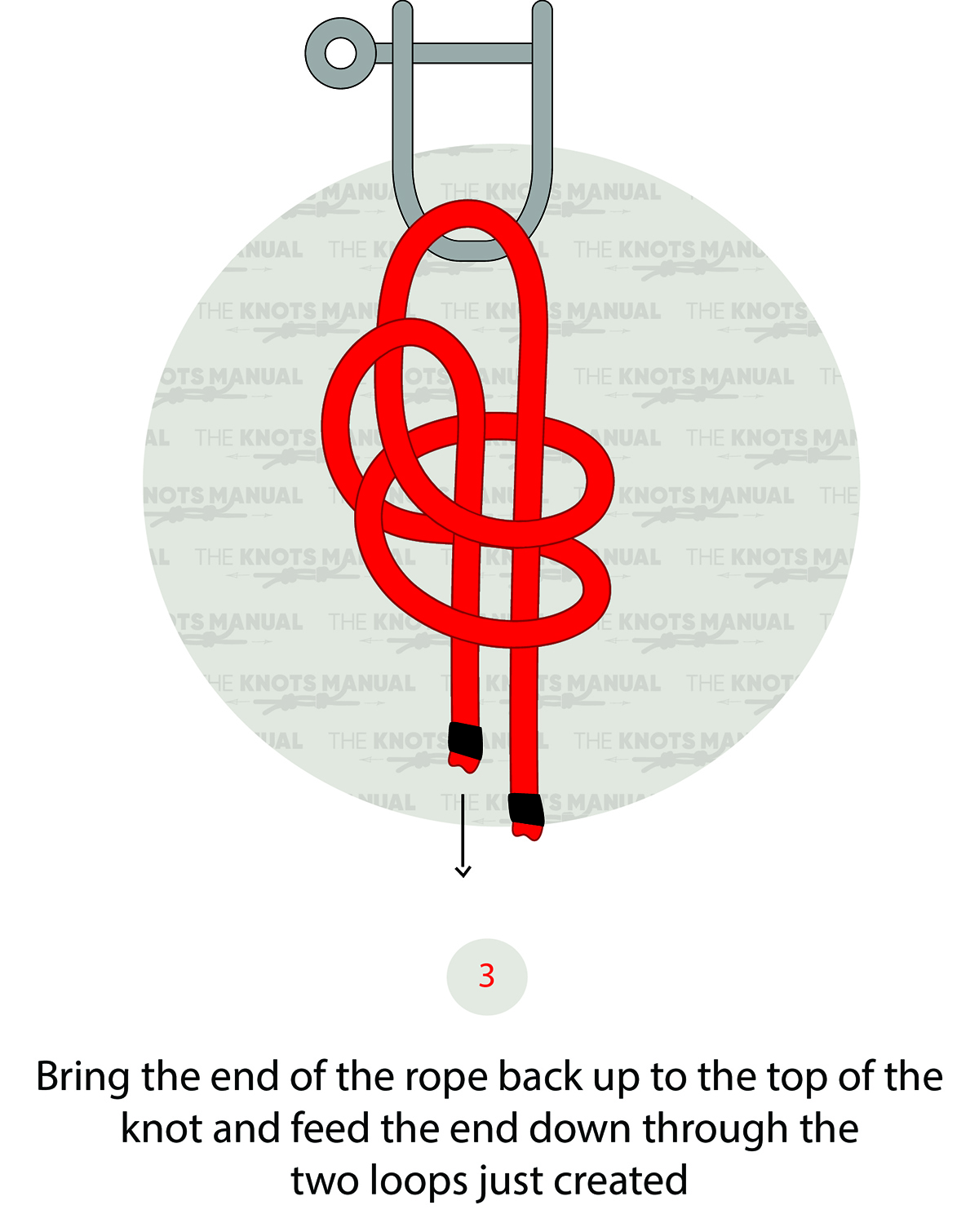

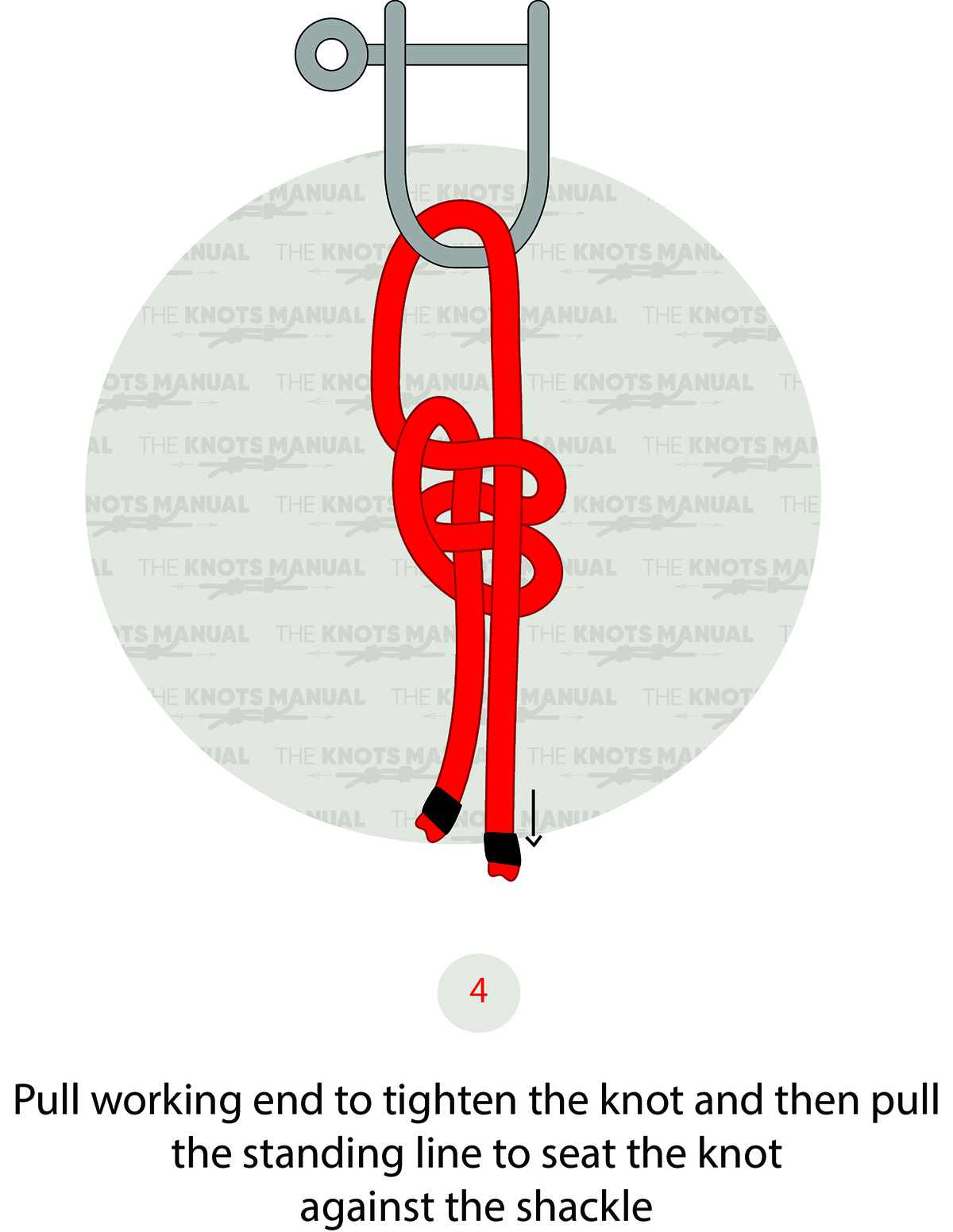

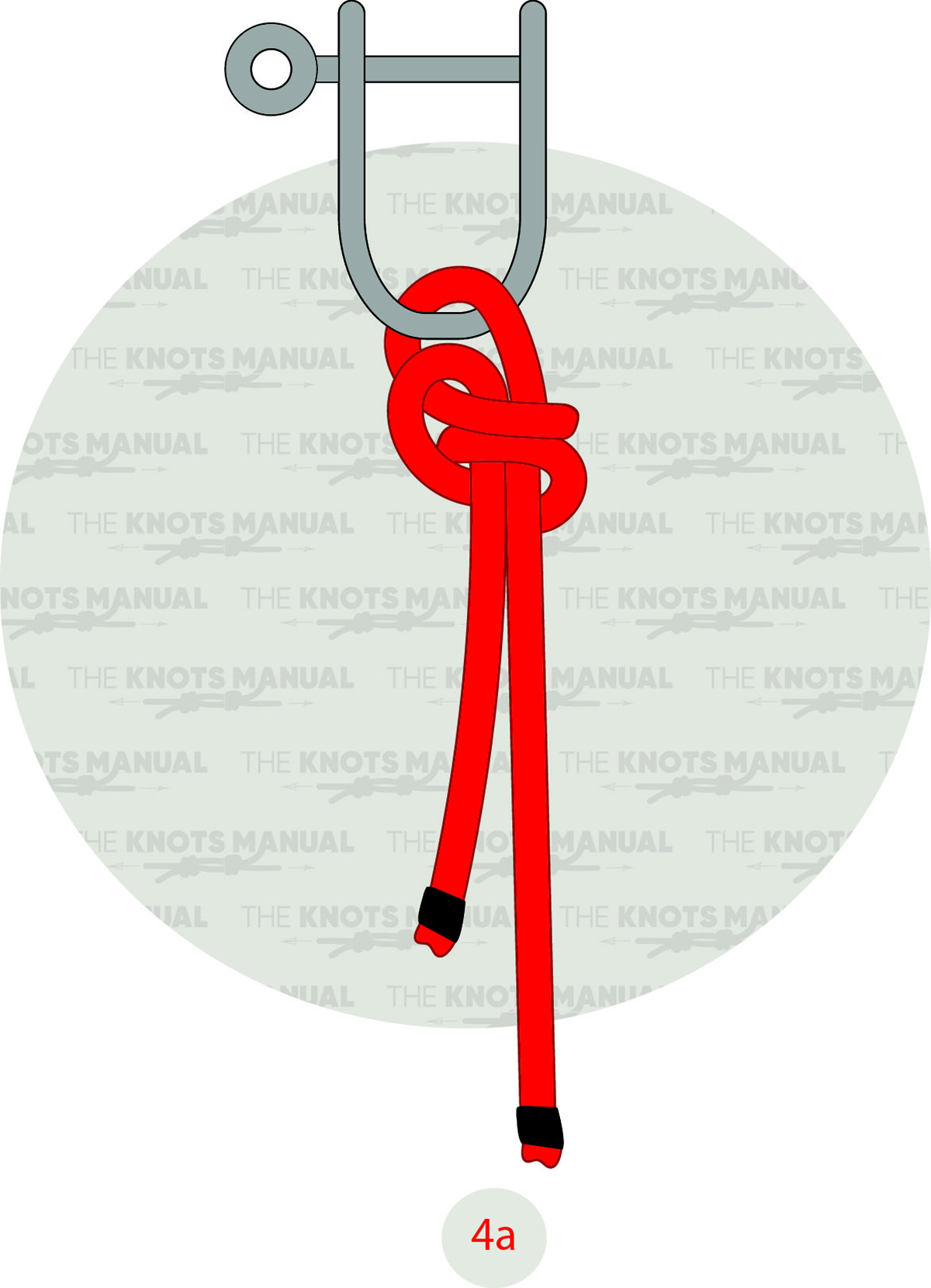

To tie the Halyard Hitch, pass the working end through the shackle, wrap it around the standing end two times, and pass the working end through both of these loops.

There are two variations on how to tie the Halyard Hitch Knot. In this guide, we’re showing the one where the working end comes out right next to the standing end.

But you can also tie it similarly to the Stevedore Stopper knot . This way, the working end comes out at the upper side. Both of these variants are similar in strength, but the variant we’re showing is less likely to come undone.

This knot is usually used for semi-permanent situations, so the end is trimmed short and heat-sealed. But if you’re using it for critical loads, make sure to keep the end long to account for slippage.

If you want to improve the strength of the Halyard Hitch, you can wrap it around the standing end three or more times, instead of only two turns.

Pros and Cons of the Halyard Hitch

The Halyard Hitch is very easy to tie and to teach to beginner knot-makers. It’s also very easy to check – it should form two parallel strands and one perpendicular on one side.

The Halyard Hitch also has a slim and compact profile. This makes it ideal for permanently connecting a rope to a shackle or a carabiner, as it’s unlikely to catch against other objects.

It’s also a strong and reliable knot, which is unlikely to come undone, even with cyclical loads. That said, it usually isn’t used for critical applications, like climbing.

The main downside of the Halyard Hitch is that it’s hard to untie once it’s been loaded with weight. The rope is often cut off rather than trying to untie the knot.

It isn’t effective with large-diameter objects. In this case, the fixed loop doesn’t tighten fully and the knot is less secure.

The Halyard Hitch is also very difficult to tie and untie under load or with one hand.

Common Uses for the Halyard Hitch

Most commonly, the Halyard hitch is used in sailing. It’s used with the Halyard rope for hoisting a ladder, flag, sail, or yard. It can be used to tie around the anchor object. But most commonly it’s attached to a shackle, carabiner, or ring to make it easy to disconnect if needed.

It’s usually used in permanent situations, like attaching a halyard rope to the sail, because it’s very difficult to untie. This knot also doesn’t loosen over time – the rope is more likely to wear down faster than the knot.

Typically, the end of the rope is cut short and heat-sealed, which acts similarly to a stopper knot. This means that it can’t be used with all types of rope materials, which are resistant to fire. With these ropes, you shouldn’t use this knot for critical applications.

The Halyard Hitch is also very commonly used as a flagpole knot due to its reliability and slim profile. You can tie two opposite Halyard Hitches to one another to turn it into a bend knot.

It’s also commonly used by firefighters and in search and rescue. It’s used for securing a ladder, but in this case, the other variation of the Halyard Hitch is used.

Knots Like the Halyard Hitch

Buntline Hitch : This knot can be used in similar applications to the Halyard Hitch. It’s similarly secure and has a slimmer profile. But it’s harder to tighten and more difficult to untie.

Bowline Knot : Some sailors use the Bowline Knot instead of the Halyard Hitch. It’s less secure, more commonly known, and much easier to untie.

Poacher’s Knot (Double Overhand Noose): The Poacher’s knot is tied very similarly to the Halyard Hitch, except the turns are tied in opposite directions. This makes the adjustable loop easier to tighten as you pull it. It’s also a bit less secure but easier to untie.

Flagpole Knot ( Halyard Bend ): In this variation, two Halyard Hitches are tied opposite to one another to connect two ropes. As you pull this knot, it tightens. It’s used as a flagpole knot because it has a very slim profile and doesn’t come undone under cyclical loads.

Anchor Hitch Knot : This hitch is also very commonly used in boating but to permanently connect to an anchor. It’s a very strong knot that is unlikely to come undone.

Two Half-Hitches: This is one of the simplest hitches, created by tieing two overhand knots in a row. It’s a secure hitch, but difficult to untie. It’s usually used for mooring boats.

Illustrated Guide: How to Tie the Halyard Hitch Knot

A step-by-step illustrated guide on how to tie a Halyard Hitch Knot.

Wrap the working end of the rope through an anchor and then wrap it around the standing end.

Wrap it around one more time and then pass the working end through both loops.

The working end should come out next to the standing end.

Tighten the knot by pulling the working and standing ends.

The finished knot should be right next to the anchor.

Frequently Asked Questions

Is the halyard knot better than a bowline.

The Halyard Knot is stronger than a Bowline Knot and also less likely to come undone. It’s even secure with cyclical loads. Its main disadvantage over the Bowline Knot is that it’s much more difficult to untie. That’s why it’s more commonly used for permanent applications. as opposed to the bowline.

Can the Halyard Knot Come Undone?

The Halyard Knot is very unlikely to come undone, especially if it’s been heat-sealed. It can only come undone when tied around larger-diameter objects instead of small poles, anchors, and shackles. In this situation, you can tie another stopper knot right after the Halyard Hitch, like the Double Overhand Stopper Knot .

Is the Halyard Knot Better Than a Splice?

A splice will always be more secure than a Halyard Knot. It creates a permanent knot, unlike the Halyard Knot which can be untied with difficulty. But for boating purposes, a Halyard Knot is more than secure enough to use on the Halyard rope.

HITCH KNOTS

- Necktie Knots

- Bowline Knot

- Hangman’s Knot (Noose)

- Privacy Policy

- Cookie policy

- Terms and Conditions

Disclaimer: Activities involving ropes are dangerous and potentially life-threatening. The illustrations contained on this website are not intended as professional instruction. We have put substantial effort into making our instructions safe and accurate. However, several factors are involved in the quality and safety of your knots: the utility of specific knots, rope materials, the age, size, and condition of the ropes, and how well you have followed the instructions.

You should always consult a professional before partaking in any dangerous activity. Do not use our instructions for activities that have a risk of property damage, injury, or death. The Knots Manual is not responsible for any incidents that may occur from the use of these materials.

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

halyard wrap

- Thread starter Mike8193

- Start date Sep 23, 2022

- Forums for All Owners

- Ask All Sailors

I was taking my sails off today. Ran into a problem taking the genoa down. It was a little windy(boat facing north and wind out of the south at the slip). It unfurled fine and then would not unfurl the last few feet. Fortunately I was able to refurl it and secure the sail. I looked up and it appears that the halyard is wrapped once around the furler and the sail is down about 4 to 6 inches from the usual position in the furling track. I am thinking I may have eased the the tension on the halyard some and created some slack while unfurling. Here is my question, I am thinking I can by hand while looking up rotate the furler and furled sail to release the wrap and then pull the halyard back up? Does that sound workable? Any suggestions welcome.

Worth a try. Besides what the forum will offer, do an internet search on "preventing jib halyard wrap" and you will find plenty of good advise like this one: Halyard Wrap, Diagnosis, Prevention and Repair. - The Yacht Rigger .

- Make sure my backstay (if you have one) is snug. Slack Backstay equals relaxed forestay.

- Snug up halyard and try to recover those 4-6 inches. That is unless the sail is already fully raised. Then the 4-6 inches is just normal

- With the sail wrapped on the furler extrusion and the sheets removed, I would try to rotate the furler extrusion and unwrap the halyard, taking up halyard slack as it unwinds. This will allow the sail to just rotate with the furler.

- Once halyard is free I would unwrap the jib/genoa from the furler and drop the sail by releasing the halyard and pulling the sail down.

Once you get jib down you may want to install a halyard restrainer.

Been there, done that. First time dropping my Genoa on my then first boat with a furler. Sandy was approaching so quite a bit of wind, halyard slipped, furling line got away and the result was halyard wrap. I did exactly what you said but with the Genoa out and flapping hard, I needed someone on the halyard and acting as a spotter as I couldn’t roll the furler by hand and see my progress at the same time. With your sail being furled, it should be easy. Yes, take the sheets off first.

....and in the future take the boat out onto the water and into the wind. The Genoa will come down with much less effort...

Roadking Larry

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

THE 10 BEST Moscow Boat Rides & Cruises

Boat rides & cruises in moscow.

- Boat Rentals

- Scuba & Snorkeling

- Fishing Charters & Tours

- Water Sports

- Stand-Up Paddleboarding

- Surfing, Windsurfing & Kitesurfing

- Kayaking & Canoeing

- Waterskiing & Jetskiing

- Parasailing & Paragliding

- River Rafting & Tubing

- Dolphin & Whale Watching

- Speed Boats Tours

- Submarine Tours

- 5.0 of 5 bubbles

- 4.0 of 5 bubbles & up

- 3.0 of 5 bubbles & up

- 2.0 of 5 bubbles & up

- 3rd Transport Ring (TTK)

- District Central (TsAO)

- Garden Ring

- District Northern (SAO)

- Good for Big Groups

- Good for Couples

- Good for a Rainy Day

- Budget-friendly

- Good for Kids

- Hidden Gems

- Honeymoon spot

- Good for Adrenaline Seekers

- Adventurous

- Things to do ranked using Tripadvisor data including reviews, ratings, photos, and popularity.

1. Flotilla Radisson Royal

2. Moscow River Boat Tours

3. Sup-Club

4. Akvanavt Diving Centre

5. Diving Center Crocus City Oceanarium

6. CheapRussia Tours

7. Kite School Kiteclass

8. SUP Center

9. Erwin. Reka

11. Easy Russia Tour Guide

12. Lovely Russia Tours

13. Capital River Boat Tours - Moscow Centre

14. Alfa Centr

15. Diving Club Divers

16. Sup Outdoor

17. MORE MOSCOW

19. Soho Sailing Style

20. Diving Center Crocodile

21. Dive-Project

22. Mosparokhodstvo

24. Kosinskiy Children Marine Club

25. Kayak Moscow

26. DIVECLUB CHE

27. FLOW Moscow

28. Moswake

29. Morskiye Volki

30. S-cruises

What travelers are saying

- CheapRussia Tours

- Easy Russia Tour Guide

- Lovely Russia Tours

- MORE MOSCOW

- Insider Moscow Tours

- Flotilla Radisson Royal

- Moscow River Boat Tours

- Capital River Boat Tours - Moscow Centre

- Diving Center Crocus City Oceanarium

Cruise Routes (Interactive Map)

Request a quote download brochure

Russian River Cruises

- Find your cruise

- Moscow — St. Petersburg

- Moscow — Astrakhan

- Astrakhan — St. Petersburg

- St. Petersburg

- Cruise Highlights

- News & Travel Tips

Lorem Ipsum

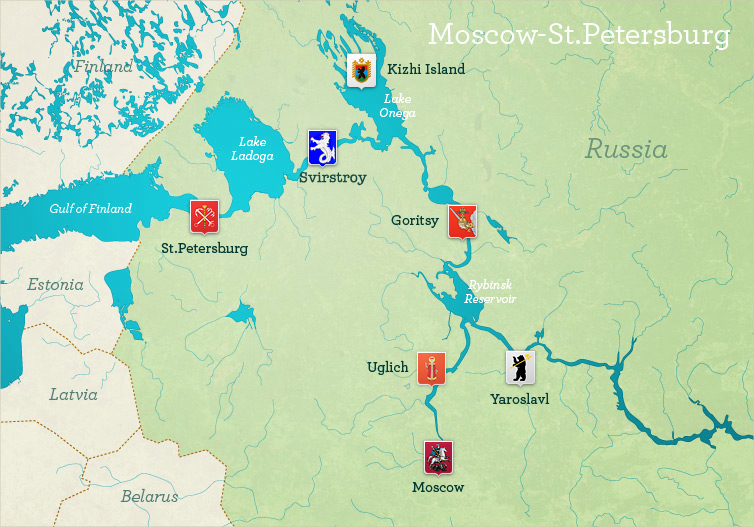

Moscow to Saint Petersburg

13 days – 12 nights

Collapse Full Itinerary

Gold, Platinum Airport transfer / Check-in at centrally located Marriott Aurora***** or Ararat Park Hyatt*****

Imperial : Private airport transfer / Check-in at the luxurious Four Seasons Moscow***** only a minute from the Kremlin and Red Square

Volga dream experience:

Gold: City Tour / Novodevichy Cemetery Imperial, Platinum: City tour / Lunch in a Moscow City Skyscraper / Novodevichy Cemetery / Sparrow Hills

Meals: Breakfast

Platinum / Imperial

Meals: Breakfast, Lunch

Gold: Moscow Kremlin / Armory Museum / Red Square / GUM Department Store

Platinum: Moscow Kremlin / Armory Museum / Red Square / St. Basil’s Cathedral / GUM Department Store / Park Zaryadye

Gold: Tretyakov Gallery / Moscow Metro Tour.

Platinum: Leo Tolstoy House-Museum in Hamovniki / Tretyakov Gallery / Moscow Metro Tour.

Meals: Breakfast, Dinner

Meals: Breakfast, Lunch, Dinner

Gold, Platinum: Town of Uglich / Church of St. Dmitri-on-the-Blood

Volga dream experience: Costumed Russian Tea Ceremony & Russian Cooking Class

Gold, Platinum: Yaroslavl City Tour / Governor’s house

Volga dream experience: Sun Deck Barbeque

Gold: Kirillo-Belozersky Monastery

Platinum: Ferapontov Monastery

Meals: Breakfast, Lunch, Russian Dinner with Vodka Tasting

Gold, Platinum: Kizhi Island / Lake Onega

Volga dream experience: Piano Concert – Compositions by Tchaikovsky and Rakhmaninov

Gold, Platinum: Svirstroy village / Local resident’s home / Local primary school

Volga dream experience: Farewell Dinner, Captain’s cocktail

Gold: City Tour / Peter and Paul Fortress

Platinum: City Tour / St. Isaac’s Cathedral / Canal boat / Yusupov Palace

Gold: The State Hermitage Museum / Peterhof: Park and a historic Cottage

Platinum: The State Hermitage Museum (Early Entrance!) / Gold Room / Peterhof: Park and a historic Cottage

Gold: Catherine’s Palace / Amber Room

Platinum: Faberge Museum / Catherine’s Palace / Amber Room

Meals: Breakfast / Imperial

Gold, Platinum, Imperial: Check-out / Airport transfer

Volga dream experience: -

The rates are set for a cruising season. The price is not dependent on the month within a selected year

Choose a date

View all months May July August

Choose Staterooms

All prices are per person based on double occupancy.

All rates are per person, based on double occupancy. Actual size of cabins can slightly differ within one category.

Request a quote

Journey: Volga Dream

Price per person: not specified

IMAGES

VIDEO

COMMENTS

There are two ways of curing halyard wrap. One is to fit a bullseye fairlead two to three inches below the sheave box, and lead the halyard through that before making it fast to the swivel. This will open up the angle the halyard makes with the headstay to 10 degrees or more and prevent it from wrapping around it.

An occasional cause of halyard wrap is a sail luff that is simply too long for the furler, thereby making it impossible to get adequate halyard (or luff) tension and most likely pulling the top swivel over the top of the foil. This is bad for several reasons. You should be able to see at least 1″ of foil sticking up above the top swivel with ...

Once the halyard wraps or 'toggles' the top swivel it can lock the swivel's ability to turn, etc. etc. u000bu000bTwo remedies if you are encountering a halyard wrap:u000bu000b1. raise the jib/genoa with the foot shackle (of the sail) on the furling drum NOT attached, raise the jib/genoa 'as far as it will go' in the foil so that the top swivel ...

By far the most common cause (in our experience) of halyard wraps is a combination of poor halyard lead angle (the angle that the halyard makes when it exits the sheave box and runs to the top furler swivel) and lack of halyard tension. To try and make this very simply. WHEN THE FURLER SPINS, THE

Q: How can halyards affect the performance of a sailboat? A: The type of halyard used can have an impact on the performance of the sailboat. For instance, a stretchy halyard may cause the sail to lose its shape by releasing the tension on the sail over time, while a stretch-resistant halyard can help the sail maintain its shape in strong winds.

A halyard restrainer helps prevent the halyard from wrapping around the foil or swivel during furling. (Photo courtesy The Yacht Riggers, St. Petersburg, FL.). Another common causes of roller furling failure to be aware of is a halyard wrap, when a slack halyard twists around the forestay above the furler top swivel.

Halyard wrap occurs when there isn't a great enough angle between the headstay and the jib halyard (left); A halyard restrainer is one way to avoid halyard wrap (middle); A halyard deflector is another (right). ... which could stop the sail from furling. "Halyard wraps are the #1 reason systems have to be replaced in the offseason ...

A halyard wrap is the term used to describe the situation in which the headsail halyard winds itself around the forestay, ultimately causing the forestay to fracture. The fundamental cause is that the angle between the forestay and the halyard is less than about 10 - 15 degrees, which provides insufficient lateral force to the upper swivel to ...

1)Fitting a strop between head of sail and the upper swivel of the furling system to reduce the length of the exposed halyard (bringing the swivel closer to the halyard sheave. 2) Fitting a diverter to the mast below the halyard sheave to increase the angle between halyard and stay. Harken recommends both those options.

Over the past four weeks I have been experiencing problems with furling the head sail due to halyard wraps. Bit of backgound info. When I purchased the boat in 2009, the head sail foil was fitted with a deflector, which on inspection was pretty much chewed up, so I replaced it with divertor, which I thought was in a good position to achieve a good angle between the foil and the halyard.

Ultimately, for the sake of a hundred dollars saved on a halyard, the owner never sees the full performance he paid for in his new sail. For an average boat in the mid-30-foot range, a new mainsail can cost from $2,000 upward, and the premium for a "performance" mainsail over a basic Dacron model starts at about $500.

Bungee to Sidestays. Using bungee cords to pull halyards away from the mast is the fastest and easiest solution . . . if you have a bunch of bungee cords. Simply slack the halyard a bit, hook the bungee on it and then hook the bungee on the sidestay. If it's too long to really pull the halyard off the mast, we tie a knot in the bungee or wrap ...

Re: Halyard Wrap Add a pennant at the tack perhaps 4-6 inches, the sail will fly correspondingly higher and this will increase the angle between the halyard and the swivel. Next time you drop the sail or sooner, inspect the condition of the upper swivel and apply silicone spray.

Watch on. To tie the Halyard Hitch, pass the working end through the shackle, wrap it around the standing end two times, and pass the working end through both of these loops. There are two variations on how to tie the Halyard Hitch Knot. In this guide, we're showing the one where the working end comes out right next to the standing end.

She always wanted to climb the mast and the perfect opportunity presented itself when the headsail halyard became wrapped around the furler. I, being one who...

Sell Your Boat Used Gear for Sale. Parts. General Marine Parts Hunter Beneteau Catalina MacGregor Oday

Walking tour around Moscow-City.Thanks for watching!MY GEAR THAT I USEMinimalist Handheld SetupiPhone 11 128GB https://amzn.to/3zfqbboMic for Street https://...

Explore the scenic and historic attractions of Moscow from the water with the best boat tours and cruises. Enjoy the views of the Kremlin, the Cathedral of Christ the Savior, and the Sparrow Hills on a relaxing or informative boat ride. Or, spice up your trip with some water sports and activities in Moscow. Find out more on Tripadvisor.

Book and travel with confidence. Moscow — St. Petersburg Moscow — Astrakhan Astrakhan — St. Petersburg. 13 days - 12 nights. Moscow and St. Petersburg are Russia's best-known cities, but the towns of Russia's historic Golden Ring are delightful too. The luxurious Volga Dream offers a unique opportunity to visit these Russian gems by ...

A River boat cruise in Moscow is one of the most exciting tours you can do in the city. The boat ride on the Moskva river allows to see all the city embankme...